fuse box NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 602 of 1226

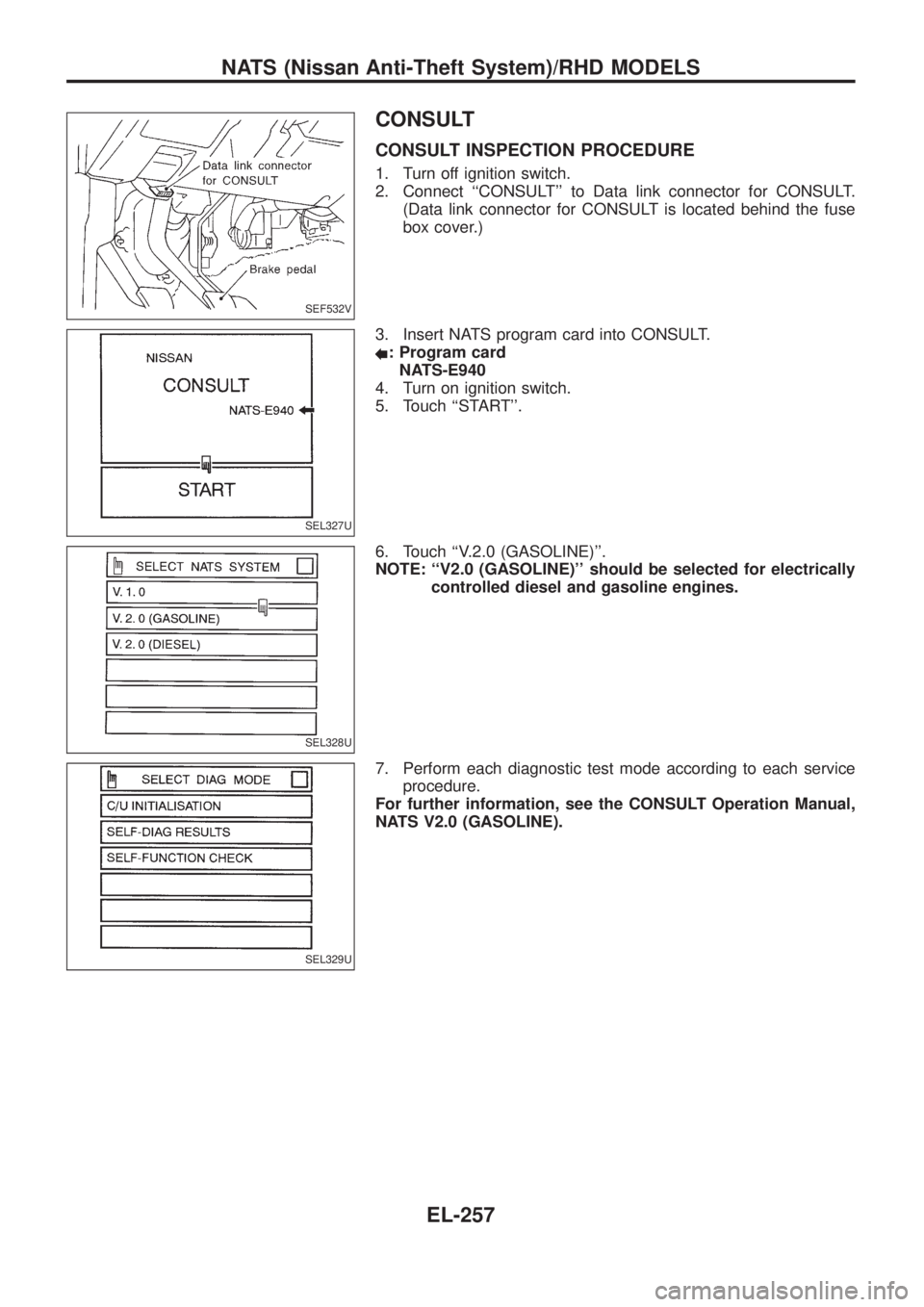

CONSULT

CONSULT INSPECTION PROCEDURE

1. Turn off ignition switch.

2. Connect ``CONSULT'' to Data link connector for CONSULT.

(Data link connector for CONSULT is located behind the fuse

box cover.)

3. Insert NATS program card into CONSULT.

: Program card

NATS-E940

4. Turn on ignition switch.

5. Touch ``START''.

6. Touch ``V.2.0 (GASOLINE)''.

NOTE: ``V2.0 (GASOLINE)'' should be selected for electrically

controlled diesel and gasoline engines.

7. Perform each diagnostic test mode according to each service

procedure.

For further information, see the CONSULT Operation Manual,

NATS V2.0 (GASOLINE).

