cooling system NISSAN PATROL 2006 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 890 of 1226

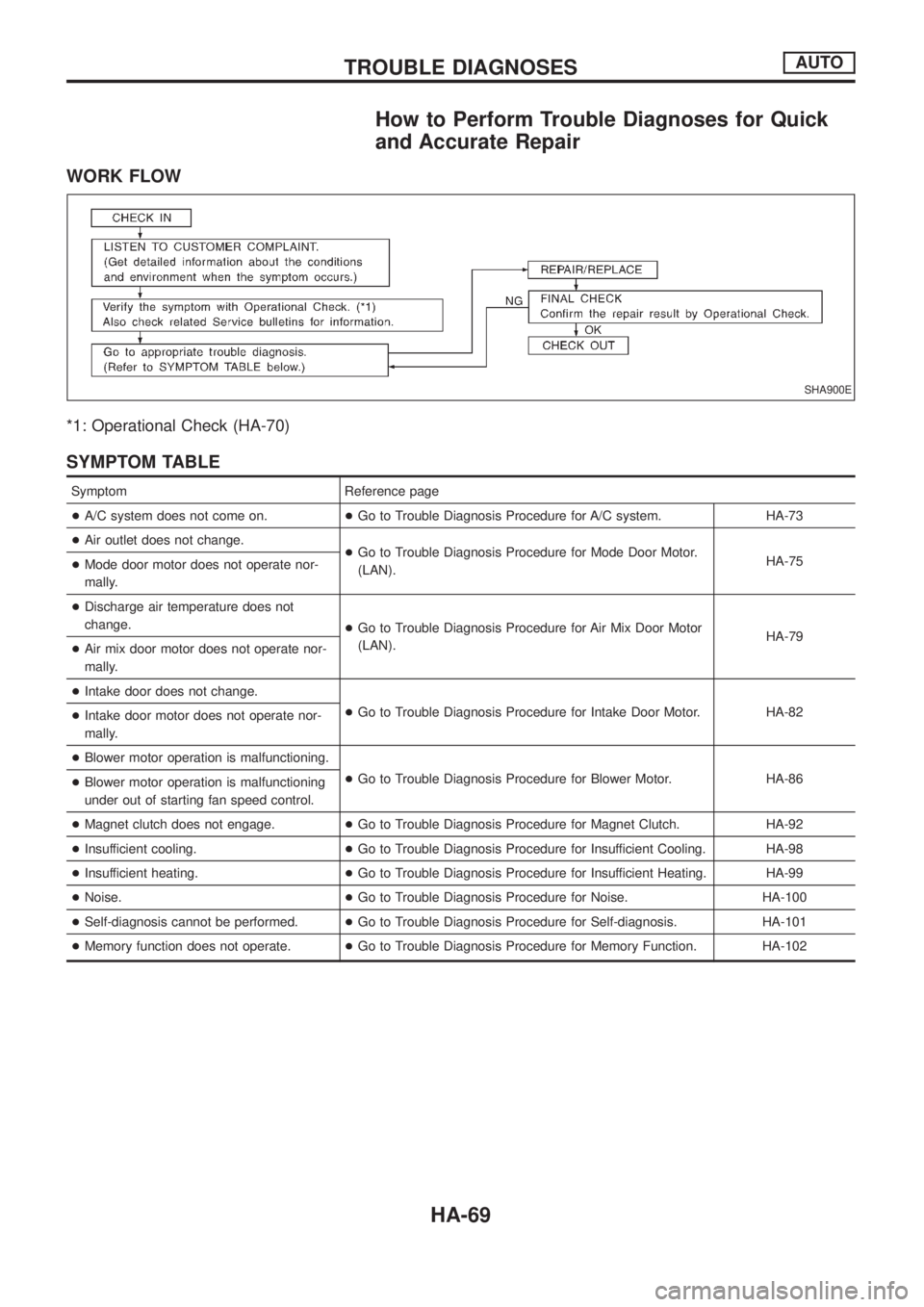

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

WORK FLOW

*1: Operational Check (HA-70)

SYMPTOM TABLE

Symptom Reference page

+A/C system does not come on.+Go to Trouble Diagnosis Procedure for A/C system. HA-73

+Air outlet does not change.

+Go to Trouble Diagnosis Procedure for Mode Door Motor.

(LAN).HA-75

+Mode door motor does not operate nor-

mally.

+Discharge air temperature does not

change.

+Go to Trouble Diagnosis Procedure for Air Mix Door Motor

(LAN).HA-79

+Air mix door motor does not operate nor-

mally.

+Intake door does not change.

+Go to Trouble Diagnosis Procedure for Intake Door Motor. HA-82

+Intake door motor does not operate nor-

mally.

+Blower motor operation is malfunctioning.

+Go to Trouble Diagnosis Procedure for Blower Motor. HA-86

+Blower motor operation is malfunctioning

under out of starting fan speed control.

+Magnet clutch does not engage.+Go to Trouble Diagnosis Procedure for Magnet Clutch. HA-92

+Insufficient cooling.+Go to Trouble Diagnosis Procedure for Insufficient Cooling. HA-98

+Insufficient heating.+Go to Trouble Diagnosis Procedure for Insufficient Heating. HA-99

+Noise.+Go to Trouble Diagnosis Procedure for Noise. HA-100

+Self-diagnosis cannot be performed.+Go to Trouble Diagnosis Procedure for Self-diagnosis. HA-101

+Memory function does not operate.+Go to Trouble Diagnosis Procedure for Memory Function. HA-102

