ECO mode NISSAN PATROL 2006 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 884 of 1226

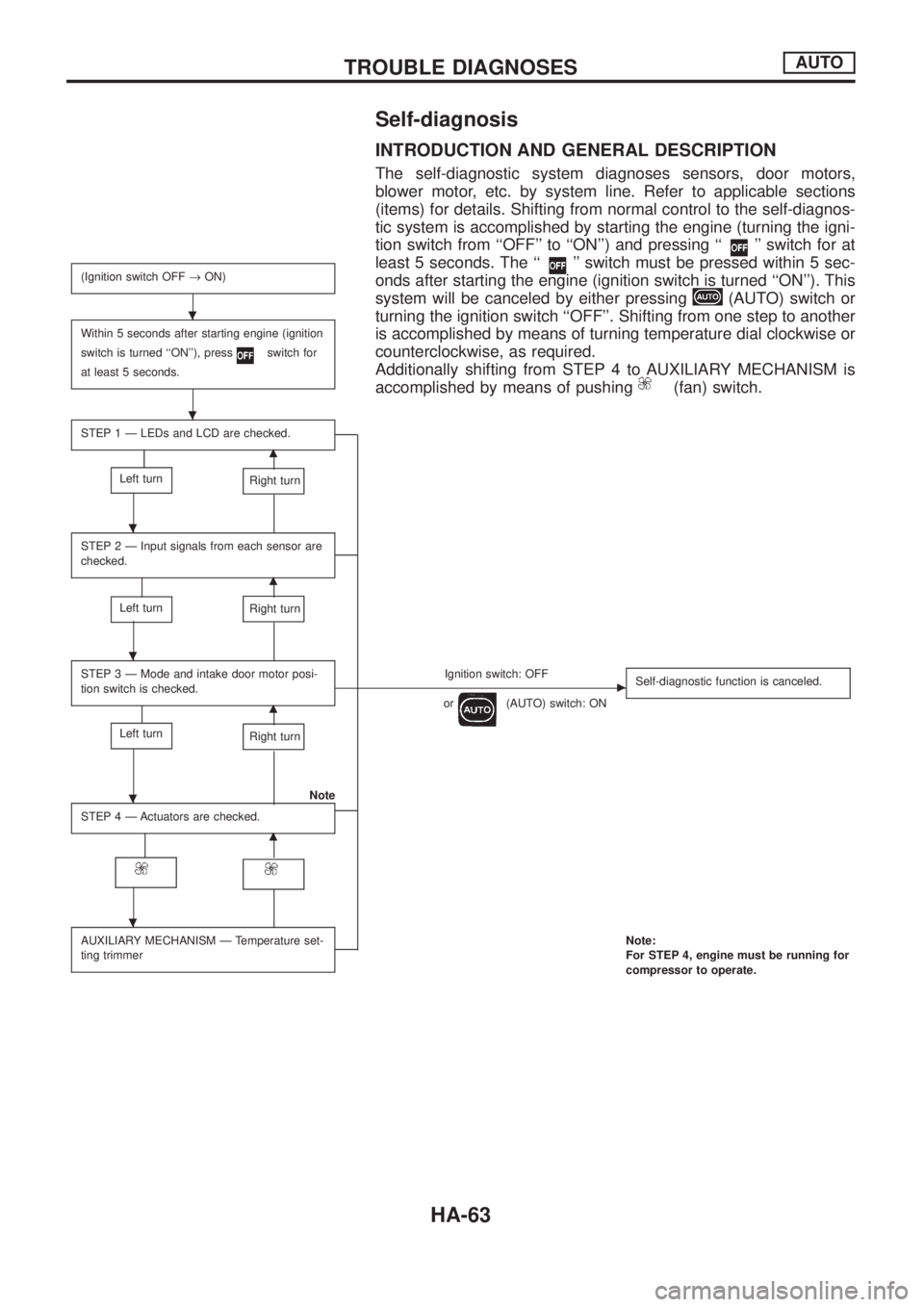

Self-diagnosis

INTRODUCTION AND GENERAL DESCRIPTION

The self-diagnostic system diagnoses sensors, door motors,

blower motor, etc. by system line. Refer to applicable sections

(items) for details. Shifting from normal control to the self-diagnos-

tic system is accomplished by starting the engine (turning the igni-

tion switch from ``OFF'' to ``ON'') and pressing ``

'' switch for at

least 5 seconds. The ``

'' switch must be pressed within 5 sec-

onds after starting the engine (ignition switch is turned ``ON''). This

system will be canceled by either pressing

(AUTO) switch or

turning the ignition switch ``OFF''. Shifting from one step to another

is accomplished by means of turning temperature dial clockwise or

counterclockwise, as required.

Additionally shifting from STEP 4 to AUXILIARY MECHANISM is

accomplished by means of pushing

(fan) switch.

(Ignition switch OFF®ON)

Within 5 seconds after starting engine (ignition

switch is turned ``ON''), press

switch for

at least 5 seconds.

