parking NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 3 of 1226

BRAKE SYSTEM

SECTION

BR

CONTENTS

PRECAUTIONS AND PREPARATION ............................1

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''...............1

Precautions for Brake System .....................................1

Commercial Service Tools ...........................................1

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .....................................................2

NVH Troubleshooting Chart.........................................2

CHECK AND ADJUSTMENT ..........................................3

Checking Brake Fluid Level.........................................3

Checking Brake Line ...................................................3

Changing Brake Fluid ..................................................3

Bleeding Brake System ...............................................4

BRAKE HYDRAULIC LINE/CONTROL VALVE ..............5

Brake Hydraulic Line ...................................................5

Load Sensing Valve .....................................................6

BRAKE PEDAL AND BRACKET ..................................10

Removal and Installation ...........................................10

Inspection...................................................................10

Adjustment .................................................................10

MASTER CYLINDER .....................................................12

Removal .....................................................................12

Disassembly...............................................................13

Inspection...................................................................13

Assembly ...................................................................13

Installation ..................................................................14

BRAKE BOOSTER ........................................................15

Brake Booster ............................................................15

VACUUM PIPING (LHD models) ..................................17

Vacuum Hose ............................................................17

VACUUM PIPING (RHD models) .................................18

Vacuum Hose ............................................................18

VACUUM PIPING ...........................................................19

VACUUM PUMP ............................................................20

Removal and Installation ...........................................20

FRONT DISC BRAKE ...................................................21

Pad Replacement ......................................................21

Removal .....................................................................23

Disassembly...............................................................23 Inspection Ð Caliper .................................................23

Inspection Ð Rotor ....................................................24

Assembly ...................................................................24

Installation ..................................................................24

REAR DISC BRAKE ......................................................25

Pad Replacement ......................................................25

Removal .....................................................................27

Disassembly...............................................................27

Inspection Ð Caliper .................................................27

Inspection Ð Rotor ....................................................28

Assembly ...................................................................28

Installation ..................................................................28

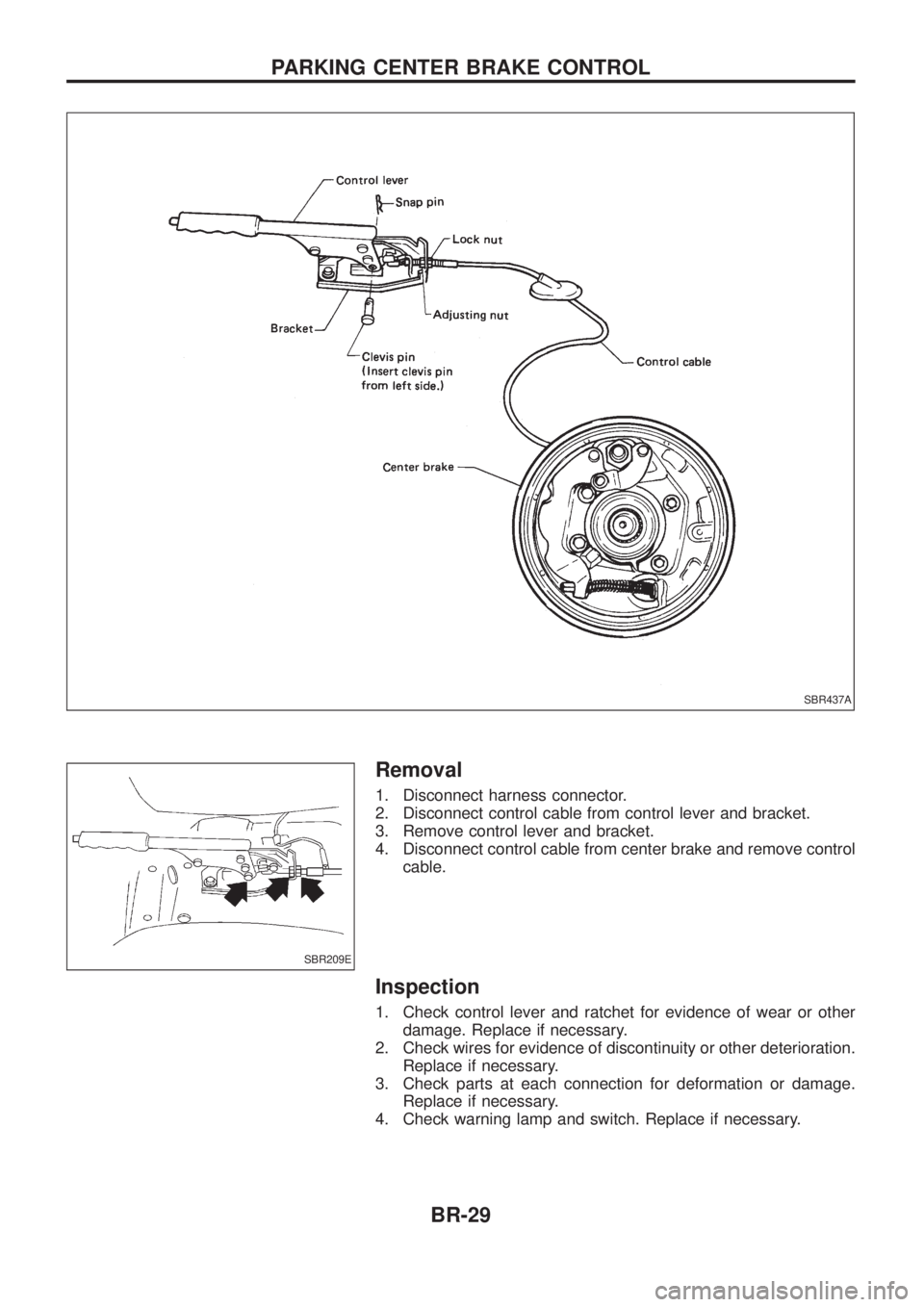

PARKING CENTER BRAKE CONTROL ......................29

Removal .....................................................................29

Inspection...................................................................29

Installation ..................................................................30

