lock NISSAN PATROL 2006 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 315 of 1226

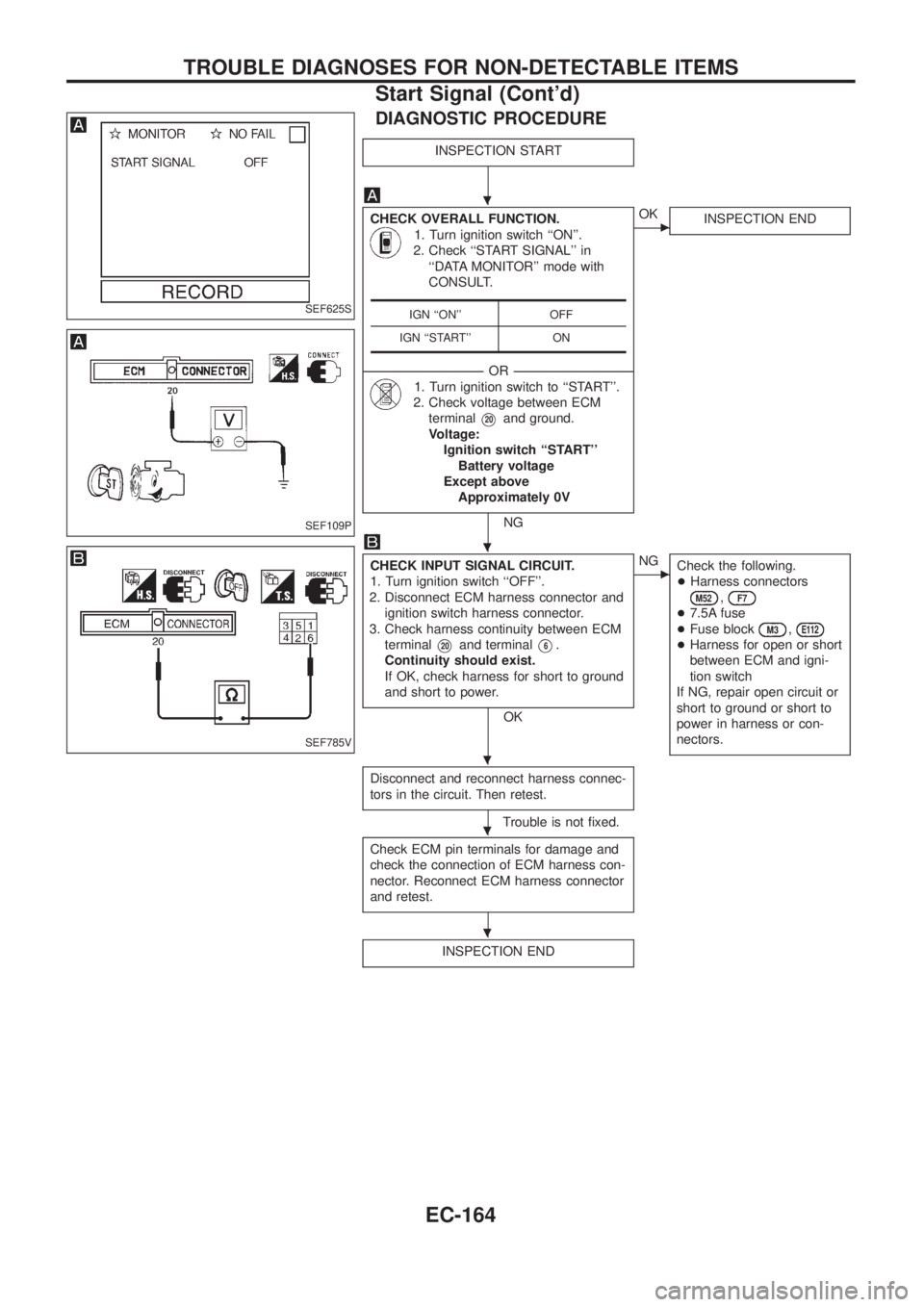

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Check ``START SIGNAL'' in

``DATA MONITOR'' mode with

CONSULT.

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch to ``START''.

2. Check voltage between ECM

terminal

V20and ground.

Voltage:

Ignition switch ``START''

Battery voltage

Except above

Approximately 0V

NG

cOK

INSPECTION END

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector and

ignition switch harness connector.

3. Check harness continuity between ECM

terminal

V20and terminalV6.

Continuity should exist.

If OK, check harness for short to ground

and short to power.

OK

cNG

Check the following.

+Harness connectors

M52,F7

+7.5A fuse

+Fuse block

M3,E112

+Harness for open or short

between ECM and igni-

tion switch

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

Disconnect and reconnect harness connec-

tors in the circuit. Then retest.

Trouble is not ®xed.

Check ECM pin terminals for damage and

check the connection of ECM harness con-

nector. Reconnect ECM harness connector

and retest.

INSPECTION END

IGN ``ON'' OFF

IGN ``START'' ONSEF625S

SEF109P

SEF785V

.