STEP 1 Ð LEDs and LCD are checked.

m

Left turnRight turn

STEP 2 Ð Input signals from each sensor are

checked.

m

Left turnRight turn

STEP 3 Ð Mode and intake door motor posi-

tion switch is checked.Ignition switch: OFFc

or(AUTO) switch: ONSelf-diagnostic function is canceled.m

Left turnRight turn

Note

STEP 4 Ð Actuators are checked.

m

AUXILIARY MECHANISM Ð Temperature set-

ting trimmerNote:

For STEP 4, engine must be running for

compressor to operate.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

HA-63

Page 885 of 1226

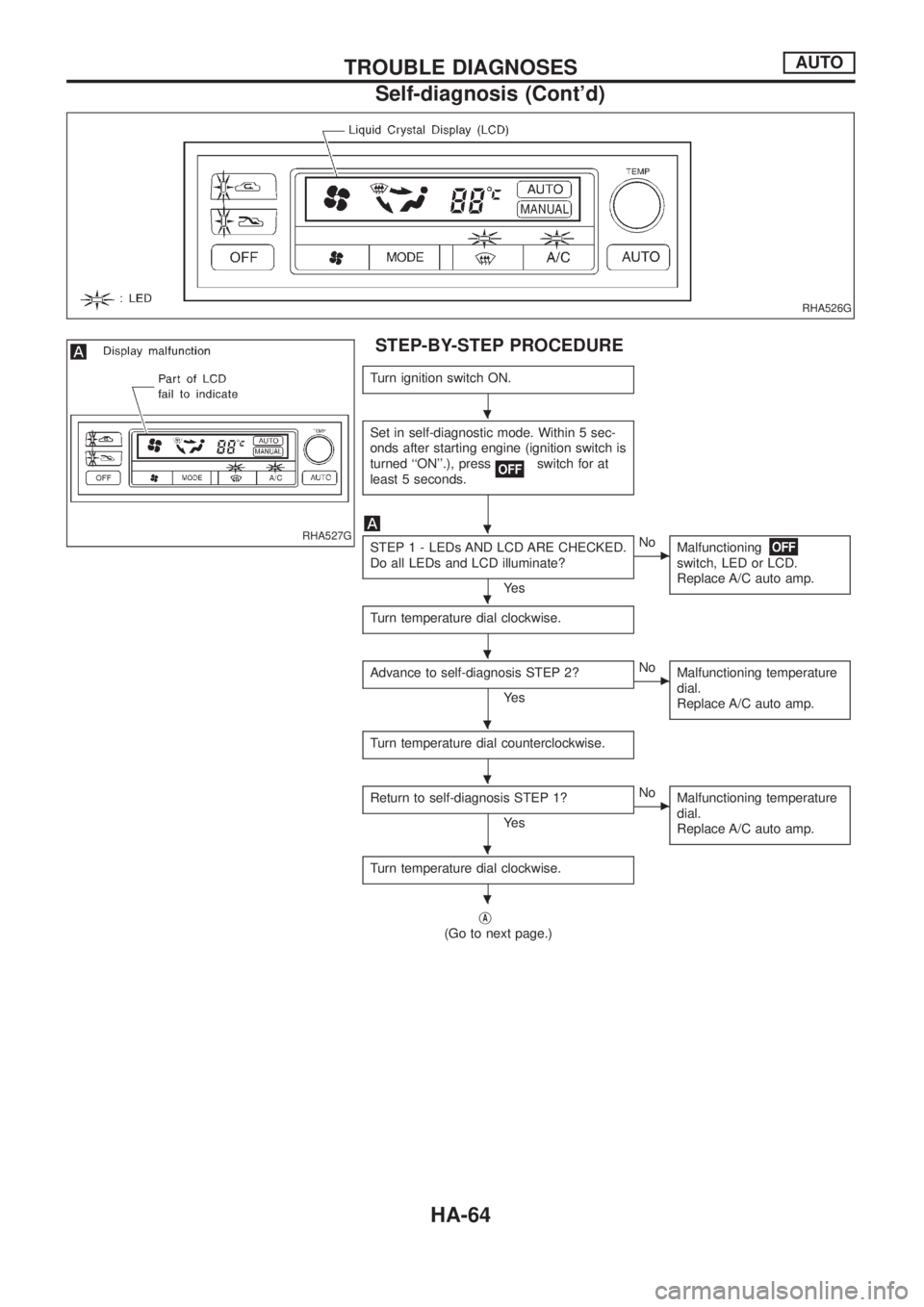

STEP-BY-STEP PROCEDURE

Turn ignition switch ON.

Set in self-diagnostic mode. Within 5 sec-

onds after starting engine (ignition switch is

turned ``ON''.), press

switch for at

least 5 seconds.

STEP 1 - LEDs AND LCD ARE CHECKED.

Do all LEDs and LCD illuminate?

Ye s

cNo

Malfunctioning

switch, LED or LCD.

Replace A/C auto amp.

Turn temperature dial clockwise.

Advance to self-diagnosis STEP 2?

Ye s

cNo

Malfunctioning temperature

dial.

Replace A/C auto amp.

Turn temperature dial counterclockwise.

Return to self-diagnosis STEP 1?

Ye s

cNo

Malfunctioning temperature

dial.

Replace A/C auto amp.

Turn temperature dial clockwise.

jA

(Go to next page.)