SHA900E

TROUBLE DIAGNOSESAUTO

HA-69

Page 935 of 1226

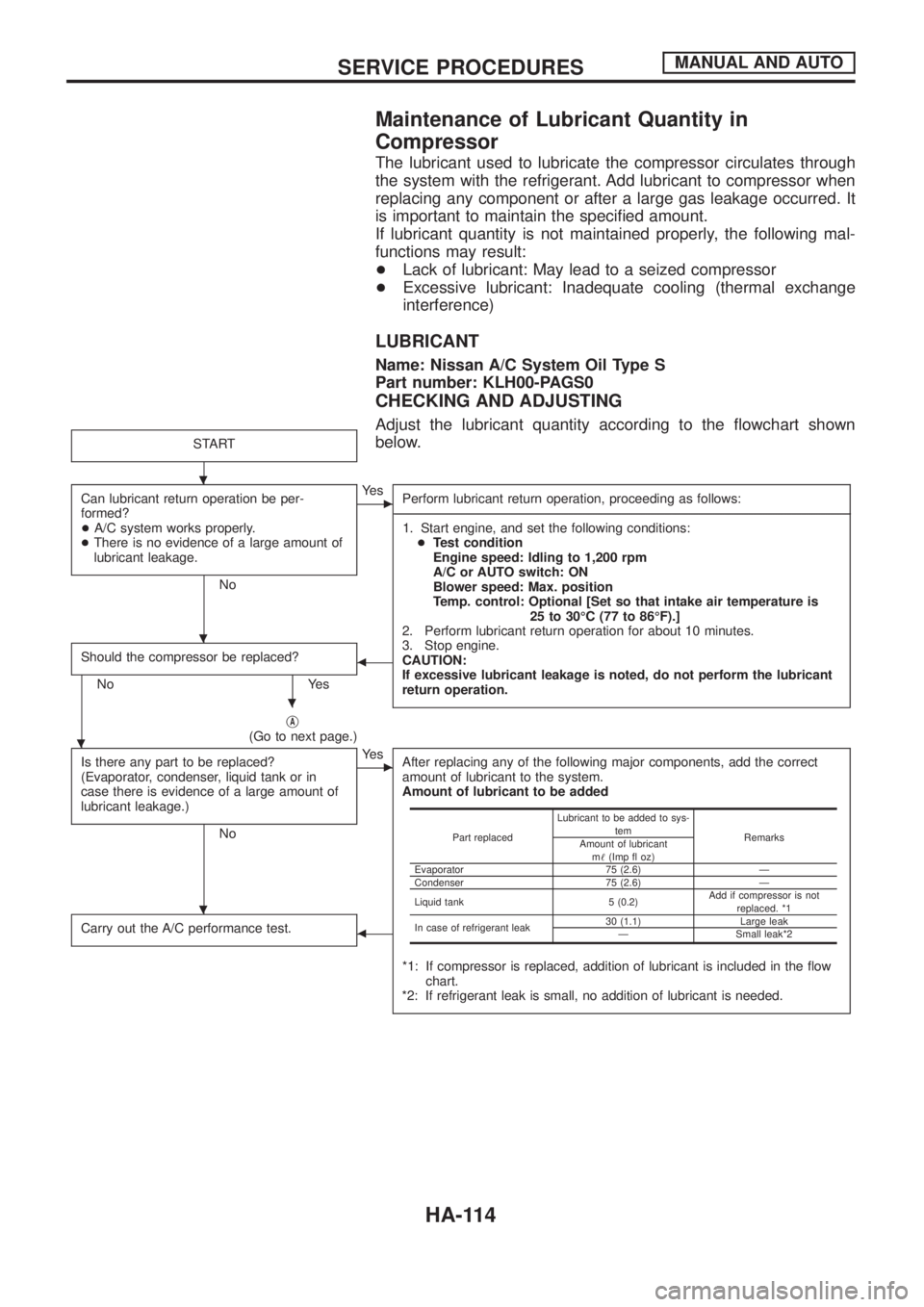

Maintenance of Lubricant Quantity in

Compressor

The lubricant used to lubricate the compressor circulates through

the system with the refrigerant. Add lubricant to compressor when

replacing any component or after a large gas leakage occurred. It

is important to maintain the speci®ed amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

+Lack of lubricant: May lead to a seized compressor

+Excessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANT

Name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

Adjust the lubricant quantity according to the ¯owchart shown

below.

START

Can lubricant return operation be per-

formed?

+A/C system works properly.

+There is no evidence of a large amount of

lubricant leakage.

No

cYe s

Perform lubricant return operation, proceeding as follows:

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

+Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is

25 to 30ÉC (77 to 86ÉF).]

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant

return operation.

Should the compressor be replaced?

No Yes

b

jA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount of

lubricant leakage.)

No

cYe s

After replacing any of the following major components, add the correct

amount of lubricant to the system.

Amount of lubricant to be added

*1: If compressor is replaced, addition of lubricant is included in the ¯ow

chart.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Carry out the A/C performance test.b

Part replacedLubricant to be added to sys-

tem

Remarks

Amount of lubricant

m!(Imp ¯ oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is not

replaced. *1

In case of refrigerant leak30 (1.1) Large leak

Ð Small leak*2

.

.

.

.

.