SEF532V

SEL327U

SEL328U

SEL329U

NATS (Nissan Anti-Theft System)/RHD MODELS

EL-257

Page 607 of 1226

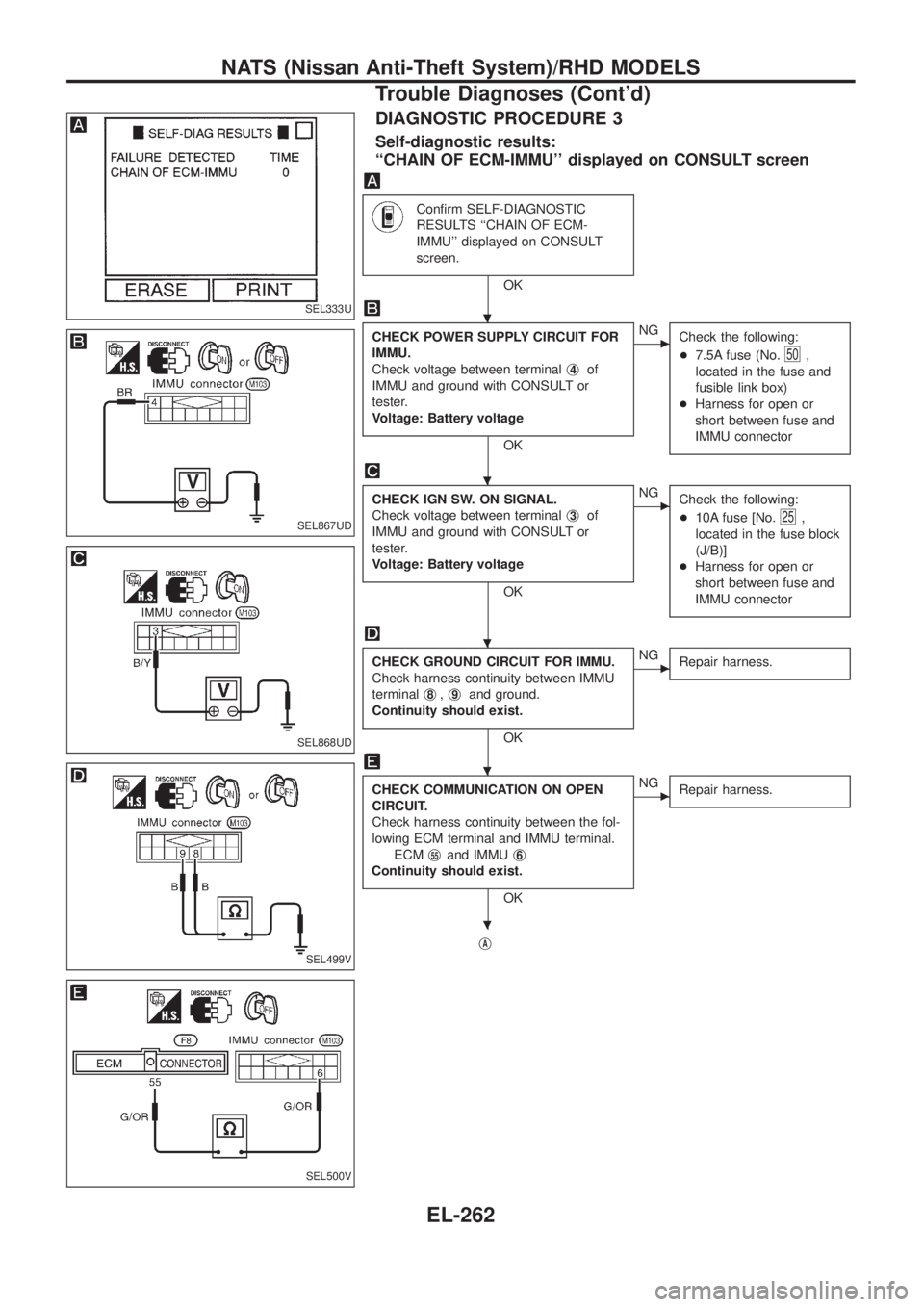

DIAGNOSTIC PROCEDURE 3

Self-diagnostic results:

``CHAIN OF ECM-IMMU'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC

RESULTS ``CHAIN OF ECM-

IMMU'' displayed on CONSULT

screen.

OK

CHECK POWER SUPPLY CIRCUIT FOR

IMMU.

Check voltage between terminalj

4of

IMMU and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following:

+7.5A fuse (No.

50,

located in the fuse and

fusible link box)

+Harness for open or

short between fuse and

IMMU connector

CHECK IGN SW. ON SIGNAL.

Check voltage between terminalj

3of

IMMU and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following:

+10A fuse [No.

25,

located in the fuse block

(J/B)]

+Harness for open or

short between fuse and

IMMU connector

CHECK GROUND CIRCUIT FOR IMMU.

Check harness continuity between IMMU

terminalj

8,j9and ground.

Continuity should exist.

OK

cNG

Repair harness.

CHECK COMMUNICATION ON OPEN

CIRCUIT.

Check harness continuity between the fol-

lowing ECM terminal and IMMU terminal.

ECMj

55and IMMUj6

Continuity should exist.

OK

cNG

Repair harness.

jA

SEL333U

SEL867UD

SEL868UD

SEL499V

SEL500V

.

.

.

.

.

NATS (Nissan Anti-Theft System)/RHD MODELS

Trouble Diagnoses (Cont'd)