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Start Signal (Cont'd)

EC-164

Page 331 of 1226

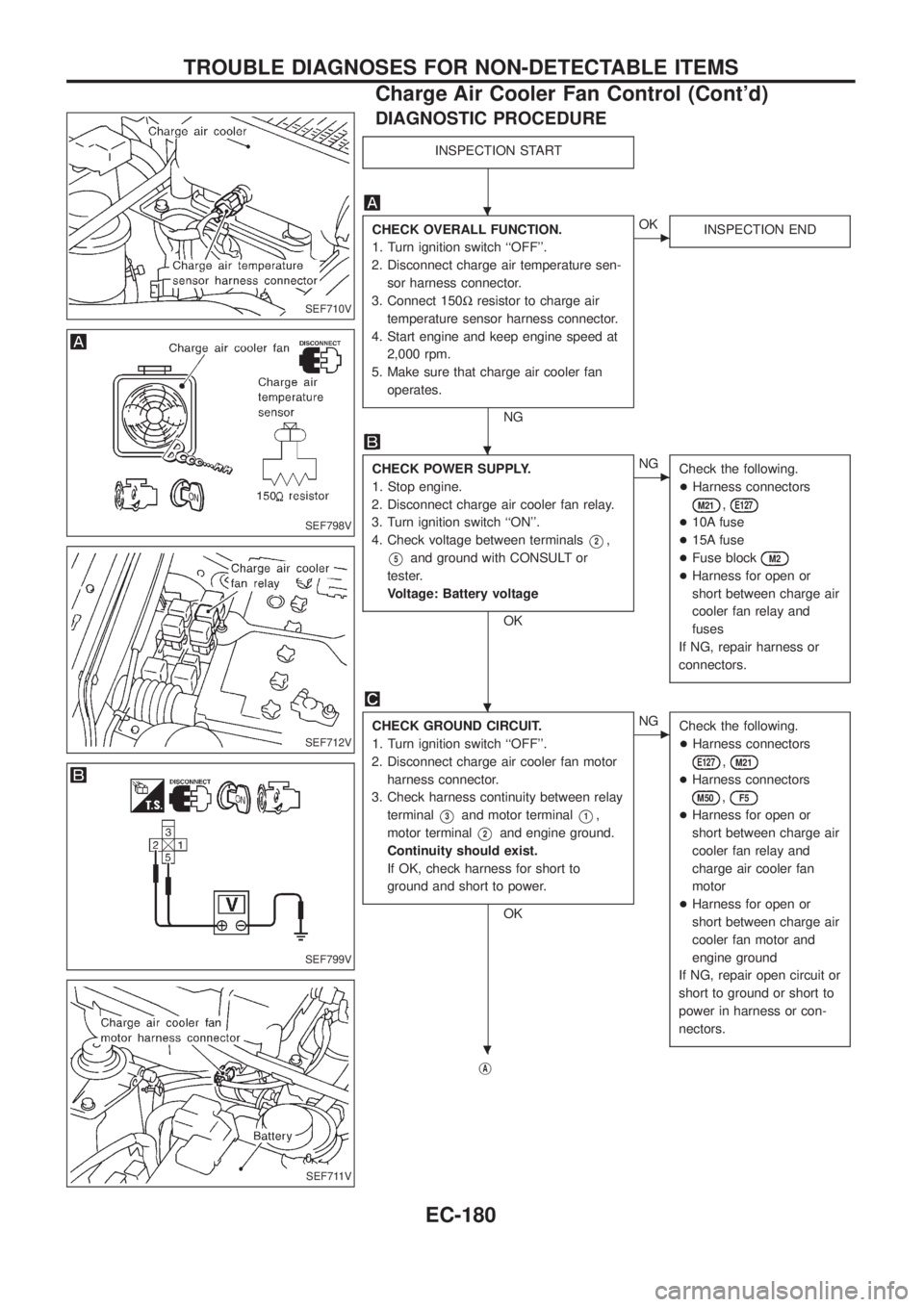

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air temperature sen-

sor harness connector.

3. Connect 150Wresistor to charge air

temperature sensor harness connector.

4. Start engine and keep engine speed at

2,000 rpm.

5. Make sure that charge air cooler fan

operates.

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect charge air cooler fan relay.

3. Turn ignition switch ``ON''.

4. Check voltage between terminals

V2,

V5and ground with CONSULT or

tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Harness connectors

M21,E127

+10A fuse

+15A fuse

+Fuse block

M2

+Harness for open or

short between charge air

cooler fan relay and

fuses

If NG, repair harness or

connectors.

CHECK GROUND CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect charge air cooler fan motor

harness connector.

3. Check harness continuity between relay

terminal

V3and motor terminalV1,

motor terminal

V2and engine ground.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

E127,M21

+Harness connectors

M50,F5

+Harness for open or

short between charge air

cooler fan relay and

charge air cooler fan

motor

+Harness for open or

short between charge air

cooler fan motor and

engine ground

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF710V

SEF798V

SEF712V

SEF799V

SEF711V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Charge Air Cooler Fan Control (Cont'd)

