ECO mode NISSAN PATROL 2006 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 517 of 1226

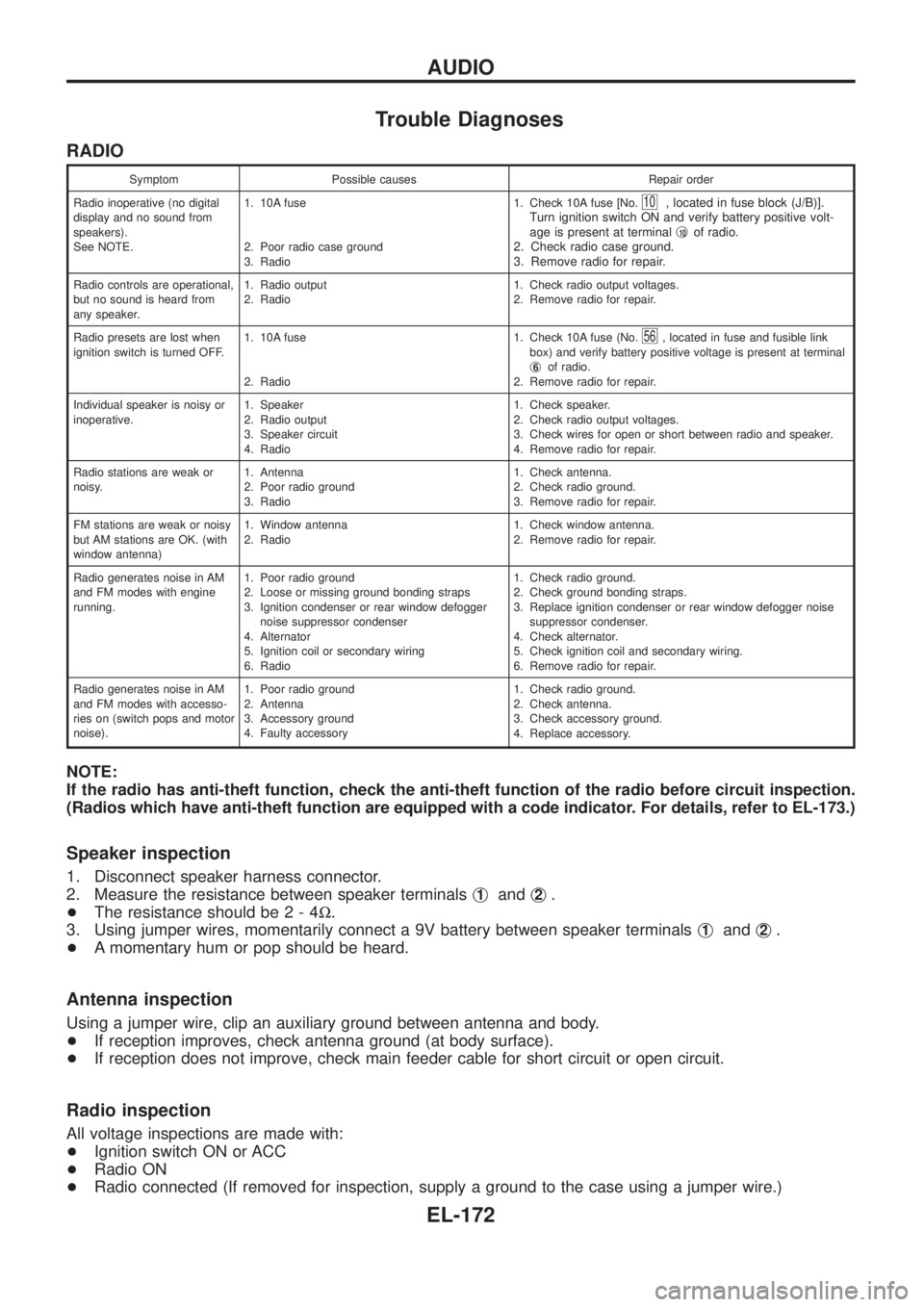

Trouble Diagnoses

RADIO

Symptom Possible causes Repair order

Radio inoperative (no digital

display and no sound from

speakers).

See NOTE.1. 10A fuse

2. Poor radio case ground

3. Radio1. Check 10A fuse [No.

10, located in fuse block (J/B)].

Turn ignition switch ON and verify battery positive volt-

age is present at terminalj

10of radio.

2. Check radio case ground.

3. Remove radio for repair.

Radio controls are operational,

but no sound is heard from

any speaker.1. Radio output

2. Radio1. Check radio output voltages.

2. Remove radio for repair.

Radio presets are lost when

ignition switch is turned OFF.1. 10A fuse

2. Radio1. Check 10A fuse (No.

56, located in fuse and fusible link

box) and verify battery positive voltage is present at terminal

j

6of radio.

2. Remove radio for repair.

Individual speaker is noisy or

inoperative.1. Speaker

2. Radio output

3. Speaker circuit

4. Radio1. Check speaker.

2. Check radio output voltages.

3. Check wires for open or short between radio and speaker.

4. Remove radio for repair.

Radio stations are weak or

noisy.1. Antenna

2. Poor radio ground

3. Radio1. Check antenna.

2. Check radio ground.

3. Remove radio for repair.

FM stations are weak or noisy

but AM stations are OK. (with

window antenna)1. Window antenna

2. Radio1. Check window antenna.

2. Remove radio for repair.

Radio generates noise in AM

and FM modes with engine

running.1. Poor radio ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Radio1. Check radio ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger noise

suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove radio for repair.

Radio generates noise in AM

and FM modes with accesso-

ries on (switch pops and motor

noise).1. Poor radio ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check radio ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

NOTE:

If the radio has anti-theft function, check the anti-theft function of the radio before circuit inspection.

(Radios which have anti-theft function are equipped with a code indicator. For details, refer to EL-173.)

Speaker inspection

1. Disconnect speaker harness connector.

2. Measure the resistance between speaker terminalsj

1andj2.

+The resistance should be2-4W.

3. Using jumper wires, momentarily connect a 9V battery between speaker terminalsj

1andj2.

