lock NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 42 of 1226

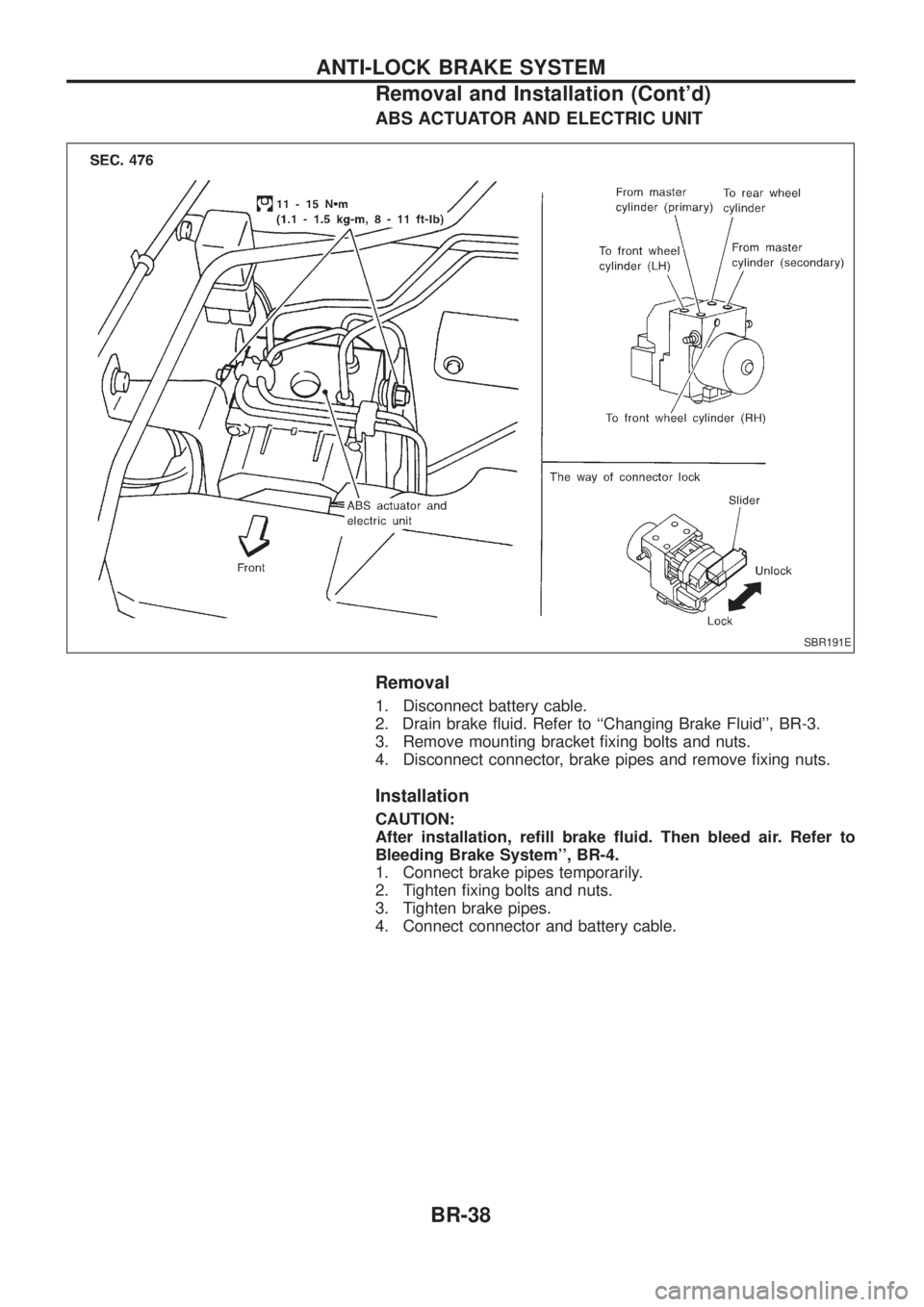

ABS ACTUATOR AND ELECTRIC UNIT

Removal

1. Disconnect battery cable.

2. Drain brake ¯uid. Refer to ``Changing Brake Fluid'', BR-3.

3. Remove mounting bracket ®xing bolts and nuts.

4. Disconnect connector, brake pipes and remove ®xing nuts.

Installation

CAUTION:

After installation, re®ll brake ¯uid. Then bleed air. Refer to

Bleeding Brake System'', BR-4.