RHA526G

RHA527G

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-64

Page 889 of 1226

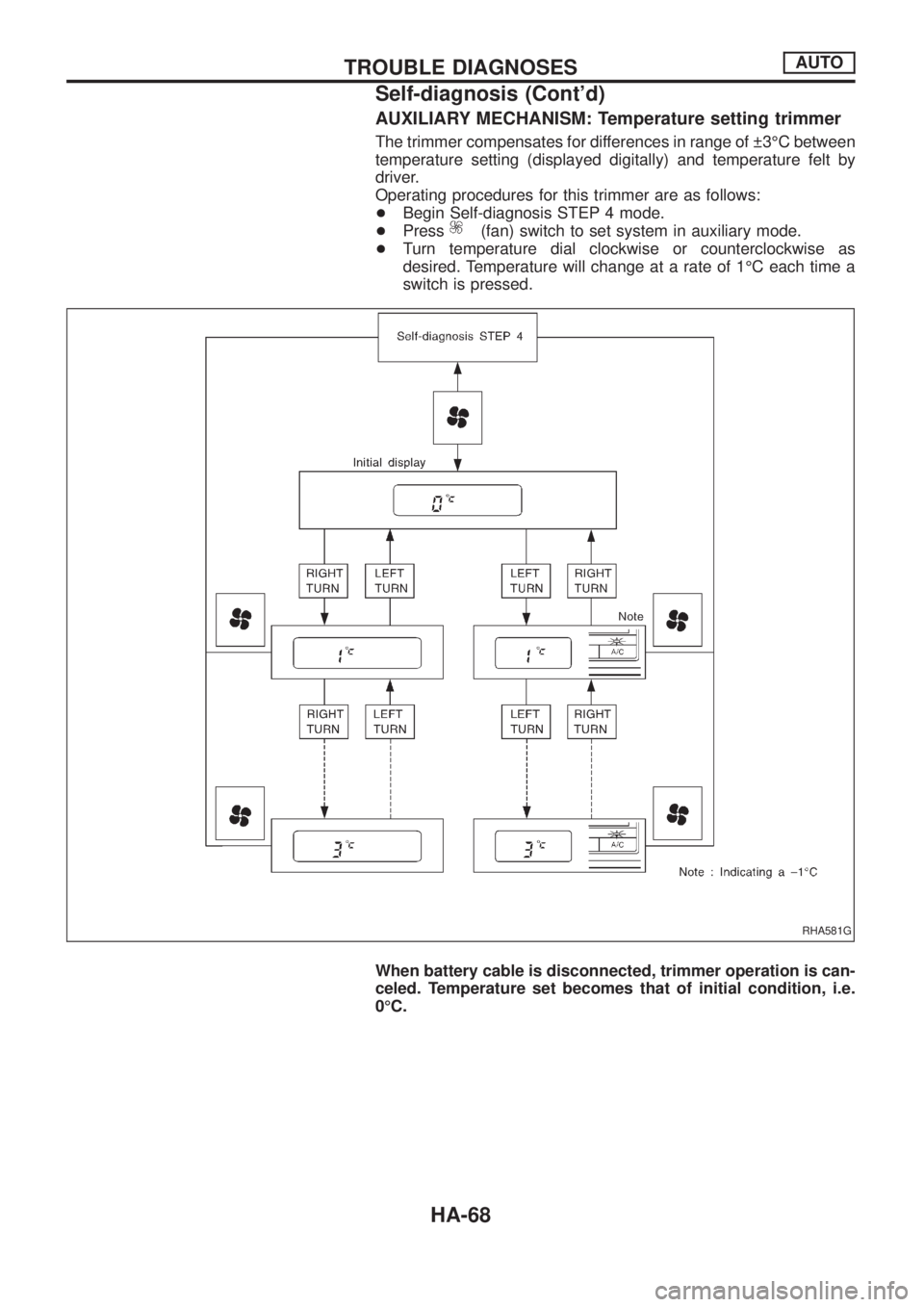

AUXILIARY MECHANISM: Temperature setting trimmer

The trimmer compensates for differences in range of 3ÉC between

temperature setting (displayed digitally) and temperature felt by

driver.

Operating procedures for this trimmer are as follows:

+Begin Self-diagnosis STEP 4 mode.

+Press

(fan) switch to set system in auxiliary mode.

+Turn temperature dial clockwise or counterclockwise as

desired. Temperature will change at a rate of 1ÉC each time a

switch is pressed.

When battery cable is disconnected, trimmer operation is can-

celed. Temperature set becomes that of initial condition, i.e.

0ÉC.

