drive shaft NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 169 of 1226

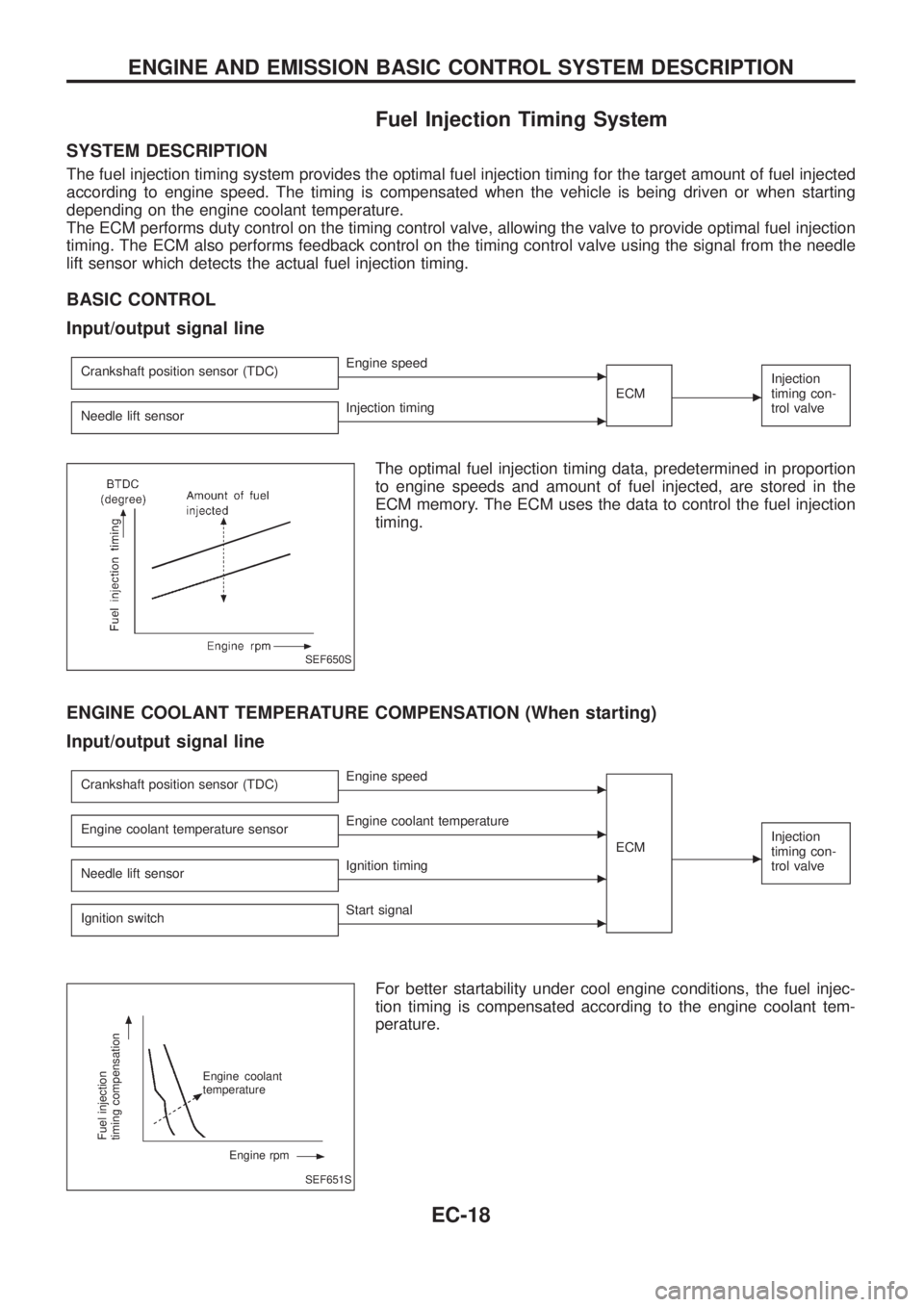

Fuel Injection Timing System

SYSTEM DESCRIPTION

The fuel injection timing system provides the optimal fuel injection timing for the target amount of fuel injected

according to engine speed. The timing is compensated when the vehicle is being driven or when starting

depending on the engine coolant temperature.

The ECM performs duty control on the timing control valve, allowing the valve to provide optimal fuel injection

timing. The ECM also performs feedback control on the timing control valve using the signal from the needle

lift sensor which detects the actual fuel injection timing.

BASIC CONTROL

Input/output signal line

Crankshaft position sensor (TDC)cEngine speed

ECM

c

Injection

timing con-

trol valve

Needle lift sensorcInjection timing

The optimal fuel injection timing data, predetermined in proportion

to engine speeds and amount of fuel injected, are stored in the

ECM memory. The ECM uses the data to control the fuel injection

timing.

ENGINE COOLANT TEMPERATURE COMPENSATION (When starting)

Input/output signal line

Crankshaft position sensor (TDC)cEngine speed

ECM

c

Injection

timing con-

trol valveEngine coolant temperature sensorcEngine coolant temperature

Needle lift sensor

cIgnition timing

Ignition switch

cStart signal

For better startability under cool engine conditions, the fuel injec-

tion timing is compensated according to the engine coolant tem-

perature.