Adjustment .................................................................30

PARKING CENTER BRAKE .........................................31

Removal and Installation ...........................................31

Inspection Ð Drum ....................................................32

Inspection Ð Lining ...................................................32

ANTI-LOCK BRAKE SYSTEM ......................................33

Purpose......................................................................33

Operation ...................................................................33

ABS Hydraulic Circuit ................................................33

System Components .................................................34

System Description ....................................................34

Removal and Installation ...........................................36

TROUBLE DIAGNOSES ...............................................39

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................39

Preliminary Check......................................................40

Component Parts and Harness Connector

Location .....................................................................41

Circuit Diagram for Quick Pinpoint Check.................42

Wiring Diagram Ð ABS Ð ........................................43

Self-diagnosis ............................................................47

CONSULT ..................................................................50

CONSULT Inspection Procedure...............................51

BR

Page 7 of 1226

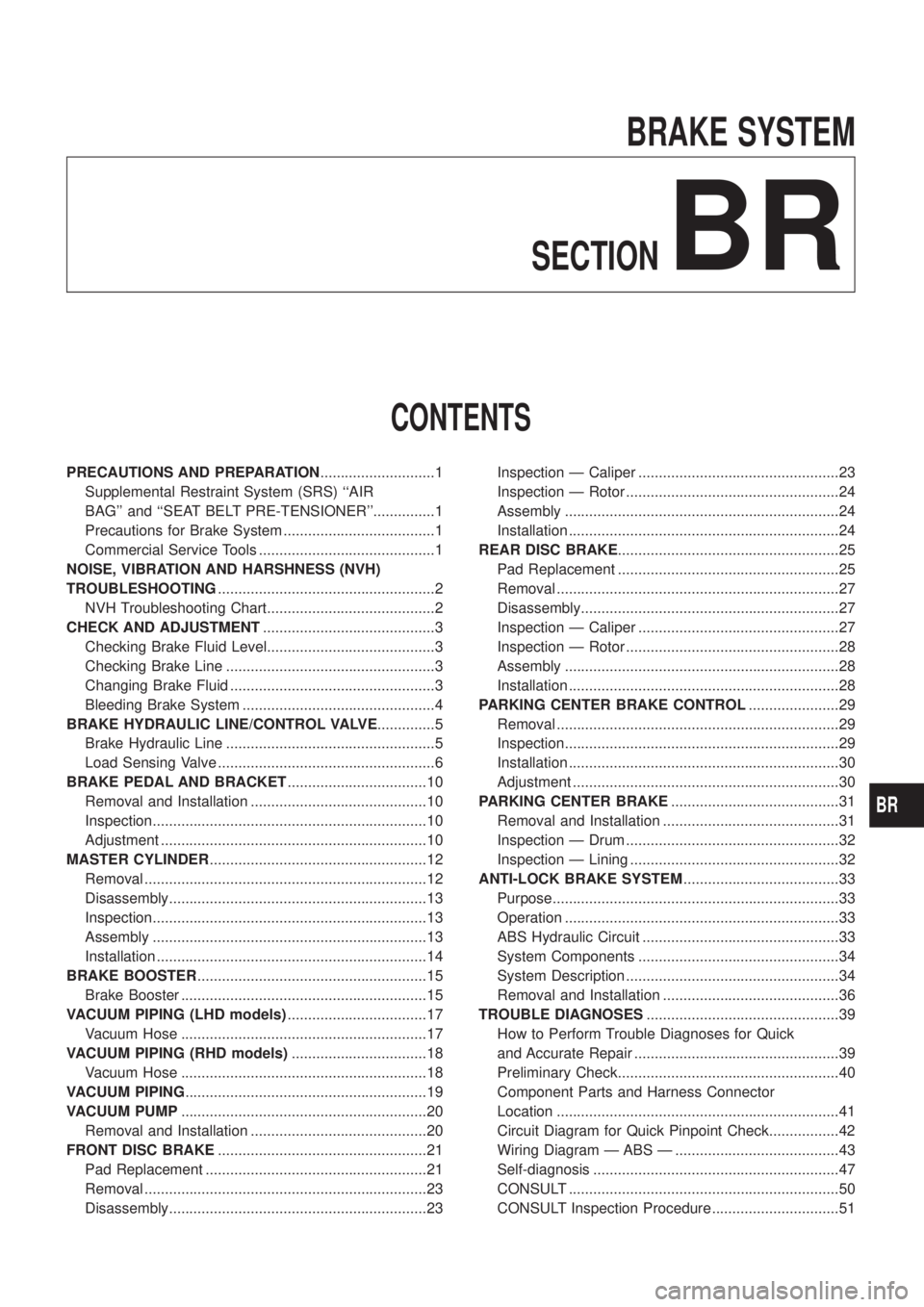

Checking Brake Fluid Level

+Check ¯uid level in reservoir tank. It should be between Max

and Min lines on reservoir tank.

+ If ¯uid level is extremely low, check brake system for leaks.

+ If the brake warning lamp comes on, check brake ¯uid level

switch and parking brake switch.

