light NISSAN PATROL 2006 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 802 of 1226

CONTROL UNIT CIRCUIT TEST

System Description: When the switch is ON, the control unit lights up the lamp.

AGI059

HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

GI-29

Page 817 of 1226

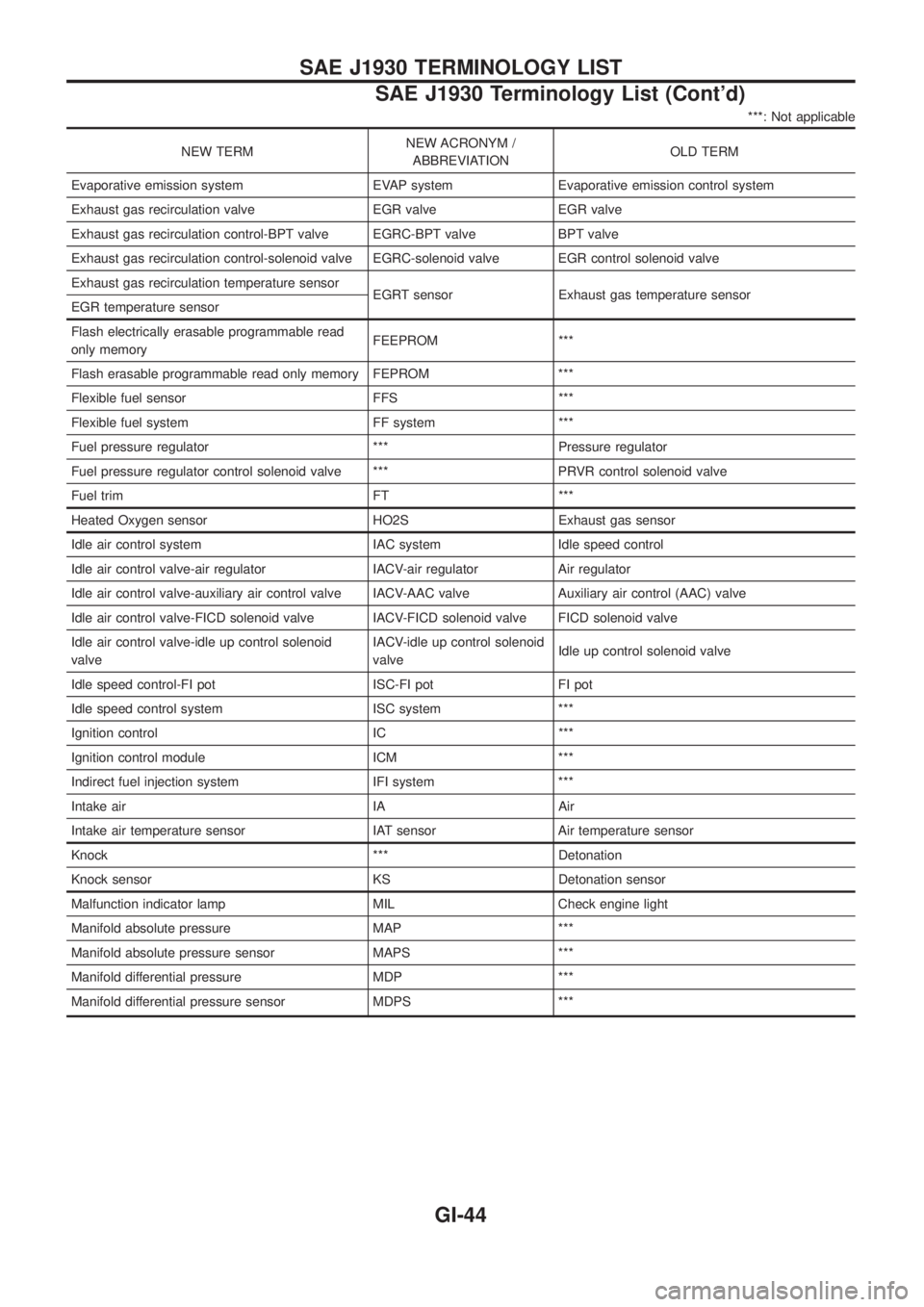

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT valve EGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid valve EGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sensor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable read

only memoryFEEPROM ***

Flash erasable programmable read only memory FEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid valve *** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control valve IACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control solenoid

valveIACV-idle up control solenoid

valveIdle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

SAE J1930 TERMINOLOGY LIST

SAE J1930 Terminology List (Cont'd)