EL-262

Page 664 of 1226

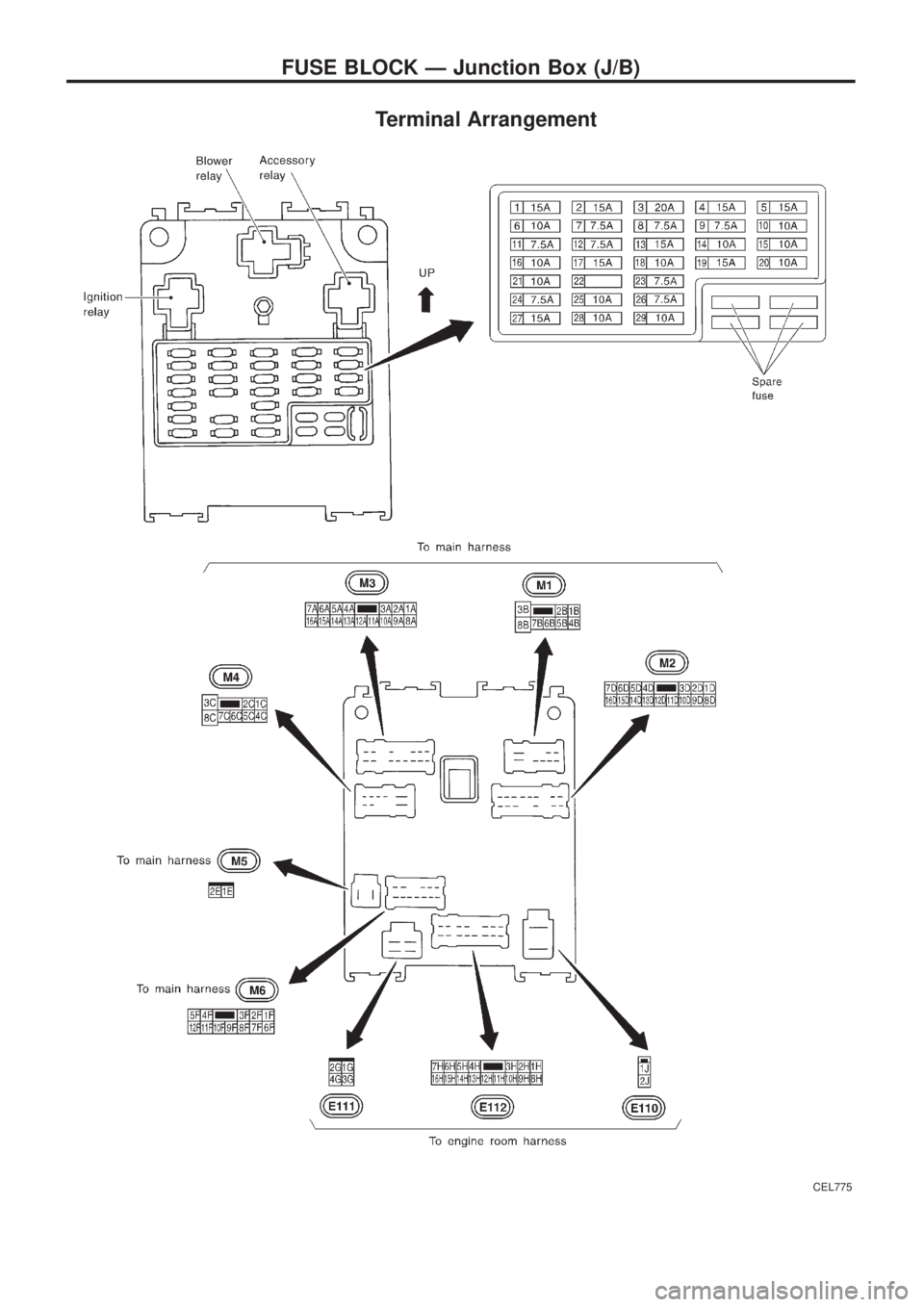

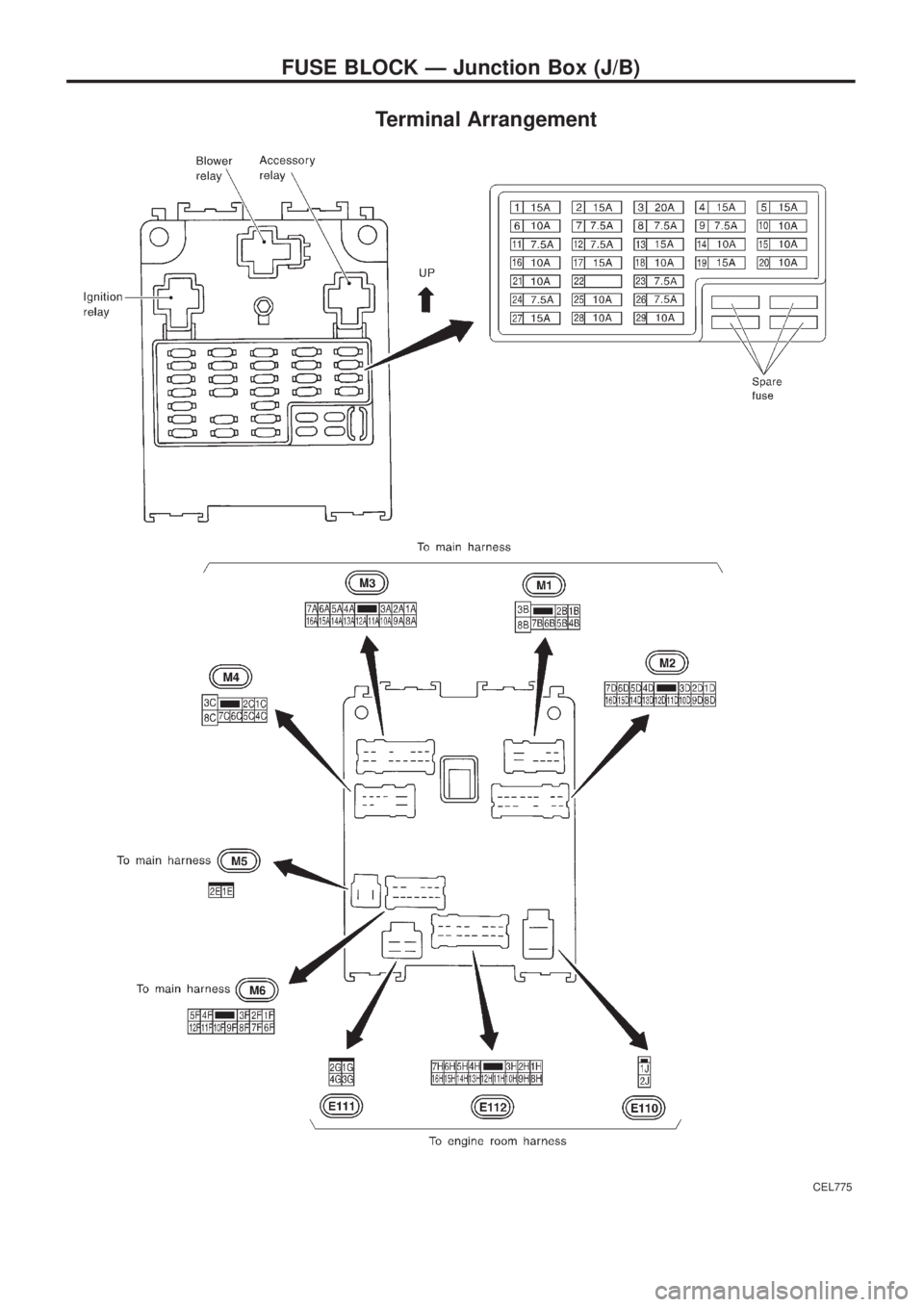

Terminal Arrangement

CEL775

FUSE BLOCK Ð Junction Box (J/B)