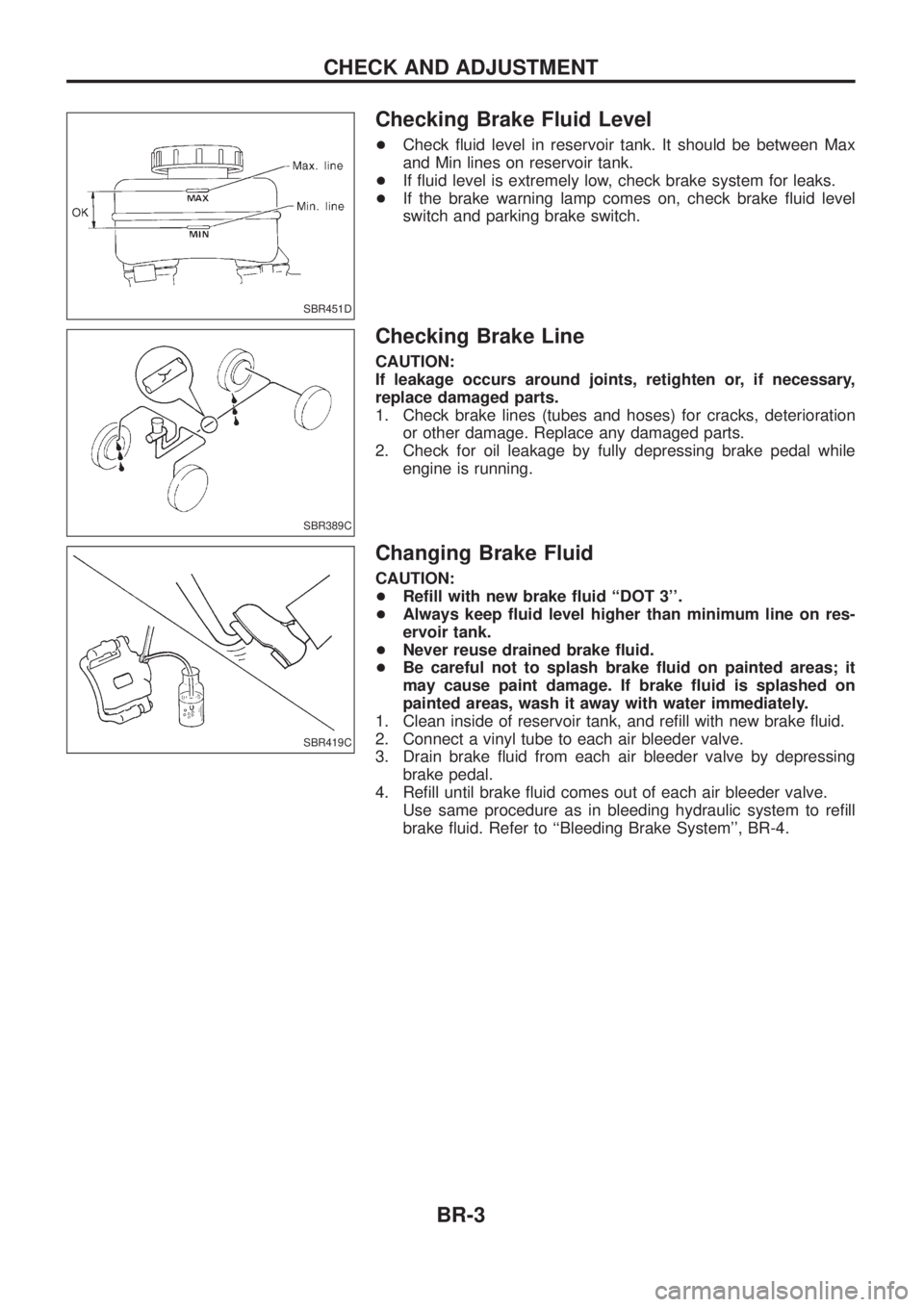

Checking Brake Line

CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

1. Check brake lines (tubes and hoses) for cracks, deterioration

or other damage. Replace any damaged parts.

2. Check for oil leakage by fully depressing brake pedal while engine is running.

Changing Brake Fluid

CAUTION:

+Re®ll with new brake ¯uid ``DOT 3''.

+ Always keep ¯uid level higher than minimum line on res-

ervoir tank.

+ Never reuse drained brake ¯uid.

+ Be careful not to splash brake ¯uid on painted areas; it

may cause paint damage. If brake ¯uid is splashed on

painted areas, wash it away with water immediately.

1. Clean inside of reservoir tank, and re®ll with new brake ¯uid.

2. Connect a vinyl tube to each air bleeder valve.

3. Drain brake ¯uid from each air bleeder valve by depressing brake pedal.

4. Re®ll until brake ¯uid comes out of each air bleeder valve. Use same procedure as in bleeding hydraulic system to re®ll

brake ¯uid. Refer to ``Bleeding Brake System'', BR-4.