RHA581G

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-68

Page 899 of 1226

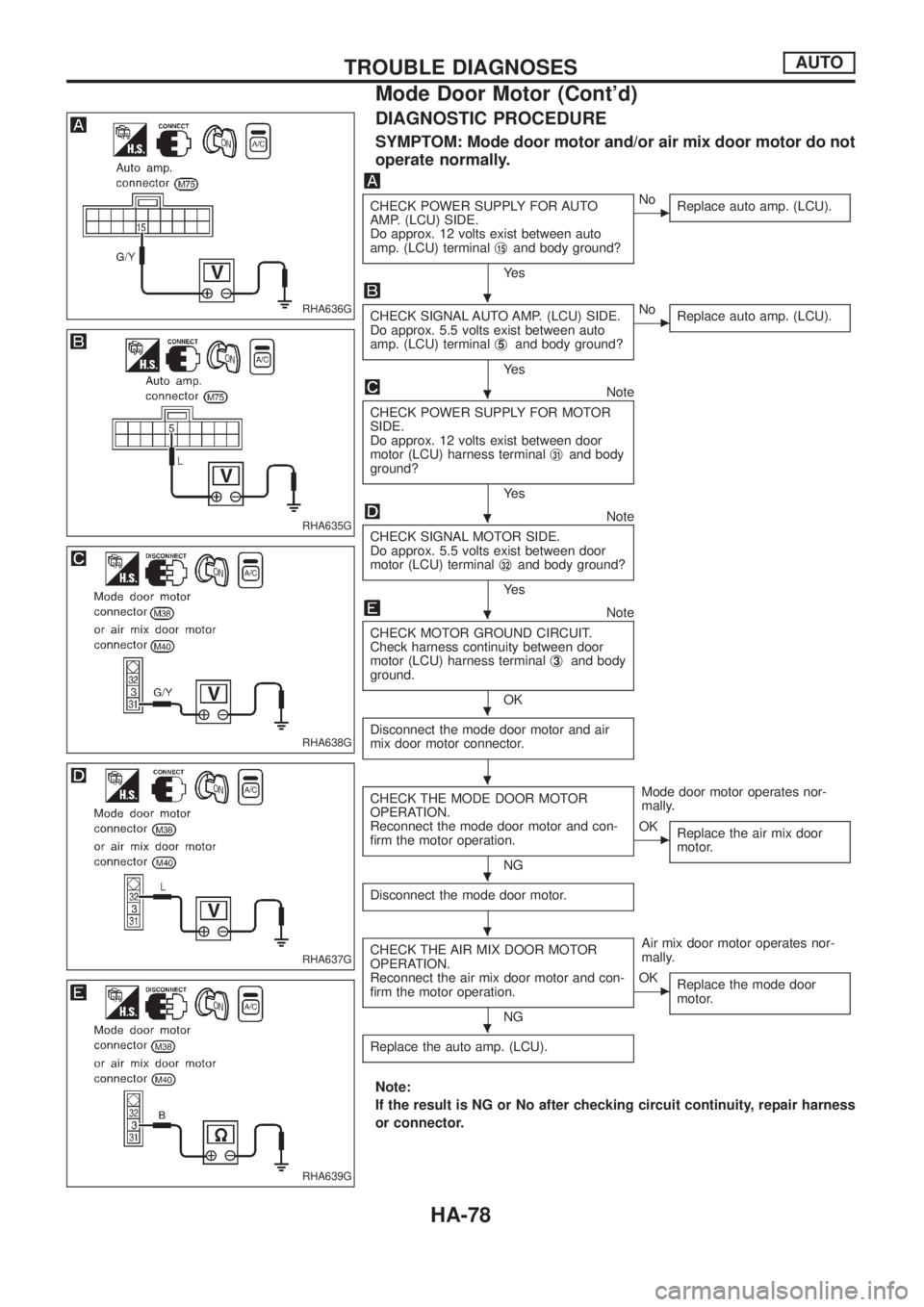

DIAGNOSTIC PROCEDURE

SYMPTOM: Mode door motor and/or air mix door motor do not

operate normally.

CHECK POWER SUPPLY FOR AUTO

AMP. (LCU) SIDE.

Do approx. 12 volts exist between auto

amp. (LCU) terminalj

15and body ground?

Ye s

cNo

Replace auto amp. (LCU).

CHECK SIGNAL AUTO AMP. (LCU) SIDE.

Do approx. 5.5 volts exist between auto

amp. (LCU) terminalj

5and body ground?

Ye s

cNo

Replace auto amp. (LCU).

Note

CHECK POWER SUPPLY FOR MOTOR

SIDE.

Do approx. 12 volts exist between door

motor (LCU) harness terminalj

31and body

ground?

Ye s

Note

CHECK SIGNAL MOTOR SIDE.

Do approx. 5.5 volts exist between door

motor (LCU) terminalj

32and body ground?

Ye s

Note

CHECK MOTOR GROUND CIRCUIT.

Check harness continuity between door

motor (LCU) harness terminalj

3and body

ground.

OK

Disconnect the mode door motor and air

mix door motor connector.

CHECK THE MODE DOOR MOTOR

OPERATION.

Reconnect the mode door motor and con-

®rm the motor operation.

NGMode door motor operates nor-

mally.

cOK

Replace the air mix door

motor.

Disconnect the mode door motor.

CHECK THE AIR MIX DOOR MOTOR

OPERATION.

Reconnect the air mix door motor and con-

®rm the motor operation.

NGAir mix door motor operates nor-

mally.

cOK

Replace the mode door

motor.

Replace the auto amp. (LCU).

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

RHA636G

RHA635G

RHA638G

RHA637G

RHA639G

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Mode Door Motor (Cont'd)