+A momentary hum or pop should be heard.

Antenna inspection

Using a jumper wire, clip an auxiliary ground between antenna and body.

+If reception improves, check antenna ground (at body surface).

+If reception does not improve, check main feeder cable for short circuit or open circuit.

Radio inspection

All voltage inspections are made with:

+Ignition switch ON or ACC

+Radio ON

+Radio connected (If removed for inspection, supply a ground to the case using a jumper wire.)

AUDIO

EL-172

Page 518 of 1226

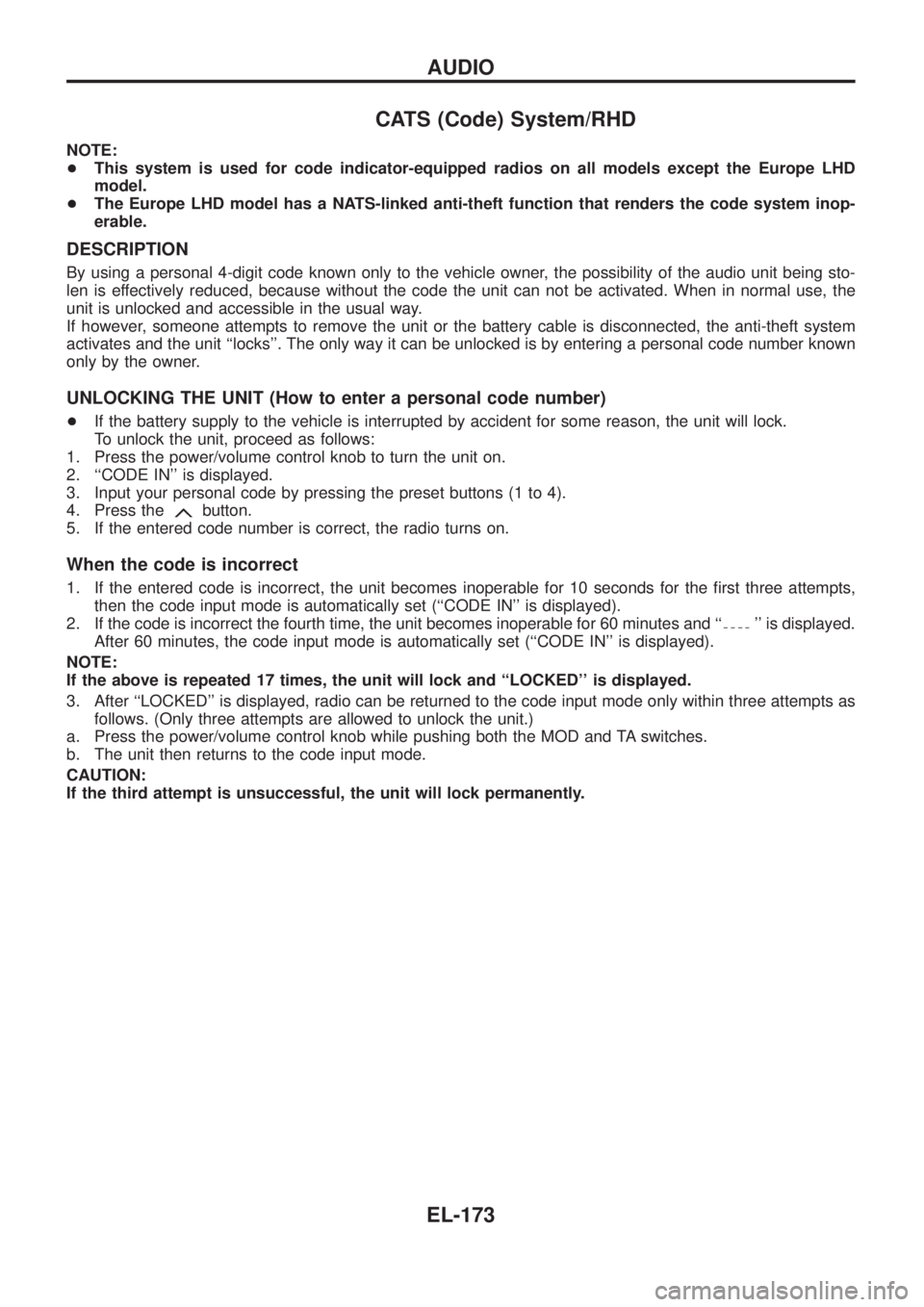

CATS (Code) System/RHD

NOTE:

+This system is used for code indicator-equipped radios on all models except the Europe LHD

model.

+The Europe LHD model has a NATS-linked anti-theft function that renders the code system inop-

erable.

DESCRIPTION

By using a personal 4-digit code known only to the vehicle owner, the possibility of the audio unit being sto-

len is effectively reduced, because without the code the unit can not be activated. When in normal use, the

unit is unlocked and accessible in the usual way.

If however, someone attempts to remove the unit or the battery cable is disconnected, the anti-theft system

activates and the unit ``locks''. The only way it can be unlocked is by entering a personal code number known

only by the owner.

UNLOCKING THE UNIT (How to enter a personal code number)

+If the battery supply to the vehicle is interrupted by accident for some reason, the unit will lock.

To unlock the unit, proceed as follows:

1. Press the power/volume control knob to turn the unit on.

2. ``CODE IN'' is displayed.

3. Input your personal code by pressing the preset buttons (1 to 4).

4. Press the

button.

5. If the entered code number is correct, the radio turns on.

When the code is incorrect

1. If the entered code is incorrect, the unit becomes inoperable for 10 seconds for the ®rst three attempts,

then the code input mode is automatically set (``CODE IN'' is displayed).

2. If the code is incorrect the fourth time, the unit becomes inoperable for 60 minutes and ``

'' is displayed.

After 60 minutes, the code input mode is automatically set (``CODE IN'' is displayed).

NOTE:

If the above is repeated 17 times, the unit will lock and ``LOCKED'' is displayed.

3. After ``LOCKED'' is displayed, radio can be returned to the code input mode only within three attempts as

follows. (Only three attempts are allowed to unlock the unit.)

a. Press the power/volume control knob while pushing both the MOD and TA switches.

b. The unit then returns to the code input mode.