SEF650S

SEF651S

Fuel injection

timing compensation

Engine coolant

temperature

Engine rpm

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTION

EC-18

Page 220 of 1226

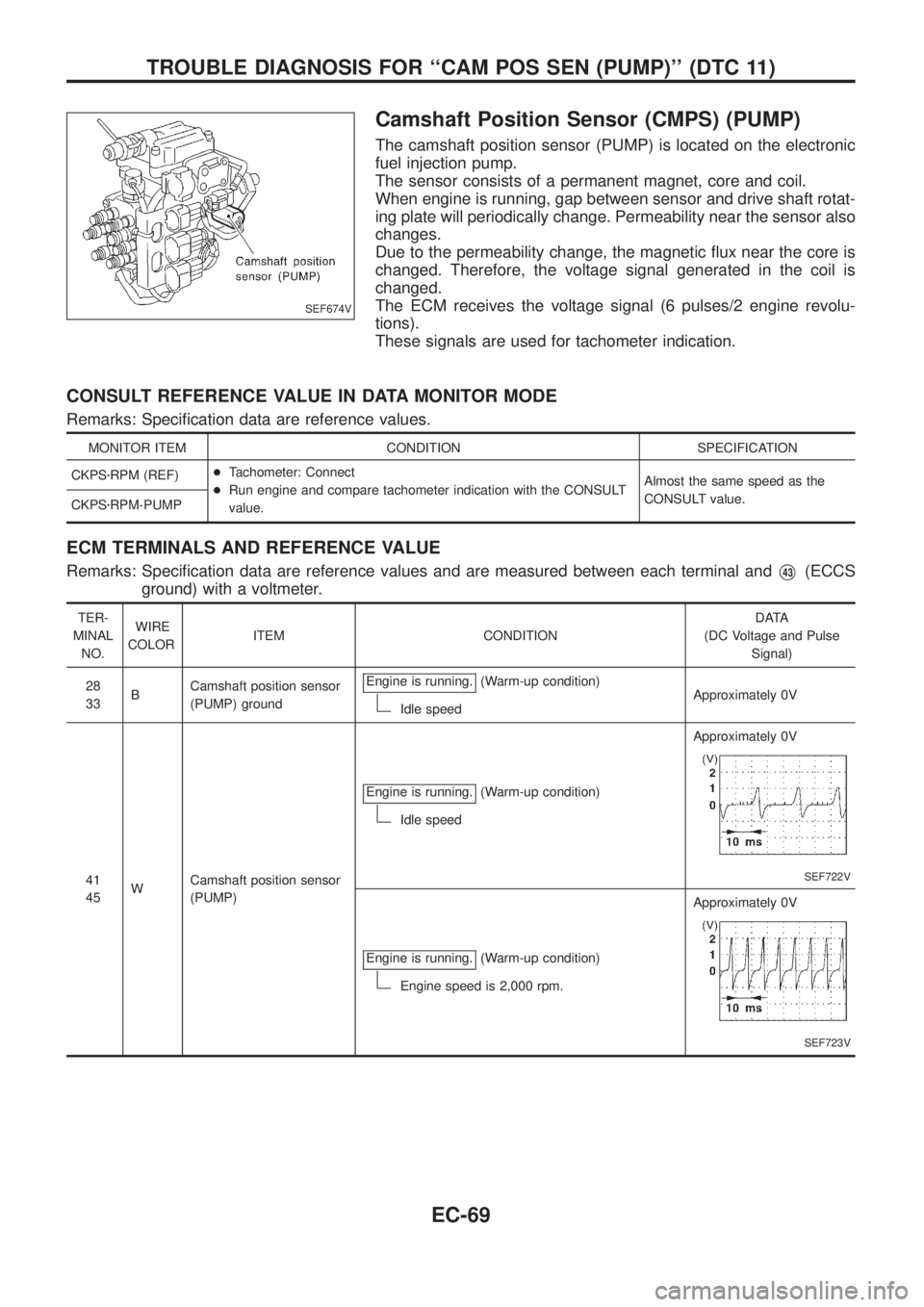

Camshaft Position Sensor (CMPS) (PUMP)

The camshaft position sensor (PUMP) is located on the electronic

fuel injection pump.

The sensor consists of a permanent magnet, core and coil.

When engine is running, gap between sensor and drive shaft rotat-

ing plate will periodically change. Permeability near the sensor also

changes.

Due to the permeability change, the magnetic ¯ux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal (6 pulses/2 engine revolu-

tions).

These signals are used for tachometer indication.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (REF)+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT

value.Almost the same speed as the

CONSULT value.

CKPSzRPM-PUMP

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

28

33BCamshaft position sensor

(PUMP) groundEngine is running.

(Warm-up condition)

Idle speedApproximately 0V

41

45WCamshaft position sensor

(PUMP)Engine is running.

(Warm-up condition)

Idle speedApproximately 0V

SEF722V

Engine is running.(Warm-up condition)

Engine speed is 2,000 rpm.Approximately 0V

SEF723V

SEF674V

TROUBLE DIAGNOSIS FOR ``CAM POS SEN (PUMP)'' (DTC 11)