SBR451D

SBR389C

SBR419C

CHECK AND ADJUSTMENT

BR-3

Page 33 of 1226

Removal

1. Disconnect harness connector.

2. Disconnect control cable from control lever and bracket.

3. Remove control lever and bracket.

4. Disconnect control cable from center brake and remove controlcable.

Inspection

1. Check control lever and ratchet for evidence of wear or otherdamage. Replace if necessary.

2. Check wires for evidence of discontinuity or other deterioration. Replace if necessary.

3. Check parts at each connection for deformation or damage. Replace if necessary.

4. Check warning lamp and switch. Replace if necessary.

SBR437A

SBR209E

PARKING CENTER BRAKE CONTROL

BR-29

Page 34 of 1226

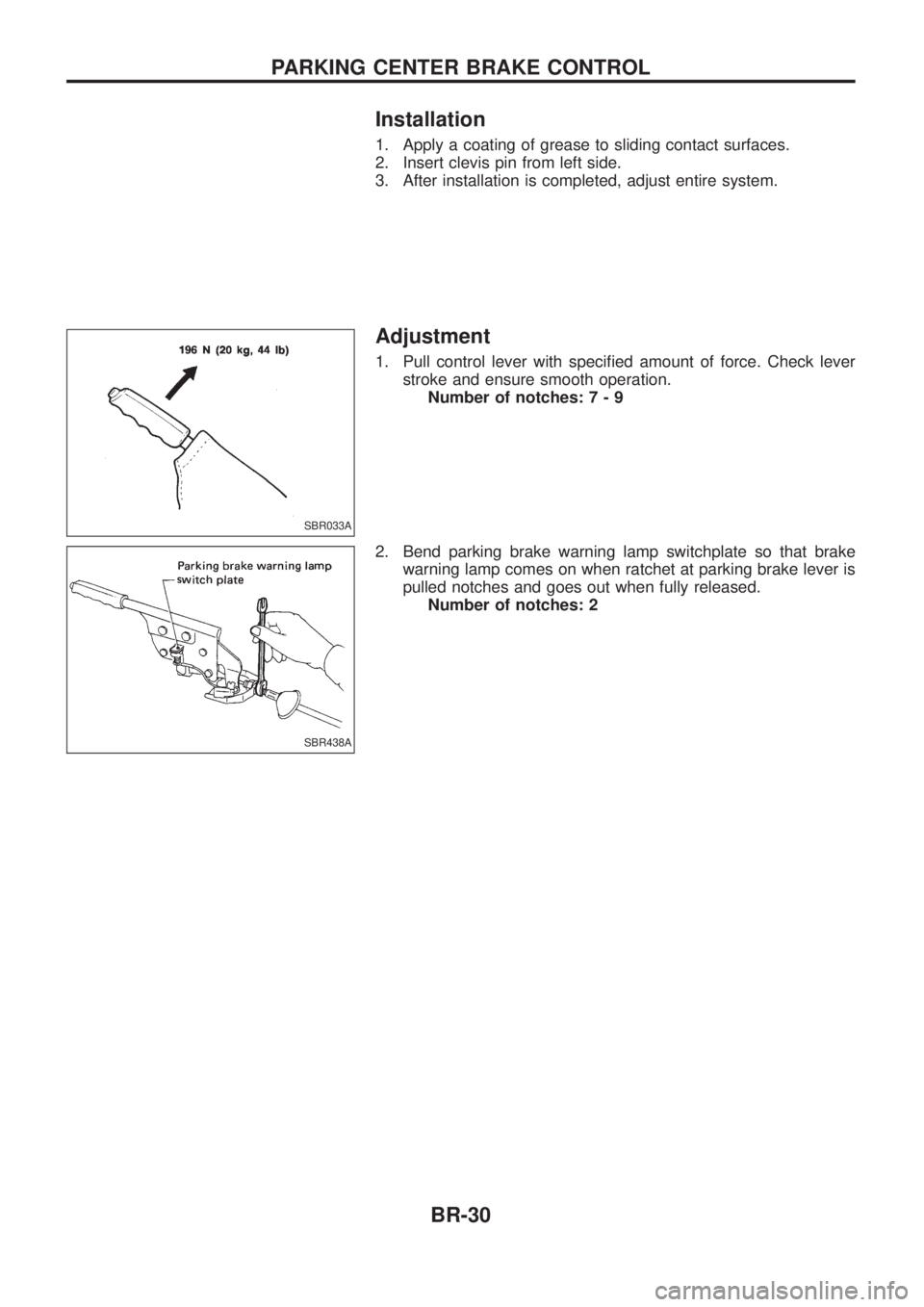

Installation

1. Apply a coating of grease to sliding contact surfaces.

2. Insert clevis pin from left side.

3. After installation is completed, adjust entire system.

Adjustment

1. Pull control lever with speci®ed amount of force. Check leverstroke and ensure smooth operation.Number of notches :7-9

2. Bend parking brake warning lamp switchplate so that brake warning lamp comes on when ratchet at parking brake lever is

pulled notches and goes out when fully released.Number of notches: 2

SBR033A

SBR438A

PARKING CENTER BRAKE CONTROL

BR-30

Page 35 of 1226

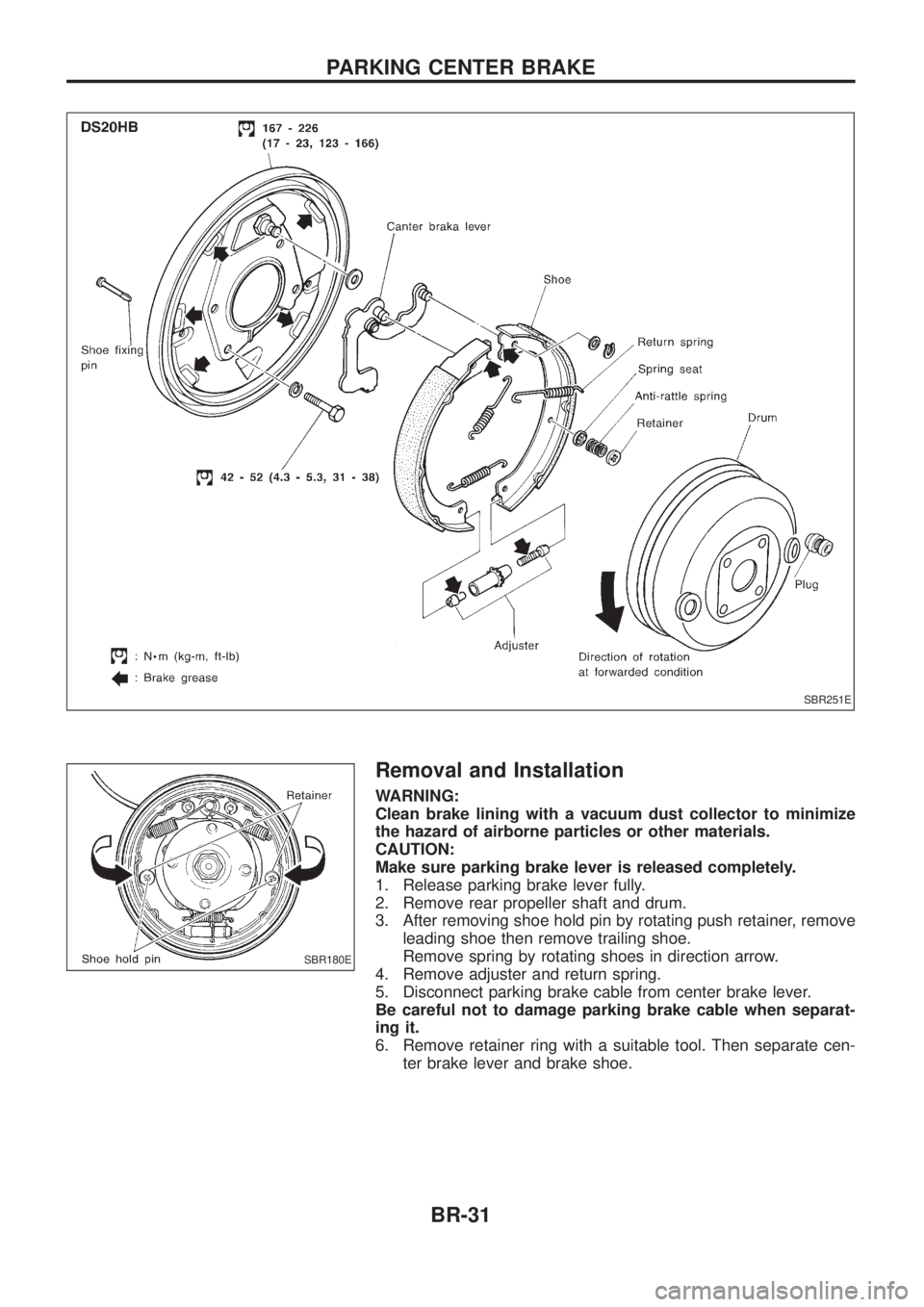

Removal and Installation

WARNING:

Clean brake lining with a vacuum dust collector to minimize

the hazard of airborne particles or other materials.

CAUTION:

Make sure parking brake lever is released completely.