CAUTION:

If the third attempt is unsuccessful, the unit will lock permanently.

AUDIO

EL-173

Page 519 of 1226

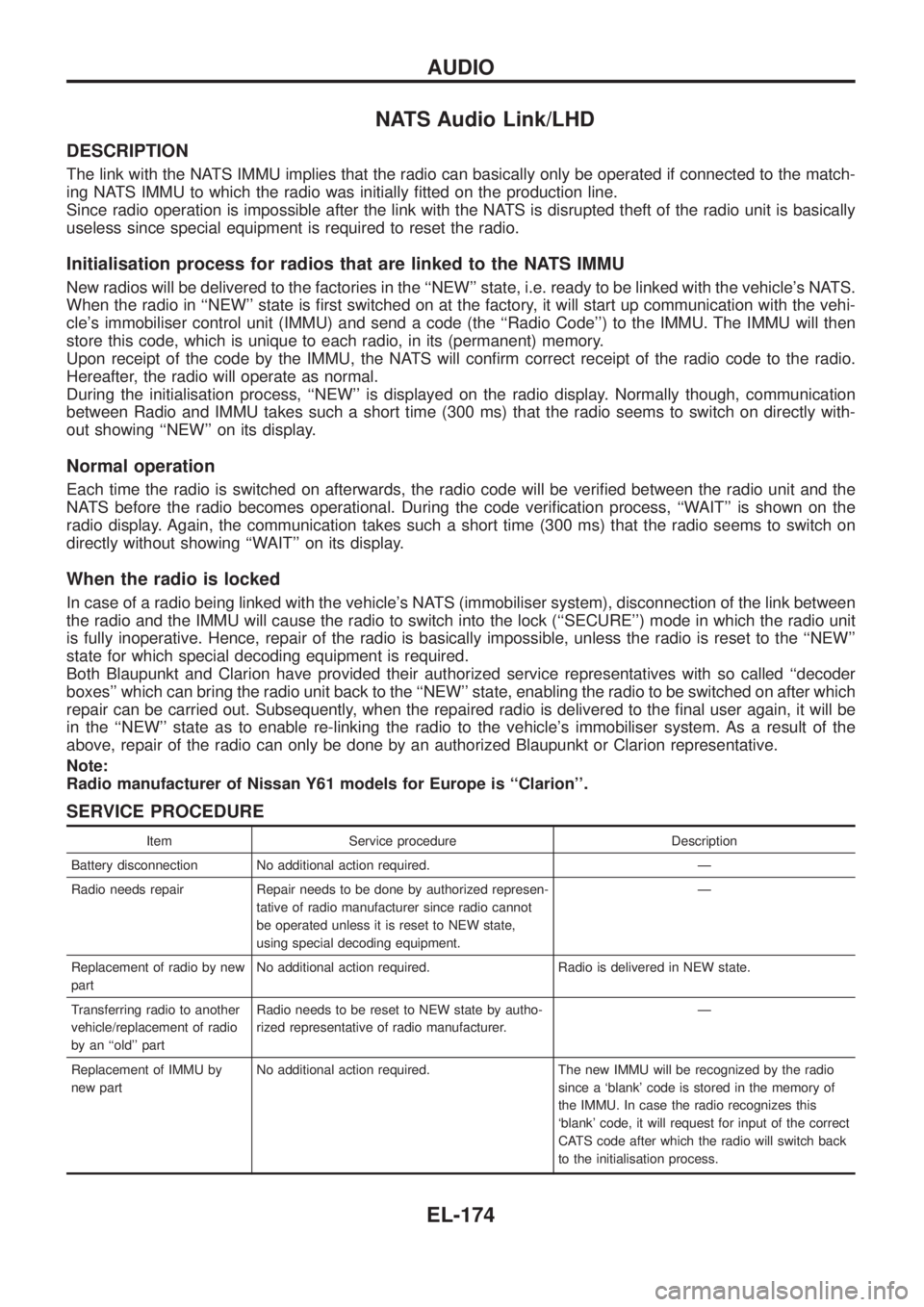

NATS Audio Link/LHD

DESCRIPTION

The link with the NATS IMMU implies that the radio can basically only be operated if connected to the match-

ing NATS IMMU to which the radio was initially ®tted on the production line.

Since radio operation is impossible after the link with the NATS is disrupted theft of the radio unit is basically

useless since special equipment is required to reset the radio.

Initialisation process for radios that are linked to the NATS IMMU

New radios will be delivered to the factories in the ``NEW'' state, i.e. ready to be linked with the vehicle's NATS.

When the radio in ``NEW'' state is ®rst switched on at the factory, it will start up communication with the vehi-

cle's immobiliser control unit (IMMU) and send a code (the ``Radio Code'') to the IMMU. The IMMU will then

store this code, which is unique to each radio, in its (permanent) memory.

Upon receipt of the code by the IMMU, the NATS will con®rm correct receipt of the radio code to the radio.

Hereafter, the radio will operate as normal.

During the initialisation process, ``NEW'' is displayed on the radio display. Normally though, communication

between Radio and IMMU takes such a short time (300 ms) that the radio seems to switch on directly with-

out showing ``NEW'' on its display.

Normal operation

Each time the radio is switched on afterwards, the radio code will be veri®ed between the radio unit and the

NATS before the radio becomes operational. During the code veri®cation process, ``WAIT'' is shown on the

radio display. Again, the communication takes such a short time (300 ms) that the radio seems to switch on

directly without showing ``WAIT'' on its display.

When the radio is locked

In case of a radio being linked with the vehicle's NATS (immobiliser system), disconnection of the link between

the radio and the IMMU will cause the radio to switch into the lock (``SECURE'') mode in which the radio unit

is fully inoperative. Hence, repair of the radio is basically impossible, unless the radio is reset to the ``NEW''

state for which special decoding equipment is required.