EC-69

Page 329 of 1226

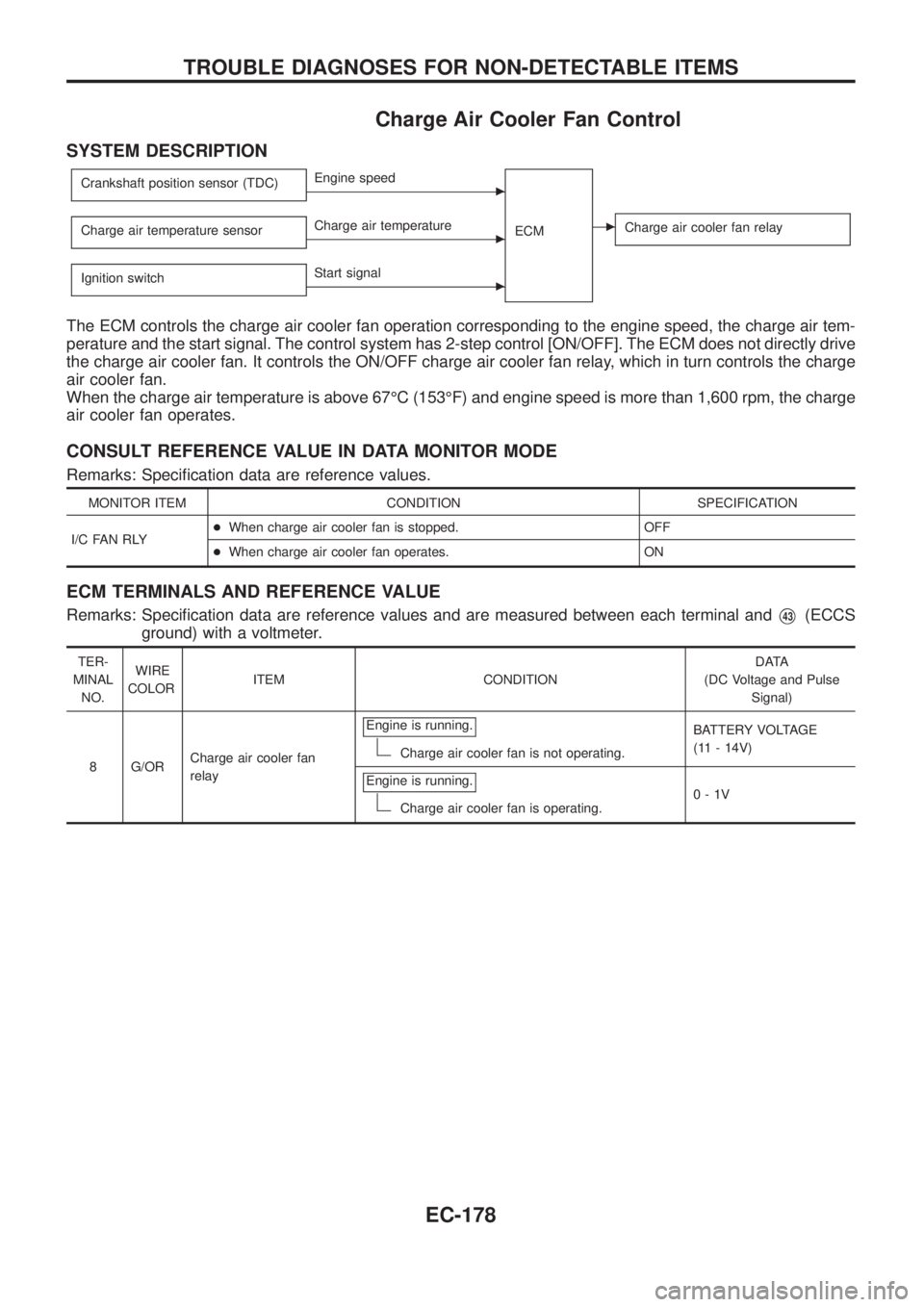

Charge Air Cooler Fan Control

SYSTEM DESCRIPTION

Crankshaft position sensor (TDC)cEngine speed

ECM

cCharge air cooler fan relayCharge air temperature sensorcCharge air temperature

Ignition switch

cStart signal

The ECM controls the charge air cooler fan operation corresponding to the engine speed, the charge air tem-

perature and the start signal. The control system has 2-step control [ON/OFF]. The ECM does not directly drive

the charge air cooler fan. It controls the ON/OFF charge air cooler fan relay, which in turn controls the charge

air cooler fan.

When the charge air temperature is above 67ÉC (153ÉF) and engine speed is more than 1,600 rpm, the charge

air cooler fan operates.

CONSULT REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Speci®cation data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

I/C FAN RLY+When charge air cooler fan is stopped. OFF

+When charge air cooler fan operates. ON

ECM TERMINALS AND REFERENCE VALUE

Remarks: Speci®cation data are reference values and are measured between each terminal andV43(ECCS

ground) with a voltmeter.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

8 G/ORCharge air cooler fan

relayEngine is running.

Charge air cooler fan is not operating.BATTERY VOLTAGE

(11 - 14V)

Engine is running.

Charge air cooler fan is operating.0-1V

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

EC-178

Page 676 of 1226

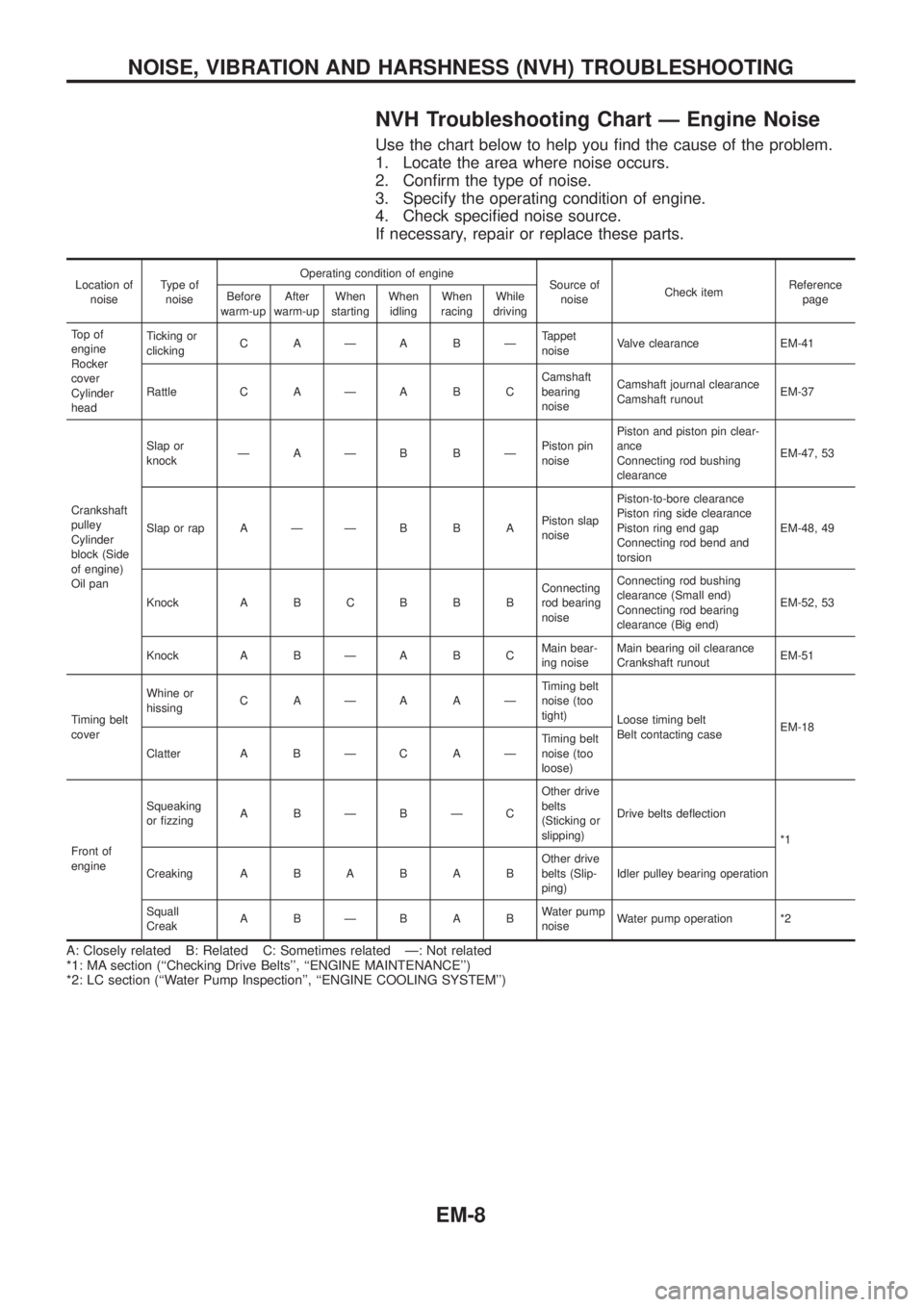

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you ®nd the cause of the problem.