SERVICE PROCEDURESMANUAL AND AUTO

HA-114

Page 941 of 1226

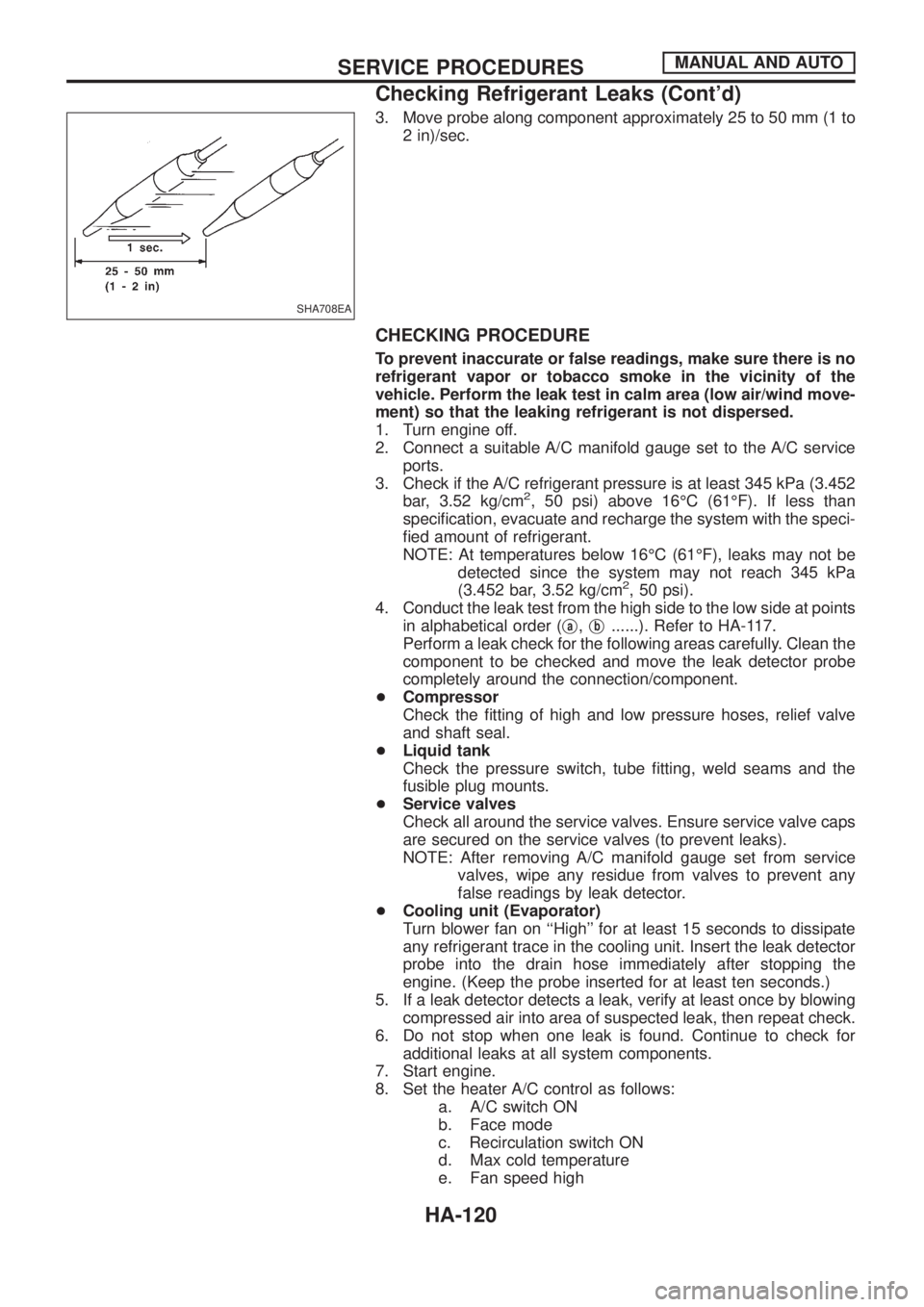

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no

refrigerant vapor or tobacco smoke in the vicinity of the

vehicle. Perform the leak test in calm area (low air/wind move-

ment) so that the leaking refrigerant is not dispersed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.452

bar, 3.52 kg/cm

2, 50 psi) above 16ÉC (61ÉF). If less than

speci®cation, evacuate and recharge the system with the speci-

®ed amount of refrigerant.

NOTE: At temperatures below 16ÉC (61ÉF), leaks may not be

detected since the system may not reach 345 kPa

(3.452 bar, 3.52 kg/cm

2, 50 psi).

4. Conduct the leak test from the high side to the low side at points

in alphabetical order (j

a,jb......). Refer to HA-117.

Perform a leak check for the following areas carefully. Clean the

component to be checked and move the leak detector probe

completely around the connection/component.

+Compressor

Check the ®tting of high and low pressure hoses, relief valve

and shaft seal.

+Liquid tank

Check the pressure switch, tube ®tting, weld seams and the

fusible plug mounts.

+Service valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE: After removing A/C manifold gauge set from service

valves, wipe any residue from valves to prevent any

false readings by leak detector.

+Cooling unit (Evaporator)

Turn blower fan on ``High'' for at least 15 seconds to dissipate

any refrigerant trace in the cooling unit. Insert the leak detector

probe into the drain hose immediately after stopping the

engine. (Keep the probe inserted for at least ten seconds.)

5. If a leak detector detects a leak, verify at least once by blowing

compressed air into area of suspected leak, then repeat check.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

7. Start engine.

8. Set the heater A/C control as follows:

a. A/C switch ON

b. Face mode

c. Recirculation switch ON

d. Max cold temperature

e. Fan speed high

SHA708EA

SERVICE PROCEDURESMANUAL AND AUTO

Checking Refrigerant Leaks (Cont'd)

HA-120

Page 950 of 1226

Combination meter........................................EL-102

Combination switch .........................................EL-57

Combustion chamber replacement ................EM-32

Compass .......................................................EL-116

Compression pressure ...................................EM-10

Compressor special service tool ......................HA-6

Connecting rod...............................................EM-47

Connecting rod...............................................EM-51

Connector inspection .......................................GI-17

Console box - See Instrument panel ..............BT-11

Control lever (Transfer) .....................................TF-9

Control sleeve position sensor .......................EC-86

Coolant mixture ratio ......................................MA-11

Coolant replacement ......................................MA-14

Cooling circuit (engine) .....................................LC-9

Cooling fan control .......................................EC-112

Cooling fan motor .........................................EC-120

Cooling fan relay ..........................................EC-120

Cooling fan......................................................LC-15

Counter gear (M/T).........................................MT-10

Counter gear (Transfer) ..................................TF-11

Coupling sleeve (M/T) ....................................MT-10

Crankcase emission control system -

See Positive crankcase ventilation.............EC-21

Crankcase ventilation system - See

Positive crankcase ventilation ....................EC-21

Crankshaft position sensor (TDC)................EC-143

Crankshaft ......................................................EM-50

Cylinder block ..........................................EM-45, 48

Cylinder head .................................................EM-28

D

D/LOCK - Wiring diagram .............................EL-205

DEF - Wiring diagram ...................................EL-159

DEICER - Wiring diagram.............................EL-167

DTRL - Wiring diagram ...................................EL-67

Data link connector for Consult......................EC-36

Daytime light system.......................................EL-65

Diagnosis sensor unit .....................................RS-12

Diagnostic trouble code (DTC) for

ECCS OBD system ....................................EC-30

Differential carrier assembly...........................PD-31

Differential carrier disassembly ......................PD-14

Differential gear oil replacement ....................MA-22

Dimensions ......................................................GI-38

Dome light - See Interior lamp .......................EL-93

Door glass .........................................................BT-9

Door lock ...........................................................BT-9

Door mirror ......................................................BT-46

Door trim .........................................................BT-18

Door, front .........................................................BT-9

Door, rear ........................................................BT-10

Drive belt inspection ......................................MA-12

Drive chain (Transfer) .....................................TF-11

Drive pinion diff. inspection ............................PD-19

Drive pinion height .........................................PD-27

Drive shaft (front) ............................................FA-23

Dual pressure switch ......................................HA-11Dual pressure switch ......................................HA-97