EC-180

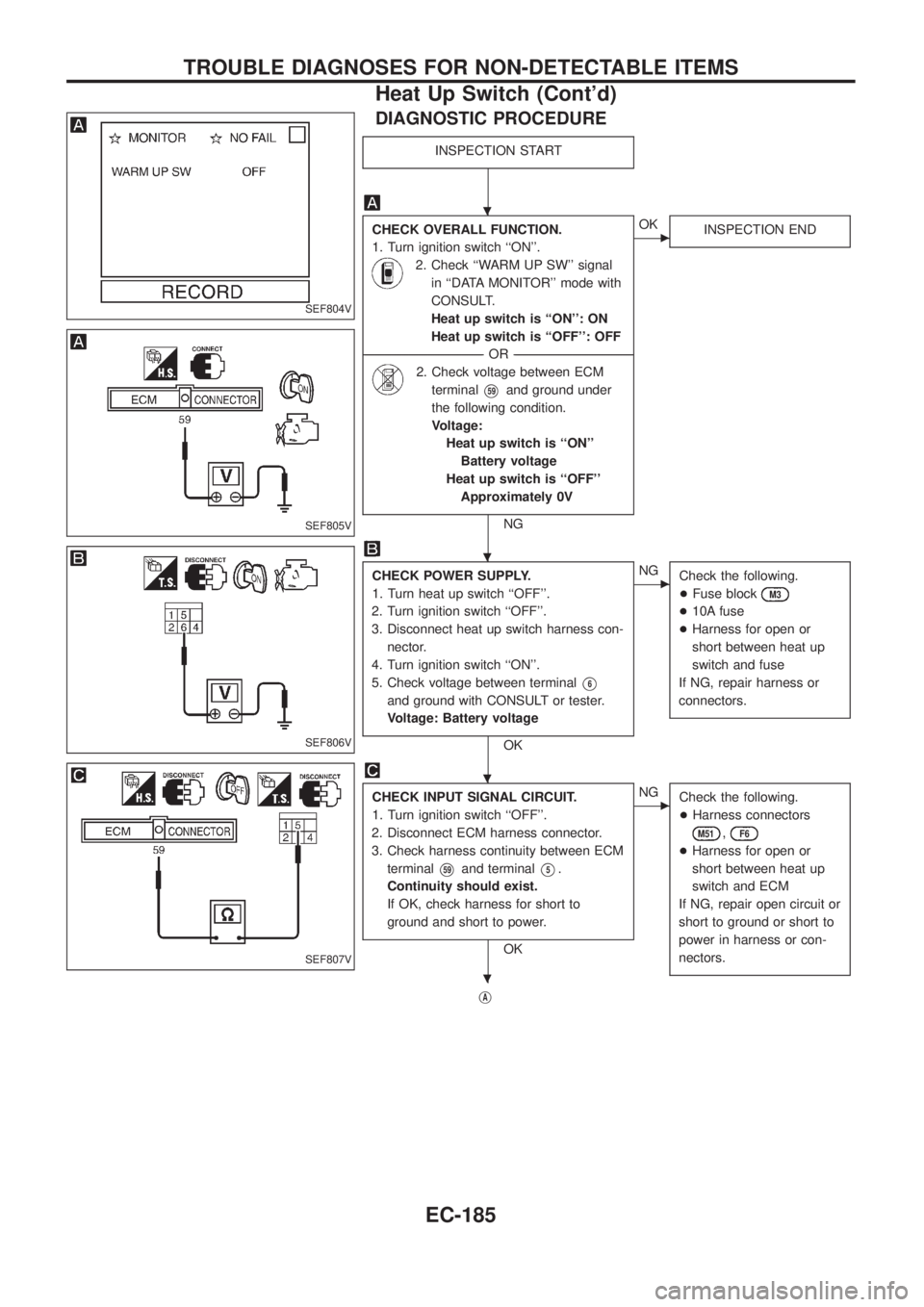

Page 336 of 1226

DIAGNOSTIC PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

1. Turn ignition switch ``ON''.

2. Check ``WARM UP SW'' signal

in ``DATA MONITOR'' mode with

CONSULT.

Heat up switch is ``ON'': ON

Heat up switch is ``OFF'': OFF

--------------------------------------------------------------------------------------------------------------------------------------OR--------------------------------------------------------------------------------------------------------------------------------------

2. Check voltage between ECM

terminal

V59and ground under

the following condition.

Voltage:

Heat up switch is ``ON''

Battery voltage

Heat up switch is ``OFF''

Approximately 0V

NG

cOK

INSPECTION END

CHECK POWER SUPPLY.

1. Turn heat up switch ``OFF''.

2. Turn ignition switch ``OFF''.

3. Disconnect heat up switch harness con-

nector.

4. Turn ignition switch ``ON''.

5. Check voltage between terminal

V6

and ground with CONSULT or tester.

Voltage: Battery voltage

OK

cNG

Check the following.

+Fuse block

M3

+10A fuse

+Harness for open or

short between heat up

switch and fuse

If NG, repair harness or

connectors.

CHECK INPUT SIGNAL CIRCUIT.

1. Turn ignition switch ``OFF''.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM

terminal

V59and terminalV5.

Continuity should exist.

If OK, check harness for short to

ground and short to power.

OK

cNG

Check the following.

+Harness connectors

M51,F6

+Harness for open or

short between heat up

switch and ECM

If NG, repair open circuit or

short to ground or short to

power in harness or con-

nectors.

jA

SEF804V

SEF805V

SEF806V

SEF807V

.

.

.

.

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Heat Up Switch (Cont'd)