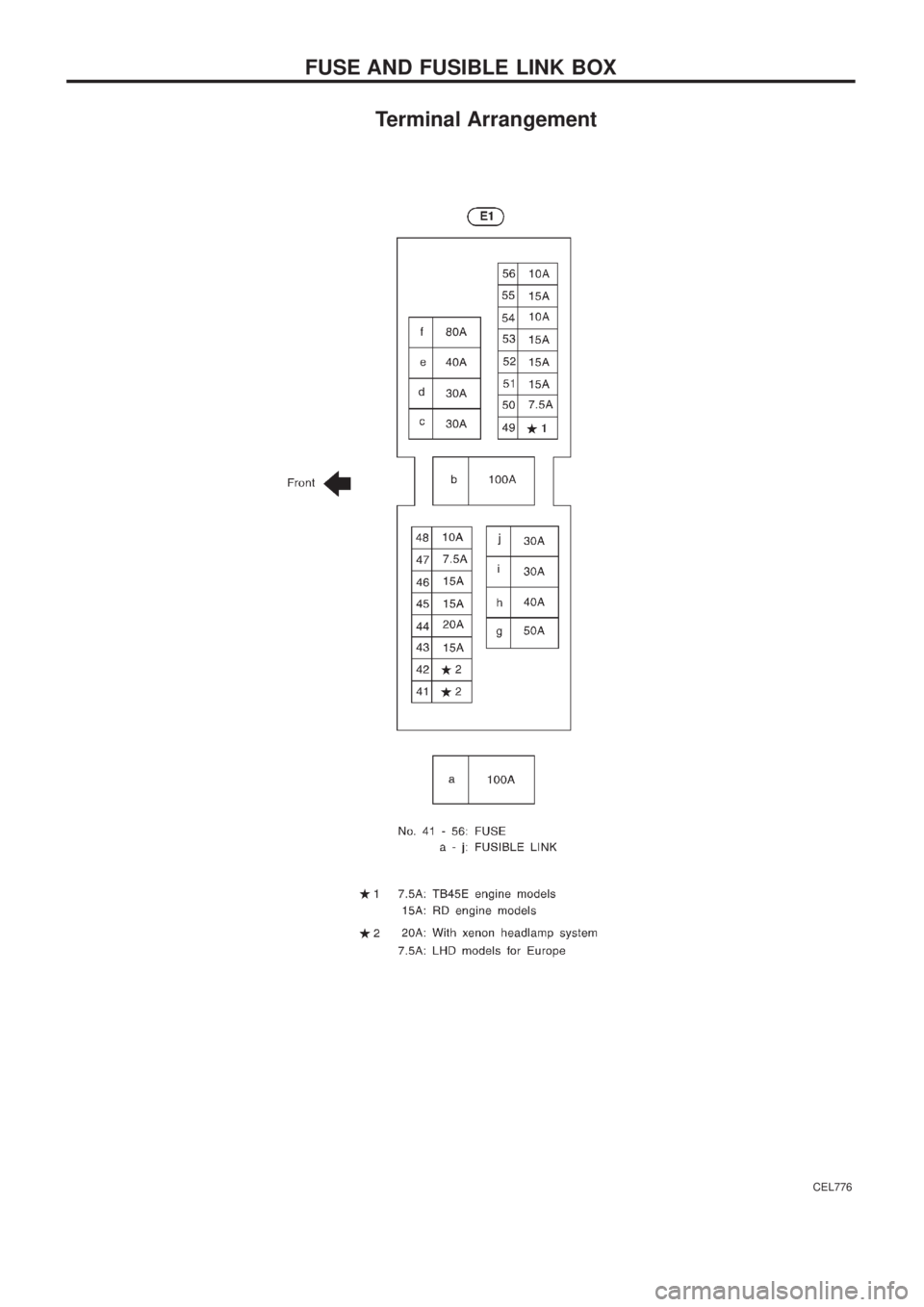

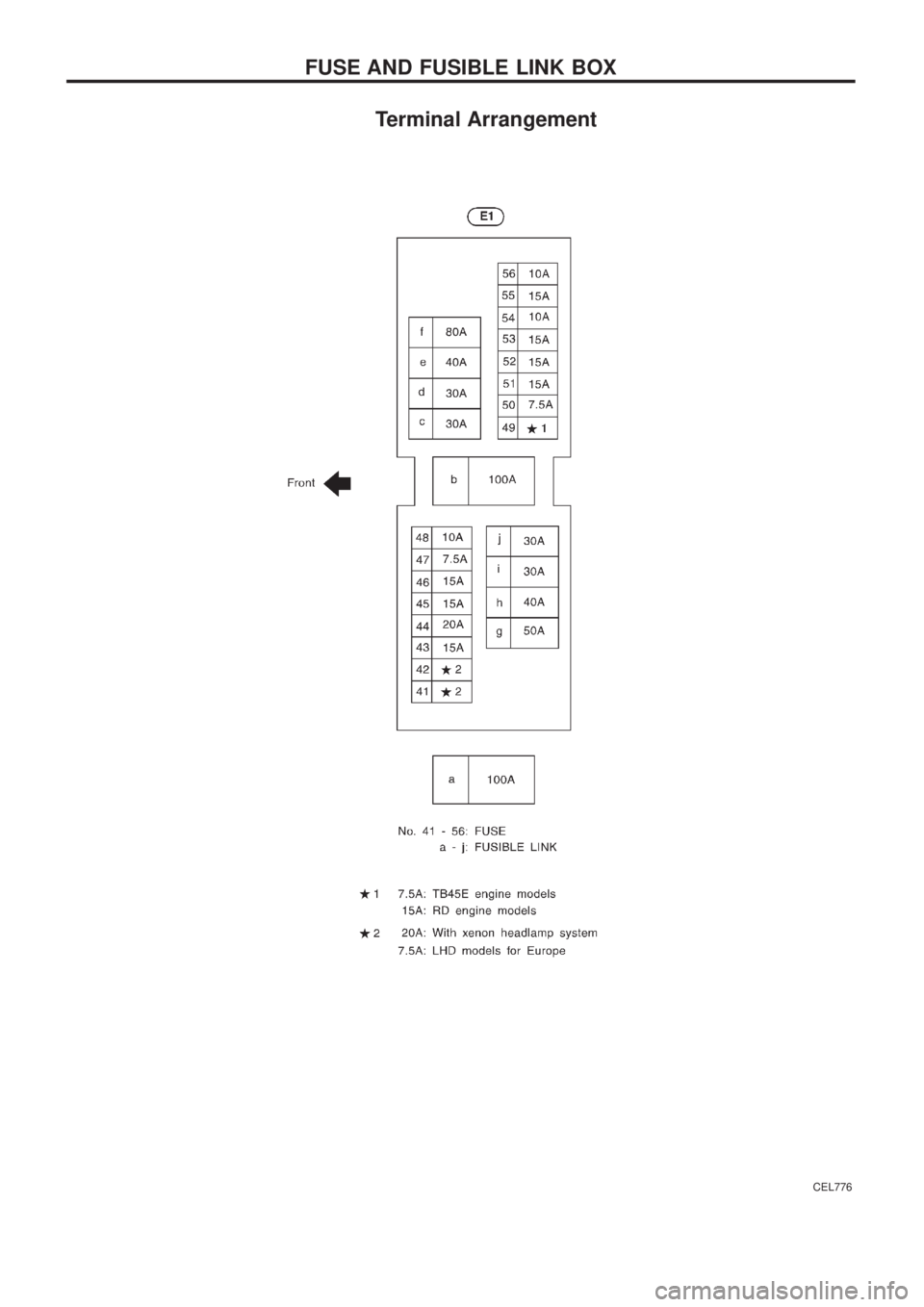

Page 665 of 1226

Terminal Arrangement

CEL776

FUSE AND FUSIBLE LINK BOX

Page 769 of 1226

Terminal Arrangement

CEL775

FUSE BLOCK Ð Junction Box (J/B)