1. Locate the area where noise occurs.

2. Con®rm the type of noise.

3. Specify the operating condition of engine.

4. Check speci®ed noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearance EM-41

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clearance

Camshaft runoutEM-37

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-47, 53

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-48, 49

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-52, 53

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-51

Timing belt

coverWhine or

hissingCAÐAAÐTiming belt

noise (too

tight)

Loose timing belt

Belt contacting caseEM-18

Clatter A B Ð C A ÐTiming belt

noise (too

loose)

Front of

engineSqueaking

or ®zzingABÐBÐCOther drive

belts

(Sticking or

slipping)Drive belts de¯ection

*1

CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

noiseWater pump operation *2

A: Closely related B: Related C: Sometimes related Ð: Not related

*1: MA section (``Checking Drive Belts'', ``ENGINE MAINTENANCE'')

*2: LC section (``Water Pump Inspection'', ``ENGINE COOLING SYSTEM'')

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

EM-8

Page 684 of 1226

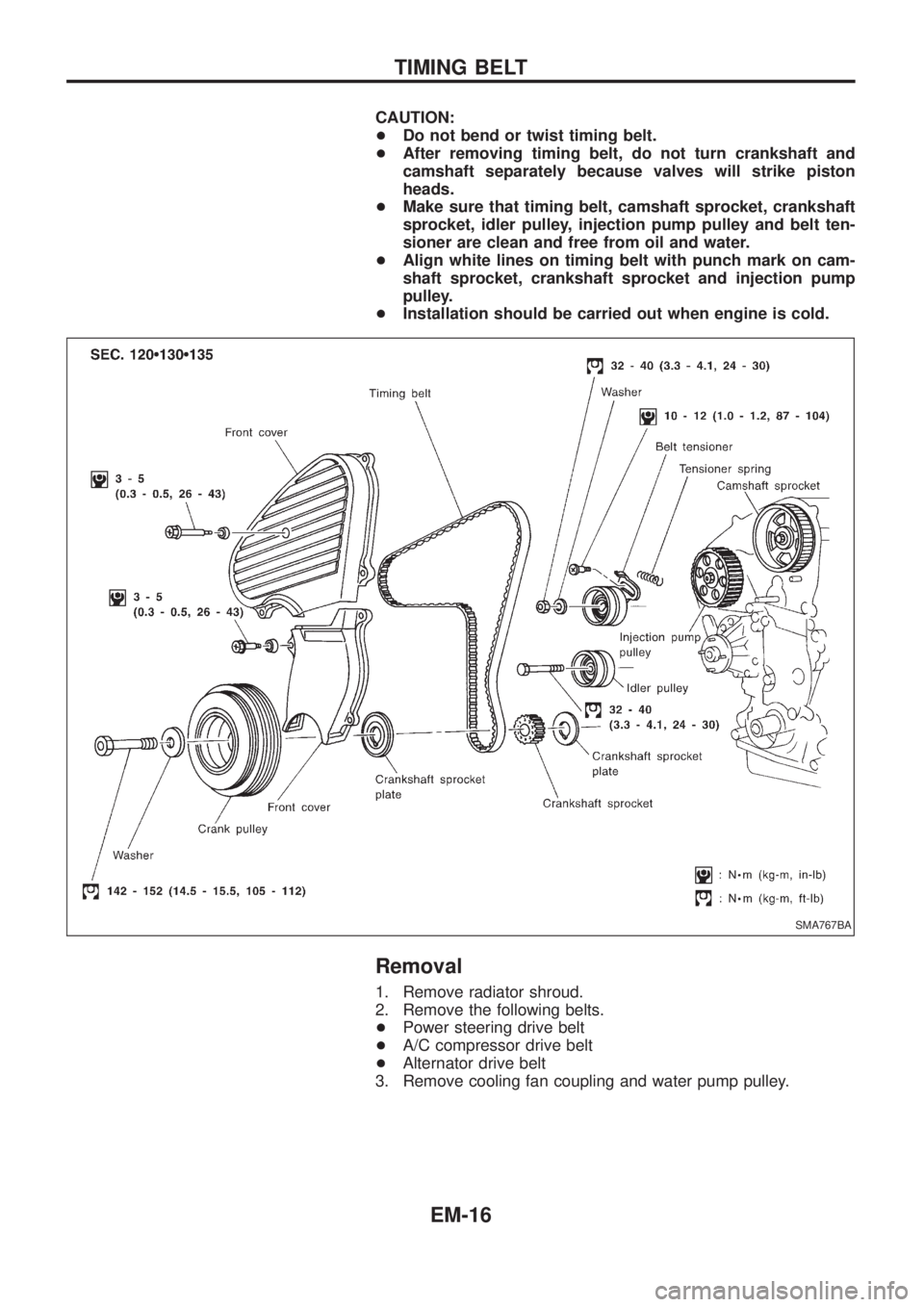

CAUTION:

+Do not bend or twist timing belt.

+After removing timing belt, do not turn crankshaft and

camshaft separately because valves will strike piston

heads.

+Make sure that timing belt, camshaft sprocket, crankshaft

sprocket, idler pulley, injection pump pulley and belt ten-

sioner are clean and free from oil and water.

+Align white lines on timing belt with punch mark on cam-

shaft sprocket, crankshaft sprocket and injection pump

pulley.

+Installation should be carried out when engine is cold.