EC-185

Page 343 of 1226

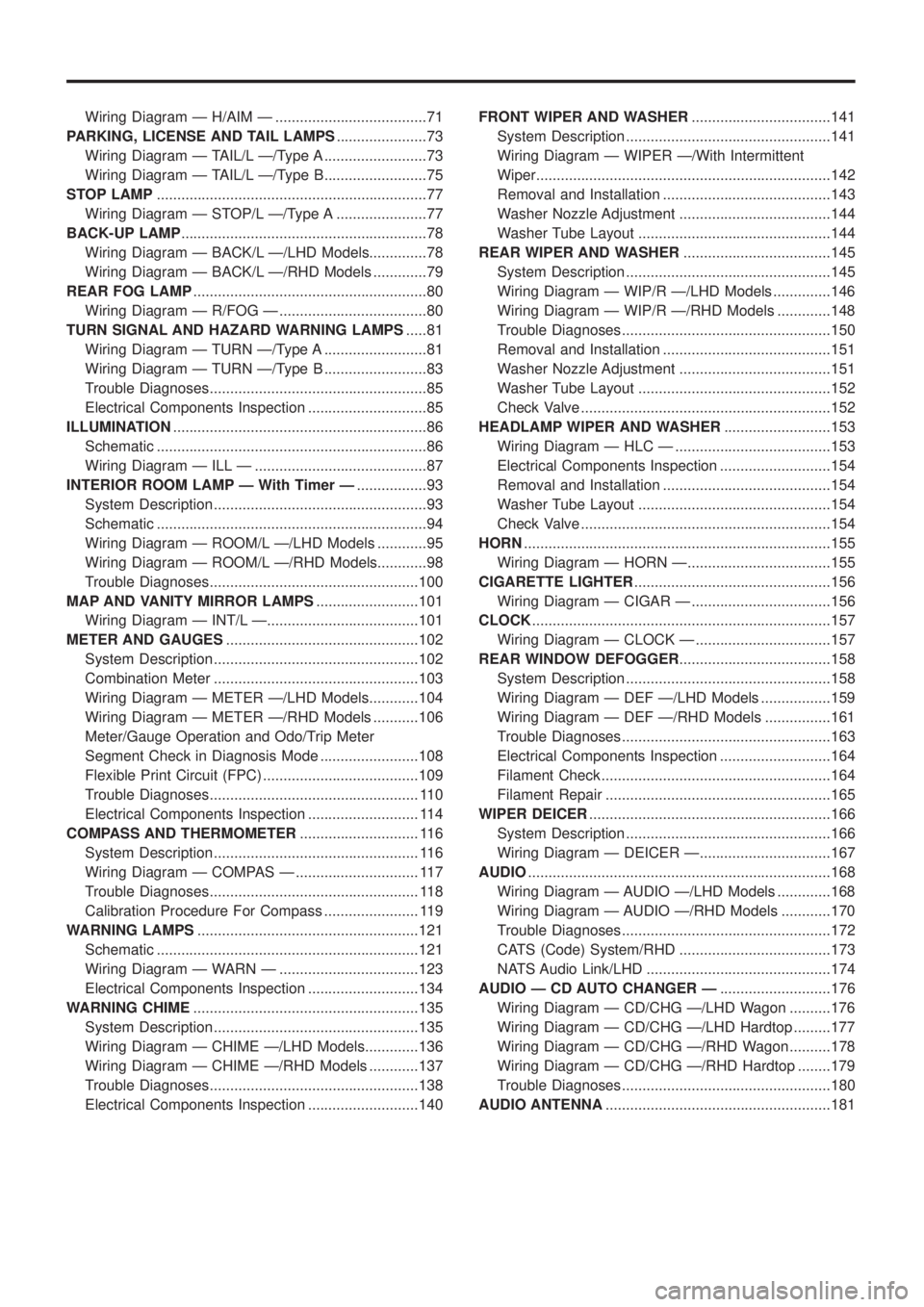

Wiring Diagram Ð H/AIM Ð .....................................71

PARKING, LICENSE AND TAIL LAMPS......................73

Wiring Diagram Ð TAIL/L Ð/Type A .........................73

Wiring Diagram Ð TAIL/L Ð/Type B.........................75

STOP LAMP..................................................................77

Wiring Diagram Ð STOP/L Ð/Type A ......................77

BACK-UP LAMP............................................................78

Wiring Diagram Ð BACK/L Ð/LHD Models..............78

Wiring Diagram Ð BACK/L Ð/RHD Models .............79

REAR FOG LAMP.........................................................80

Wiring Diagram Ð R/FOG Ð ....................................80

TURN SIGNAL AND HAZARD WARNING LAMPS.....81

Wiring Diagram Ð TURN Ð/Type A .........................81

Wiring Diagram Ð TURN Ð/Type B .........................83

Trouble Diagnoses.....................................................85

Electrical Components Inspection .............................85

ILLUMINATION..............................................................86

Schematic ..................................................................86

Wiring Diagram Ð ILL Ð ..........................................87

INTERIOR ROOM LAMP Ð With Timer Ð.................93

System Description ....................................................93

Schematic ..................................................................94

Wiring Diagram Ð ROOM/L Ð/LHD Models ............95

Wiring Diagram Ð ROOM/L Ð/RHD Models............98

Trouble Diagnoses...................................................100

MAP AND VANITY MIRROR LAMPS.........................101

Wiring Diagram Ð INT/L Ð.....................................101

METER AND GAUGES...............................................102

System Description ..................................................102

Combination Meter ..................................................103

Wiring Diagram Ð METER Ð/LHD Models............104

Wiring Diagram Ð METER Ð/RHD Models ...........106

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ........................108

Flexible Print Circuit (FPC) ......................................109

Trouble Diagnoses................................................... 110

Electrical Components Inspection ........................... 114

COMPASS AND THERMOMETER............................. 116

System Description .................................................. 116

Wiring Diagram Ð COMPAS Ð .............................. 117

Trouble Diagnoses................................................... 118

Calibration Procedure For Compass ....................... 119

WARNING LAMPS......................................................121

Schematic ................................................................121

Wiring Diagram Ð WARN Ð ..................................123

Electrical Components Inspection ...........................134

WARNING CHIME.......................................................135

System Description ..................................................135

Wiring Diagram Ð CHIME Ð/LHD Models.............136

Wiring Diagram Ð CHIME Ð/RHD Models ............137

Trouble Diagnoses...................................................138

Electrical Components Inspection ...........................140FRONT WIPER AND WASHER..................................141