1. Release parking brake lever fully.

2. Remove rear propeller shaft and drum.

3. After removing shoe hold pin by rotating push retainer, removeleading shoe then remove trailing shoe.

Remove spring by rotating shoes in direction arrow.

4. Remove adjuster and return spring.

5. Disconnect parking brake cable from center brake lever.

Be careful not to damage parking brake cable when separat-

ing it.

6. Remove retainer ring with a suitable tool. Then separate cen- ter brake lever and brake shoe.

SBR251E

SBR180E

PARKING CENTER BRAKE

BR-31

Page 36 of 1226

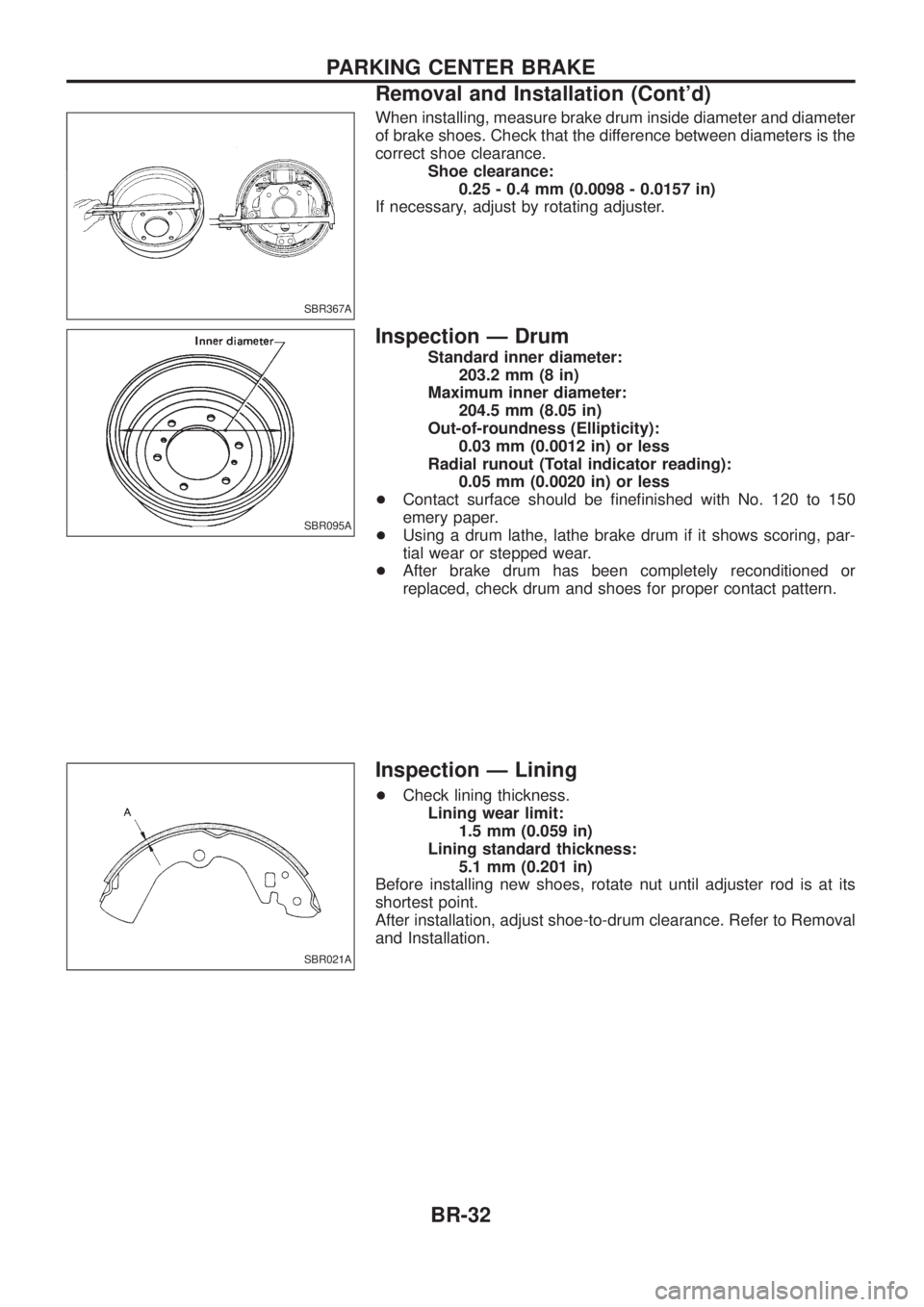

When installing, measure brake drum inside diameter and diameter

of brake shoes. Check that the difference between diameters is the

correct shoe clearance.Shoe clearance:0.25 - 0.4 mm (0.0098 - 0.0157 in)

If necessary, adjust by rotating adjuster.

Inspection Ð Drum

Standard inner diameter: 203.2 mm (8 in)

Maximum inner diameter: 204.5 mm (8.05 in)

Out-of-roundness (Ellipticity): 0.03 mm (0.0012 in) or less

Radial runout (Total indicator reading): 0.05 mm (0.0020 in) or less

+ Contact surface should be ®ne®nished with No. 120 to 150

emery paper.

+ Using a drum lathe, lathe brake drum if it shows scoring, par-

tial wear or stepped wear.

+ After brake drum has been completely reconditioned or

replaced, check drum and shoes for proper contact pattern.

Inspection Ð Lining

+Check lining thickness.

Lining wear limit: 1.5 mm (0.059 in)

Lining standard thickness: 5.1 mm (0.201 in)

Before installing new shoes, rotate nut until adjuster rod is at its

shortest point.

After installation, adjust shoe-to-drum clearance. Refer to Removal

and Installation.