GI-44

Page 828 of 1226

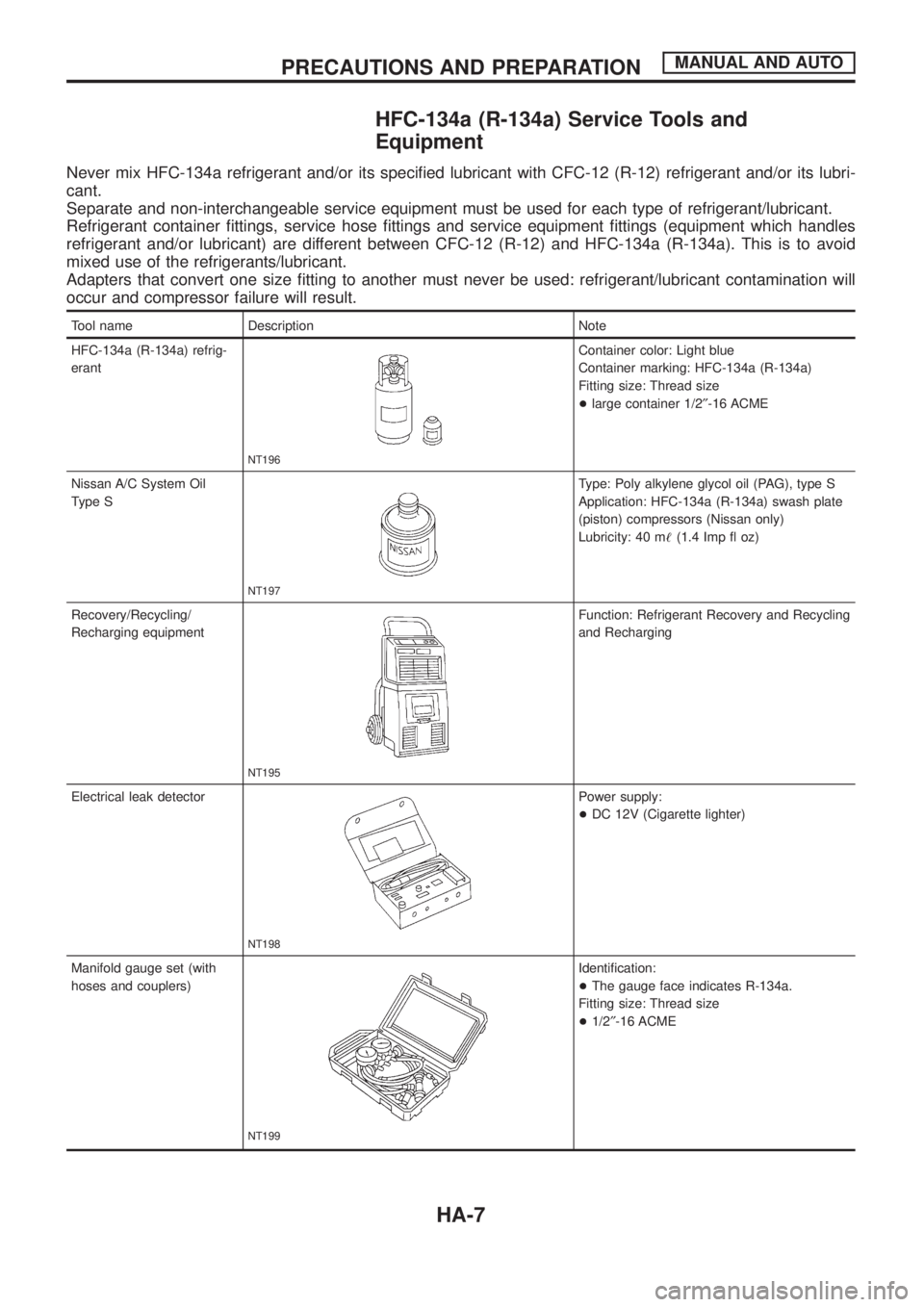

HFC-134a (R-134a) Service Tools and

Equipment

Never mix HFC-134a refrigerant and/or its speci®ed lubricant with CFC-12 (R-12) refrigerant and/or its lubri-

cant.

Separate and non-interchangeable service equipment must be used for each type of refrigerant/lubricant.

Refrigerant container ®ttings, service hose ®ttings and service equipment ®ttings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size ®tting to another must never be used: refrigerant/lubricant contamination will

occur and compressor failure will result.

Tool name Description Note

HFC-134a (R-134a) refrig-

erant

NT196

Container color: Light blue

Container marking: HFC-134a (R-134a)

Fitting size: Thread size

+large container 1/2²-16 ACME

Nissan A/C System Oil

Type S

NT197

Type: Poly alkylene glycol oil (PAG), type S

Application: HFC-134a (R-134a) swash plate

(piston) compressors (Nissan only)

Lubricity: 40 m!(1.4 Imp ¯ oz)

Recovery/Recycling/

Recharging equipment

NT195

Function: Refrigerant Recovery and Recycling

and Recharging

Electrical leak detector

NT198

Power supply:

+DC 12V (Cigarette lighter)

Manifold gauge set (with

hoses and couplers)

NT199

Identi®cation:

+The gauge face indicates R-134a.