System Description ..................................................141

Wiring Diagram Ð WIPER Ð/With Intermittent

Wiper........................................................................142

Removal and Installation .........................................143

Washer Nozzle Adjustment .....................................144

Washer Tube Layout ...............................................144

REAR WIPER AND WASHER....................................145

System Description ..................................................145

Wiring Diagram Ð WIP/R Ð/LHD Models ..............146

Wiring Diagram Ð WIP/R Ð/RHD Models .............148

Trouble Diagnoses...................................................150

Removal and Installation .........................................151

Washer Nozzle Adjustment .....................................151

Washer Tube Layout ...............................................152

Check Valve .............................................................152

HEADLAMP WIPER AND WASHER..........................153

Wiring Diagram Ð HLC Ð ......................................153

Electrical Components Inspection ...........................154

Removal and Installation .........................................154

Washer Tube Layout ...............................................154

Check Valve .............................................................154

HORN...........................................................................155

Wiring Diagram Ð HORN Ð...................................155

CIGARETTE LIGHTER................................................156

Wiring Diagram Ð CIGAR Ð ..................................156

CLOCK.........................................................................157

Wiring Diagram Ð CLOCK Ð .................................157

REAR WINDOW DEFOGGER.....................................158

System Description ..................................................158

Wiring Diagram Ð DEF Ð/LHD Models .................159

Wiring Diagram Ð DEF Ð/RHD Models ................161

Trouble Diagnoses...................................................163

Electrical Components Inspection ...........................164

Filament Check ........................................................164

Filament Repair .......................................................165

WIPER DEICER...........................................................166

System Description ..................................................166

Wiring Diagram Ð DEICER Ð................................167

AUDIO..........................................................................168

Wiring Diagram Ð AUDIO Ð/LHD Models .............168

Wiring Diagram Ð AUDIO Ð/RHD Models ............170

Trouble Diagnoses...................................................172

CATS (Code) System/RHD .....................................173

NATS Audio Link/LHD .............................................174

AUDIO Ð CD AUTO CHANGER Ð...........................176

Wiring Diagram Ð CD/CHG Ð/LHD Wagon ..........176

Wiring Diagram Ð CD/CHG Ð/LHD Hardtop .........177

Wiring Diagram Ð CD/CHG Ð/RHD Wagon ..........178

Wiring Diagram Ð CD/CHG Ð/RHD Hardtop ........179

Trouble Diagnoses...................................................180

AUDIO ANTENNA.......................................................181

Page 344 of 1226

Wiring Diagram Ð P/ANT Ð/LHD Models..............181

Wiring Diagram Ð P/ANT Ð/RHD Models .............182

Trouble Diagnoses...................................................183

Location of Antenna .................................................183

Antenna Rod Replacement .....................................183

Window Antenna Repair ..........................................184

ELECTRIC SUNROOF................................................186

Wiring Diagram Ð SROOF Ð ................................186

POWER DOOR MIRROR............................................188

Wiring Diagram Ð MIRROR Ð/LHD Models..........188

Wiring Diagram Ð MIRROR Ð/RHD Models .........189

POWER SEAT.............................................................190

Wiring Diagram Ð SEAT Ð/LHD Models ...............190

Wiring Diagram Ð SEAT Ð/RHD Models...............192

HEATED SEAT............................................................194

Wiring Diagram Ð HSEAT Ð..................................194

POWER WINDOW.......................................................196

System Description ..................................................196

Schematic ................................................................197

Wiring Diagram Ð WINDOW Ð .............................198

Trouble Diagnoses...................................................203

POWER DOOR LOCK.................................................204

System Description ..................................................204

Wiring Diagram Ð D/LOCK Ð ................................205

Trouble Diagnosis ....................................................207

POWER DOOR LOCK Ð Super Lock Ð.................. 211

Component Parts and Harness Connector

Location ................................................................... 211

System Description ..................................................212

Schematic ................................................................214

Wiring Diagram Ð S/LOCK Ð/LHD Models ...........215

Wiring Diagram Ð S/LOCK Ð/RHD Models ..........219

Trouble Diagnoses...................................................223

MULTI-REMOTE CONTROL SYSTEM.......................234

System Description ..................................................234

Wiring Diagram Ð MULTI Ð/LHD Models..............235

Trouble Diagnoses...................................................237

ID Code Entry Procedure ........................................239

NATS (Nissan Anti-Theft System)/LHD MODELS....240System Description ..................................................240