Both Blaupunkt and Clarion have provided their authorized service representatives with so called ``decoder

boxes'' which can bring the radio unit back to the ``NEW'' state, enabling the radio to be switched on after which

repair can be carried out. Subsequently, when the repaired radio is delivered to the ®nal user again, it will be

in the ``NEW'' state as to enable re-linking the radio to the vehicle's immobiliser system. As a result of the

above, repair of the radio can only be done by an authorized Blaupunkt or Clarion representative.

Note:

Radio manufacturer of Nissan Y61 models for Europe is ``Clarion''.

SERVICE PROCEDURE

Item Service procedure Description

Battery disconnection No additional action required. Ð

Radio needs repair Repair needs to be done by authorized represen-

tative of radio manufacturer since radio cannot

be operated unless it is reset to NEW state,

using special decoding equipment.Ð

Replacement of radio by new

partNo additional action required. Radio is delivered in NEW state.

Transferring radio to another

vehicle/replacement of radio

by an ``old'' partRadio needs to be reset to NEW state by autho-

rized representative of radio manufacturer.Ð

Replacement of IMMU by

new partNo additional action required. The new IMMU will be recognized by the radio

since a `blank' code is stored in the memory of

the IMMU. In case the radio recognizes this

`blank' code, it will request for input of the correct

CATS code after which the radio will switch back

to the initialisation process.

AUDIO

EL-174

Page 576 of 1226

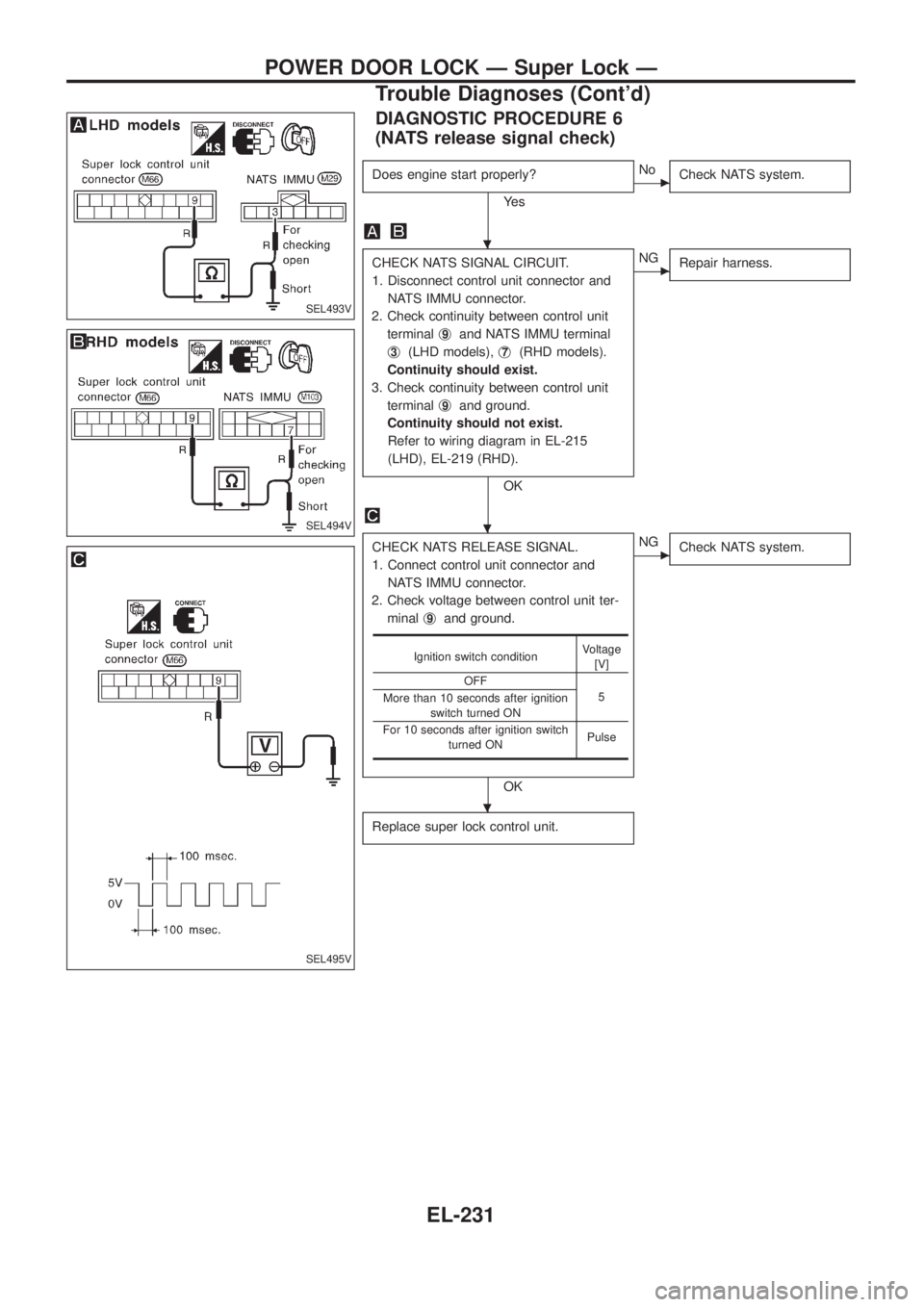

DIAGNOSTIC PROCEDURE 6

(NATS release signal check)

Does engine start properly?

Ye s

cNo

Check NATS system.

CHECK NATS SIGNAL CIRCUIT.

1. Disconnect control unit connector and

NATS IMMU connector.

2. Check continuity between control unit

terminalj

9and NATS IMMU terminal

j

3(LHD models),j7(RHD models).

Continuity should exist.

3. Check continuity between control unit

terminalj

9and ground.

Continuity should not exist.

Refer to wiring diagram in EL-215

(LHD), EL-219 (RHD).

OK

cNG

Repair harness.

CHECK NATS RELEASE SIGNAL.

1. Connect control unit connector and

NATS IMMU connector.

2. Check voltage between control unit ter-

minalj

9and ground.

OK

cNG

Check NATS system.

Replace super lock control unit.