SBR367A

SBR095A

SBR021A

PARKING CENTER BRAKE

Removal and Installation (Cont'd)

BR-32

Page 77 of 1226

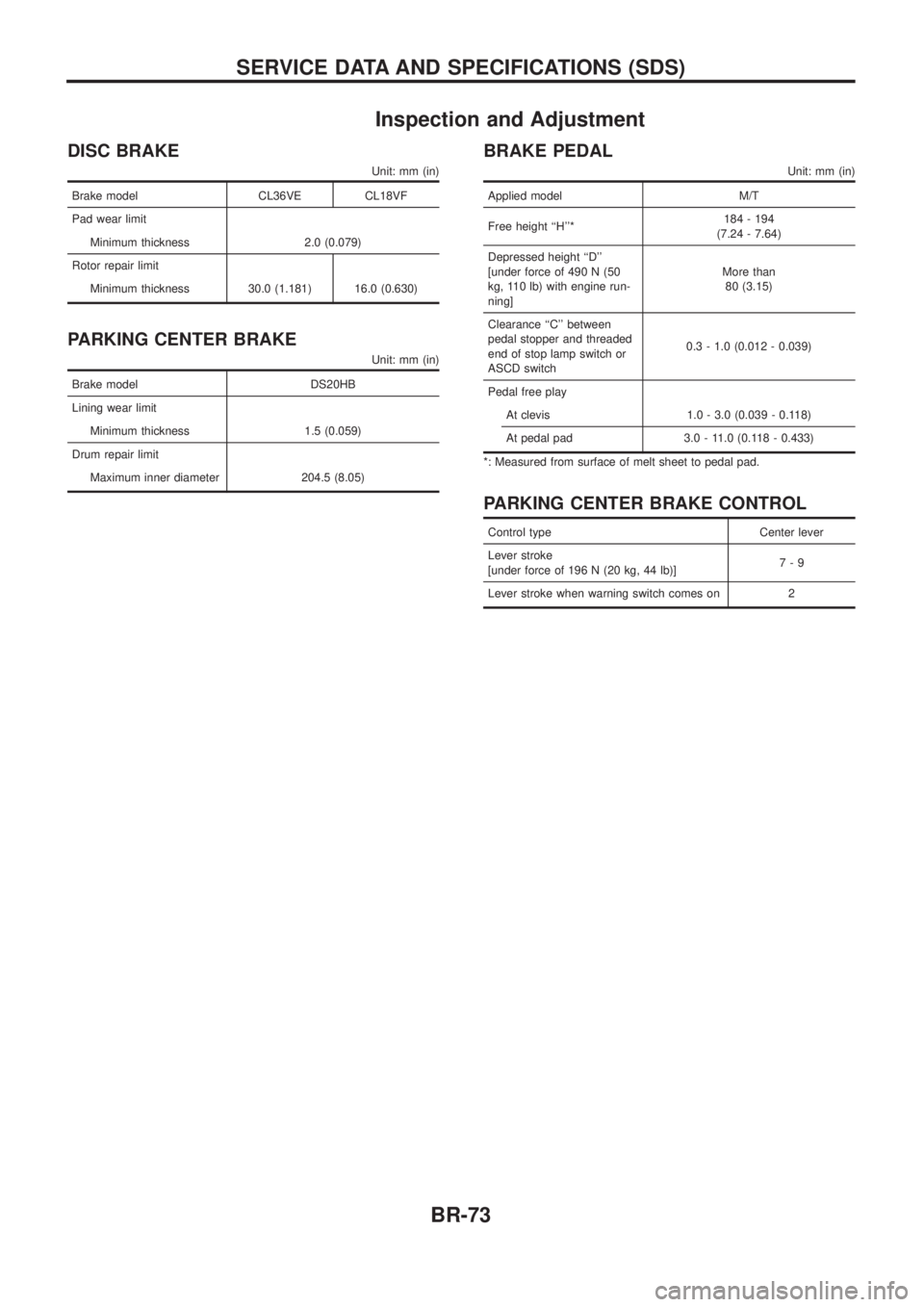

Inspection and Adjustment

DISC BRAKE

Unit: mm (in)

Brake model CL36VE CL18VF

Pad wear limit

Minimum thickness 2.0 (0.079)

Rotor repair limit

Minimum thickness 30.0 (1.181) 16.0 (0.630)

PARKING CENTER BRAKE

Unit: mm (in)

Brake model DS20HB

Lining wear limit

Minimum thickness 1.5 (0.059)

Drum repair limit

Maximum inner diameter 204.5 (8.05)

BRAKE PEDAL

Unit: mm (in)

Applied model M/T

Free height ``H''*184 - 194

(7.24 - 7.64)

Depressed height ``D''

[under force of 490 N (50

kg, 110 lb) with engine run-

ning]More than

80 (3.15)

Clearance ``C'' between

pedal stopper and threaded

end of stop lamp switch or

ASCD switch0.3 - 1.0 (0.012 - 0.039)

Pedal free play

At clevis 1.0 - 3.0 (0.039 - 0.118)

At pedal pad 3.0 - 11.0 (0.118 - 0.433)

*: Measured from surface of melt sheet to pedal pad.