System Composition ................................................240

Wiring Diagram Ð NATS Ð ....................................241

CONSULT ................................................................242

Trouble Diagnoses...................................................244

How to Replace NATS IMMU ..................................253

NATS (Nissan Anti-Theft System)/RHD MODELS...254

Component Parts and Harness Connector

Location ...................................................................254

System Description ..................................................255

System Composition ................................................255

Wiring Diagram Ð NATS Ð ....................................256

CONSULT ................................................................257

Trouble Diagnoses...................................................259

LOCATION OF ELECTRICAL UNITS.........................269

Engine Compartment ...............................................269

Passenger Compartment Ð LHD Models ...............270

Passenger Compartment Ð RHD Models ..............272

HARNESS LAYOUT....................................................275

How to Read Harness Layout .................................275

Outline/LHD Models.................................................276

Outline/RHD Models ................................................277

Main Harness/LHD Models......................................278

Main Harness/RHD Models .....................................282

Engine Room Harness/LHD Models .......................286

Engine Room Harness/RHD Models .......................290

Engine Harness .......................................................294

Engine Control Harness and Alternator Harness ....295

Body Harness/LHD Models .....................................296

Body Harness/RHD Models.....................................300

Body No. 2 Harness/LHD Models ...........................304

Body No. 2 Harness/RHD Models...........................306

Chassis Harness......................................................308

Room Lamp Harness...............................................309

Front Door Harness (Driver side) ............................310

Front Door Harness (Passenger side) .................... 311

Rear Door Harness..................................................312

Back Door Harness and Rear Window Defogger

Harness....................................................................313

Page 345 of 1226

BULB SPECIFICATIONS............................................314

Headlamp.................................................................314

Exterior Lamp ..........................................................314

Interior Lamp............................................................314

WIRING DIAGRAM CODES (CELL CODES) .............315

WIRING DIAGRAM REFERENCE CHART

ECCS, IGNITION SYSTEM ........................................................................\

................... EC SECTION

ANTI-LOCK BRAKE SYSTEM ........................................................................\

.............. BR SECTION

SRS ``AIR BAG'' ........................................................................\

.................................... RS SECT ION

HEATER AND AIR CONDITIONER ........................................................................\

...... HA SECTION

DIFFERENTIAL CARRIER ........................................................................\

.................... PD SECTION

REAR SUSPENSION ........................................................................\

............................. RA SECTION

FUEL SYSTEM ........................................................................\

....................................... FE SECT ION

Page 347 of 1226

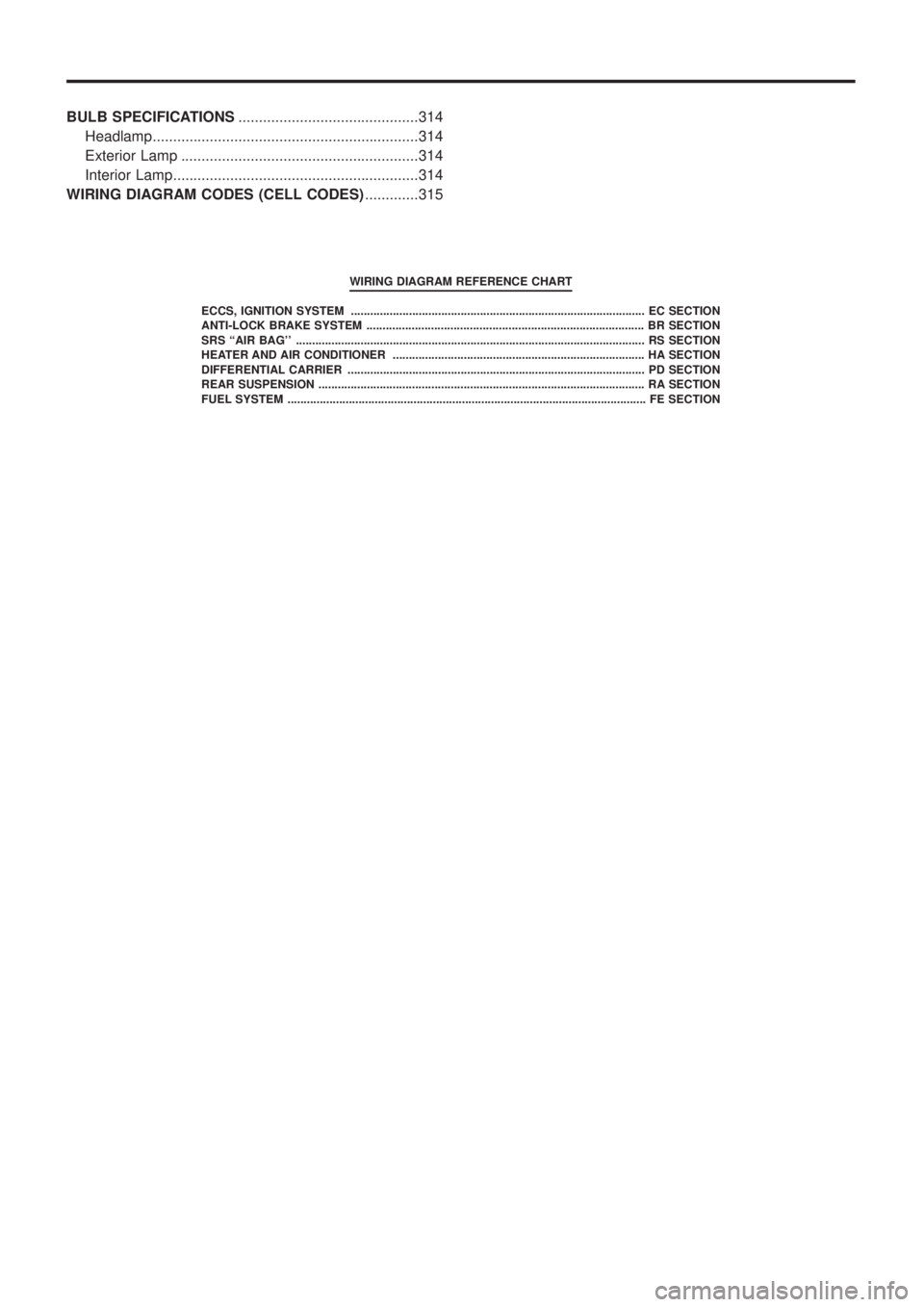

Description

HARNESS CONNECTOR

+All harness connectors have been modi®ed to prevent accidental looseness or disconnection.