Ignition switch conditionVoltage

[V]

OFF

5

More than 10 seconds after ignition

switch turned ON

For 10 seconds after ignition switch

turned ONPulse

SEL493V

SEL494V

SEL495V

.

.

.

POWER DOOR LOCK Ð Super Lock Ð

Trouble Diagnoses (Cont'd)

EL-231

Page 584 of 1226

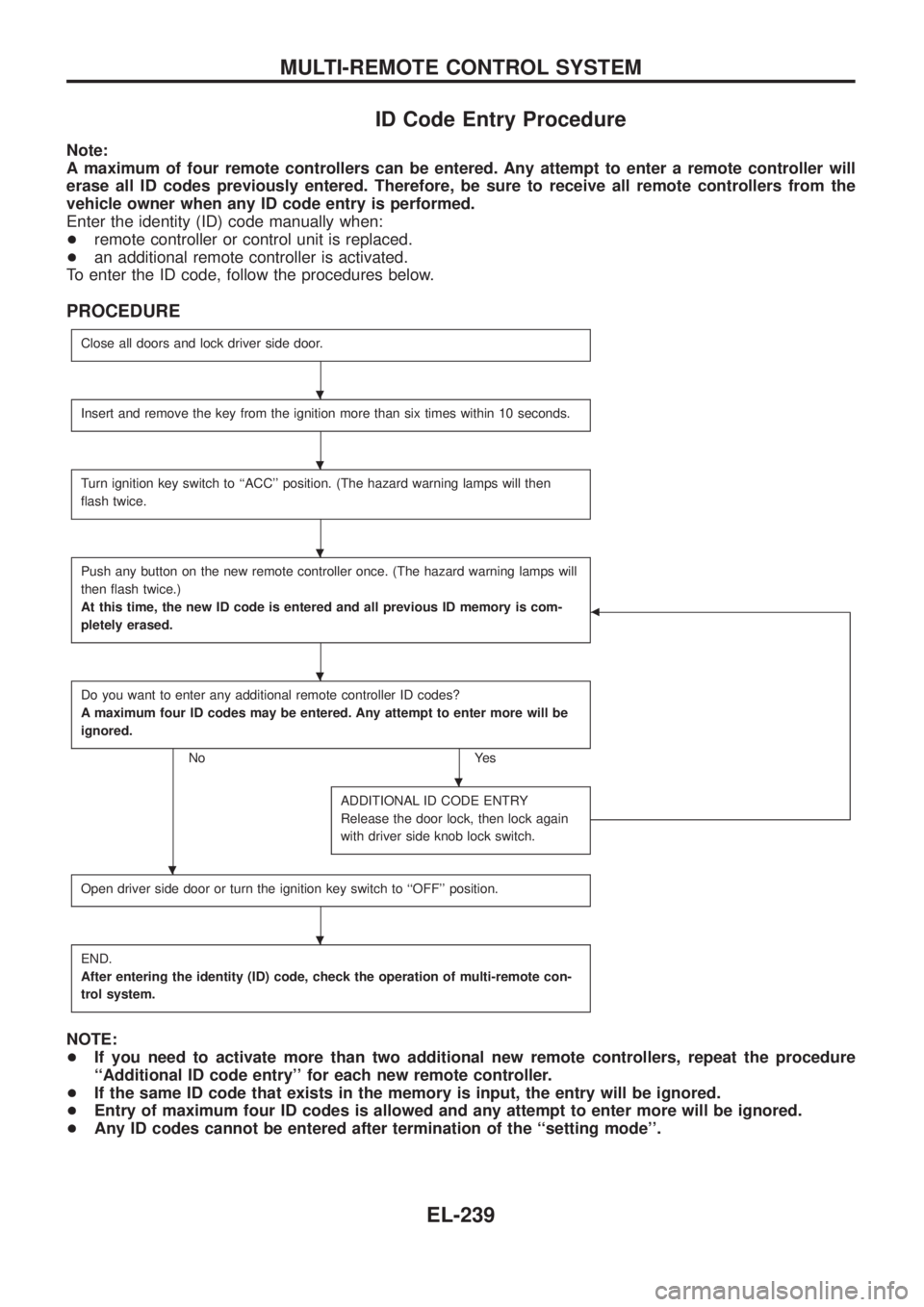

ID Code Entry Procedure

Note:

A maximum of four remote controllers can be entered. Any attempt to enter a remote controller will

erase all ID codes previously entered. Therefore, be sure to receive all remote controllers from the

vehicle owner when any ID code entry is performed.

Enter the identity (ID) code manually when:

+remote controller or control unit is replaced.

+an additional remote controller is activated.

To enter the ID code, follow the procedures below.

PROCEDURE

Close all doors and lock driver side door.

Insert and remove the key from the ignition more than six times within 10 seconds.

Turn ignition key switch to ``ACC'' position. (The hazard warning lamps will then

¯ash twice.

Push any button on the new remote controller once. (The hazard warning lamps will

then ¯ash twice.)

At this time, the new ID code is entered and all previous ID memory is com-

pletely erased.

b

Do you want to enter any additional remote controller ID codes?

A maximum four ID codes may be entered. Any attempt to enter more will be

ignored.

No Yes

ADDITIONAL ID CODE ENTRY

Release the door lock, then lock again

with driver side knob lock switch.

Open driver side door or turn the ignition key switch to ``OFF'' position.

END.

After entering the identity (ID) code, check the operation of multi-remote con-

trol system.

NOTE:

+If you need to activate more than two additional new remote controllers, repeat the procedure

``Additional ID code entry'' for each new remote controller.

+If the same ID code that exists in the memory is input, the entry will be ignored.

+Entry of maximum four ID codes is allowed and any attempt to enter more will be ignored.

+Any ID codes cannot be entered after termination of the ``setting mode''.

.

.

.

.

.

.

.