HA-78

Page 908 of 1226

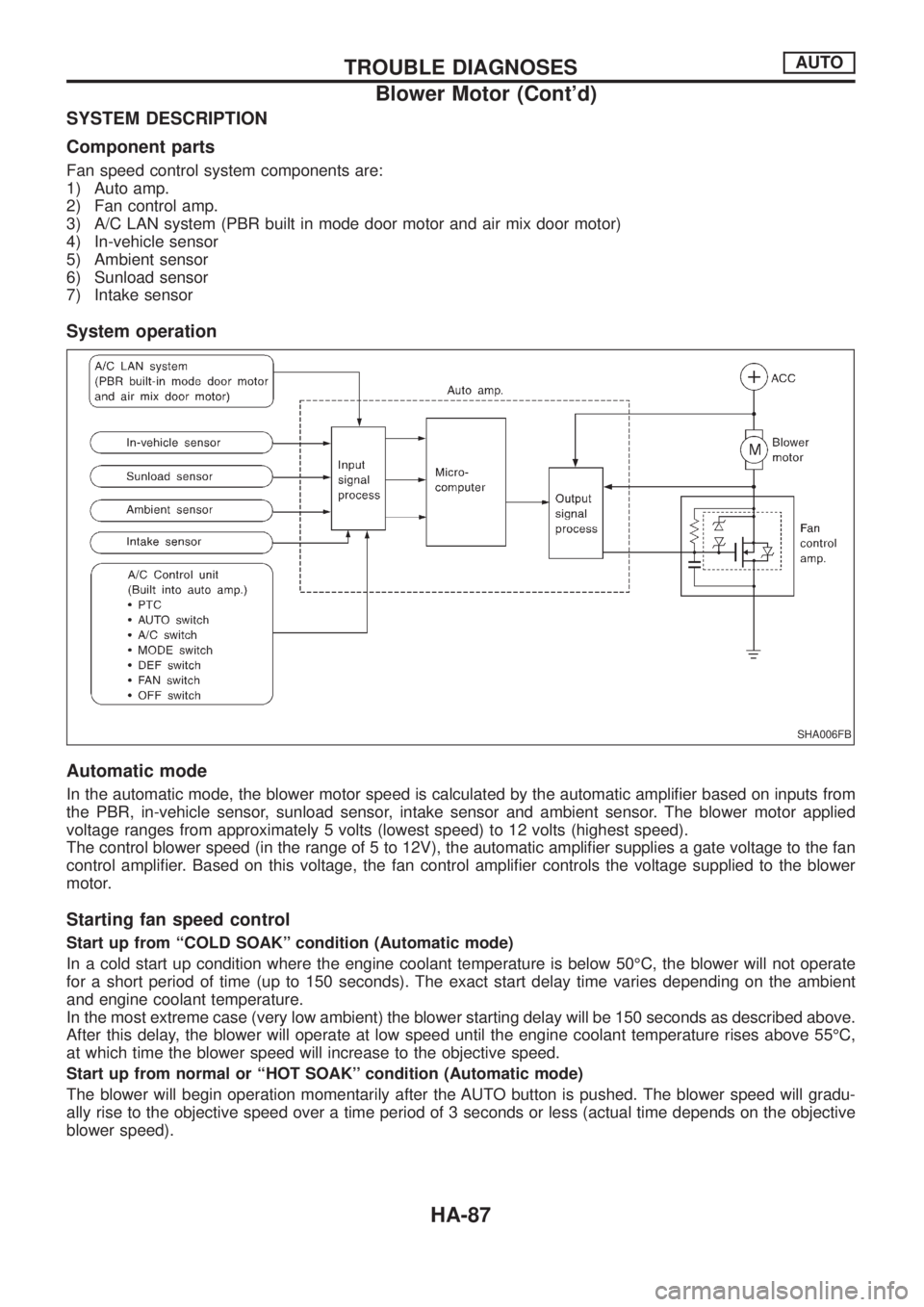

SYSTEM DESCRIPTION

Component parts

Fan speed control system components are:

1) Auto amp.

2) Fan control amp.

3) A/C LAN system (PBR built in mode door motor and air mix door motor)

4) In-vehicle sensor

5) Ambient sensor

6) Sunload sensor

7) Intake sensor

System operation

Automatic mode

In the automatic mode, the blower motor speed is calculated by the automatic ampli®er based on inputs from

the PBR, in-vehicle sensor, sunload sensor, intake sensor and ambient sensor. The blower motor applied

voltage ranges from approximately 5 volts (lowest speed) to 12 volts (highest speed).

The control blower speed (in the range of 5 to 12V), the automatic ampli®er supplies a gate voltage to the fan

control ampli®er. Based on this voltage, the fan control ampli®er controls the voltage supplied to the blower

motor.

Starting fan speed control

Start up from ``COLD SOAK'' condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 50ÉC, the blower will not operate

for a short period of time (up to 150 seconds). The exact start delay time varies depending on the ambient

and engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described above.

After this delay, the blower will operate at low speed until the engine coolant temperature rises above 55ÉC,

at which time the blower speed will increase to the objective speed.

Start up from normal or ``HOT SOAK'' condition (Automatic mode)

The blower will begin operation momentarily after the AUTO button is pushed. The blower speed will gradu-

ally rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

SHA006FB

TROUBLE DIAGNOSESAUTO

Blower Motor (Cont'd)