1. Connect brake pipes temporarily.

2. Tighten ®xing bolts and nuts.

3. Tighten brake pipes.

4. Connect connector and battery cable.

SBR191E

ANTI-LOCK BRAKE SYSTEM

Removal and Installation (Cont'd)BR-38

Page 51 of 1226

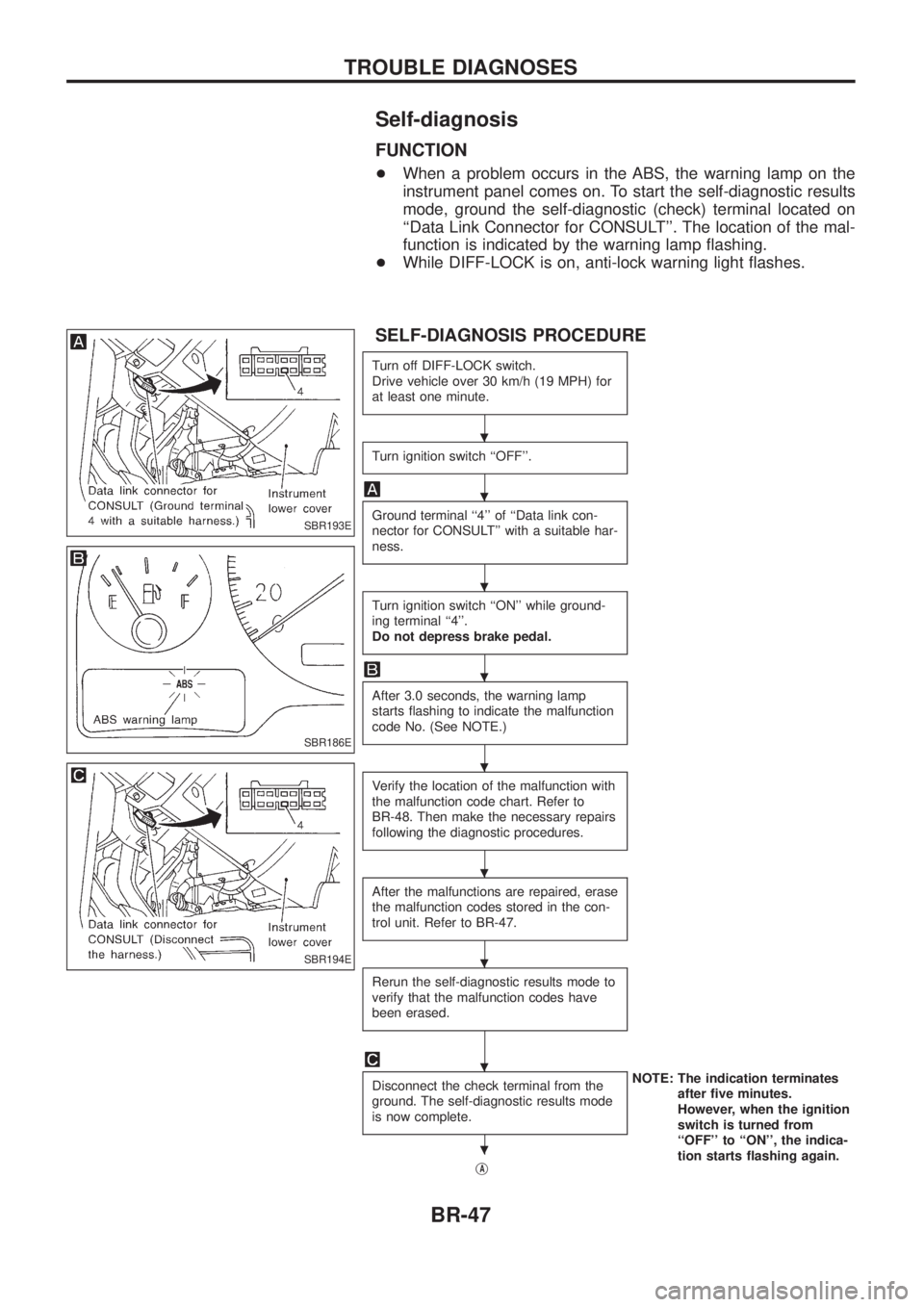

Self-diagnosis

FUNCTION

+When a problem occurs in the ABS, the warning lamp on the

instrument panel comes on. To start the self-diagnostic results

mode, ground the self-diagnostic (check) terminal located on

``Data Link Connector for CONSULT''. The location of the mal-

function is indicated by the warning lamp ¯ashing.

+ While DIFF-LOCK is on, anti-lock warning light ¯ashes.

SELF-DIAGNOSIS PROCEDURE

Turn off DIFF-LOCK switch.

Drive vehicle over 30 km/h (19 MPH) for

at least one minute.

Turn ignition switch ``OFF''.

Ground terminal ``4'' of ``Data link con-

nector for CONSULT'' with a suitable har-

ness.

Turn ignition switch ``ON'' while ground-

ing terminal ``4''.

Do not depress brake pedal.

After 3.0 seconds, the warning lamp

starts ¯ashing to indicate the malfunction

code No. (See NOTE.)

Verify the location of the malfunction with

the malfunction code chart. Refer to

BR-48. Then make the necessary repairs

following the diagnostic procedures.

After the malfunctions are repaired, erase

the malfunction codes stored in the con-

trol unit. Refer to BR-47.

Rerun the self-diagnostic results mode to

verify that the malfunction codes have

been erased.

Disconnect the check terminal from the

ground. The self-diagnostic results mode

is now complete.NOTE: The indication terminates

after ®ve minutes.

However, when the ignition

switch is turned from

``OFF'' to ``ON'', the indica-

tion starts ¯ashing again.