Removal

1. Remove radiator shroud.

2. Remove the following belts.

+Power steering drive belt

+A/C compressor drive belt

+Alternator drive belt

3. Remove cooling fan coupling and water pump pulley.

SMA767BA

TIMING BELT

EM-16

Page 688 of 1226

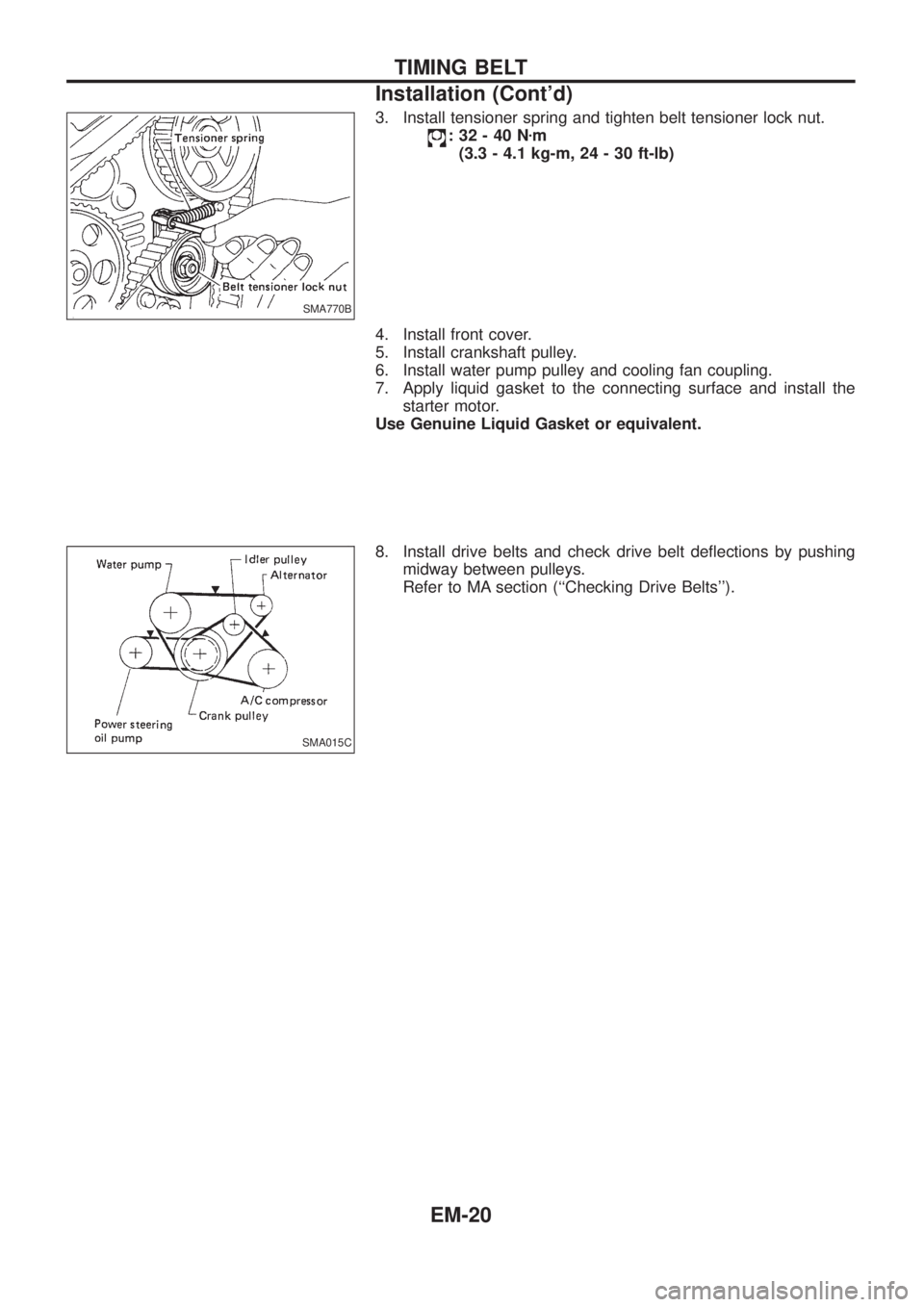

3. Install tensioner spring and tighten belt tensioner lock nut.

:32-40Nzm

(3.3 - 4.1 kg-m, 24 - 30 ft-lb)

4. Install front cover.

5. Install crankshaft pulley.

6. Install water pump pulley and cooling fan coupling.

7. Apply liquid gasket to the connecting surface and install the

starter motor.

Use Genuine Liquid Gasket or equivalent.

8. Install drive belts and check drive belt de¯ections by pushing

midway between pulleys.

Refer to MA section (``Checking Drive Belts'').

SMA770B

SMA015C

TIMING BELT

Installation (Cont'd)