+The connector can be disconnected by pushing or lifting the locking section.

CAUTION:

Do not pull the harness when disconnecting the connector.

[Example]

SEL769D

HARNESS CONNECTOR

EL-2

Page 393 of 1226

2. Continuity test (between ``S'' terminal and ``M'' terminal).

+No continuity ... Replace.

PINION/CLUTCH CHECK

1. Inspect pinion teeth.

+Replace pinion if teeth are worn or damaged. (Also check con-

dition of ring gear teeth.)

2. Inspect reduction gear teeth (If equipped).

+Replace reduction gear if teeth are worn or damaged. (Also

check condition of armature shaft gear teeth.)

3. Check to see if pinion locks in one direction and rotates

smoothly in the opposite direction.

+If it locks or rotates in both directions, or unusual resistance is

evident. ... Replace.

BRUSH CHECK

Brush

Check wear of brush.

Wear limit length:

Refer to SDS (EL-51).

+Excessive wear ... Replace.

Brush spring pressure

Check brush spring pressure with brush spring detached from

brush.

Spring pressure (with new brush):

Refer to SDS (EL-51).

+Not within the speci®ed values ... Replace.

Brush holder

1. Perform insulation test between brush holder (positive side)

and its base (negative side).

+Continuity exists. ... Replace.

2. Check brush to see if it moves smoothly.

+If brush holder is bent, replace it; if sliding surface is dirty, clean.

SEL038H

SEL630BA

SEL014Z

SEL015Z

SEL568B

STARTING SYSTEM

Inspection (Cont'd)

EL-48

Page 399 of 1226

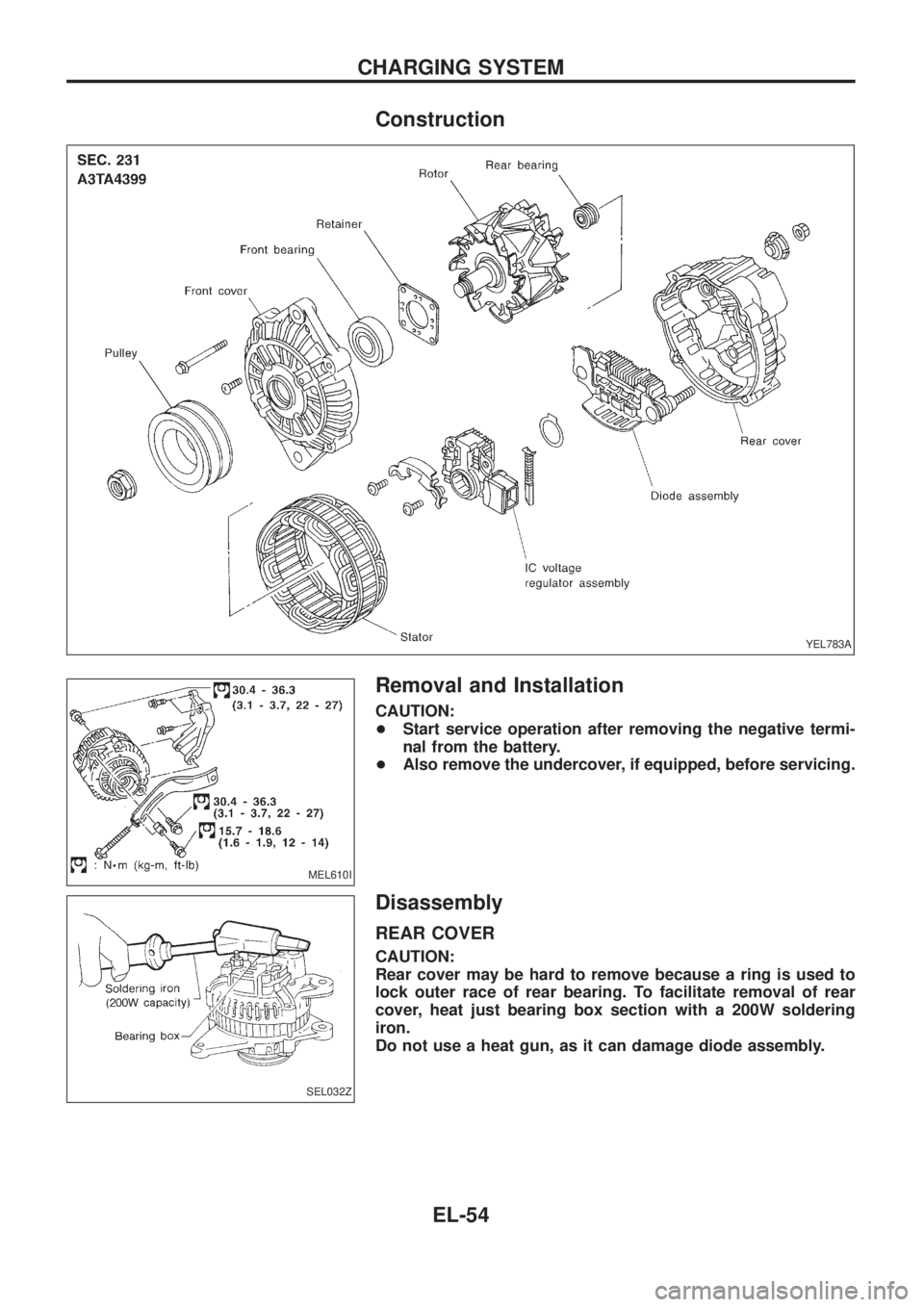

Construction

Removal and Installation

CAUTION:

+Start service operation after removing the negative termi-

nal from the battery.