PARKING CENTER BRAKE CONTROL

Control type Center lever

Lever stroke

[under force of 196 N (20 kg, 44 lb)]7-9

Lever stroke when warning switch comes on 2

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-73

Page 125 of 1226

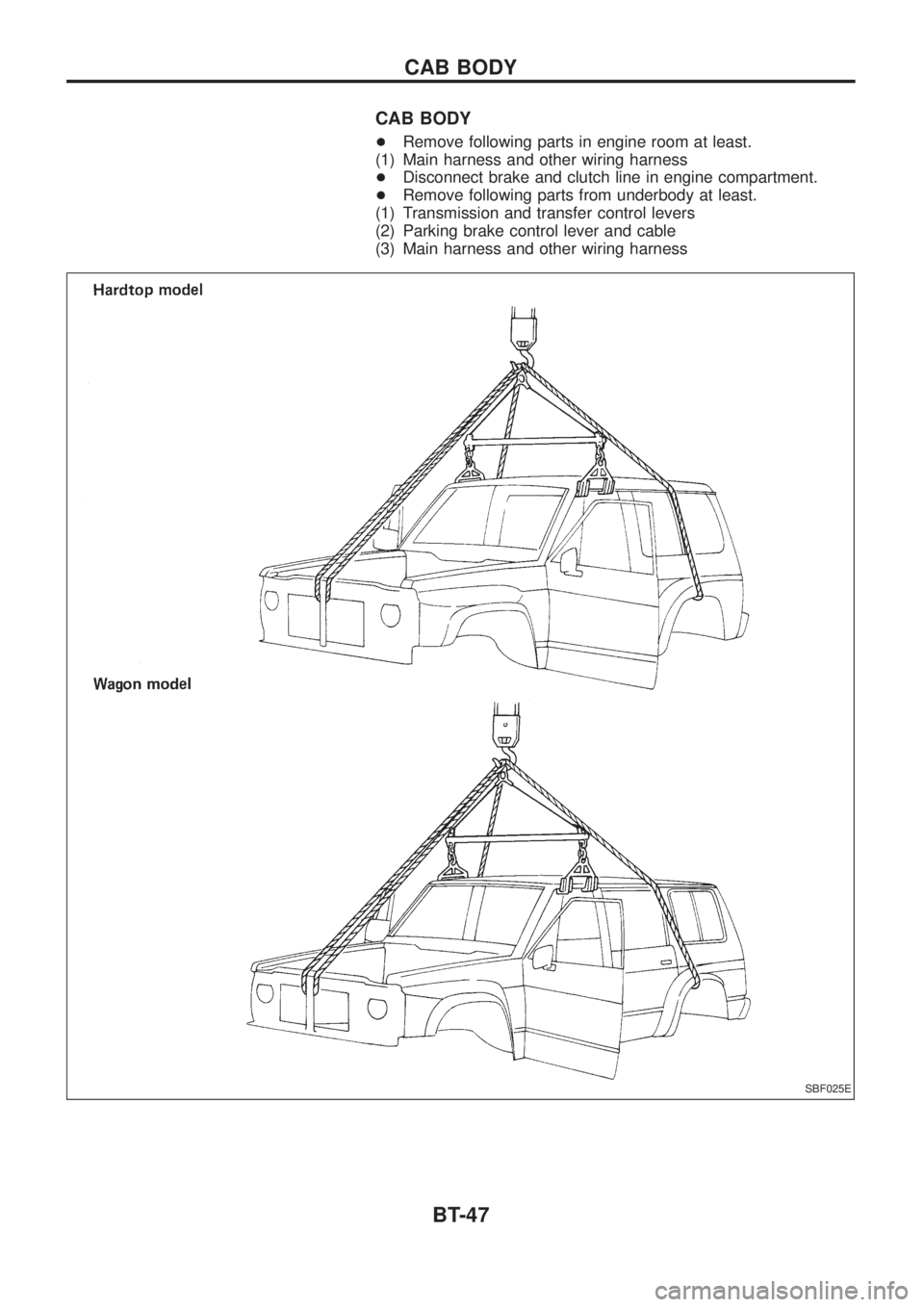

CAB BODY

+Remove following parts in engine room at least.

(1) Main harness and other wiring harness

+Disconnect brake and clutch line in engine compartment.

+Remove following parts from underbody at least.

(1) Transmission and transfer control levers

(2) Parking brake control lever and cable

(3) Main harness and other wiring harness

SBF025E

CAB BODY

BT-47

Page 343 of 1226

Wiring Diagram Ð H/AIM Ð .....................................71

PARKING, LICENSE AND TAIL LAMPS......................73

Wiring Diagram Ð TAIL/L Ð/Type A .........................73

Wiring Diagram Ð TAIL/L Ð/Type B.........................75

STOP LAMP..................................................................77

Wiring Diagram Ð STOP/L Ð/Type A ......................77

BACK-UP LAMP............................................................78

Wiring Diagram Ð BACK/L Ð/LHD Models..............78

Wiring Diagram Ð BACK/L Ð/RHD Models .............79

REAR FOG LAMP.........................................................80

Wiring Diagram Ð R/FOG Ð ....................................80

TURN SIGNAL AND HAZARD WARNING LAMPS.....81

Wiring Diagram Ð TURN Ð/Type A .........................81

Wiring Diagram Ð TURN Ð/Type B .........................83

Trouble Diagnoses.....................................................85

Electrical Components Inspection .............................85

ILLUMINATION..............................................................86

Schematic ..................................................................86

Wiring Diagram Ð ILL Ð ..........................................87

INTERIOR ROOM LAMP Ð With Timer Ð.................93

System Description ....................................................93

Schematic ..................................................................94

Wiring Diagram Ð ROOM/L Ð/LHD Models ............95

Wiring Diagram Ð ROOM/L Ð/RHD Models............98

Trouble Diagnoses...................................................100

MAP AND VANITY MIRROR LAMPS.........................101

Wiring Diagram Ð INT/L Ð.....................................101

METER AND GAUGES...............................................102

System Description ..................................................102

Combination Meter ..................................................103

Wiring Diagram Ð METER Ð/LHD Models............104

Wiring Diagram Ð METER Ð/RHD Models ...........106

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ........................108

Flexible Print Circuit (FPC) ......................................109

Trouble Diagnoses................................................... 110

Electrical Components Inspection ........................... 114

COMPASS AND THERMOMETER............................. 116

System Description .................................................. 116

Wiring Diagram Ð COMPAS Ð .............................. 117

Trouble Diagnoses................................................... 118

Calibration Procedure For Compass ....................... 119

WARNING LAMPS......................................................121

Schematic ................................................................121

Wiring Diagram Ð WARN Ð ..................................123

Electrical Components Inspection ...........................134

WARNING CHIME.......................................................135

System Description ..................................................135

Wiring Diagram Ð CHIME Ð/LHD Models.............136

Wiring Diagram Ð CHIME Ð/RHD Models ............137

Trouble Diagnoses...................................................138

Electrical Components Inspection ...........................140FRONT WIPER AND WASHER..................................141