E

ECCS basic inspection...................................EC-46

ECCS circuit diagram .....................................EC-11

ECCS component parts location ......................EC-8

ECCS on board diagnostic system ................EC-30

ECCS symptom matrix chart..........................EC-48

ECCS system diagram and chart ..................EC-12

ECCS-D control module .........................EC-54, 110

ECM input/output signal .................................EC-54

ECTS - Wiring diagram ..................................EC-78

EGR control (EGRC) - solenoid valve .........EC-155

EGR control valve ........................................EC-161

EGRC/V - Wiring diagram ............................EC-155

Electric governor ....................................EC-95, 148

Electric sunroof .............................................EL-186

Electrical diagnoses.........................................GI-20

Electrical unit.................................................EL-321

Electrical units location .................................EL-269

Electronic fuel injection pump ........................EC-27

Engine compartment .......................................BT-49

Engine coolant temperature sensor

(ECTS) ........................................................EC-78

Engine oil ®lter replacement ..........................MA-14

Engine oil precautions .......................................GI-4

Engine oil replacement ..................................MA-13

Engine outer component parts ........................EM-8

Engine removal ..............................................EM-43

Engine room - See Engine

compartment ...............................................BT-49

Engine serial number ......................................GI-37

Exhaust system inspection ............................MA-20

Exhaust system ................................................FE-3

Exterior ............................................................BT-26

F

FCUT - Wiring diagram ................................EC-129

FTS - Wiring diagram ...................................EC-134

Fan control amp. ............................................HA-88

Final drive disassembly ..................................PD-14

Final drive removal and installation................PD-11

Finisher, interior - See Trim ............................BT-14

Floor trim .........................................................BT-14

Flow charts ......................................................GI-30

Fluids................................................................MA-9

Flywheel (clutch).......................................CL-13, 14

Flywheel runout..............................................EM-52

Fog lamp, rear ................................................EL-80

Fork rod (M/T) ................................................MT-12

Front axle ........................................................FA-10

Front bumper ....................................................BT-4

Front case (Transfer) ......................................TF-10

Front disc brake .............................................BR-20

Front door .........................................................BT-9

ALPHABETICAL INDEX

IDX-3

Page 955 of 1226

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

PRECAUTIONS AND PREPARATION............................1

Liquid Gasket Application Procedure ..........................1

Special Service Tools ..................................................2

ENGINE LUBRICATION SYSTEM..................................3

Lubrication Circuit ........................................................3

Oil Pressure Check......................................................3

Oil Pump ......................................................................4

Oil Cooler .....................................................................7

Oil Jet...........................................................................7

Turbocharger ...............................................................8

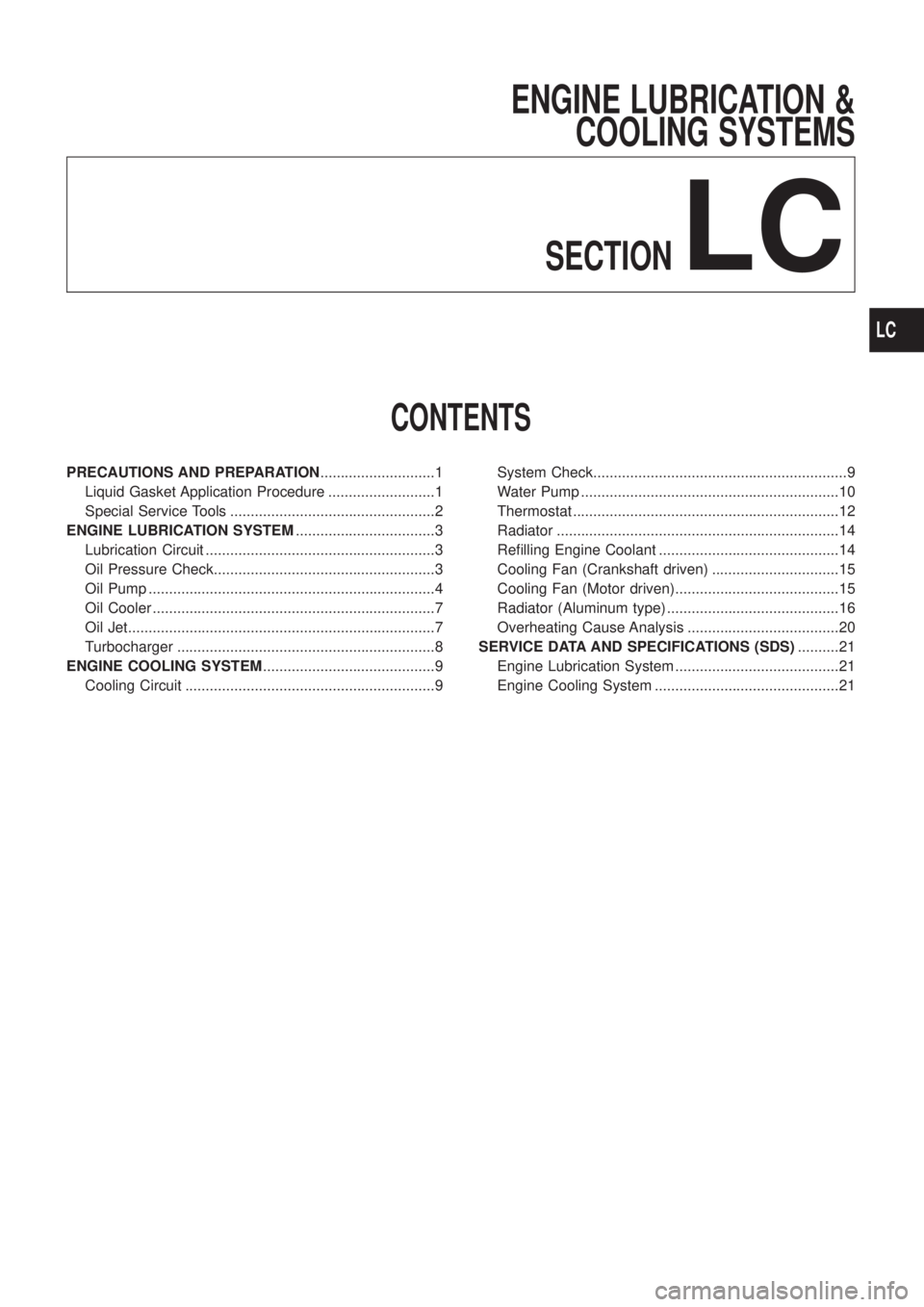

ENGINE COOLING SYSTEM..........................................9

Cooling Circuit .............................................................9System Check..............................................................9