Fitting size: Thread size

+1/2²-16 ACME

PRECAUTIONS AND PREPARATIONMANUAL AND AUTO

HA-7

Page 837 of 1226

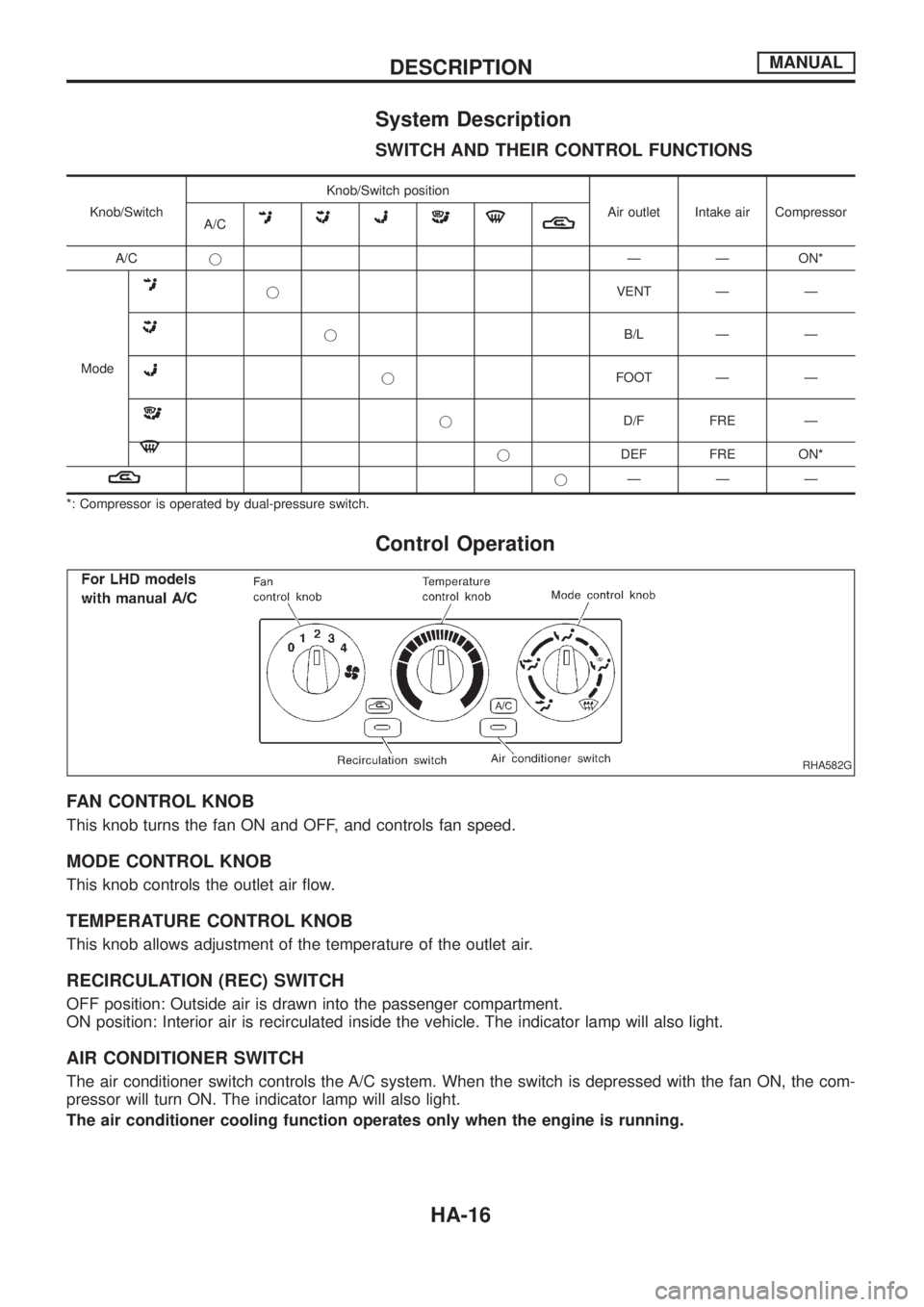

System Description

SWITCH AND THEIR CONTROL FUNCTIONS

Knob/SwitchKnob/Switch position

Air outlet Intake air Compressor

A/C

A/CjÐ Ð ON*

Mode

jVENT Ð Ð

jB/L Ð Ð

jFOOT Ð Ð

jD/F FRE Ð

jDEF FRE ON*

jÐÐÐ

*: Compressor is operated by dual-pressure switch.

Control Operation

FAN CONTROL KNOB

This knob turns the fan ON and OFF, and controls fan speed.

MODE CONTROL KNOB

This knob controls the outlet air ¯ow.

TEMPERATURE CONTROL KNOB

This knob allows adjustment of the temperature of the outlet air.

RECIRCULATION (REC) SWITCH

OFF position: Outside air is drawn into the passenger compartment.

ON position: Interior air is recirculated inside the vehicle. The indicator lamp will also light.

AIR CONDITIONER SWITCH

The air conditioner switch controls the A/C system. When the switch is depressed with the fan ON, the com-

pressor will turn ON. The indicator lamp will also light.

The air conditioner cooling function operates only when the engine is running.