Page 770 of 1226

Terminal Arrangement

CEL776

FUSE AND FUSIBLE LINK BOX

Page 783 of 1226

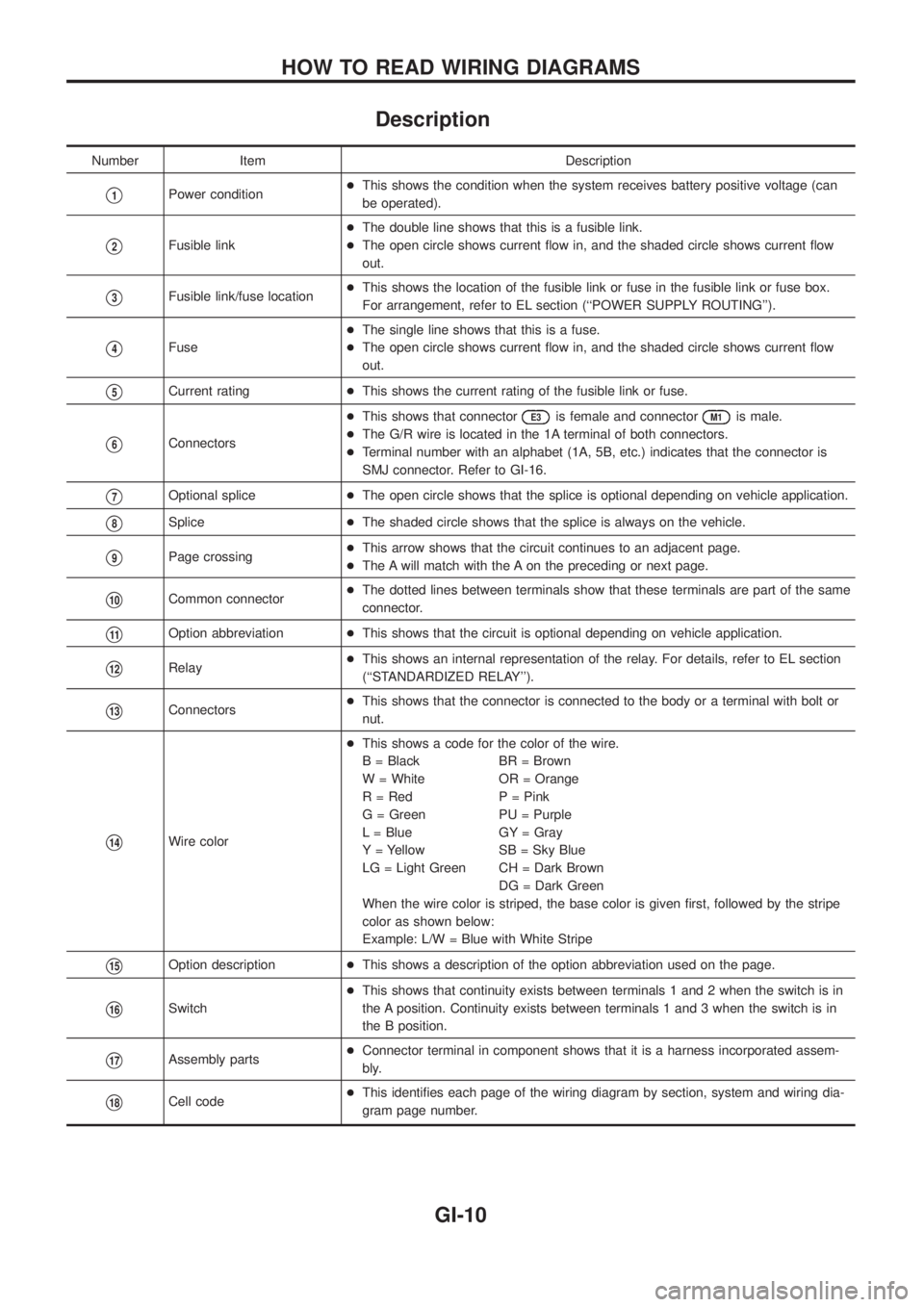

Description

Number Item Description

V1Power condition+This shows the condition when the system receives battery positive voltage (can

be operated).

V2Fusible link+The double line shows that this is a fusible link.

+The open circle shows current ¯ow in, and the shaded circle shows current ¯ow

out.

V3Fusible link/fuse location+This shows the location of the fusible link or fuse in the fusible link or fuse box.

For arrangement, refer to EL section (``POWER SUPPLY ROUTING'').

V4Fuse+The single line shows that this is a fuse.

+The open circle shows current ¯ow in, and the shaded circle shows current ¯ow

out.

V5Current rating+This shows the current rating of the fusible link or fuse.

V6Connectors+This shows that connector

E3is female and connectorM1is male.

+The G/R wire is located in the 1A terminal of both connectors.

+Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is

SMJ connector. Refer to GI-16.

V7Optional splice+The open circle shows that the splice is optional depending on vehicle application.

V8Splice+The shaded circle shows that the splice is always on the vehicle.

V9Page crossing+This arrow shows that the circuit continues to an adjacent page.

+The A will match with the A on the preceding or next page.

V10Common connector+The dotted lines between terminals show that these terminals are part of the same

connector.

V11Option abbreviation+This shows that the circuit is optional depending on vehicle application.

V12Relay+This shows an internal representation of the relay. For details, refer to EL section

(``STANDARDIZED RELAY'').

V13Connectors+This shows that the connector is connected to the body or a terminal with bolt or

nut.

V14Wire color+This shows a code for the color of the wire.

B = Black BR = Brown

W = White OR = Orange

R = Red P = Pink

G = Green PU = Purple

L = Blue GY = Gray

Y = Yellow SB = Sky Blue

LG = Light Green CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given ®rst, followed by the stripe

color as shown below:

Example: L/W = Blue with White Stripe

V15Option description+This shows a description of the option abbreviation used on the page.

V16Switch+This shows that continuity exists between terminals 1 and 2 when the switch is in

the A position. Continuity exists between terminals 1 and 3 when the switch is in

the B position.

V17Assembly parts+Connector terminal in component shows that it is a harness incorporated assem-

bly.

V18Cell code+This identi®es each page of the wiring diagram by section, system and wiring dia-

gram page number.