j

A

SBR193E

SBR186E

SBR194E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-47

Page 82 of 1226

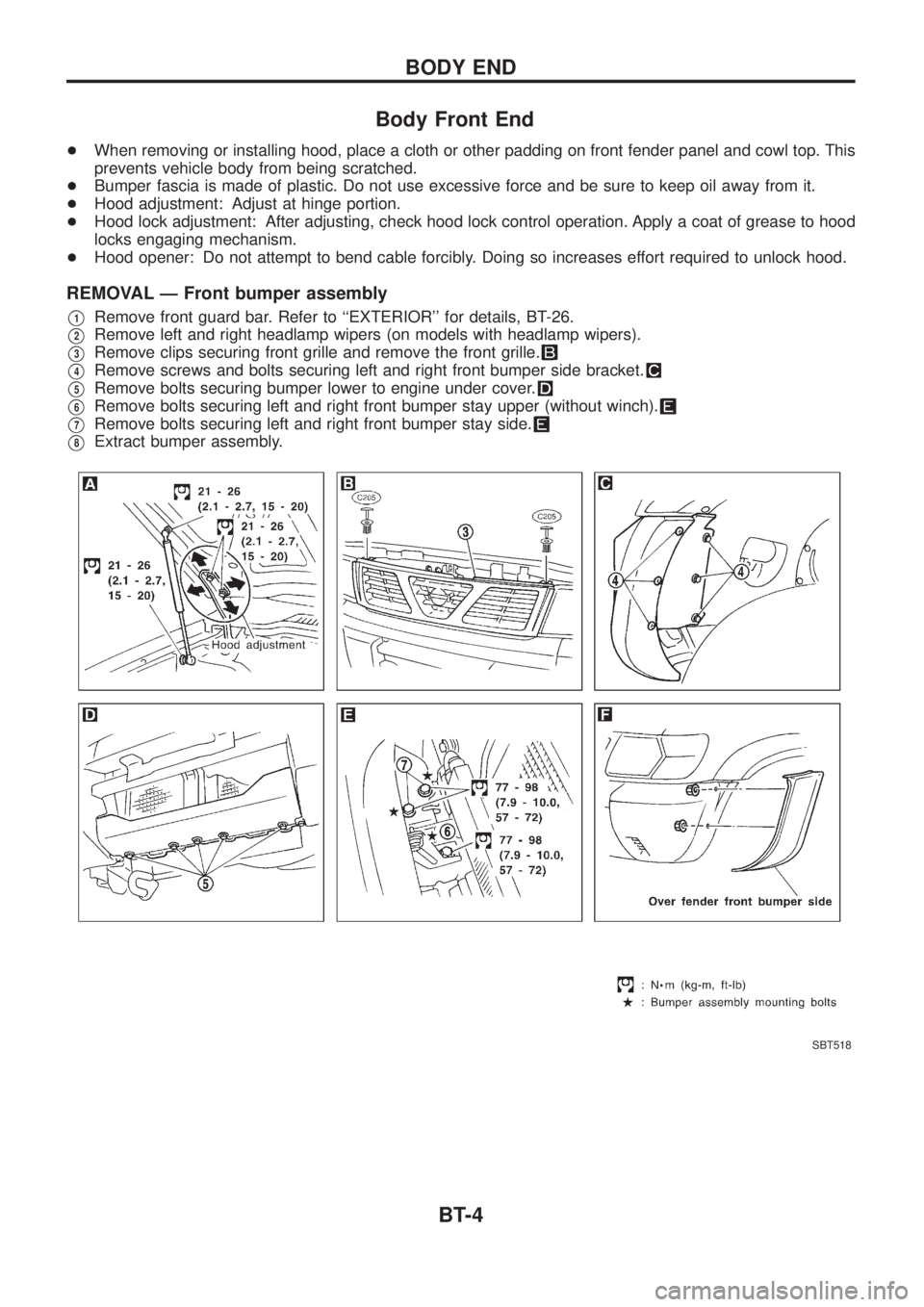

Body Front End

+When removing or installing hood, place a cloth or other padding on front fender panel and cowl top. This

prevents vehicle body from being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Hood adjustment: Adjust at hinge portion.

+Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

+Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

REMOVAL Ð Front bumper assembly

V1Remove front guard bar. Refer to ``EXTERIOR'' for details, BT-26.

V2Remove left and right headlamp wipers (on models with headlamp wipers).

V3Remove clips securing front grille and remove the front grille.

V4Remove screws and bolts securing left and right front bumper side bracket.

V5Remove bolts securing bumper lower to engine under cover.

V6Remove bolts securing left and right front bumper stay upper (without winch).

V7Remove bolts securing left and right front bumper stay side.

V8Extract bumper assembly.

SBT518

BODY END

BT-4

Page 84 of 1226

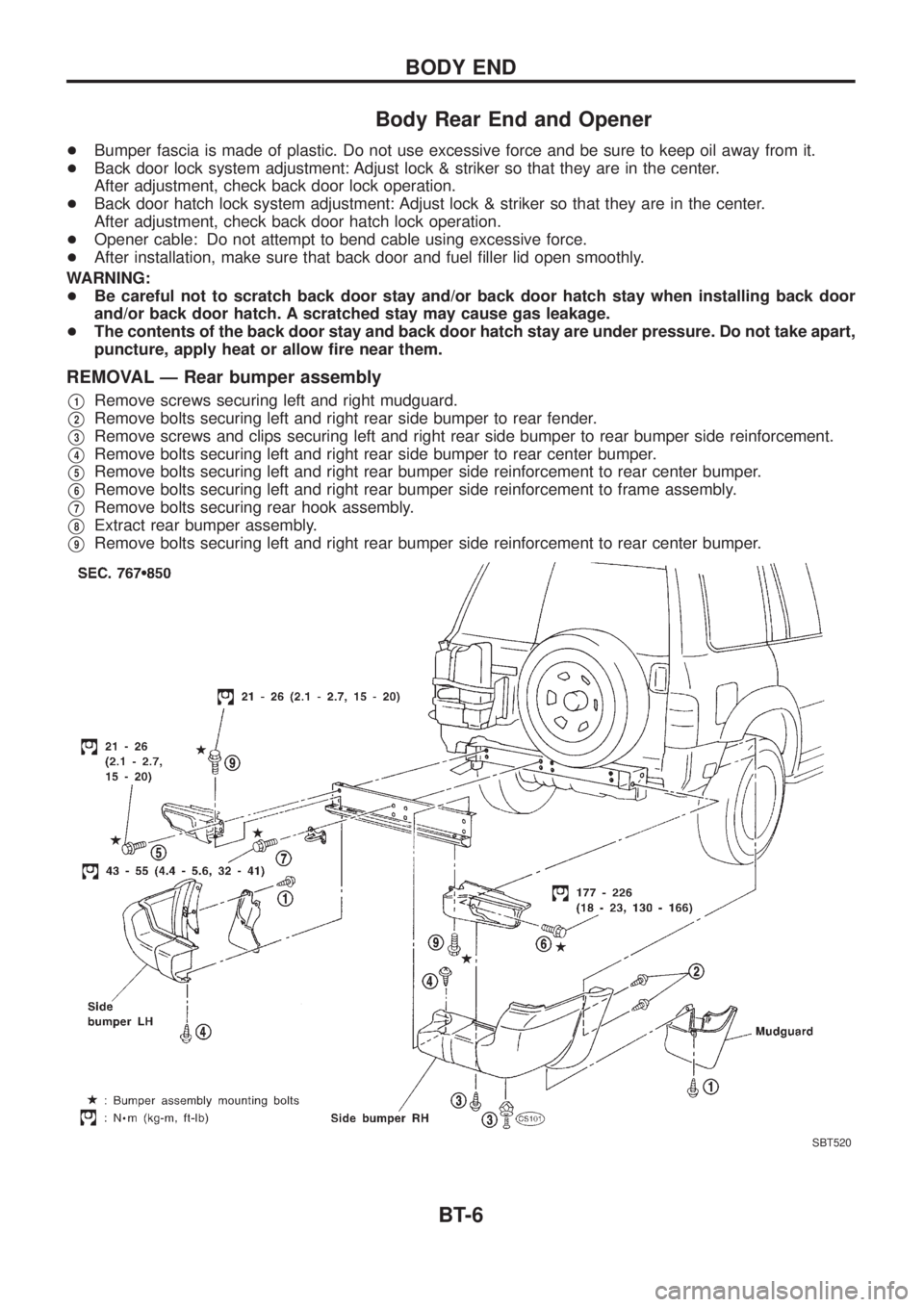

Body Rear End and Opener

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Back door lock system adjustment: Adjust lock & striker so that they are in the center.