Water Pump ...............................................................10

Thermostat .................................................................12

Radiator .....................................................................14

Re®lling Engine Coolant ............................................14

Cooling Fan (Crankshaft driven) ...............................15

Cooling Fan (Motor driven)........................................15

Radiator (Aluminum type) ..........................................16

Overheating Cause Analysis .....................................20

SERVICE DATA AND SPECIFICATIONS (SDS)..........21

Engine Lubrication System ........................................21

Engine Cooling System .............................................21

LC

Page 964 of 1226

Cooling Circuit

System Check

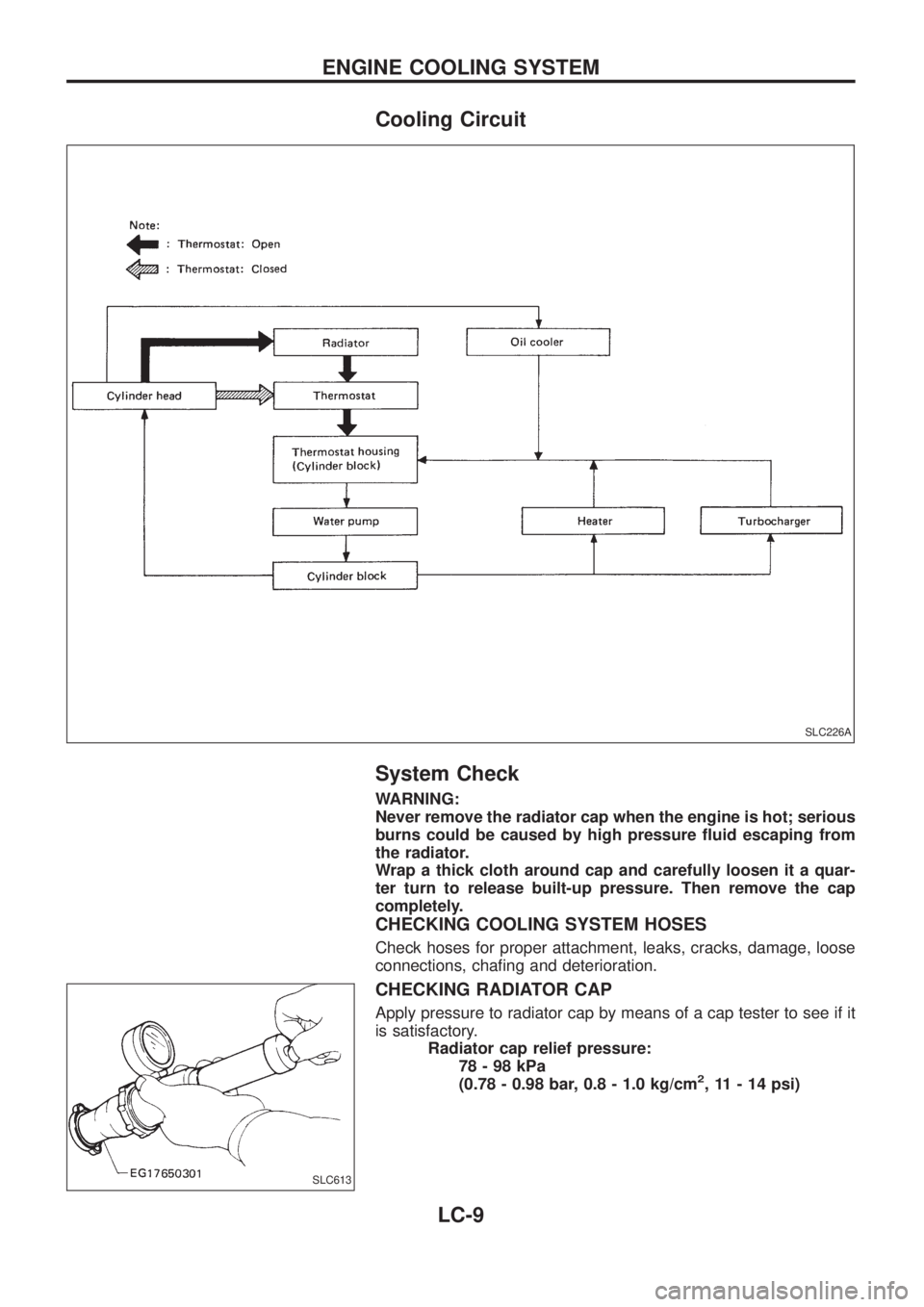

WARNING:

Never remove the radiator cap when the engine is hot; serious

burns could be caused by high pressure ¯uid escaping from

the radiator.

Wrap a thick cloth around cap and carefully loosen it a quar-

ter turn to release built-up pressure. Then remove the cap

completely.

CHECKING COOLING SYSTEM HOSES

Check hoses for proper attachment, leaks, cracks, damage, loose

connections, cha®ng and deterioration.

CHECKING RADIATOR CAP

Apply pressure to radiator cap by means of a cap tester to see if it

is satisfactory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

SLC226A

SLC613

ENGINE COOLING SYSTEM

LC-9

Page 965 of 1226

Pull the negative pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system by means of a tester to check

for leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of pressure higher than the speci®ed value may cause

damage to radiator.