MULTI-REMOTE CONTROL SYSTEM

EL-239

Page 613 of 1226

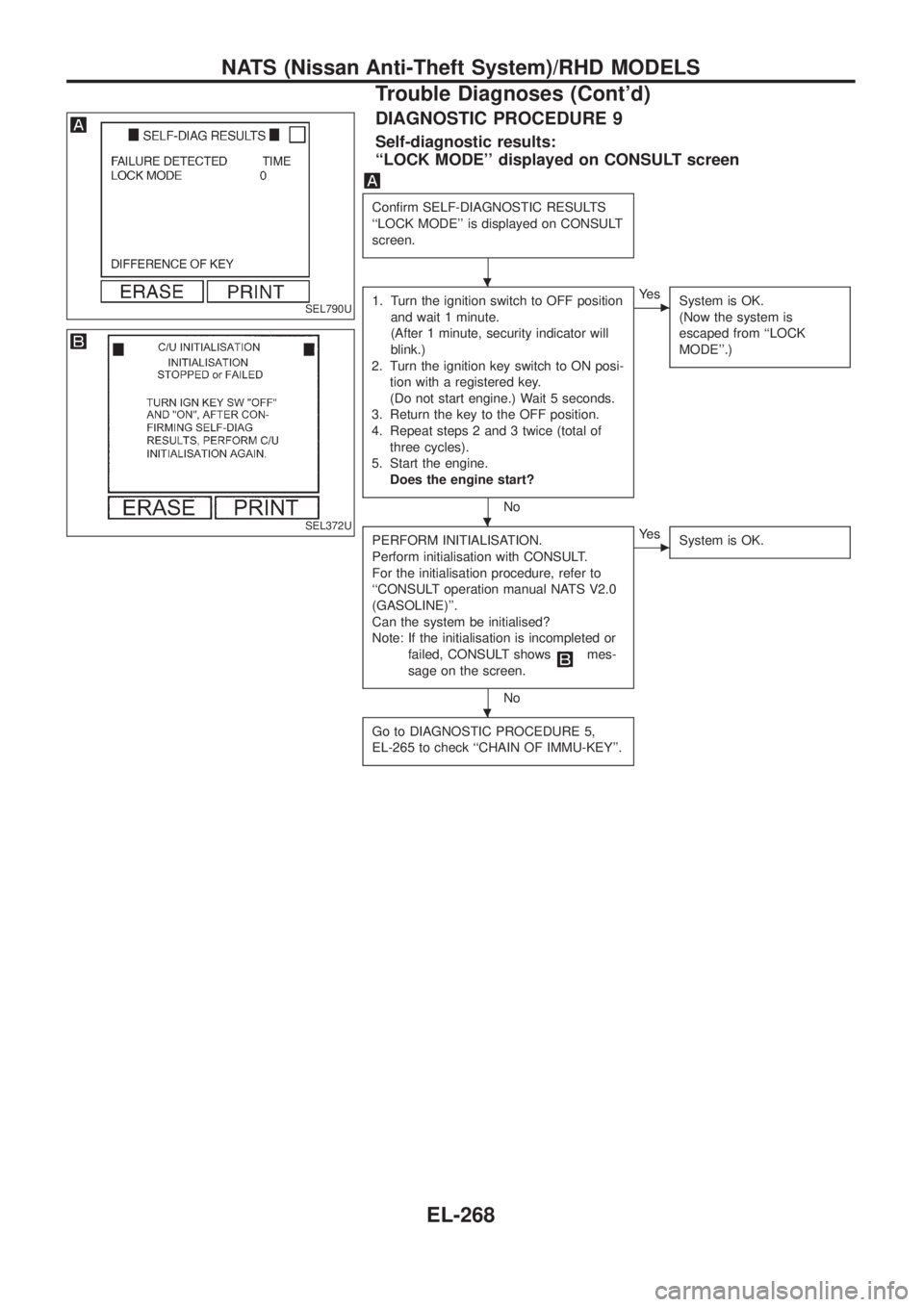

DIAGNOSTIC PROCEDURE 9

Self-diagnostic results:

``LOCK MODE'' displayed on CONSULT screen

Con®rm SELF-DIAGNOSTIC RESULTS

``LOCK MODE'' is displayed on CONSULT

screen.

1. Turn the ignition switch to OFF position

and wait 1 minute.

(After 1 minute, security indicator will

blink.)

2. Turn the ignition key switch to ON posi-

tion with a registered key.

(Do not start engine.) Wait 5 seconds.

3. Return the key to the OFF position.

4. Repeat steps 2 and 3 twice (total of

three cycles).

5. Start the engine.

Does the engine start?

No

cYe s

System is OK.

(Now the system is

escaped from ``LOCK

MODE''.)

PERFORM INITIALISATION.

Perform initialisation with CONSULT.

For the initialisation procedure, refer to

``CONSULT operation manual NATS V2.0

(GASOLINE)''.

Can the system be initialised?

Note: If the initialisation is incompleted or

failed, CONSULT shows

mes-

sage on the screen.

No

cYe s

System is OK.

Go to DIAGNOSTIC PROCEDURE 5,

EL-265 to check ``CHAIN OF IMMU-KEY''.

SEL790U

SEL372U

.

.

.

NATS (Nissan Anti-Theft System)/RHD MODELS

Trouble Diagnoses (Cont'd)

EL-268

Page 778 of 1226

Dispose of used oil and used oil ®lters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning the pollution of the environment

will vary from country to country.

Precautions for Fuel

GASOLINE ENGINE:

Three way catalyst equipped models ... unleaded gasoline of at

least 91 octane (RON)

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Except for the above models ... unleaded or leaded gasoline of

above 88 octane (RON)

Use unleaded fuel if instructed on the fuel ®ller lid.

DIESEL ENGINE*:

Diesel fuel of above 45 cetane for TD42 engine and above 50 cet-

ane for RD28ET engine

* If two types of diesel fuel are available, use summer or winter

fuel properly according to the following temperature conditions.

+Above þ7ÉC (20ÉF) ... Summer type diesel fuel.

+Below þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

+Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

+Do not use summer fuel at temperature below þ7ÉC (20ÉF).

The cold temperature will cause wax to form in the fuel. As

a result, it may prevent the engine from running smoothly.

+Do not add gasoline or other alternate fuels to diesel fuel.