+Also remove the undercover, if equipped, before servicing.

Disassembly

REAR COVER

CAUTION:

Rear cover may be hard to remove because a ring is used to

lock outer race of rear bearing. To facilitate removal of rear

cover, heat just bearing box section with a 200W soldering

iron.

Do not use a heat gun, as it can damage diode assembly.

YEL783A

MEL610I

SEL032Z

CHARGING SYSTEM

EL-54

Page 408 of 1226

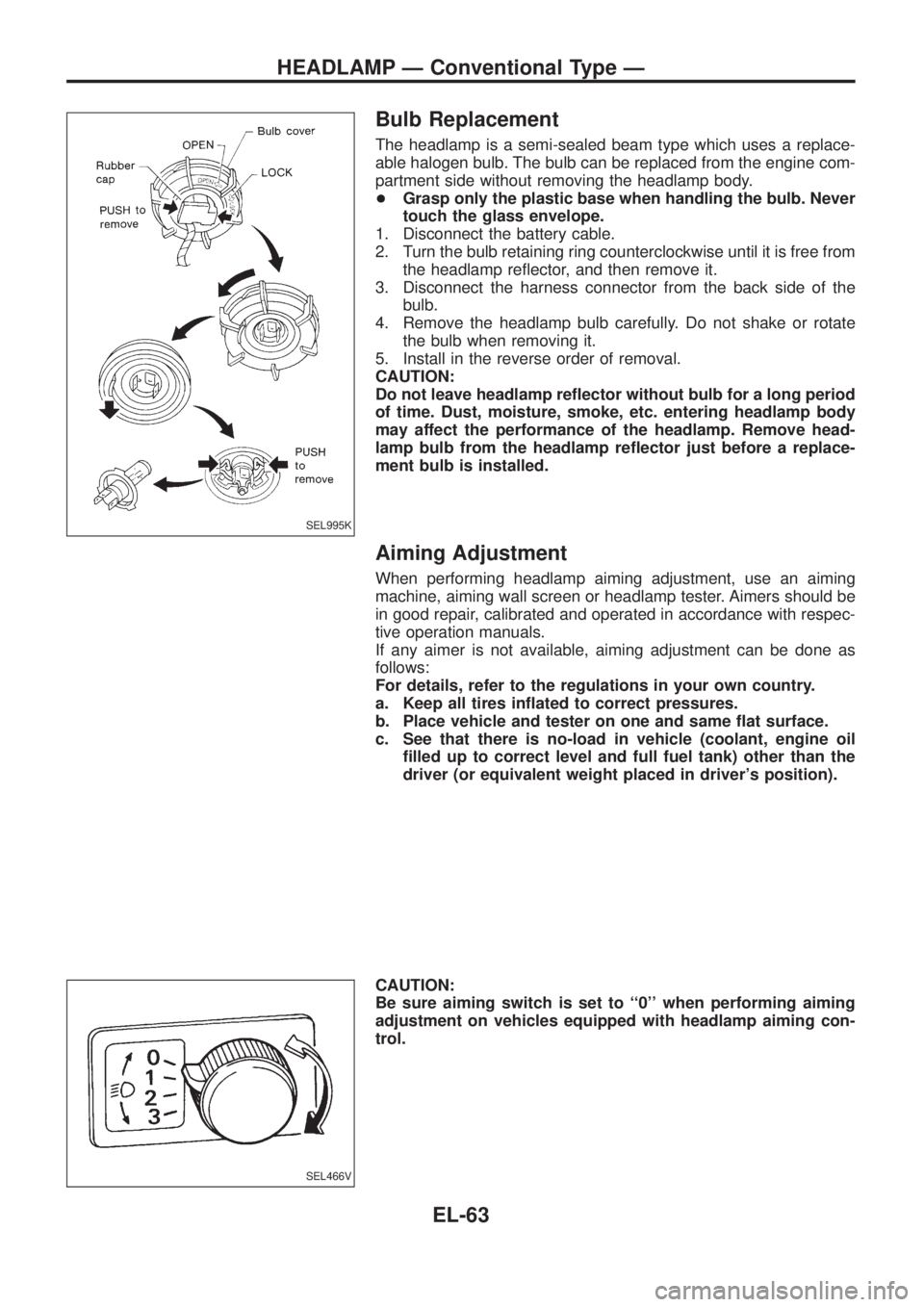

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine com-

partment side without removing the headlamp body.

+Grasp only the plastic base when handling the bulb. Never

touch the glass envelope.

1. Disconnect the battery cable.

2. Turn the bulb retaining ring counterclockwise until it is free from

the headlamp re¯ector, and then remove it.

3. Disconnect the harness connector from the back side of the

bulb.

4. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

5. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp re¯ector without bulb for a long period

of time. Dust, moisture, smoke, etc. entering headlamp body

may affect the performance of the headlamp. Remove head-

lamp bulb from the headlamp re¯ector just before a replace-

ment bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should be

in good repair, calibrated and operated in accordance with respec-

tive operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires in¯ated to correct pressures.

b. Place vehicle and tester on one and same ¯at surface.

c. See that there is no-load in vehicle (coolant, engine oil

®lled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ``0'' when performing aiming

adjustment on vehicles equipped with headlamp aiming con-

trol.

SEL995K

SEL466V

HEADLAMP Ð Conventional Type Ð

EL-63