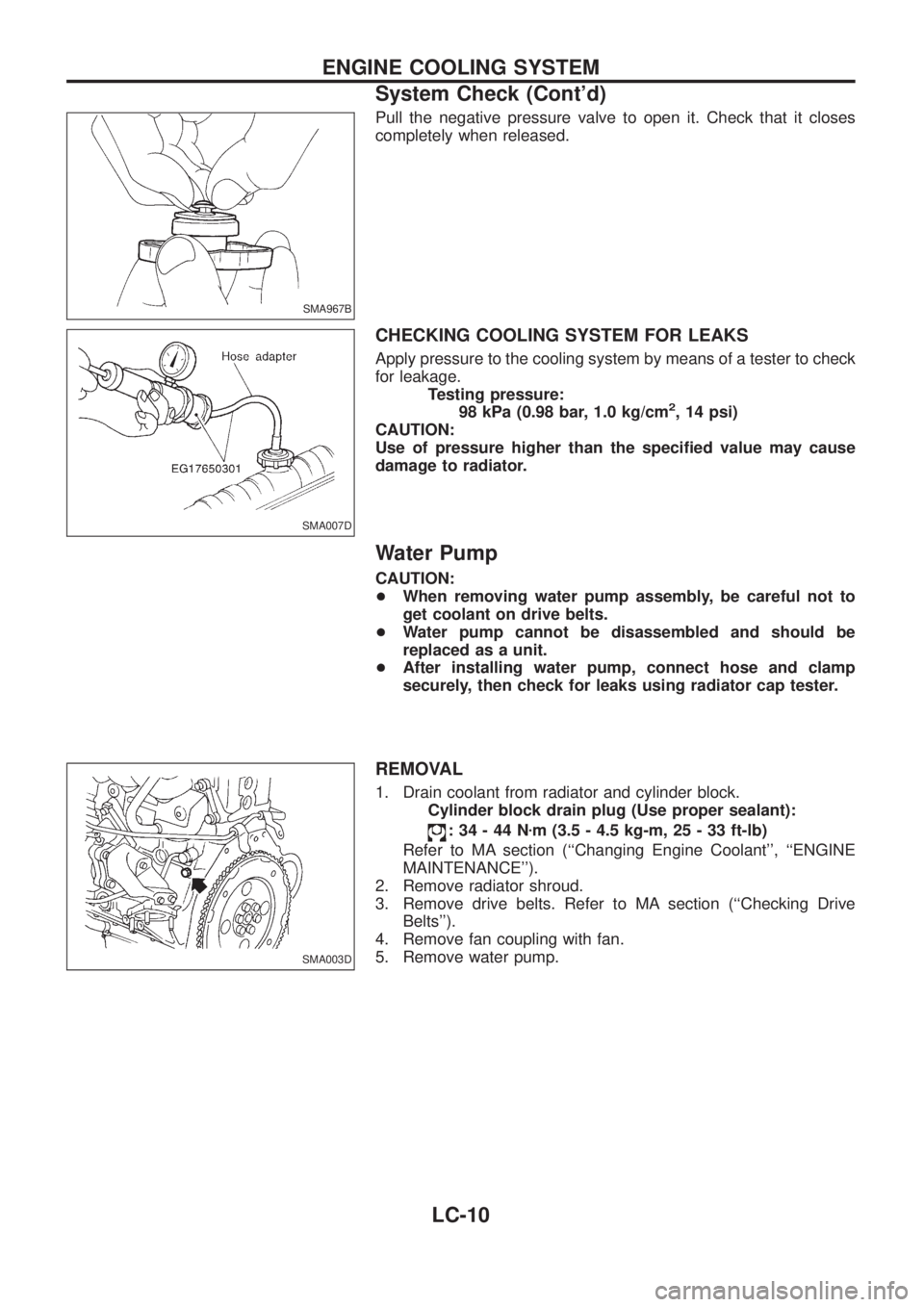

Water Pump

CAUTION:

+When removing water pump assembly, be careful not to

get coolant on drive belts.

+Water pump cannot be disassembled and should be

replaced as a unit.

+After installing water pump, connect hose and clamp

securely, then check for leaks using radiator cap tester.

REMOVAL

1. Drain coolant from radiator and cylinder block.

Cylinder block drain plug (Use proper sealant):

:34-44Nzm (3.5 - 4.5 kg-m, 25 - 33 ft-lb)

Refer to MA section (``Changing Engine Coolant'', ``ENGINE

MAINTENANCE'').

2. Remove radiator shroud.

3. Remove drive belts. Refer to MA section (``Checking Drive

Belts'').

4. Remove fan coupling with fan.

5. Remove water pump.

SMA967B

SMA007D

SMA003D

ENGINE COOLING SYSTEM

System Check (Cont'd)