HA-87

Page 941 of 1226

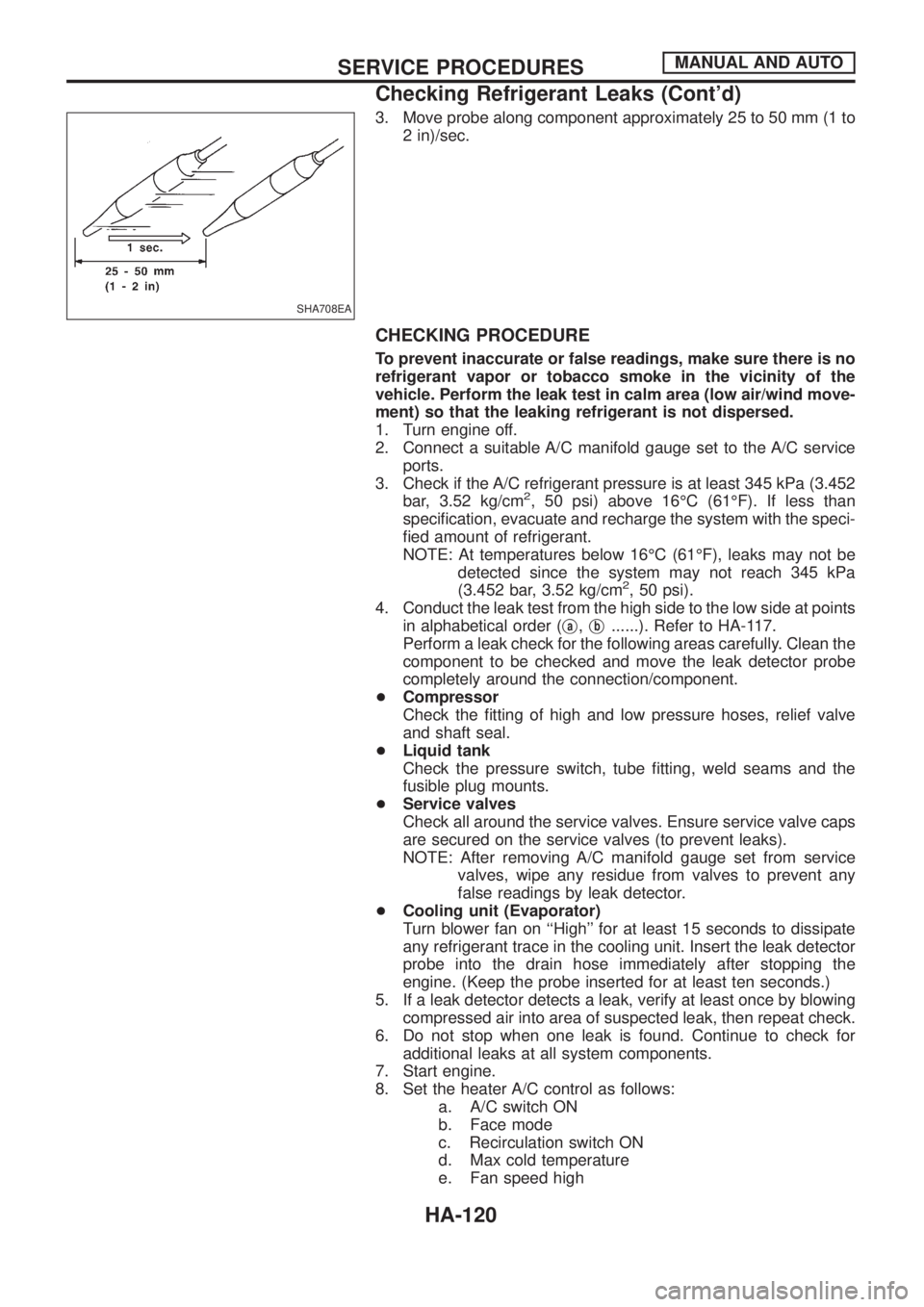

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no

refrigerant vapor or tobacco smoke in the vicinity of the

vehicle. Perform the leak test in calm area (low air/wind move-

ment) so that the leaking refrigerant is not dispersed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.452

bar, 3.52 kg/cm

2, 50 psi) above 16ÉC (61ÉF). If less than

speci®cation, evacuate and recharge the system with the speci-

®ed amount of refrigerant.

NOTE: At temperatures below 16ÉC (61ÉF), leaks may not be

detected since the system may not reach 345 kPa

(3.452 bar, 3.52 kg/cm

2, 50 psi).

4. Conduct the leak test from the high side to the low side at points

in alphabetical order (j

a,jb......). Refer to HA-117.

Perform a leak check for the following areas carefully. Clean the

component to be checked and move the leak detector probe

completely around the connection/component.

+Compressor

Check the ®tting of high and low pressure hoses, relief valve

and shaft seal.

+Liquid tank

Check the pressure switch, tube ®tting, weld seams and the

fusible plug mounts.

+Service valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE: After removing A/C manifold gauge set from service

valves, wipe any residue from valves to prevent any

false readings by leak detector.

+Cooling unit (Evaporator)

Turn blower fan on ``High'' for at least 15 seconds to dissipate

any refrigerant trace in the cooling unit. Insert the leak detector

probe into the drain hose immediately after stopping the

engine. (Keep the probe inserted for at least ten seconds.)

5. If a leak detector detects a leak, verify at least once by blowing

compressed air into area of suspected leak, then repeat check.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

7. Start engine.

8. Set the heater A/C control as follows:

a. A/C switch ON

b. Face mode

c. Recirculation switch ON

d. Max cold temperature

e. Fan speed high

SHA708EA

SERVICE PROCEDURESMANUAL AND AUTO

Checking Refrigerant Leaks (Cont'd)

HA-120

Page 979 of 1226

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for speci®cations.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose connec-

tions for leaks

hBattery ¯uid level, speci®c gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel ®lter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir ¯uid level and ¯uid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir ¯uid level

hPower steering reservoir ¯uid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hXRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and ®ttings for ®t and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for ®t and alignment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and ®t

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if applicable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

h

XInstall deodorizing ®lter to air puri®er (If appli-

cable)

h

XRemove wiper blade protectors (If applicable)

UNDER BODY

hManual transmission/transaxle gear oil, transfer

¯uid and differential gear oil level

hBrake and fuel lines and oil/¯uid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and drive

shafts

h

XTighten rear body bolts and nuts (Models with

wooden bed only)

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hAutomatic transmission/transaxle shift timing

and kickdown

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hAutomatic transmission/transaxle ¯uid level

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud ¯aps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 980 of 1226

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise

speci®ed.