HOW TO READ WIRING DIAGRAMS

GI-10

Page 784 of 1226

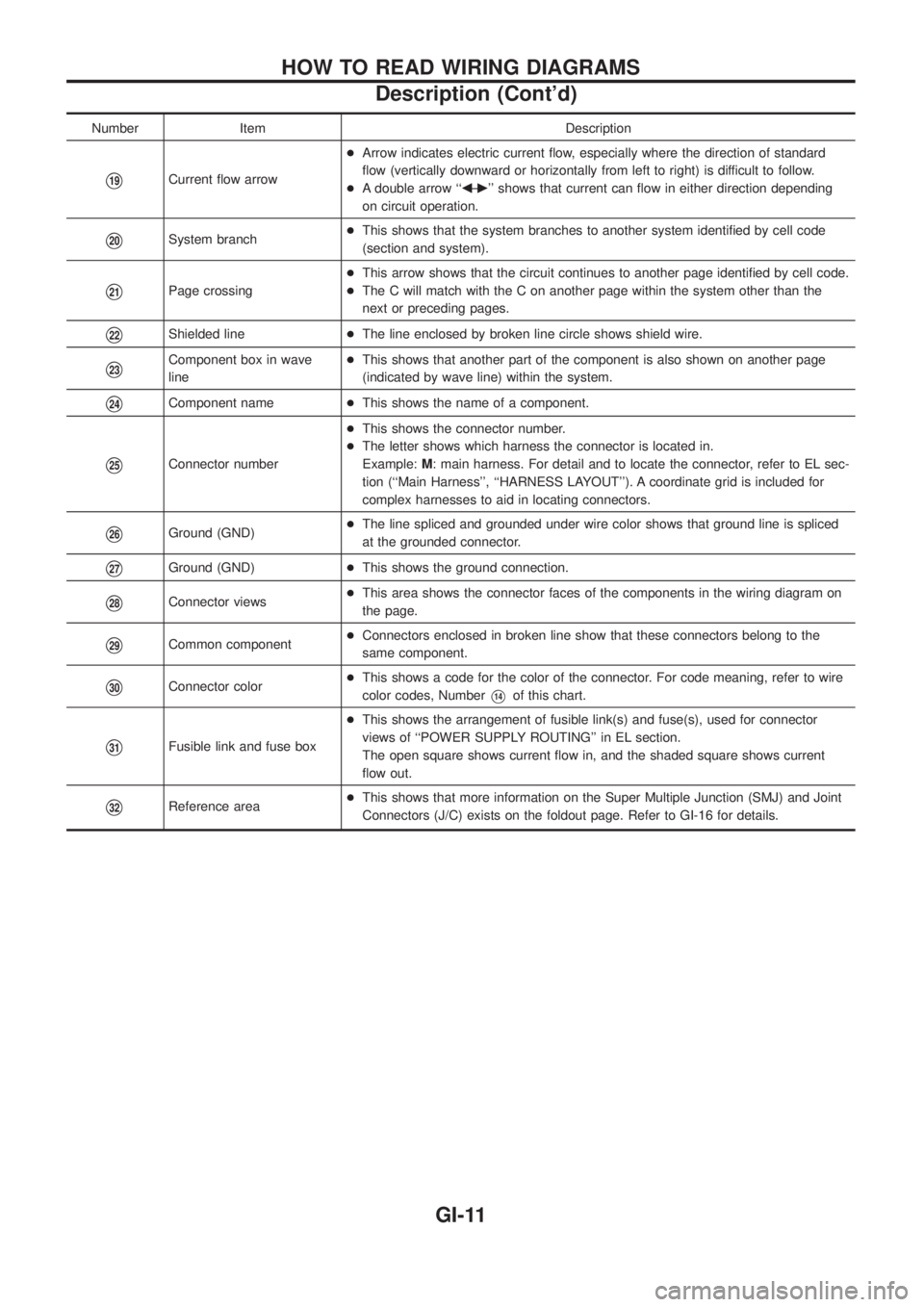

Number Item Description

V19Current ¯ow arrow+Arrow indicates electric current ¯ow, especially where the direction of standard

¯ow (vertically downward or horizontally from left to right) is difficult to follow.

+A double arrow ``bÐ

c'' shows that current can ¯ow in either direction depending

on circuit operation.

V20System branch+This shows that the system branches to another system identi®ed by cell code

(section and system).

V21Page crossing+This arrow shows that the circuit continues to another page identi®ed by cell code.

+The C will match with the C on another page within the system other than the

next or preceding pages.

V22Shielded line+The line enclosed by broken line circle shows shield wire.

V23Component box in wave

line+This shows that another part of the component is also shown on another page

(indicated by wave line) within the system.

V24Component name+This shows the name of a component.

V25Connector number+This shows the connector number.

+The letter shows which harness the connector is located in.

Example:M: main harness. For detail and to locate the connector, refer to EL sec-

tion (``Main Harness'', ``HARNESS LAYOUT''). A coordinate grid is included for

complex harnesses to aid in locating connectors.

V26Ground (GND)+The line spliced and grounded under wire color shows that ground line is spliced

at the grounded connector.

V27Ground (GND)+This shows the ground connection.

V28Connector views+This area shows the connector faces of the components in the wiring diagram on

the page.

V29Common component+Connectors enclosed in broken line show that these connectors belong to the

same component.

V30Connector color+This shows a code for the color of the connector. For code meaning, refer to wire

color codes, NumberV14of this chart.