RHA582G

DESCRIPTIONMANUAL

HA-16

Page 844 of 1226

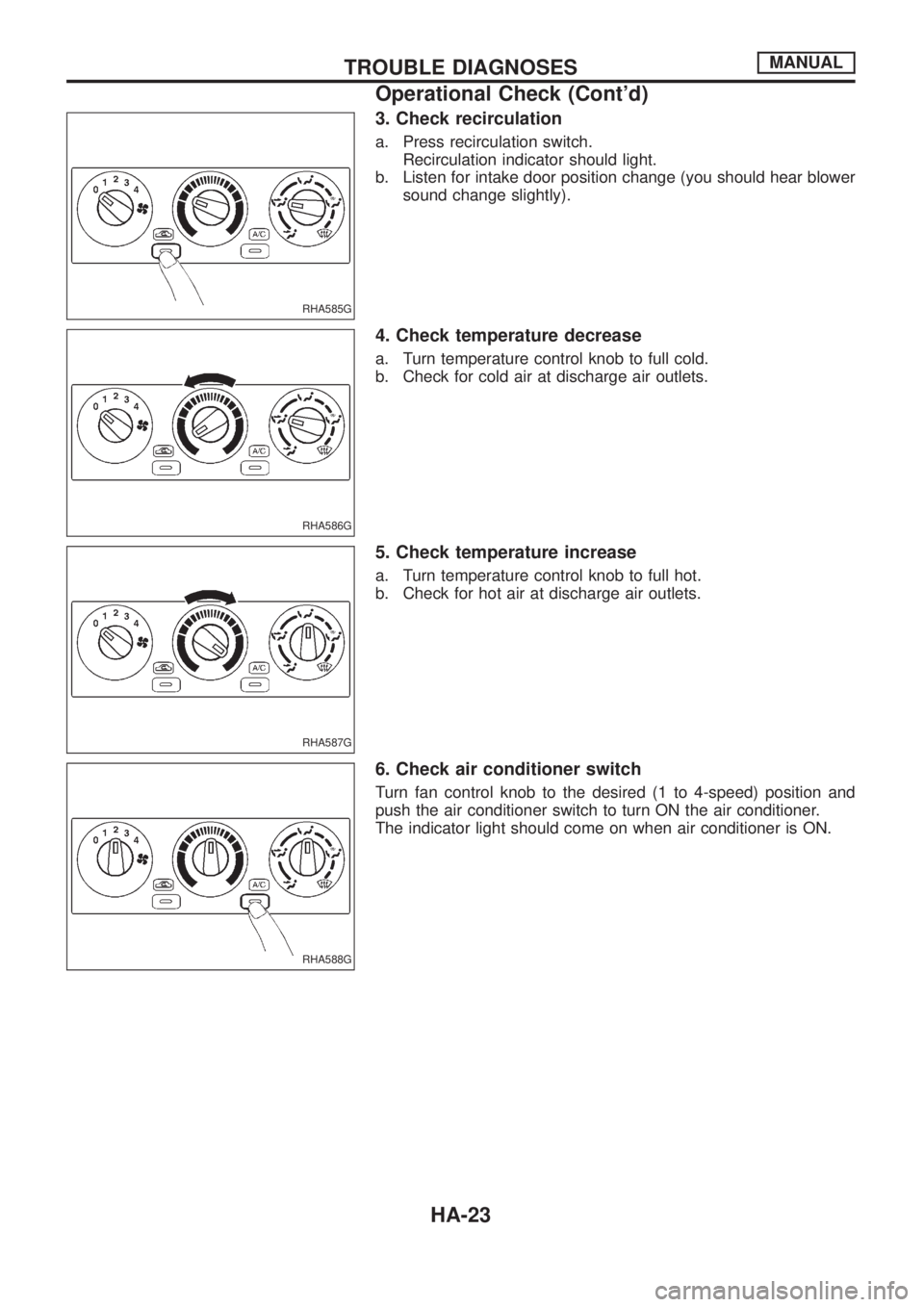

3. Check recirculation

a. Press recirculation switch.

Recirculation indicator should light.

b. Listen for intake door position change (you should hear blower

sound change slightly).

4. Check temperature decrease

a. Turn temperature control knob to full cold.

b. Check for cold air at discharge air outlets.

5. Check temperature increase

a. Turn temperature control knob to full hot.

b. Check for hot air at discharge air outlets.

6. Check air conditioner switch

Turn fan control knob to the desired (1 to 4-speed) position and

push the air conditioner switch to turn ON the air conditioner.

The indicator light should come on when air conditioner is ON.

RHA585G

RHA586G

RHA587G

RHA588G

TROUBLE DIAGNOSESMANUAL

Operational Check (Cont'd)

HA-23

Page 886 of 1226

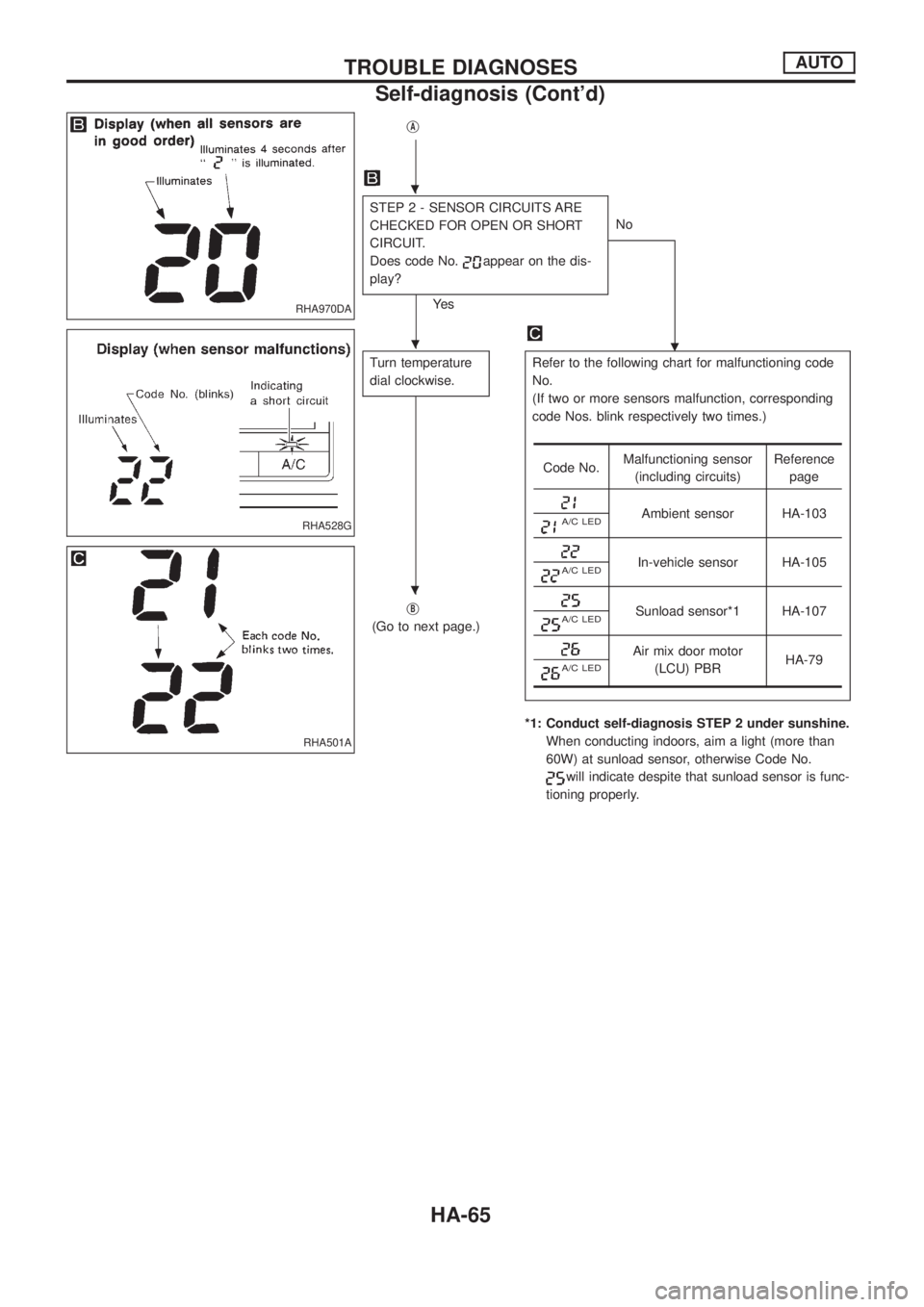

jA

STEP 2 - SENSOR CIRCUITS ARE

CHECKED FOR OPEN OR SHORT

CIRCUIT.

Does code No.

appear on the dis-

play?

Ye sNo

.

Turn temperature

dial clockwise.Refer to the following chart for malfunctioning code

No.

(If two or more sensors malfunction, corresponding

code Nos. blink respectively two times.)