EM-20

Page 698 of 1226

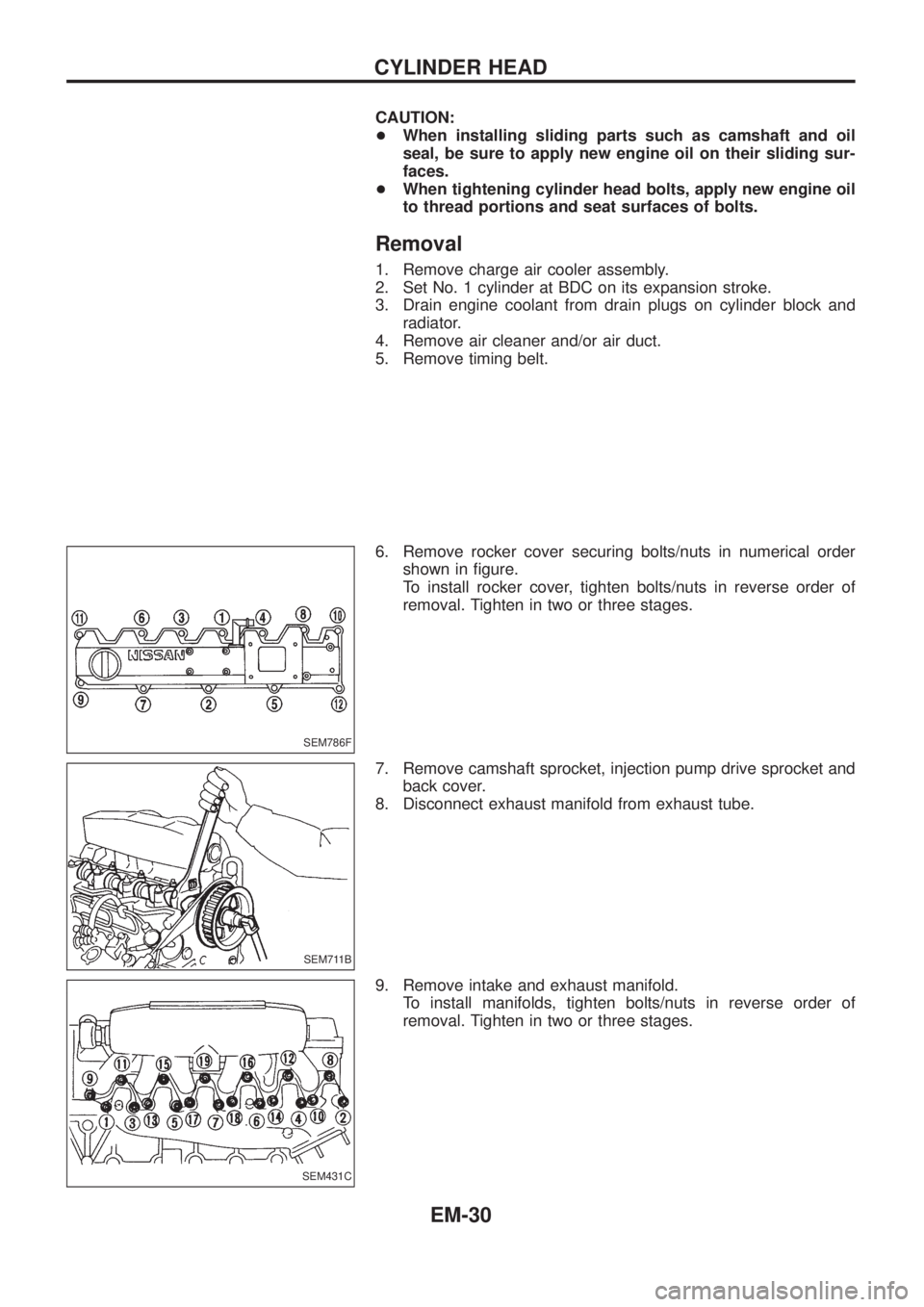

CAUTION:

+When installing sliding parts such as camshaft and oil

seal, be sure to apply new engine oil on their sliding sur-

faces.

+When tightening cylinder head bolts, apply new engine oil

to thread portions and seat surfaces of bolts.

Removal

1. Remove charge air cooler assembly.

2. Set No. 1 cylinder at BDC on its expansion stroke.

3. Drain engine coolant from drain plugs on cylinder block and

radiator.

4. Remove air cleaner and/or air duct.

5. Remove timing belt.

6. Remove rocker cover securing bolts/nuts in numerical order

shown in ®gure.

To install rocker cover, tighten bolts/nuts in reverse order of

removal. Tighten in two or three stages.

7. Remove camshaft sprocket, injection pump drive sprocket and

back cover.

8. Disconnect exhaust manifold from exhaust tube.

9. Remove intake and exhaust manifold.

To install manifolds, tighten bolts/nuts in reverse order of

removal. Tighten in two or three stages.

SEM786F

SEM711B

SEM431C

CYLINDER HEAD

EM-30

Page 710 of 1226

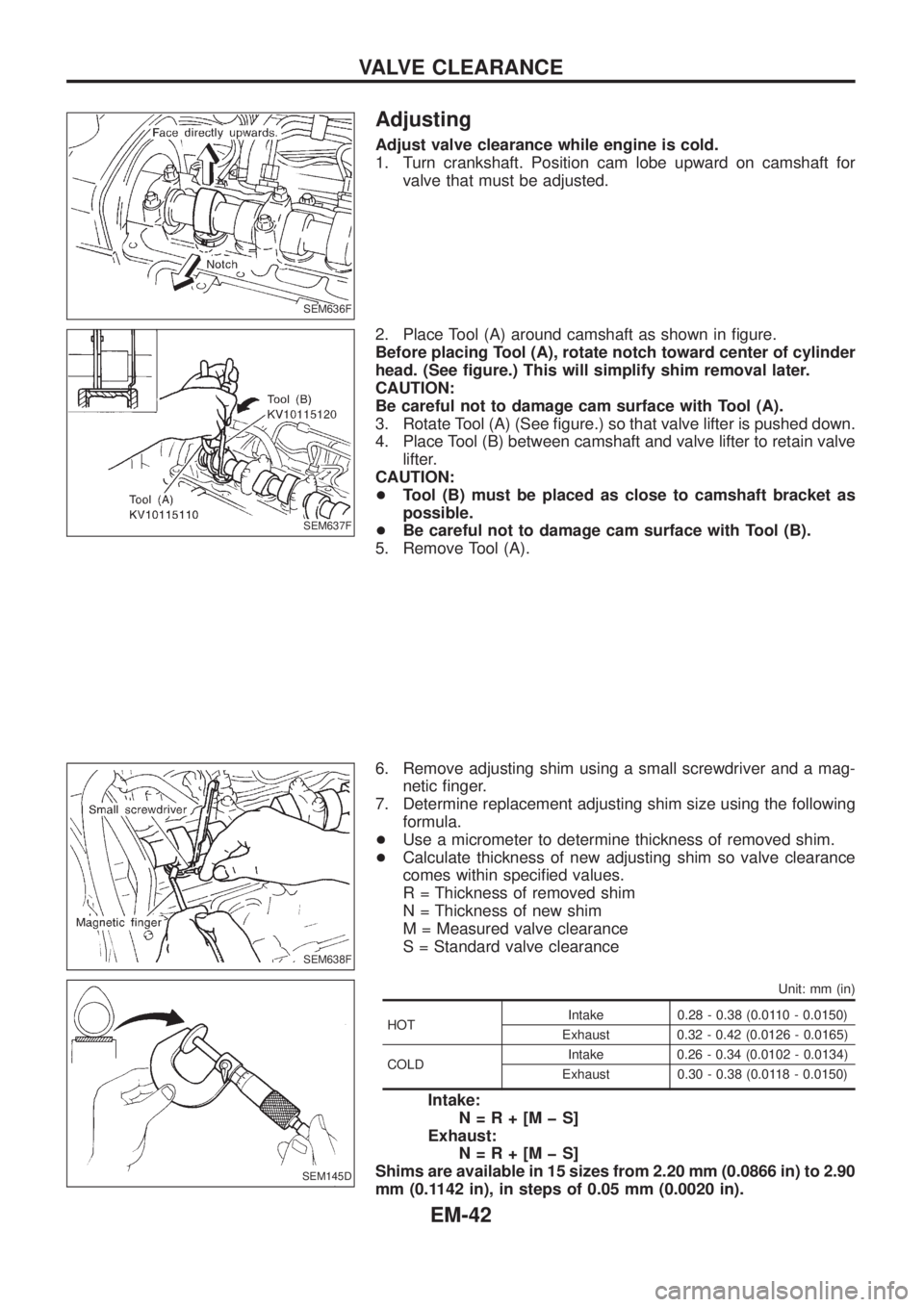

Adjusting

Adjust valve clearance while engine is cold.

1. Turn crankshaft. Position cam lobe upward on camshaft for

valve that must be adjusted.

2. Place Tool (A) around camshaft as shown in ®gure.

Before placing Tool (A), rotate notch toward center of cylinder

head. (See ®gure.) This will simplify shim removal later.