After adjustment, check back door lock operation.

+Back door hatch lock system adjustment: Adjust lock & striker so that they are in the center.

After adjustment, check back door hatch lock operation.

+Opener cable: Do not attempt to bend cable using excessive force.

+After installation, make sure that back door and fuel ®ller lid open smoothly.

WARNING:

+Be careful not to scratch back door stay and/or back door hatch stay when installing back door

and/or back door hatch. A scratched stay may cause gas leakage.

+The contents of the back door stay and back door hatch stay are under pressure. Do not take apart,

puncture, apply heat or allow ®re near them.

REMOVAL Ð Rear bumper assembly

V1Remove screws securing left and right mudguard.

V2Remove bolts securing left and right rear side bumper to rear fender.

V3Remove screws and clips securing left and right rear side bumper to rear bumper side reinforcement.

V4Remove bolts securing left and right rear side bumper to rear center bumper.

V5Remove bolts securing left and right rear bumper side reinforcement to rear center bumper.

V6Remove bolts securing left and right rear bumper side reinforcement to frame assembly.

V7Remove bolts securing rear hook assembly.

V8Extract rear bumper assembly.

V9Remove bolts securing left and right rear bumper side reinforcement to rear center bumper.

SBT520

BODY END

BT-6

Page 87 of 1226

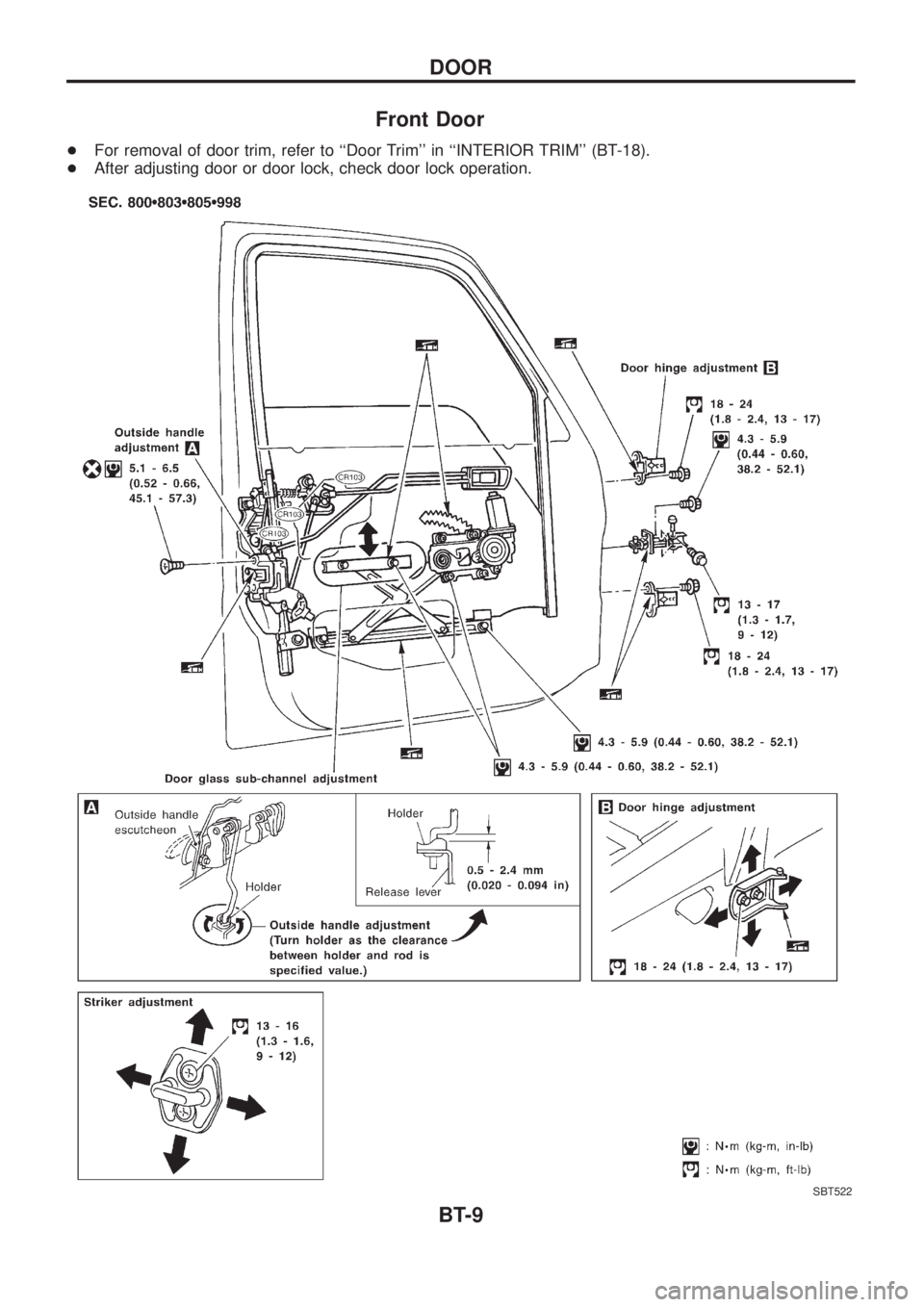

Front Door

+For removal of door trim, refer to ``Door Trim'' in ``INTERIOR TRIM'' (BT-18).

+After adjusting door or door lock, check door lock operation.