TiresCheck the pressure with a gauge periodically when at a service station, including the

spare, and adjust to the speci®ed pressure if necessary. Check carefully for damage, cuts or

excessive wear.Ð

Windshield wiper bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers and

links if necessary. Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication fre-

quently.MA-27

Tire rotationTires should be rotated every 5,000 km (3,000 miles) for 4WD models. MA-25

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle, etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating properly and installed securely. Also check headlight aim.Ð

Warning lights and chimesMake sure that all warning lights and chimes are operating prop-

erly.Ð

Steering wheelCheck for change in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear or damage.MA-27

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer ¯uidCheck that there is adequate ¯uid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-14, 15

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the

engine.MA-13, 14

Brake and clutch ¯uid levelMake sure that the brake and clutch ¯uid levels are between the

``MAX'' and ``MIN'' lines on the reservoir.MA-20, 23

BatteryCheck the ¯uid level in each cell. It should be between the ``MAX'' and ``MIN'' lines. Ð

GENERAL MAINTENANCE

MA-3

Page 987 of 1226

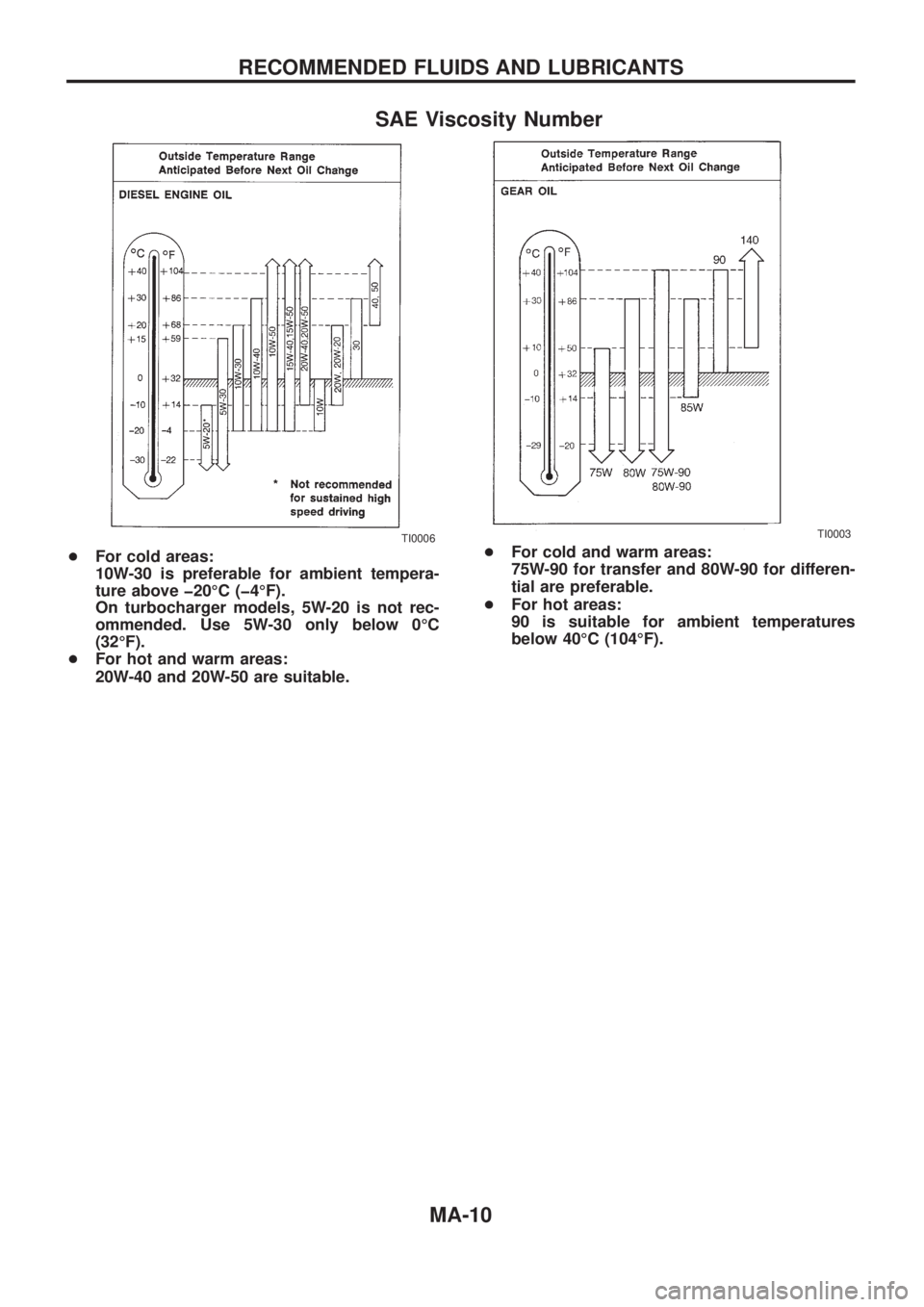

SAE Viscosity Number

+For cold areas:

10W-30 is preferable for ambient tempera-

ture above þ20ÉC (þ4ÉF).

On turbocharger models, 5W-20 is not rec-

ommended. Use 5W-30 only below 0ÉC

(32ÉF).

+For hot and warm areas:

20W-40 and 20W-50 are suitable.+For cold and warm areas:

75W-90 for transfer and 80W-90 for differen-

tial are preferable.

+For hot areas:

90 is suitable for ambient temperatures

below 40ÉC (104ÉF).