*1: Conduct self-diagnosis STEP 2 under sunshine.

When conducting indoors, aim a light (more than

60W) at sunload sensor, otherwise Code No.

will indicate despite that sunload sensor is func-

tioning properly. j

B

(Go to next page.)

Code No.Malfunctioning sensor

(including circuits)Reference

page

Ambient sensor HA-103A/C LED

In-vehicle sensor HA-105A/C LED

Sunload sensor*1 HA-107A/C LED

Air mix door motor

(LCU) PBRHA-79

A/C LED

RHA970DA

RHA528G

RHA501A

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-65

Page 892 of 1226

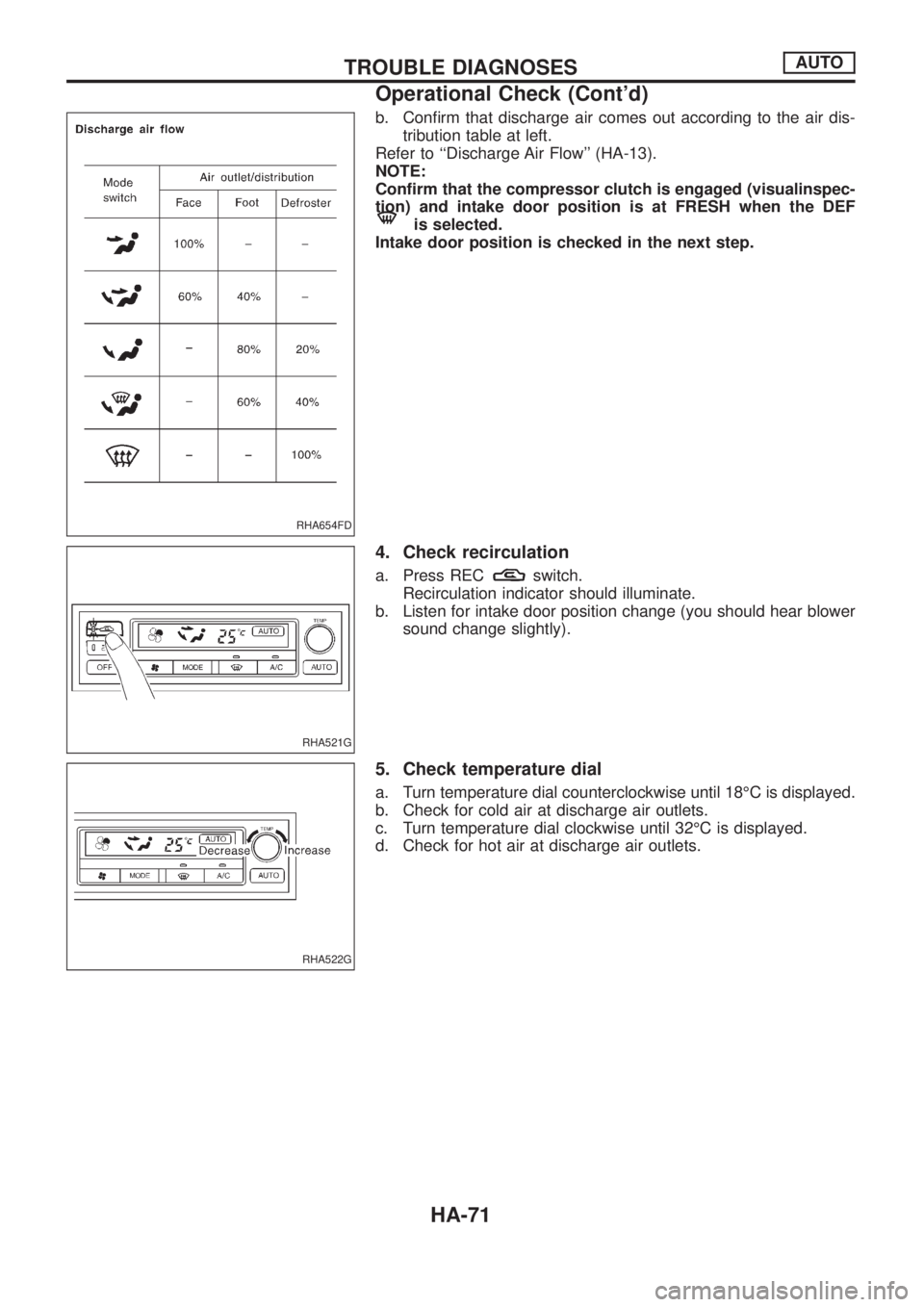

b. Con®rm that discharge air comes out according to the air dis-

tribution table at left.

Refer to ``Discharge Air Flow'' (HA-13).

NOTE:

Con®rm that the compressor clutch is engaged (visualinspec-

tion) and intake door position is at FRESH when the DEF

is selected.

Intake door position is checked in the next step.

4. Check recirculation

a. Press RECswitch.

Recirculation indicator should illuminate.

b. Listen for intake door position change (you should hear blower

sound change slightly).

5. Check temperature dial

a. Turn temperature dial counterclockwise until 18ÉC is displayed.

b. Check for cold air at discharge air outlets.

c. Turn temperature dial clockwise until 32ÉC is displayed.

d. Check for hot air at discharge air outlets.