SBT522

DOOR

BT-9

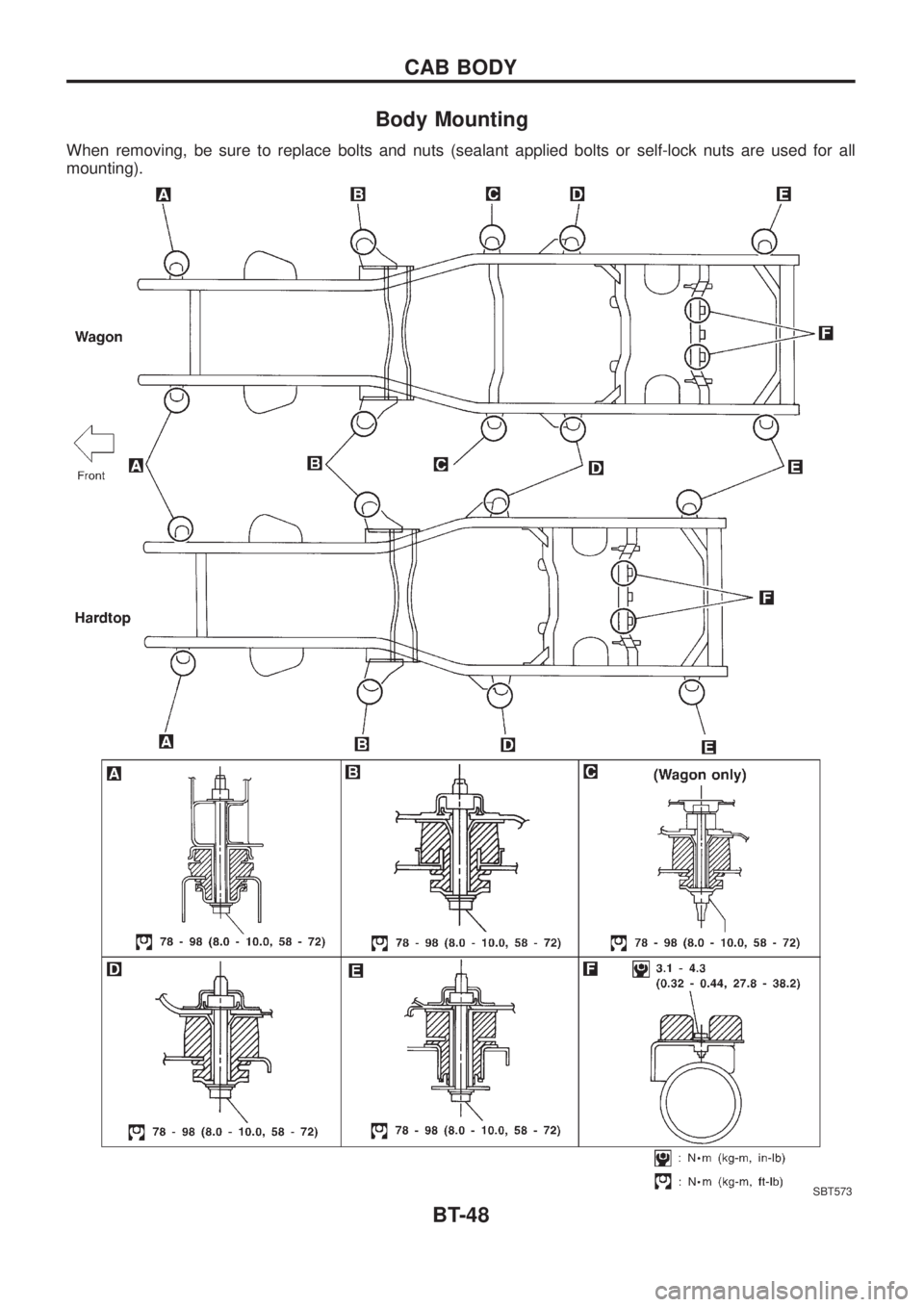

Page 126 of 1226

Body Mounting

When removing, be sure to replace bolts and nuts (sealant applied bolts or self-lock nuts are used for all

mounting).