LC-10

Page 966 of 1226

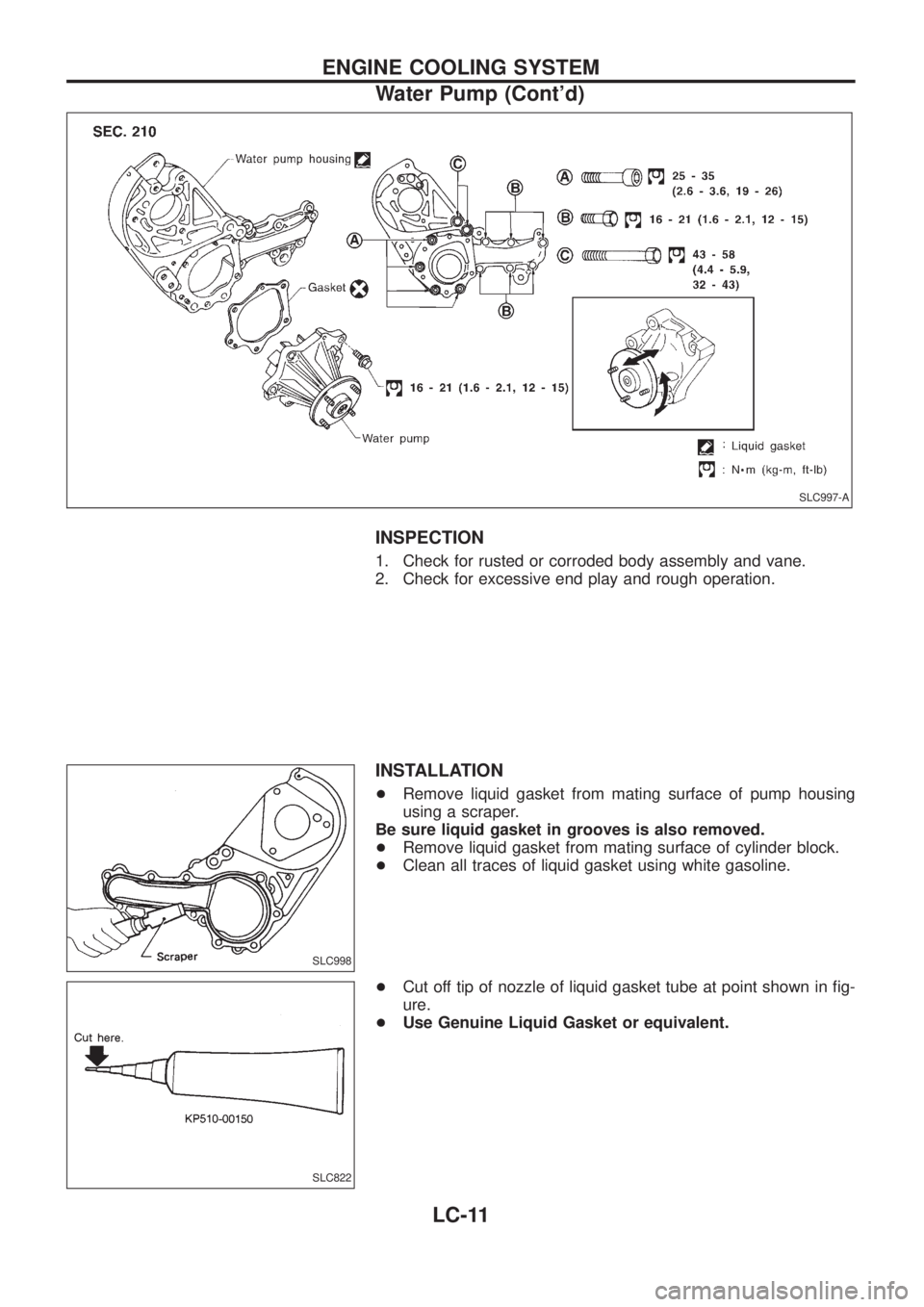

INSPECTION

1. Check for rusted or corroded body assembly and vane.

2. Check for excessive end play and rough operation.

INSTALLATION

+Remove liquid gasket from mating surface of pump housing

using a scraper.

Be sure liquid gasket in grooves is also removed.

+Remove liquid gasket from mating surface of cylinder block.

+Clean all traces of liquid gasket using white gasoline.

+Cut off tip of nozzle of liquid gasket tube at point shown in ®g-

ure.

+Use Genuine Liquid Gasket or equivalent.

SLC997-A

SLC998

SLC822

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-11

Page 967 of 1226

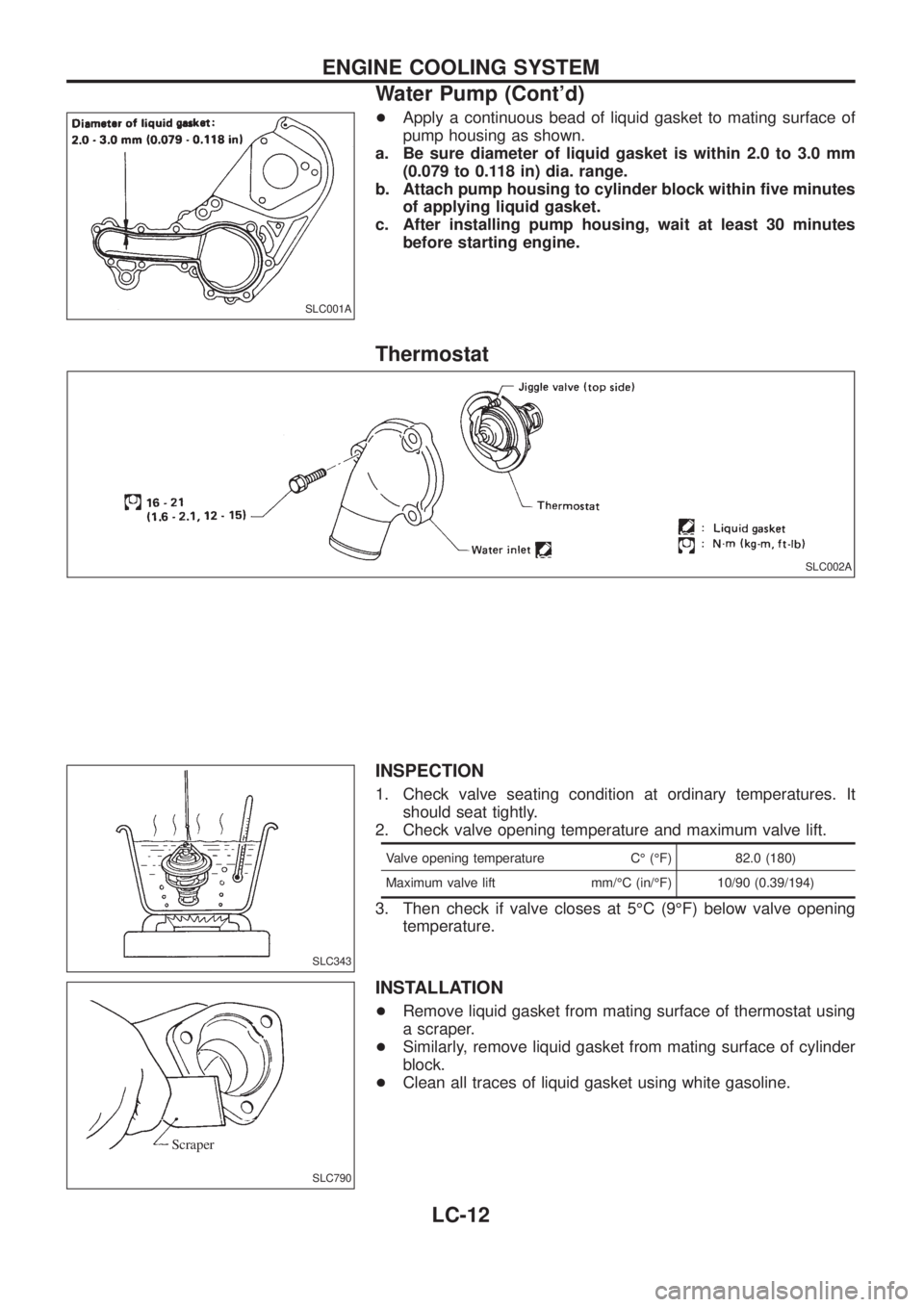

+Apply a continuous bead of liquid gasket to mating surface of

pump housing as shown.

a. Be sure diameter of liquid gasket is within 2.0 to 3.0 mm

(0.079 to 0.118 in) dia. range.

b. Attach pump housing to cylinder block within ®ve minutes

of applying liquid gasket.

c. After installing pump housing, wait at least 30 minutes

before starting engine.