Precautions for Air Conditioning

Use an approved refrigerant recovery unit any time the air condi-

tioning system must be discharged. Refer to HA section (``HFC-

134a (R-134a) Service Procedure'', ``SERVICE PROCEDURES'')

for speci®c instructions.

PRECAUTIONS

Precautions for Engine Oils (Cont'd)

GI-5

Page 806 of 1226

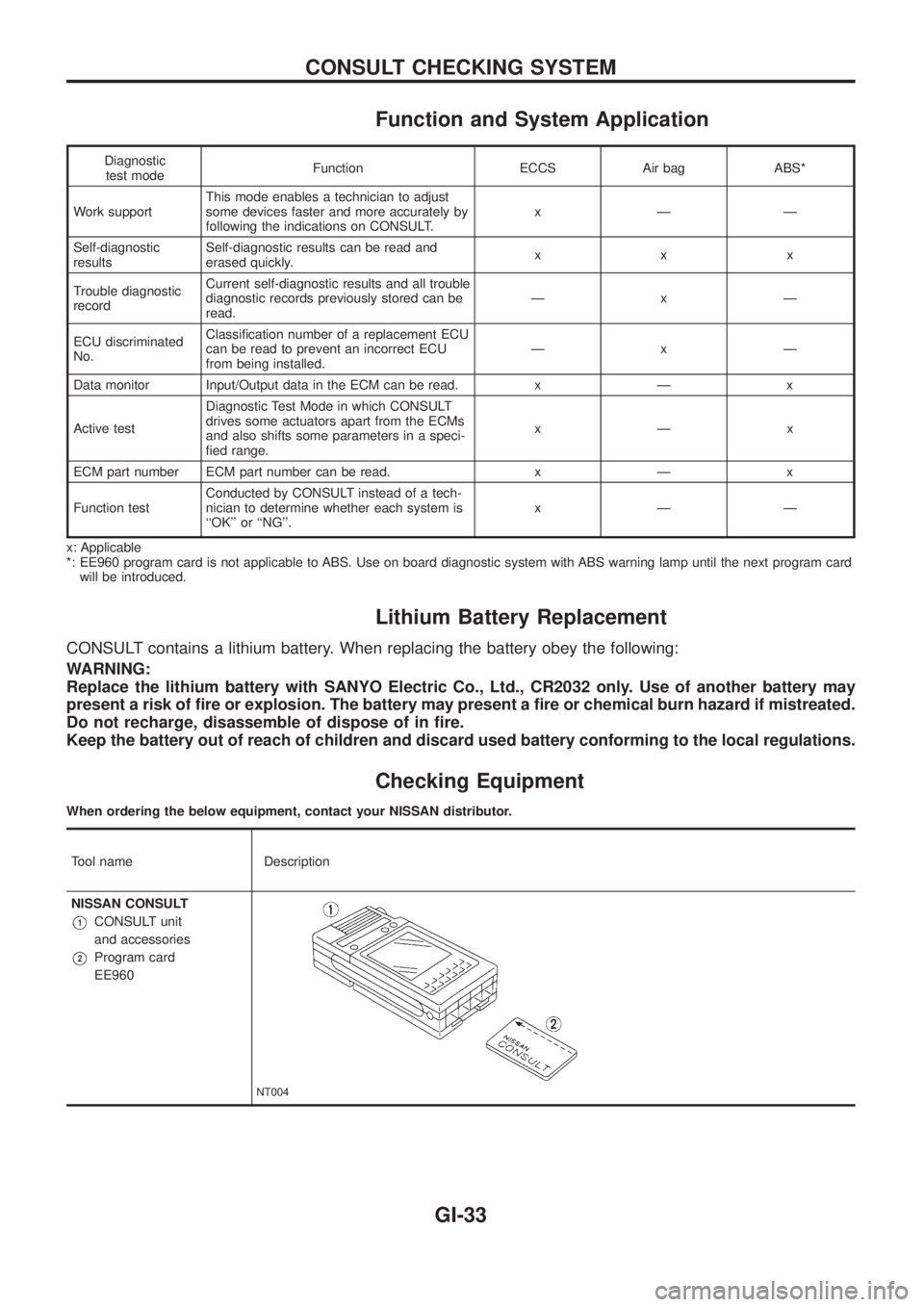

Function and System Application

Diagnostic

test modeFunction ECCS Air bag ABS*

Work supportThis mode enables a technician to adjust

some devices faster and more accurately by

following the indications on CONSULT.xÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read and

erased quickly.xxx

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble

diagnostic records previously stored can be

read.ÐxÐ

ECU discriminated

No.Classi®cation number of a replacement ECU

can be read to prevent an incorrect ECU

from being installed.ÐxÐ

Data monitor Input/Output data in the ECM can be read. x Ð x

Active testDiagnostic Test Mode in which CONSULT

drives some actuators apart from the ECMs

and also shifts some parameters in a speci-

®ed range.xÐx

ECM part number ECM part number can be read. x Ð x

Function testConducted by CONSULT instead of a tech-

nician to determine whether each system is

``OK'' or ``NG''.xÐÐ

x: Applicable

*: EE960 program card is not applicable to ABS. Use on board diagnostic system with ABS warning lamp until the next program card

will be introduced.

Lithium Battery Replacement

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd., CR2032 only. Use of another battery may

present a risk of ®re or explosion. The battery may present a ®re or chemical burn hazard if mistreated.

Do not recharge, disassemble of dispose of in ®re.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking Equipment

When ordering the below equipment, contact your NISSAN distributor.