SBT573

CAB BODY

BT-48

Page 138 of 1226

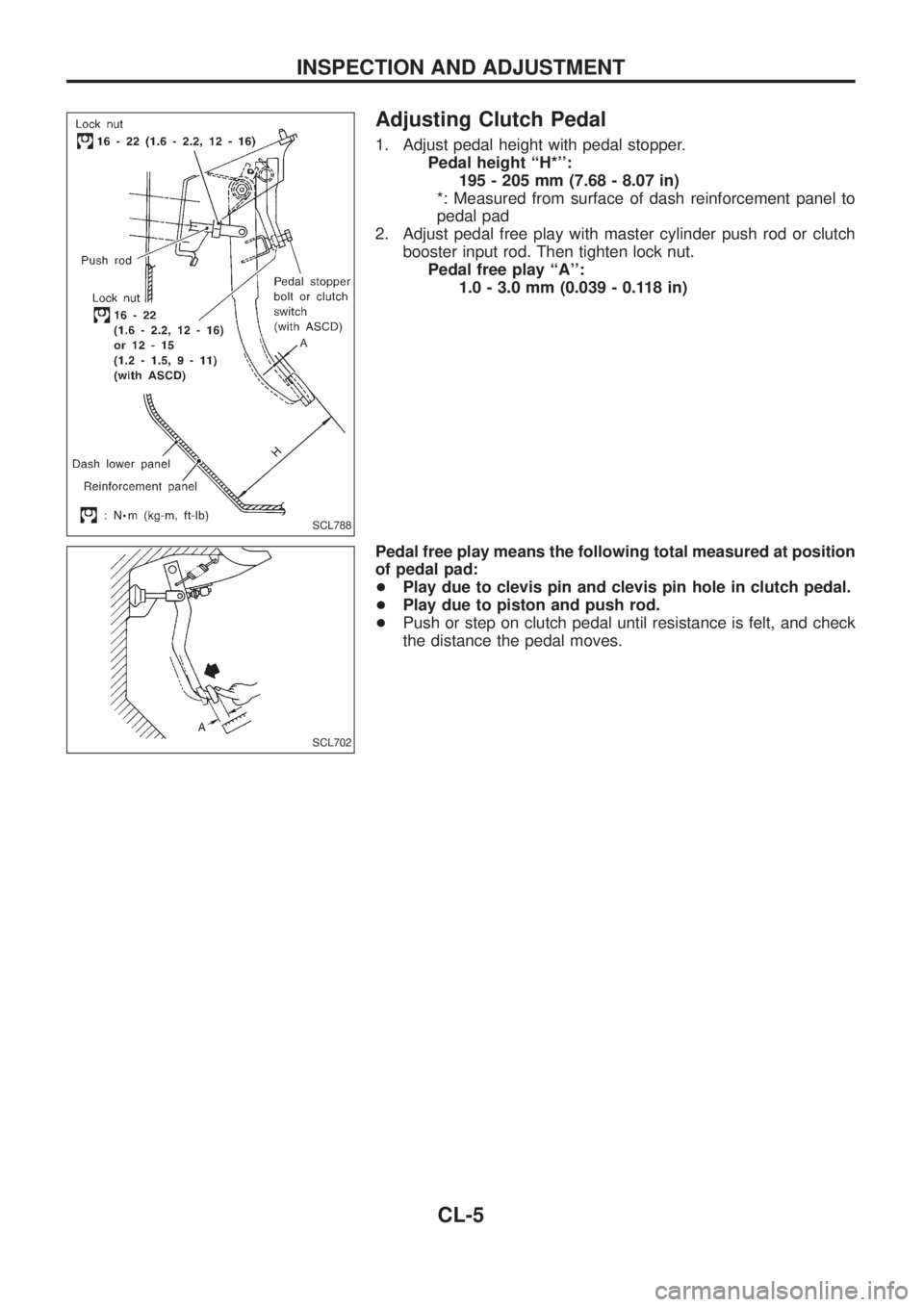

Adjusting Clutch Pedal

1. Adjust pedal height with pedal stopper.

Pedal height ``H*'':

195 - 205 mm (7.68 - 8.07 in)

*: Measured from surface of dash reinforcement panel to

pedal pad

2. Adjust pedal free play with master cylinder push rod or clutch

booster input rod. Then tighten lock nut.

Pedal free play ``A'':

1.0 - 3.0 mm (0.039 - 0.118 in)

Pedal free play means the following total measured at position

of pedal pad:

+Play due to clevis pin and clevis pin hole in clutch pedal.

+Play due to piston and push rod.

+Push or step on clutch pedal until resistance is felt, and check

the distance the pedal moves.

SCL788

SCL702

INSPECTION AND ADJUSTMENT

CL-5

Page 147 of 1226

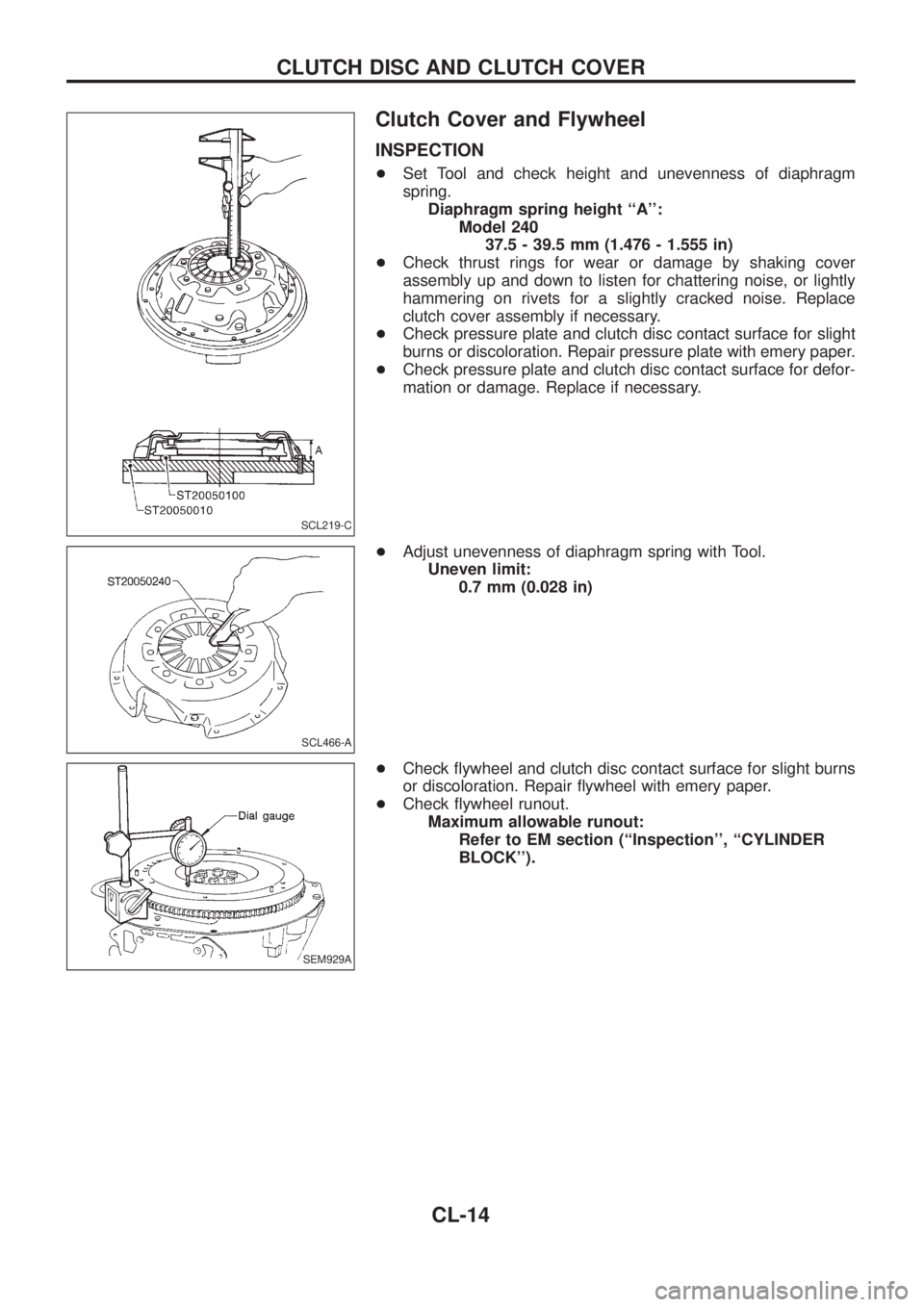

Clutch Cover and Flywheel

INSPECTION

+Set Tool and check height and unevenness of diaphragm

spring.

Diaphragm spring height ``A'':

Model 240

37.5 - 39.5 mm (1.476 - 1.555 in)

+Check thrust rings for wear or damage by shaking cover

assembly up and down to listen for chattering noise, or lightly

hammering on rivets for a slightly cracked noise. Replace

clutch cover assembly if necessary.