V31Fusible link and fuse box+This shows the arrangement of fusible link(s) and fuse(s), used for connector

views of ``POWER SUPPLY ROUTING'' in EL section.

The open square shows current ¯ow in, and the shaded square shows current

¯ow out.

V32Reference area+This shows that more information on the Super Multiple Junction (SMJ) and Joint

Connectors (J/C) exists on the foldout page. Refer to GI-16 for details.

HOW TO READ WIRING DIAGRAMS

Description (Cont'd)

GI-11

Page 951 of 1226

Front drive shaft (Transfer) .............................TF-11

Front ®nal drive disassembly (4WD) ..............PD-14

Front ®nal drive removal and installa-

tion (4WD)...................................................PD-11

Front passenger air bag.............................RS-8, 14

Front seat belt ..................................................RS-2

Front seat ........................................................BT-32

Front suspension ............................................FA-24

Front washer .................................................EL-141

Front wiper ....................................................EL-141

Fuel cut control (at no load & high

engine speed) .............................................EC-20

Fuel cut solenoid valve ................................EC-129

Fuel ®ller lid.......................................................BT-6

Fuel ®lter replacement ...................................MA-16

Fuel gauge ....................................................EL-102

Fuel injection system......................................EC-15

Fuel line inspection ........................................MA-17

Fuel precautions ................................................GI-5

Fuel temperature sensor ..............................EC-134

Fuse block.....................................................EL-319

Fuse ................................................................EL-14

Fusible link ......................................................EL-14

G

GLOW - Wiring diagram...............................EC-150

GOVNR - Wiring diagram ..............................EC-95

Garage jack and safety stand .........................GI-39

Gauges..........................................................EL-102

Gear components (M/T) .................................MT-10

Glass .................................................................BT-9

Glow plug .............................................EC-150, 154

Glow relay ............................................EC-150, 154

Grease .............................................................MA-9

Ground distribution..........................................EL-15

H

H/AIM - Wiring diagram ..................................EL-71

H/LAMP - Wiring diagram ...............................EL-61

HEAT UP - Wiring diagram ..........................EC-182

HFC134a (R134a) system service

procedure ..................................................HA-112

HLC - Wiring diagram ...................................EL-153

HORN - Wiring diagram................................EL-155

Harness connector inspection .........................GI-17

Harness connector ............................................EL-2

Harness layout ..............................................EL-275

Headlamp aiming control ................................EL-70

Headlamp leveler - See Headlamp

aiming control ..............................................EL-70

Headlamp wiper ............................................EL-153

Headlamp ........................................................EL-61

Headlining - See Roof trim .............................BT-20

Heat up switch..............................................EC-182

Heated seat.....................................................BT-34Hood..................................................................BT-4

Horn ..............................................................EL-155

How to erase DTC for ECCS OBD

system ........................................................EC-30

I

IATS - Wiring diagram ..................................EC-121

IC/FAN - Wiring diagram ..............................EC-177

ILL - Wiring diagram .......................................EL-87

INT/L - Wiring diagram..................................EL-101

Identi®cation plate............................................GI-37

Idle speed inspection .....................................MA-19

Idle speed .......................................................EC-46

Illumination ......................................................EL-86

In vehicle sensor ..........................................HA-105

Injection nozzle inspection .............................MA-18

Injection nozzle...............................................EC-22

Injection timing control valve ........................EC-100

Instrument panel .............................................BT-11

Intake door control linkage adjustment ..........HA-84

Intake door motor ...........................................HA-25

Intake sensor ................................................HA-111

Interior lamp ....................................................EL-93

Interior .............................................................BT-14

J

Jacking points ..................................................GI-39

Joint connector (J/C).....................................EL-322

Journal bearing assembly (propeller

shaft) .............................................................PD-8

Journal bearing disassembly (propeller

shaft) .............................................................PD-7

Junction box (J/B) .........................................EL-319

L

LSV (Load sensing valve) ................................BR-6

Lifting points ....................................................GI-40

Limited slip diff. adjustment............................PD-23

Limited slip diff. assembly ..............................PD-24

Limited slip diff. disassembly .........................PD-21

Limited slip diff. inspection .............................PD-21

Location of electrical units ............................EL-269

Lock, door .........................................................BT-9

Lubricant (R134a) A/C ..................................HA-114

Lubricants.........................................................MA-9

Lubrication circuit (engine) ...............................LC-3

Lubrication-locks, hinges and hood

latches ........................................................MA-27

Luggage compartment trim .............................BT-14

Luggage room lamp ........................................EL-93

ALPHABETICAL INDEX

IDX-4

Page 979 of 1226

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for speci®cations.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose connec-

tions for leaks

hBattery ¯uid level, speci®c gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel ®lter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir ¯uid level and ¯uid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir ¯uid level

hPower steering reservoir ¯uid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hXRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and ®ttings for ®t and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for ®t and alignment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and ®t

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if applicable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

h

XInstall deodorizing ®lter to air puri®er (If appli-

cable)

h

XRemove wiper blade protectors (If applicable)

UNDER BODY

hManual transmission/transaxle gear oil, transfer

¯uid and differential gear oil level

hBrake and fuel lines and oil/¯uid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and drive

shafts

h

XTighten rear body bolts and nuts (Models with

wooden bed only)

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hAutomatic transmission/transaxle shift timing

and kickdown

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hAutomatic transmission/transaxle ¯uid level

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud ¯aps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-2