Tool name Description

NISSAN CONSULT

V1CONSULT unit

and accessories

V2Program card

EE960

NT004

CONSULT CHECKING SYSTEM

GI-33

Page 814 of 1226

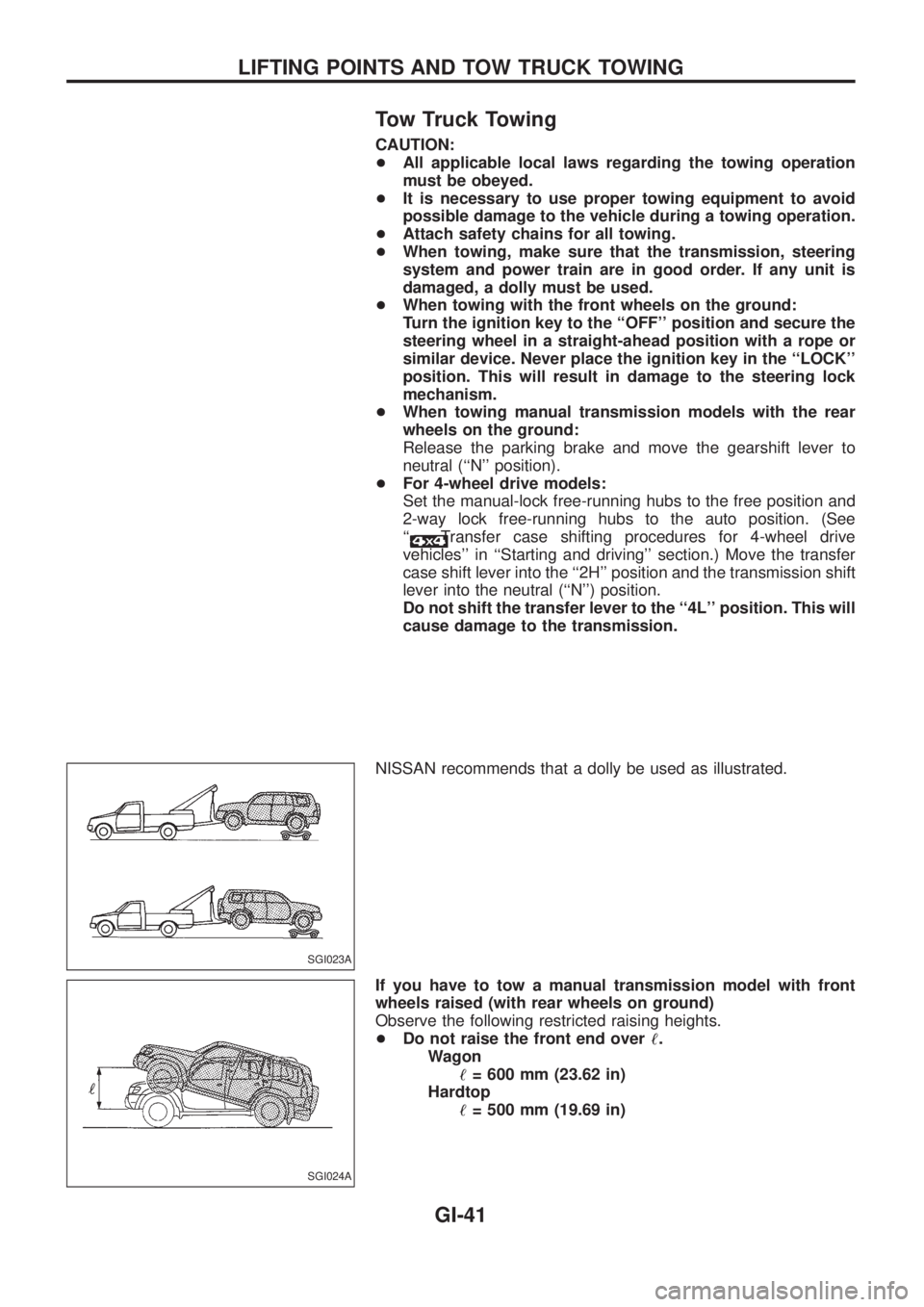

Tow Truck Towing

CAUTION:

+All applicable local laws regarding the towing operation

must be obeyed.

+It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during a towing operation.

+Attach safety chains for all towing.

+When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, a dolly must be used.

+When towing with the front wheels on the ground:

Turn the ignition key to the ``OFF'' position and secure the

steering wheel in a straight-ahead position with a rope or

similar device. Never place the ignition key in the ``LOCK''

position. This will result in damage to the steering lock

mechanism.

+When towing manual transmission models with the rear

wheels on the ground:

Release the parking brake and move the gearshift lever to

neutral (``N'' position).

+For 4-wheel drive models:

Set the manual-lock free-running hubs to the free position and

2-way lock free-running hubs to the auto position. (See

``

Transfer case shifting procedures for 4-wheel drive

vehicles'' in ``Starting and driving'' section.) Move the transfer

case shift lever into the ``2H'' position and the transmission shift

lever into the neutral (``N'') position.

Do not shift the transfer lever to the ``4L'' position. This will

cause damage to the transmission.

NISSAN recommends that a dolly be used as illustrated.

If you have to tow a manual transmission model with front

wheels raised (with rear wheels on ground)

Observe the following restricted raising heights.

+Do not raise the front end over!.

Wagon

!= 600 mm (23.62 in)

Hardtop

!= 500 mm (19.69 in)

SGI023A

SGI024A

LIFTING POINTS AND TOW TRUCK TOWING

GI-41

Page 822 of 1226

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

Precautions for Working with HFC-134a

(R-134a)

WARNING:

+CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refriger-

ants must never be mixed, even in the smallest amounts. If the refrigerants are mixed, compres-

sor failure is likely to occur.

+Use only speci®ed lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) com-

ponents. If lubricant other than that speci®ed is used, compressor failure is likely to occur.

+The speci®ed HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The

following handling precautions must be observed:

a: When removing refrigerant components from a vehicle, immediately cap (seal) the component

to minimize the entry of moisture from the atmosphere.

b: When installing refrigerant components to a vehicle, do not remove the caps (unseal) until

just before connecting the components. Connect all refrigerant loop components as quickly

as possible to minimize the entry of moisture into system.

c: Only use the speci®ed lubricant from a sealed container. Immediately reseal containers of

lubricant. Without proper sealing, lubricant will become moisture saturated and should not

be used.

d: Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a)

refrigerant. If accidental system discharge occurs, ventilate work area before resuming ser-

vice. Additional health and safety information may be obtained from refrigerant and lubricant

manufacturers.

e: Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam

parts. Damage may result.

PRECAUTIONS AND PREPARATIONMANUAL AND AUTO

HA-1