+Check pressure plate and clutch disc contact surface for slight

burns or discoloration. Repair pressure plate with emery paper.

+Check pressure plate and clutch disc contact surface for defor-

mation or damage. Replace if necessary.

+Adjust unevenness of diaphragm spring with Tool.

Uneven limit:

0.7 mm (0.028 in)

+Check ¯ywheel and clutch disc contact surface for slight burns

or discoloration. Repair ¯ywheel with emery paper.

+Check ¯ywheel runout.

Maximum allowable runout:

Refer to EM section (``Inspection'', ``CYLINDER

BLOCK'').

SCL219-C

SCL466-A

SEM929A

CLUTCH DISC AND CLUTCH COVER

CL-14

Page 198 of 1226

jA

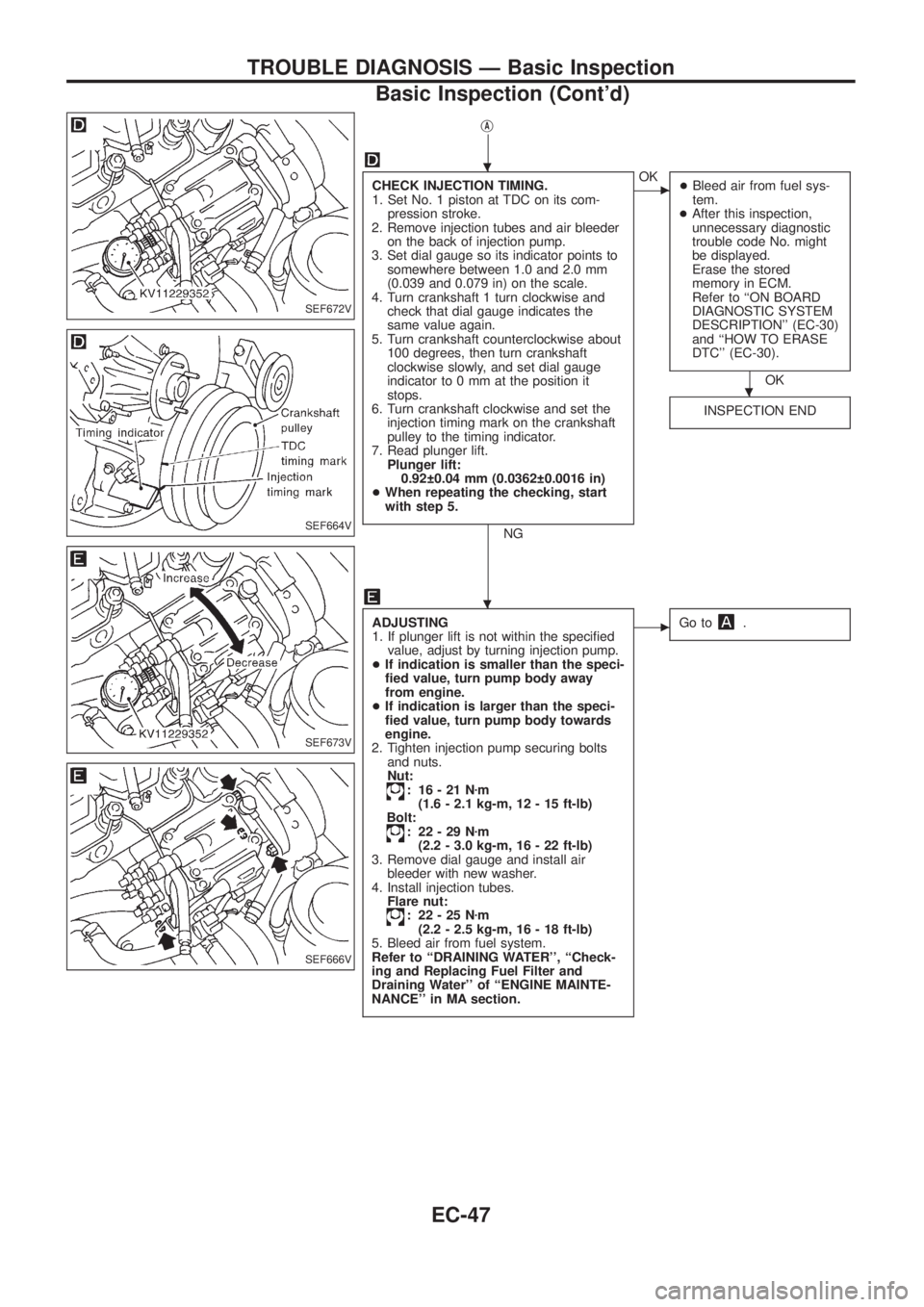

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

2. Remove injection tubes and air bleeder

on the back of injection pump.

3. Set dial gauge so its indicator points to

somewhere between 1.0 and 2.0 mm

(0.039 and 0.079 in) on the scale.

4. Turn crankshaft 1 turn clockwise and

check that dial gauge indicates the

same value again.

5. Turn crankshaft counterclockwise about

100 degrees, then turn crankshaft

clockwise slowly, and set dial gauge

indicator to 0 mm at the position it

stops.

6. Turn crankshaft clockwise and set the

injection timing mark on the crankshaft

pulley to the timing indicator.

7. Read plunger lift.

Plunger lift:

0.92 0.04 mm (0.0362 0.0016 in)

+When repeating the checking, start

with step 5.

NG

cOK

+Bleed air from fuel sys-

tem.

+After this inspection,

unnecessary diagnostic

trouble code No. might

be displayed.

Erase the stored

memory in ECM.

Refer to ``ON BOARD

DIAGNOSTIC SYSTEM

DESCRIPTION'' (EC-30)

and ``HOW TO ERASE

DTC'' (EC-30).

OK

INSPECTION END

ADJUSTING

1. If plunger lift is not within the speci®ed

value, adjust by turning injection pump.

+If indication is smaller than the speci-

®ed value, turn pump body away

from engine.

+If indication is larger than the speci-

®ed value, turn pump body towards

engine.

2. Tighten injection pump securing bolts

and nuts.