Thermostat

INSPECTION

1. Check valve seating condition at ordinary temperatures. It

should seat tightly.

2. Check valve opening temperature and maximum valve lift.

Valve opening temperature CÉ (ÉF) 82.0 (180)

Maximum valve lift mm/ÉC (in/ÉF) 10/90 (0.39/194)

3. Then check if valve closes at 5ÉC (9ÉF) below valve opening

temperature.

INSTALLATION

+Remove liquid gasket from mating surface of thermostat using

a scraper.

+Similarly, remove liquid gasket from mating surface of cylinder

block.

+Clean all traces of liquid gasket using white gasoline.

SLC001A

SLC002A

SLC343

SLC790

Scraper

ENGINE COOLING SYSTEM

Water Pump (Cont'd)

LC-12

Page 968 of 1226

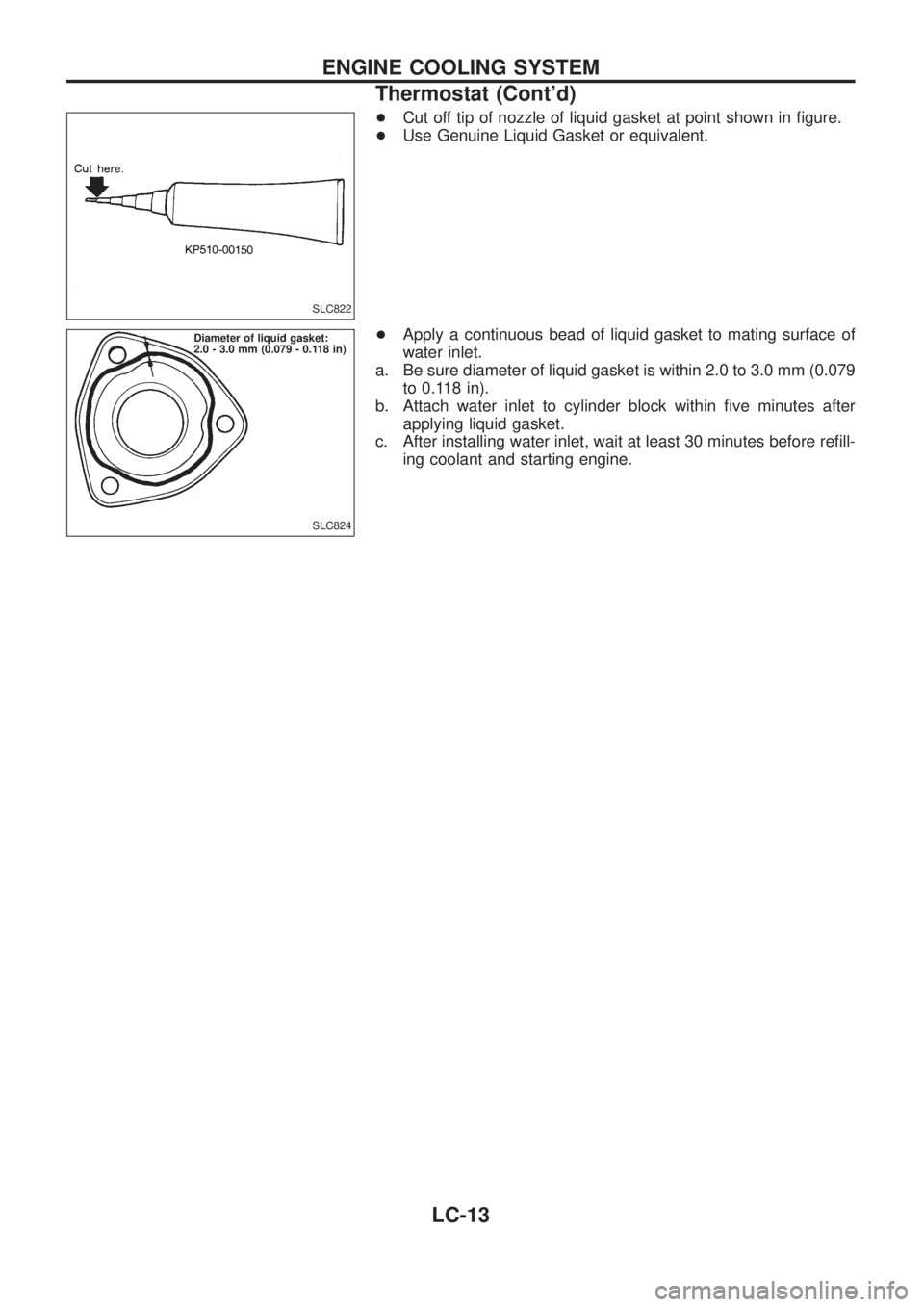

+Cut off tip of nozzle of liquid gasket at point shown in ®gure.

+Use Genuine Liquid Gasket or equivalent.

+Apply a continuous bead of liquid gasket to mating surface of

water inlet.

a. Be sure diameter of liquid gasket is within 2.0 to 3.0 mm (0.079

to 0.118 in).

b. Attach water inlet to cylinder block within ®ve minutes after

applying liquid gasket.

c. After installing water inlet, wait at least 30 minutes before re®ll-

ing coolant and starting engine.

SLC822

SLC824 Diameter of liquid gasket:

2.0 - 3.0 mm (0.079 - 0.118 in)

ENGINE COOLING SYSTEM

Thermostat (Cont'd)

LC-13