RHA654FD

RHA521G

RHA522G

TROUBLE DIAGNOSESAUTO

Operational Check (Cont'd)

HA-71

Page 893 of 1226

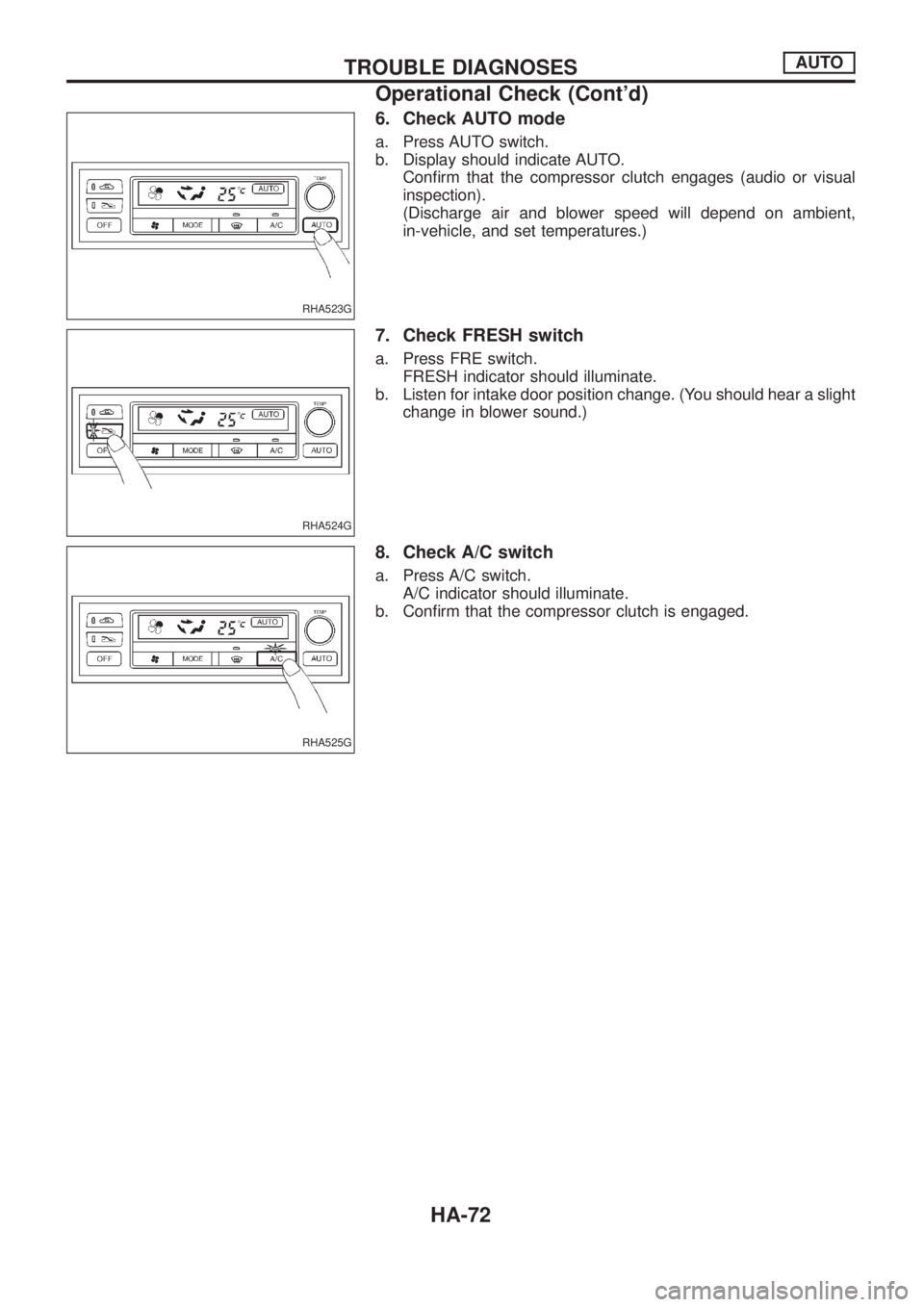

6. Check AUTO mode

a. Press AUTO switch.

b. Display should indicate AUTO.

Con®rm that the compressor clutch engages (audio or visual

inspection).

(Discharge air and blower speed will depend on ambient,

in-vehicle, and set temperatures.)

7. Check FRESH switch

a. Press FRE switch.

FRESH indicator should illuminate.

b. Listen for intake door position change. (You should hear a slight

change in blower sound.)

8. Check A/C switch

a. Press A/C switch.

A/C indicator should illuminate.

b. Con®rm that the compressor clutch is engaged.

RHA523G

RHA524G

RHA525G

TROUBLE DIAGNOSESAUTO

Operational Check (Cont'd)