Nut:

: 16-21Nzm

(1.6 - 2.1 kg-m, 12 - 15 ft-lb)

Bolt:

: 22-29Nzm

(2.2 - 3.0 kg-m, 16 - 22 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 22-25Nzm

(2.2 - 2.5 kg-m, 16 - 18 ft-lb)

5. Bleed air from fuel system.

Refer to ``DRAINING WATER'', ``Check-

ing and Replacing Fuel Filter and

Draining Water'' of ``ENGINE MAINTE-

NANCE'' in MA section.

cGo to.

SEF672V

SEF664V

SEF673V

SEF666V

.

.

.

TROUBLE DIAGNOSIS Ð Basic Inspection

Basic Inspection (Cont'd)

EC-47

Page 271 of 1226

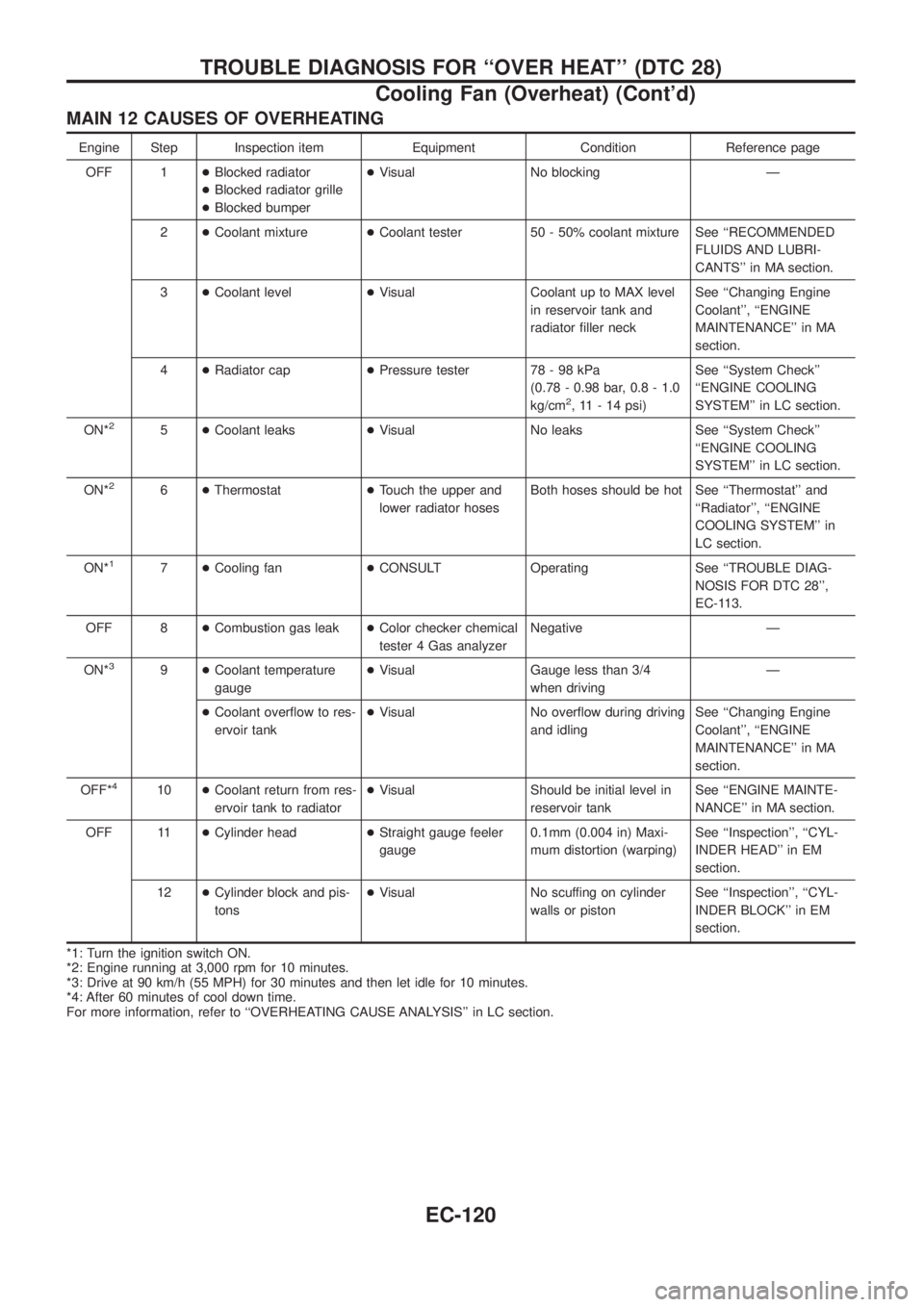

MAIN 12 CAUSES OF OVERHEATING

Engine Step Inspection item Equipment Condition Reference page

OFF 1+Blocked radiator

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 50 - 50% coolant mixture See ``RECOMMENDED

FLUIDS AND LUBRI-

CANTS'' in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator ®ller neckSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)See ``System Check''

``ENGINE COOLING

SYSTEM'' in LC section.

ON*

25+Coolant leaks+Visual No leaks See ``System Check''

``ENGINE COOLING

SYSTEM'' in LC section.

ON*

26+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot See ``Thermostat'' and

``Radiator'', ``ENGINE

COOLING SYSTEM'' in

LC section.

ON*

17+Cooling fan+CONSULT Operating See ``TROUBLE DIAG-

NOSIS FOR DTC 28'',

EC-113.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 Gas analyzerNegative Ð

ON*

39+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant over¯ow to res-

ervoir tank+Visual No over¯ow during driving

and idlingSee ``Changing Engine

Coolant'', ``ENGINE

MAINTENANCE'' in MA

section.

OFF*

410+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ``ENGINE MAINTE-

NANCE'' in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1mm (0.004 in) Maxi-

mum distortion (warping)See ``Inspection'', ``CYL-

INDER HEAD'' in EM

section.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ``Inspection'', ``CYL-

INDER BLOCK'' in EM

section.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ``OVERHEATING CAUSE ANALYSIS'' in LC section.

TROUBLE DIAGNOSIS FOR ``OVER HEAT'' (DTC 28)

Cooling Fan (Overheat) (Cont'd)

EC-120