System Description ..................................................141

Wiring Diagram Ð WIPER Ð/With Intermittent

Wiper........................................................................142

Removal and Installation .........................................143

Washer Nozzle Adjustment .....................................144

Washer Tube Layout ...............................................144

REAR WIPER AND WASHER....................................145

System Description ..................................................145

Wiring Diagram Ð WIP/R Ð/LHD Models ..............146

Wiring Diagram Ð WIP/R Ð/RHD Models .............148

Trouble Diagnoses...................................................150

Removal and Installation .........................................151

Washer Nozzle Adjustment .....................................151

Washer Tube Layout ...............................................152

Check Valve .............................................................152

HEADLAMP WIPER AND WASHER..........................153

Wiring Diagram Ð HLC Ð ......................................153

Electrical Components Inspection ...........................154

Removal and Installation .........................................154

Washer Tube Layout ...............................................154

Check Valve .............................................................154

HORN...........................................................................155

Wiring Diagram Ð HORN Ð...................................155

CIGARETTE LIGHTER................................................156

Wiring Diagram Ð CIGAR Ð ..................................156

CLOCK.........................................................................157

Wiring Diagram Ð CLOCK Ð .................................157

REAR WINDOW DEFOGGER.....................................158

System Description ..................................................158

Wiring Diagram Ð DEF Ð/LHD Models .................159

Wiring Diagram Ð DEF Ð/RHD Models ................161

Trouble Diagnoses...................................................163

Electrical Components Inspection ...........................164

Filament Check ........................................................164

Filament Repair .......................................................165

WIPER DEICER...........................................................166

System Description ..................................................166

Wiring Diagram Ð DEICER Ð................................167

AUDIO..........................................................................168

Wiring Diagram Ð AUDIO Ð/LHD Models .............168

Wiring Diagram Ð AUDIO Ð/RHD Models ............170

Trouble Diagnoses...................................................172

CATS (Code) System/RHD .....................................173

NATS Audio Link/LHD .............................................174

AUDIO Ð CD AUTO CHANGER Ð...........................176

Wiring Diagram Ð CD/CHG Ð/LHD Wagon ..........176

Wiring Diagram Ð CD/CHG Ð/LHD Hardtop .........177

Wiring Diagram Ð CD/CHG Ð/RHD Wagon ..........178

Wiring Diagram Ð CD/CHG Ð/RHD Hardtop ........179

Trouble Diagnoses...................................................180

AUDIO ANTENNA.......................................................181

Page 410 of 1226

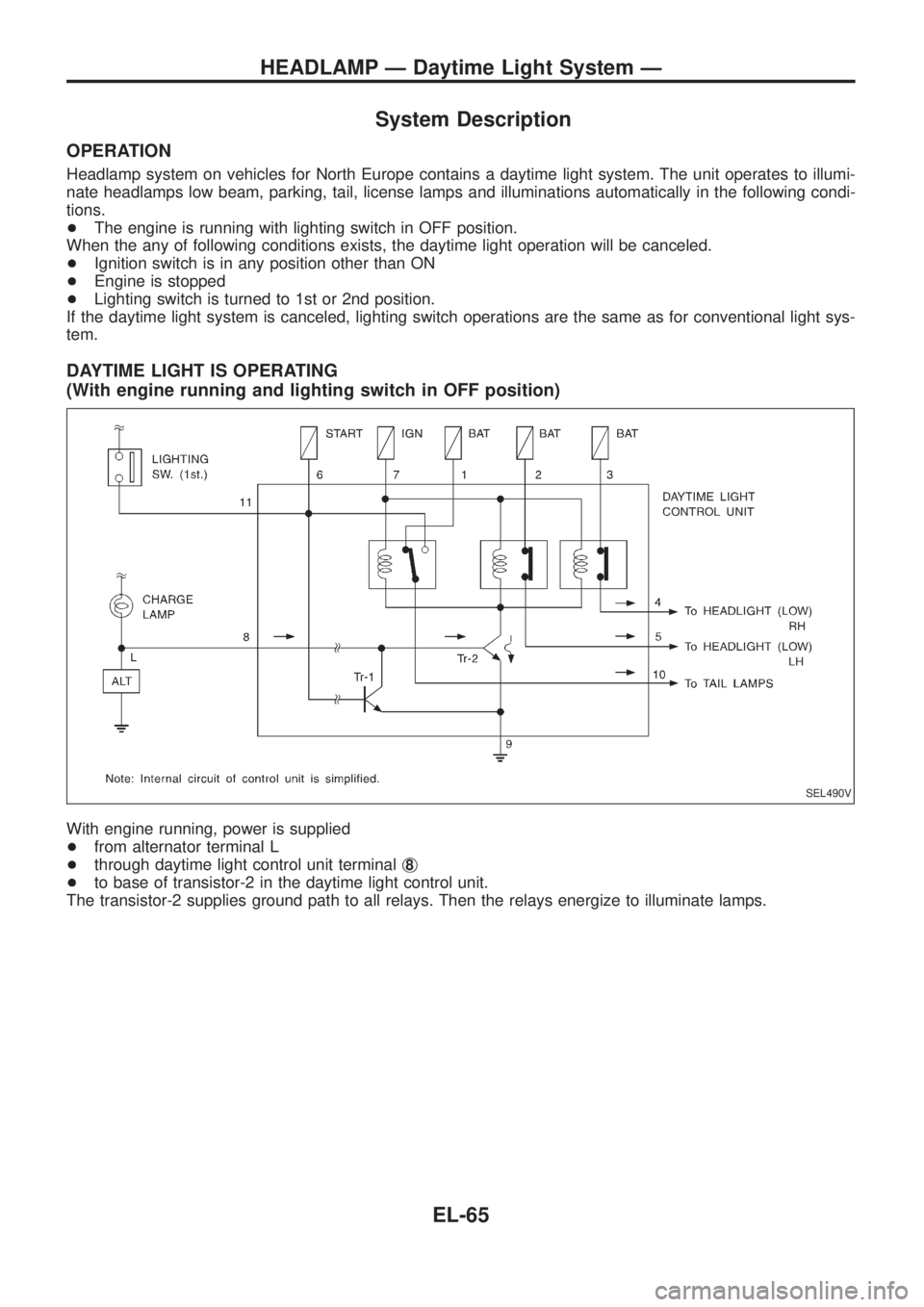

System Description

OPERATION

Headlamp system on vehicles for North Europe contains a daytime light system. The unit operates to illumi-

nate headlamps low beam, parking, tail, license lamps and illuminations automatically in the following condi-

tions.

+The engine is running with lighting switch in OFF position.

When the any of following conditions exists, the daytime light operation will be canceled.

+Ignition switch is in any position other than ON

+Engine is stopped

+Lighting switch is turned to 1st or 2nd position.

If the daytime light system is canceled, lighting switch operations are the same as for conventional light sys-

tem.

DAYTIME LIGHT IS OPERATING

(With engine running and lighting switch in OFF position)

With engine running, power is supplied

+from alternator terminal L

+through daytime light control unit terminalj

8

+to base of transistor-2 in the daytime light control unit.

The transistor-2 supplies ground path to all relays. Then the relays energize to illuminate lamps.

SEL490V

HEADLAMP Ð Daytime Light System Ð

EL-65