CAUTION:

Be careful not to damage cam surface with Tool (A).

3. Rotate Tool (A) (See ®gure.) so that valve lifter is pushed down.

4. Place Tool (B) between camshaft and valve lifter to retain valve

lifter.

CAUTION:

+Tool (B) must be placed as close to camshaft bracket as

possible.

+Be careful not to damage cam surface with Tool (B).

5. Remove Tool (A).

6. Remove adjusting shim using a small screwdriver and a mag-

netic ®nger.

7. Determine replacement adjusting shim size using the following

formula.

+Use a micrometer to determine thickness of removed shim.

+Calculate thickness of new adjusting shim so valve clearance

comes within speci®ed values.

R = Thickness of removed shim

N = Thickness of new shim

M = Measured valve clearance

S = Standard valve clearance

Unit: mm (in)

HOTIntake 0.28 - 0.38 (0.0110 - 0.0150)

Exhaust 0.32 - 0.42 (0.0126 - 0.0165)

COLDIntake 0.26 - 0.34 (0.0102 - 0.0134)

Exhaust 0.30 - 0.38 (0.0118 - 0.0150)

Intake:

N=R+[MþS]

Exhaust:

N=R+[MþS]

Shims are available in 15 sizes from 2.20 mm (0.0866 in) to 2.90

mm (0.1142 in), in steps of 0.05 mm (0.0020 in).

SEM636F

SEM637F

SEM638F

SEM145D

VALVE CLEARANCE

EM-42

Page 715 of 1226

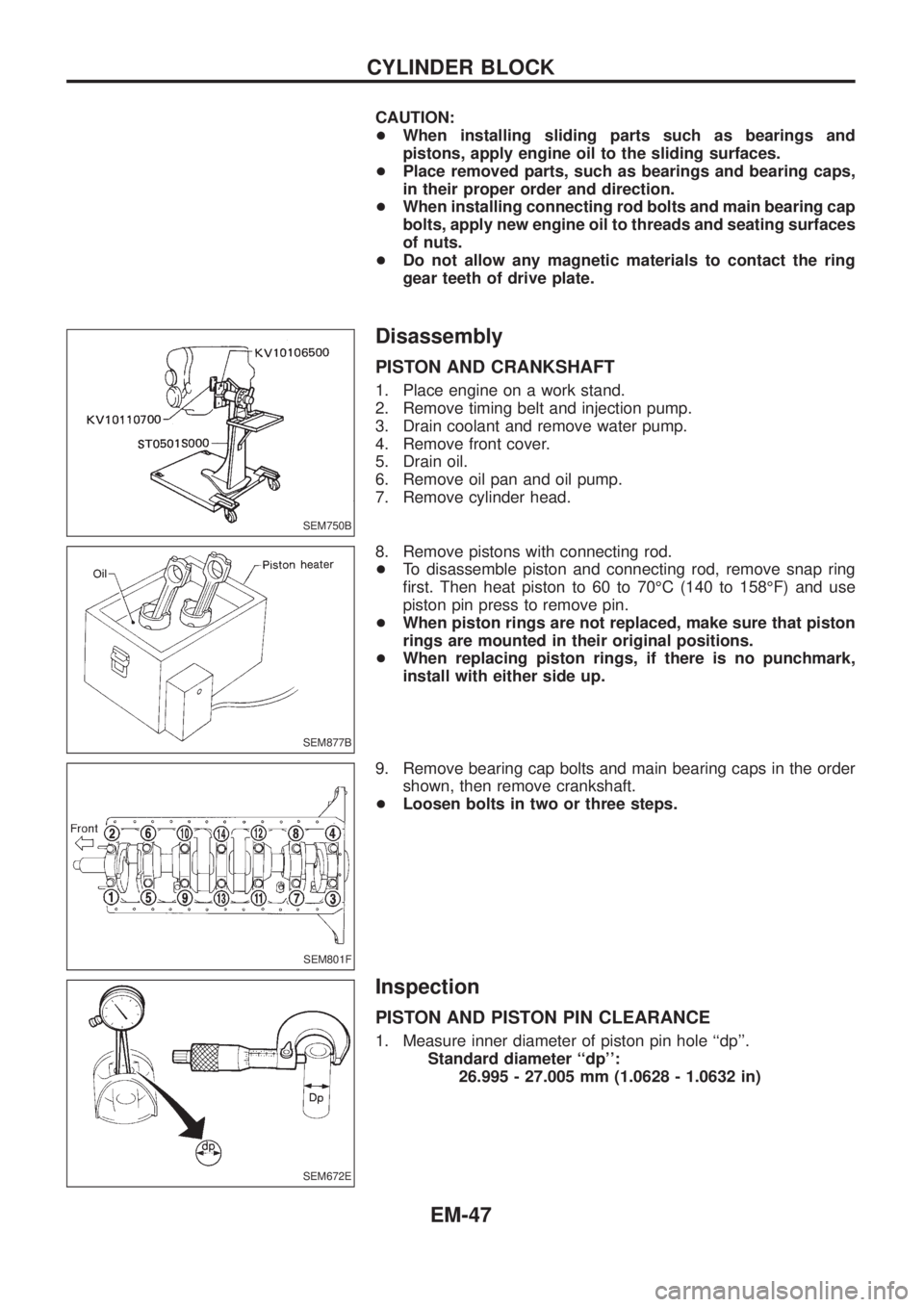

CAUTION:

+When installing sliding parts such as bearings and

pistons, apply engine oil to the sliding surfaces.

+Place removed parts, such as bearings and bearing caps,

in their proper order and direction.

+When installing connecting rod bolts and main bearing cap

bolts, apply new engine oil to threads and seating surfaces

of nuts.

+Do not allow any magnetic materials to contact the ring

gear teeth of drive plate.

Disassembly

PISTON AND CRANKSHAFT

1. Place engine on a work stand.

2. Remove timing belt and injection pump.

3. Drain coolant and remove water pump.

4. Remove front cover.

5. Drain oil.

6. Remove oil pan and oil pump.

7. Remove cylinder head.

8. Remove pistons with connecting rod.

+To disassemble piston and connecting rod, remove snap ring

®rst. Then heat piston to 60 to 70ÉC (140 to 158ÉF) and use

piston pin press to remove pin.

+When piston rings are not replaced, make sure that piston

rings are mounted in their original positions.