HA-72

Page 928 of 1226

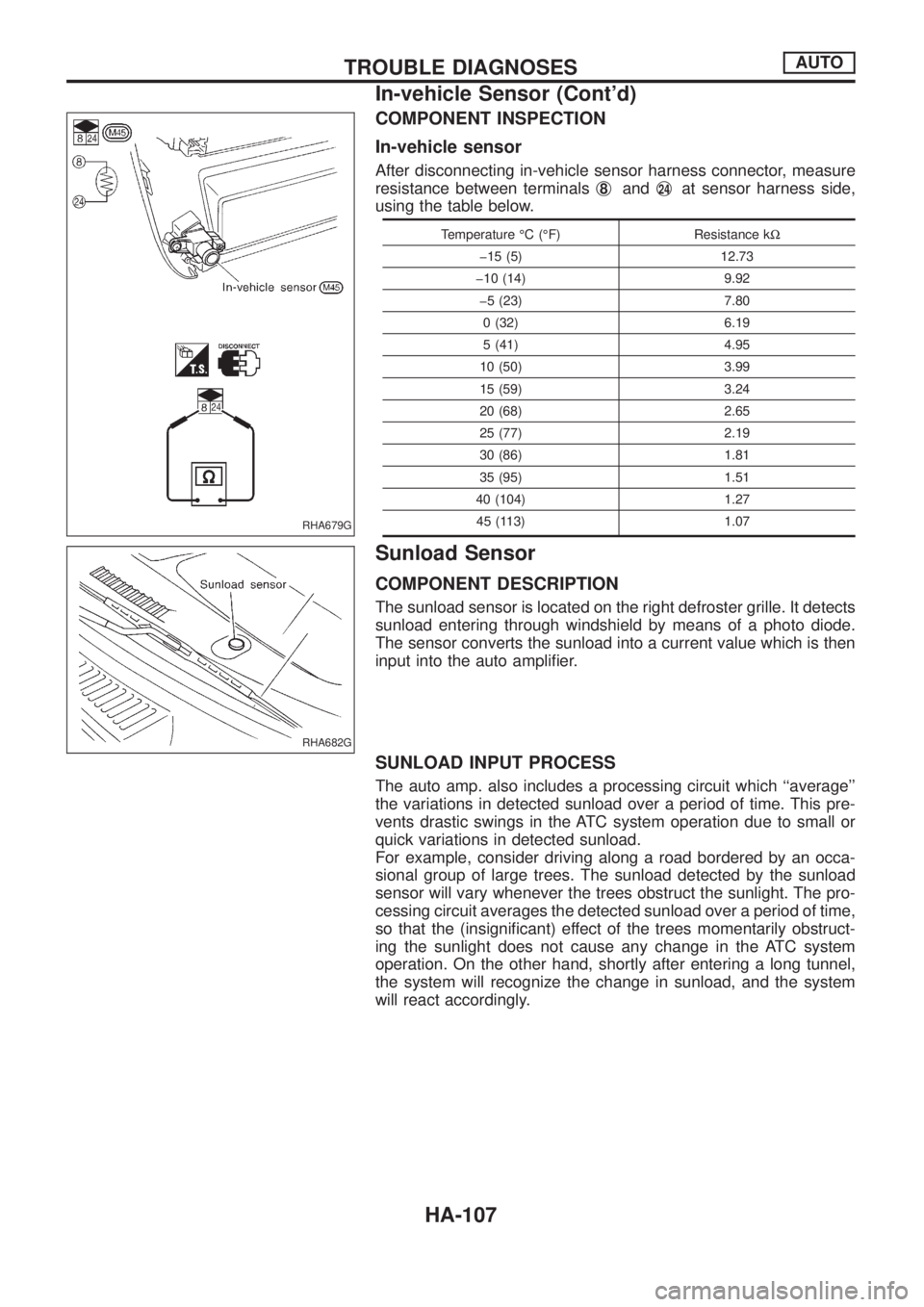

COMPONENT INSPECTION

In-vehicle sensor

After disconnecting in-vehicle sensor harness connector, measure

resistance between terminalsj

8andj24at sensor harness side,

using the table below.

Temperature ÉC (ÉF) Resistance kW

þ15 (5) 12.73

þ10 (14) 9.92

þ5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07

Sunload Sensor

COMPONENT DESCRIPTION

The sunload sensor is located on the right defroster grille. It detects

sunload entering through windshield by means of a photo diode.

The sensor converts the sunload into a current value which is then

input into the auto ampli®er.

SUNLOAD INPUT PROCESS

The auto amp. also includes a processing circuit which ``average''

the variations in detected sunload over a period of time. This pre-

vents drastic swings in the ATC system operation due to small or

quick variations in detected sunload.

For example, consider driving along a road bordered by an occa-

sional group of large trees. The sunload detected by the sunload

sensor will vary whenever the trees obstruct the sunlight. The pro-

cessing circuit averages the detected sunload over a period of time,

so that the (insigni®cant) effect of the trees momentarily obstruct-

ing the sunlight does not cause any change in the ATC system

operation. On the other hand, shortly after entering a long tunnel,

the system will recognize the change in sunload, and the system

will react accordingly.

RHA679G

RHA682G

TROUBLE DIAGNOSESAUTO

In-vehicle Sensor (Cont'd)