TI0006TI0003

RECOMMENDED FLUIDS AND LUBRICANTS

MA-10

Page 992 of 1226

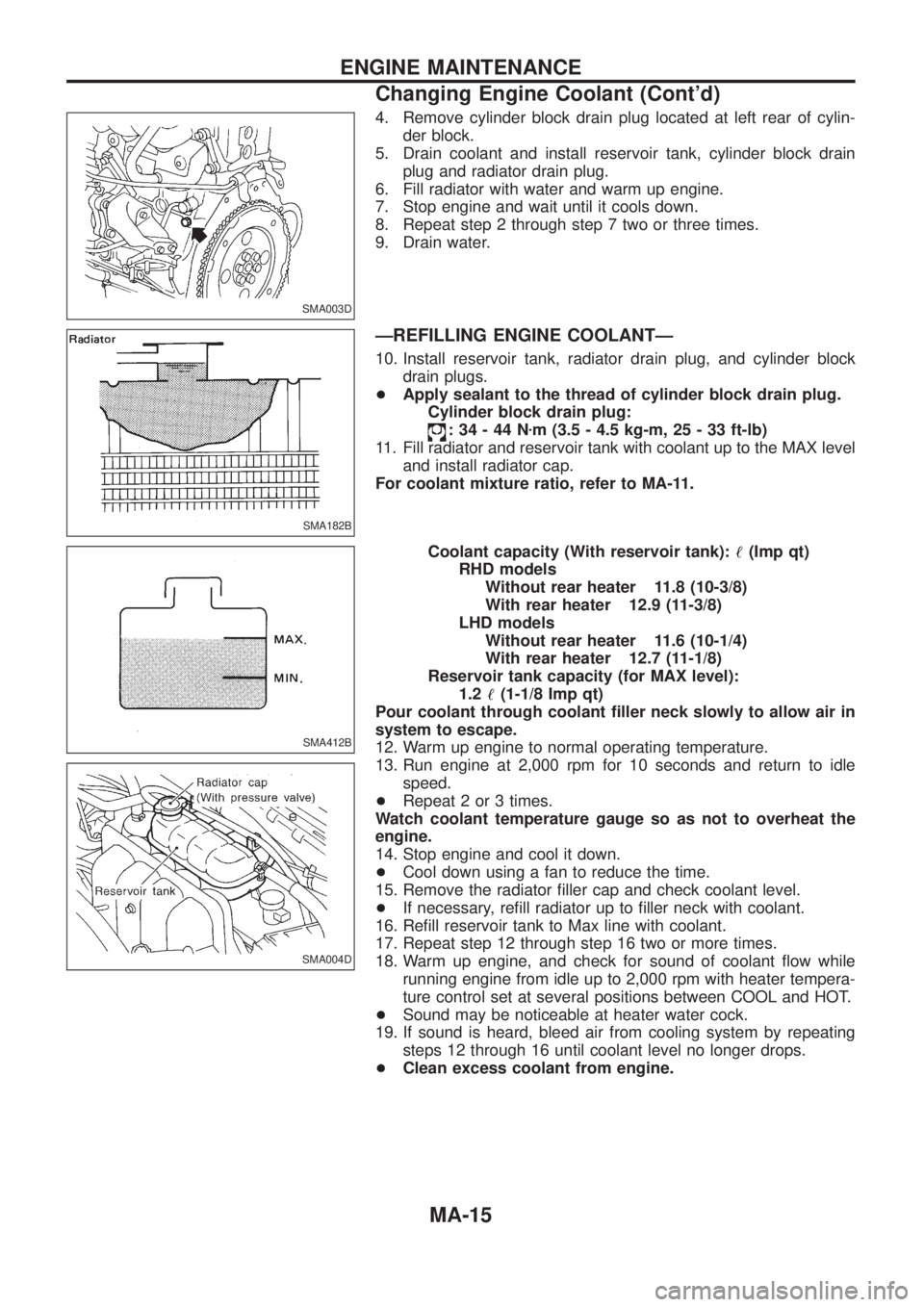

4. Remove cylinder block drain plug located at left rear of cylin-

der block.

5. Drain coolant and install reservoir tank, cylinder block drain

plug and radiator drain plug.

6. Fill radiator with water and warm up engine.

7. Stop engine and wait until it cools down.

8. Repeat step 2 through step 7 two or three times.

9. Drain water.

ÐREFILLING ENGINE COOLANTÐ

10. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

+Apply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:34-44Nzm (3.5 - 4.5 kg-m, 25 - 33 ft-lb)

11. Fill radiator and reservoir tank with coolant up to the MAX level

and install radiator cap.

For coolant mixture ratio, refer to MA-11.

Coolant capacity (With reservoir tank):!(Imp qt)

RHD models

Without rear heater 11.8 (10-3/8)

With rear heater 12.9 (11-3/8)

LHD models

Without rear heater 11.6 (10-1/4)

With rear heater 12.7 (11-1/8)

Reservoir tank capacity (for MAX level):

1.2!(1-1/8 Imp qt)

Pour coolant through coolant ®ller neck slowly to allow air in

system to escape.

12. Warm up engine to normal operating temperature.

13. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

+Repeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

14. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

15. Remove the radiator ®ller cap and check coolant level.

+If necessary, re®ll radiator up to ®ller neck with coolant.

16. Re®ll reservoir tank to Max line with coolant.

17. Repeat step 12 through step 16 two or more times.

18. Warm up engine, and check for sound of coolant ¯ow while

running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

+Sound may be noticeable at heater water cock.

19. If sound is heard, bleed air from cooling system by repeating

steps 12 through 16 until coolant level no longer drops.

+Clean excess coolant from engine.

SMA003D

SMA182B

SMA412B

SMA004D

ENGINE MAINTENANCE

Changing Engine Coolant (Cont'd)

MA-15