+When replacing piston rings, if there is no punchmark,

install with either side up.

9. Remove bearing cap bolts and main bearing caps in the order

shown, then remove crankshaft.

+Loosen bolts in two or three steps.

Inspection

PISTON AND PISTON PIN CLEARANCE

1. Measure inner diameter of piston pin hole ``dp''.

Standard diameter ``dp'':

26.995 - 27.005 mm (1.0628 - 1.0632 in)

SEM750B

SEM877B

SEM801F

SEM672E

CYLINDER BLOCK

EM-47

Page 721 of 1226

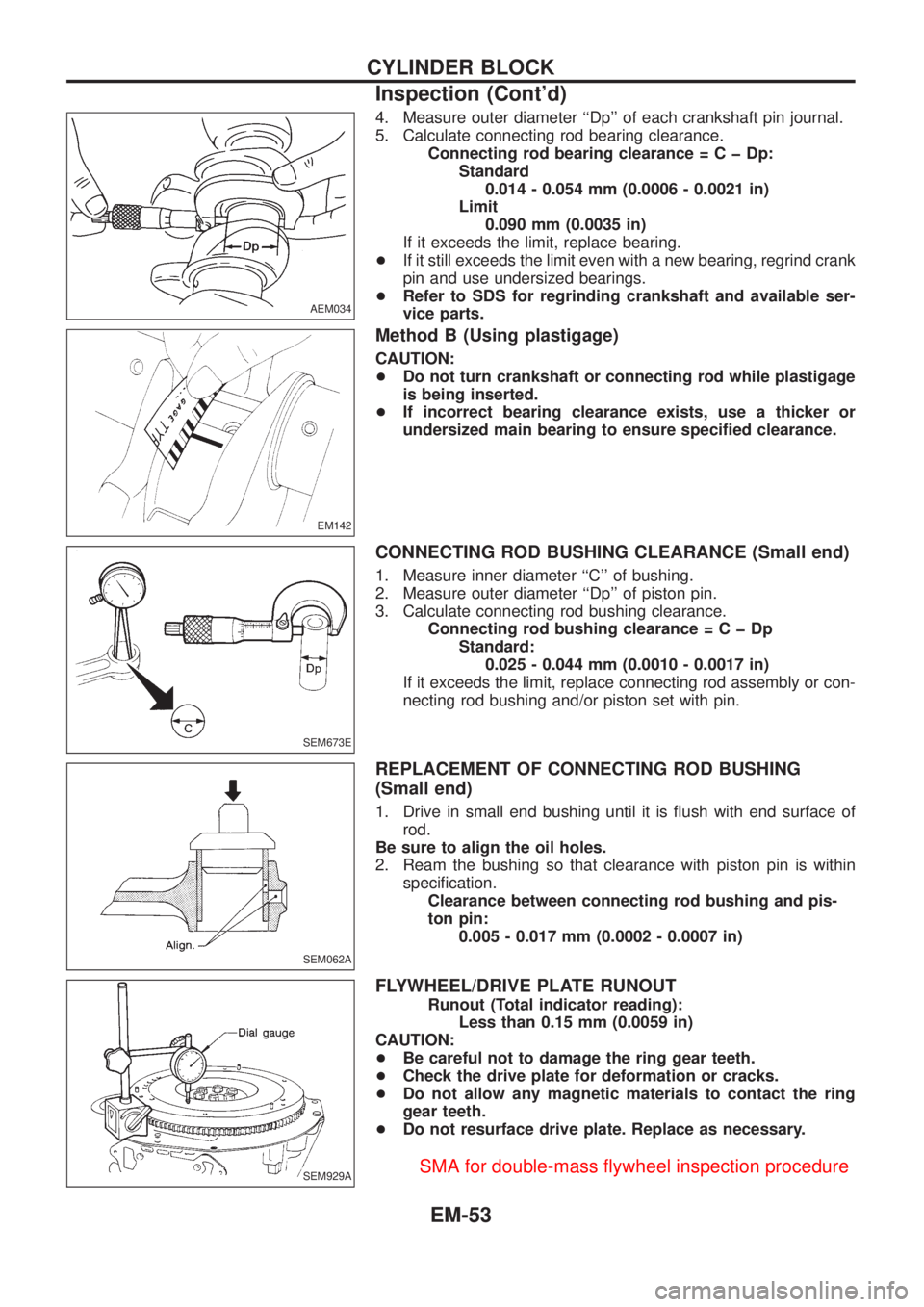

4. Measure outer diameter ``Dp'' of each crankshaft pin journal.

5. Calculate connecting rod bearing clearance.

Connecting rod bearing clearance=CþDp:

Standard

0.014 - 0.054 mm (0.0006 - 0.0021 in)

Limit

0.090 mm (0.0035 in)

If it exceeds the limit, replace bearing.

+If it still exceeds the limit even with a new bearing, regrind crank

pin and use undersized bearings.

+Refer to SDS for regrinding crankshaft and available ser-

vice parts.

Method B (Using plastigage)

CAUTION:

+Do not turn crankshaft or connecting rod while plastigage

is being inserted.

+If incorrect bearing clearance exists, use a thicker or

undersized main bearing to ensure speci®ed clearance.

CONNECTING ROD BUSHING CLEARANCE (Small end)

1. Measure inner diameter ``C'' of bushing.

2. Measure outer diameter ``Dp'' of piston pin.

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance=CþDp

Standard:

0.025 - 0.044 mm (0.0010 - 0.0017 in)

If it exceeds the limit, replace connecting rod assembly or con-

necting rod bushing and/or piston set with pin.

REPLACEMENT OF CONNECTING ROD BUSHING

(Small end)

1. Drive in small end bushing until it is ¯ush with end surface of

rod.

Be sure to align the oil holes.

2. Ream the bushing so that clearance with piston pin is within

speci®cation.

Clearance between connecting rod bushing and pis-

ton pin:

0.005 - 0.017 mm (0.0002 - 0.0007 in)

FLYWHEEL/DRIVE PLATE RUNOUT

Runout (Total indicator reading):

Less than 0.15 mm (0.0059 in)

CAUTION:

+Be careful not to damage the ring gear teeth.

+Check the drive plate for deformation or cracks.

+Do not allow any magnetic materials to contact the ring

gear teeth.

+Do not resurface drive plate. Replace as necessary.

AEM034

EM142

SEM673E

SEM062A

SEM929A

CYLINDER BLOCK

Inspection (Cont'd)

EM-53