HA-107

Page 949 of 1226

A

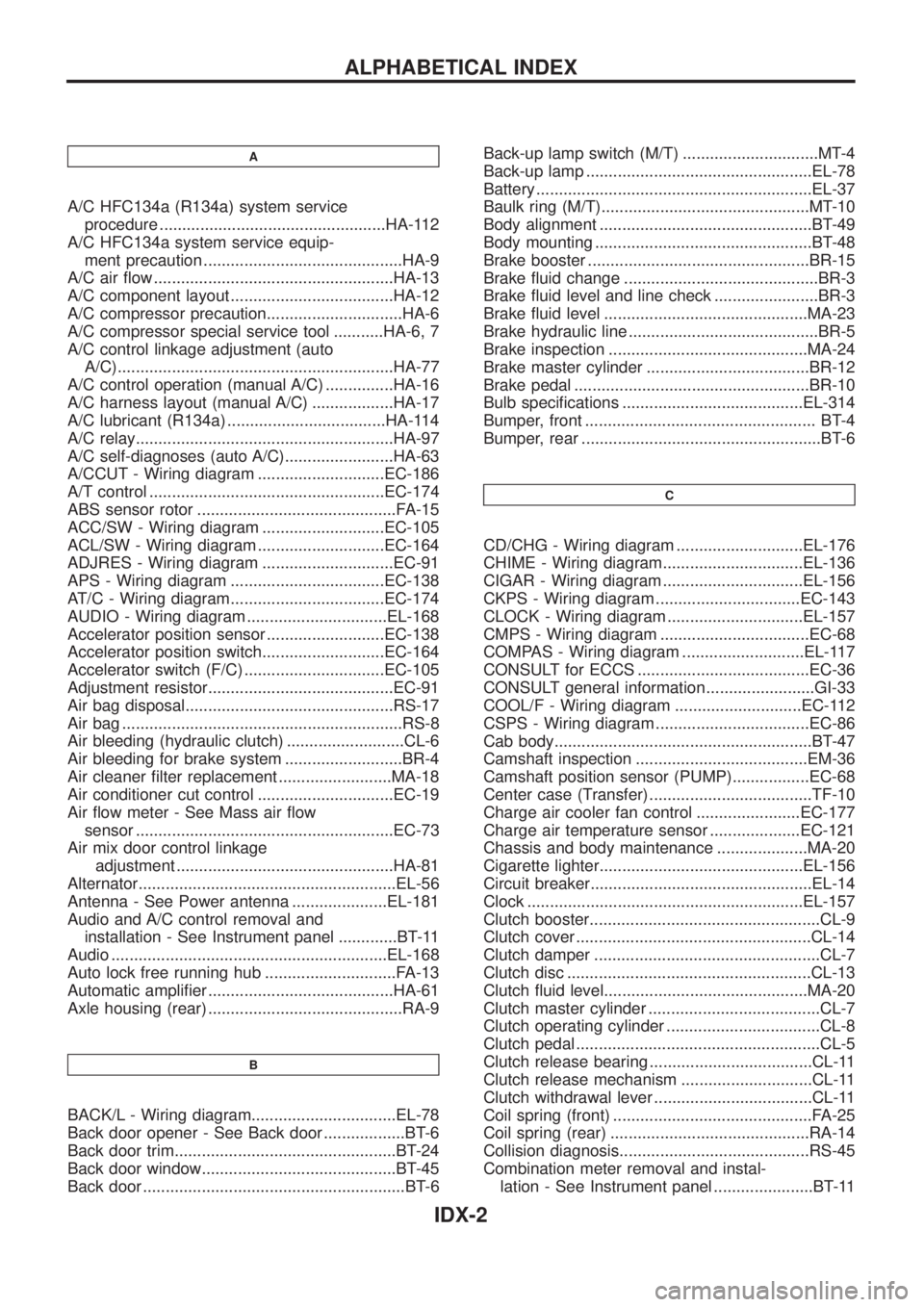

A/C HFC134a (R134a) system service

procedure ..................................................HA-112

A/C HFC134a system service equip-

ment precaution ............................................HA-9

A/C air ¯ow .....................................................HA-13

A/C component layout ....................................HA-12

A/C compressor precaution..............................HA-6

A/C compressor special service tool ...........HA-6, 7

A/C control linkage adjustment (auto

A/C).............................................................HA-77

A/C control operation (manual A/C) ...............HA-16

A/C harness layout (manual A/C) ..................HA-17

A/C lubricant (R134a) ...................................HA-114

A/C relay.........................................................HA-97

A/C self-diagnoses (auto A/C)........................HA-63

A/CCUT - Wiring diagram ............................EC-186

A/T control ....................................................EC-174

ABS sensor rotor ............................................FA-15

ACC/SW - Wiring diagram ...........................EC-105

ACL/SW - Wiring diagram ............................EC-164

ADJRES - Wiring diagram .............................EC-91

APS - Wiring diagram ..................................EC-138

AT/C - Wiring diagram..................................EC-174

AUDIO - Wiring diagram ...............................EL-168

Accelerator position sensor ..........................EC-138

Accelerator position switch...........................EC-164

Accelerator switch (F/C) ...............................EC-105

Adjustment resistor.........................................EC-91

Air bag disposal..............................................RS-17

Air bag ..............................................................RS-8

Air bleeding (hydraulic clutch) ..........................CL-6

Air bleeding for brake system ..........................BR-4

Air cleaner ®lter replacement .........................MA-18

Air conditioner cut control ..............................EC-19

Air ¯ow meter - See Mass air ¯ow

sensor .........................................................EC-73

Air mix door control linkage

adjustment ................................................HA-81

Alternator.........................................................EL-56

Antenna - See Power antenna .....................EL-181

Audio and A/C control removal and

installation - See Instrument panel .............BT-11

Audio .............................................................EL-168

Auto lock free running hub .............................FA-13

Automatic ampli®er .........................................HA-61

Axle housing (rear) ...........................................RA-9

B

BACK/L - Wiring diagram................................EL-78

Back door opener - See Back door ..................BT-6

Back door trim.................................................BT-24

Back door window...........................................BT-45

Back door ..........................................................BT-6Back-up lamp switch (M/T) ..............................MT-4

Back-up lamp ..................................................EL-78

Battery .............................................................EL-37

Baulk ring (M/T)..............................................MT-10

Body alignment ...............................................BT-49

Body mounting ................................................BT-48

Brake booster .................................................BR-15

Brake ¯uid change ...........................................BR-3

Brake ¯uid level and line check .......................BR-3

Brake ¯uid level .............................................MA-23

Brake hydraulic line ..........................................BR-5

Brake inspection ............................................MA-24

Brake master cylinder ....................................BR-12

Brake pedal ....................................................BR-10

Bulb speci®cations ........................................EL-314

Bumper, front ................................................... BT-4

Bumper, rear .....................................................BT-6

C

CD/CHG - Wiring diagram ............................EL-176

CHIME - Wiring diagram...............................EL-136

CIGAR - Wiring diagram ...............................EL-156

CKPS - Wiring diagram ................................EC-143

CLOCK - Wiring diagram ..............................EL-157

CMPS - Wiring diagram .................................EC-68

COMPAS - Wiring diagram ...........................EL-117

CONSULT for ECCS ......................................EC-36

CONSULT general information ........................GI-33

COOL/F - Wiring diagram ............................EC-112

CSPS - Wiring diagram ..................................EC-86

Cab body.........................................................BT-47

Camshaft inspection ......................................EM-36

Camshaft position sensor (PUMP).................EC-68

Center case (Transfer) ....................................TF-10

Charge air cooler fan control .......................EC-177

Charge air temperature sensor ....................EC-121

Chassis and body maintenance ....................MA-20

Cigarette lighter.............................................EL-156

Circuit breaker.................................................EL-14

Clock .............................................................EL-157

Clutch booster...................................................CL-9

Clutch cover ....................................................CL-14

Clutch damper ..................................................CL-7

Clutch disc ......................................................CL-13

Clutch ¯uid level.............................................MA-20

Clutch master cylinder ......................................CL-7

Clutch operating cylinder ..................................CL-8

Clutch pedal ......................................................CL-5

Clutch release bearing ....................................CL-11

Clutch release mechanism .............................CL-11

Clutch withdrawal lever ...................................CL-11

Coil spring (front) ............................................FA-25

Coil spring (rear) ............................................RA-14

Collision diagnosis..........................................RS-45

Combination meter removal and instal-

lation - See Instrument panel ......................BT-11

ALPHABETICAL INDEX

IDX-2