checking oil NISSAN PICK-UP 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 896 of 1659

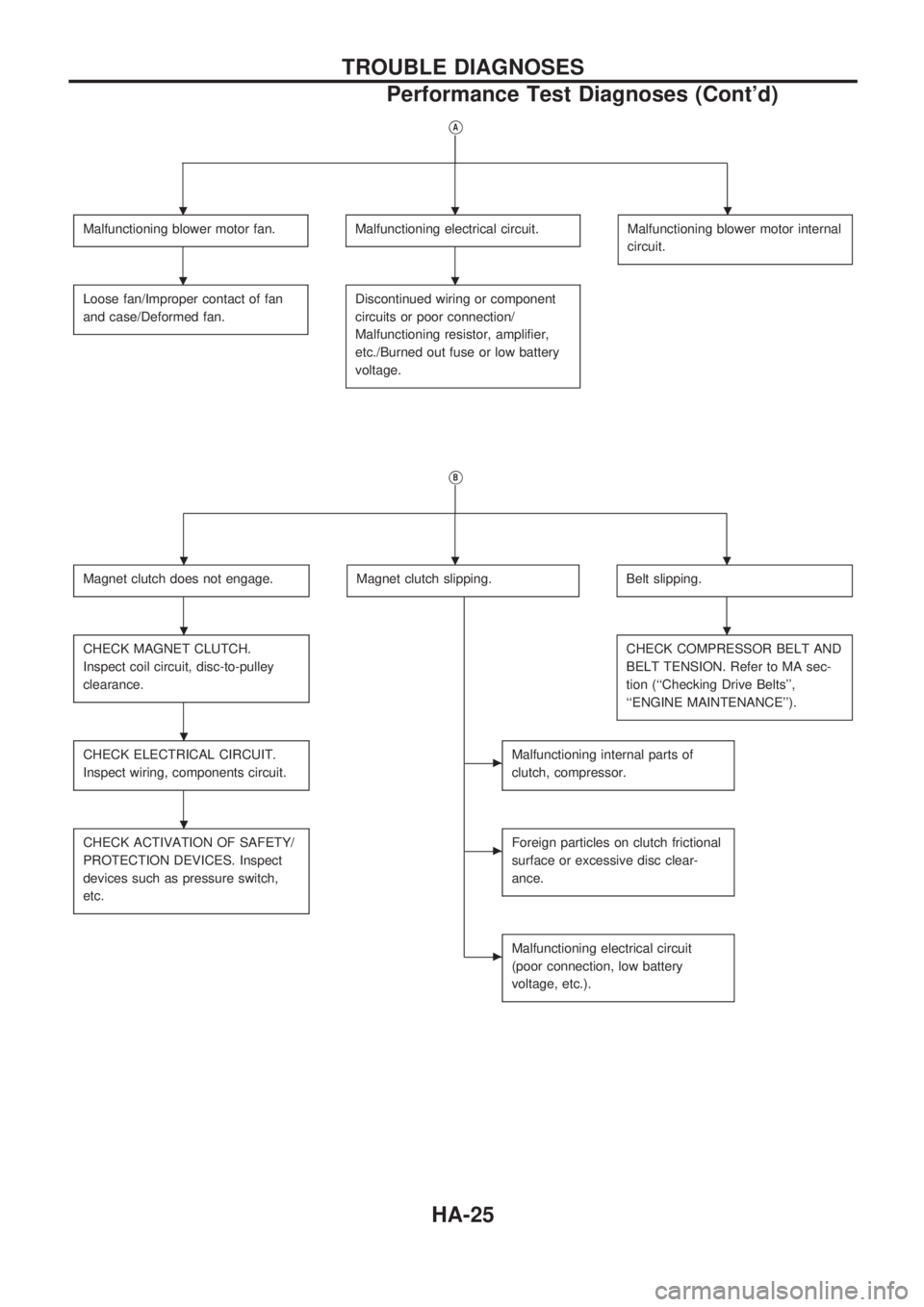

VA

Malfunctioning blower motor fan.Malfunctioning electrical circuit.Malfunctioning blower motor internal

circuit.

Loose fan/Improper contact of fan

and case/Deformed fan.Discontinued wiring or component

circuits or poor connection/

Malfunctioning resistor, amplifier,

etc./Burned out fuse or low battery

voltage.

VB

Magnet clutch does not engage.Magnet clutch slipping.Belt slipping.

CHECK MAGNET CLUTCH.

Inspect coil circuit, disc-to-pulley

clearance.CHECK COMPRESSOR BELT AND

BELT TENSION. Refer to MA sec-

tion (``Checking Drive Belts'',

``ENGINE MAINTENANCE'').

CHECK ELECTRICAL CIRCUIT.

Inspect wiring, components circuit.cMalfunctioning internal parts of

clutch, compressor.

CHECK ACTIVATION OF SAFETY/

PROTECTION DEVICES. Inspect

devices such as pressure switch,

etc.cForeign particles on clutch frictional

surface or excessive disc clear-

ance.

cMalfunctioning electrical circuit

(poor connection, low battery

voltage, etc.).

...

..

...

..

.

.

TROUBLE DIAGNOSES

Performance Test Diagnoses (Cont'd)

HA-25

Page 910 of 1659

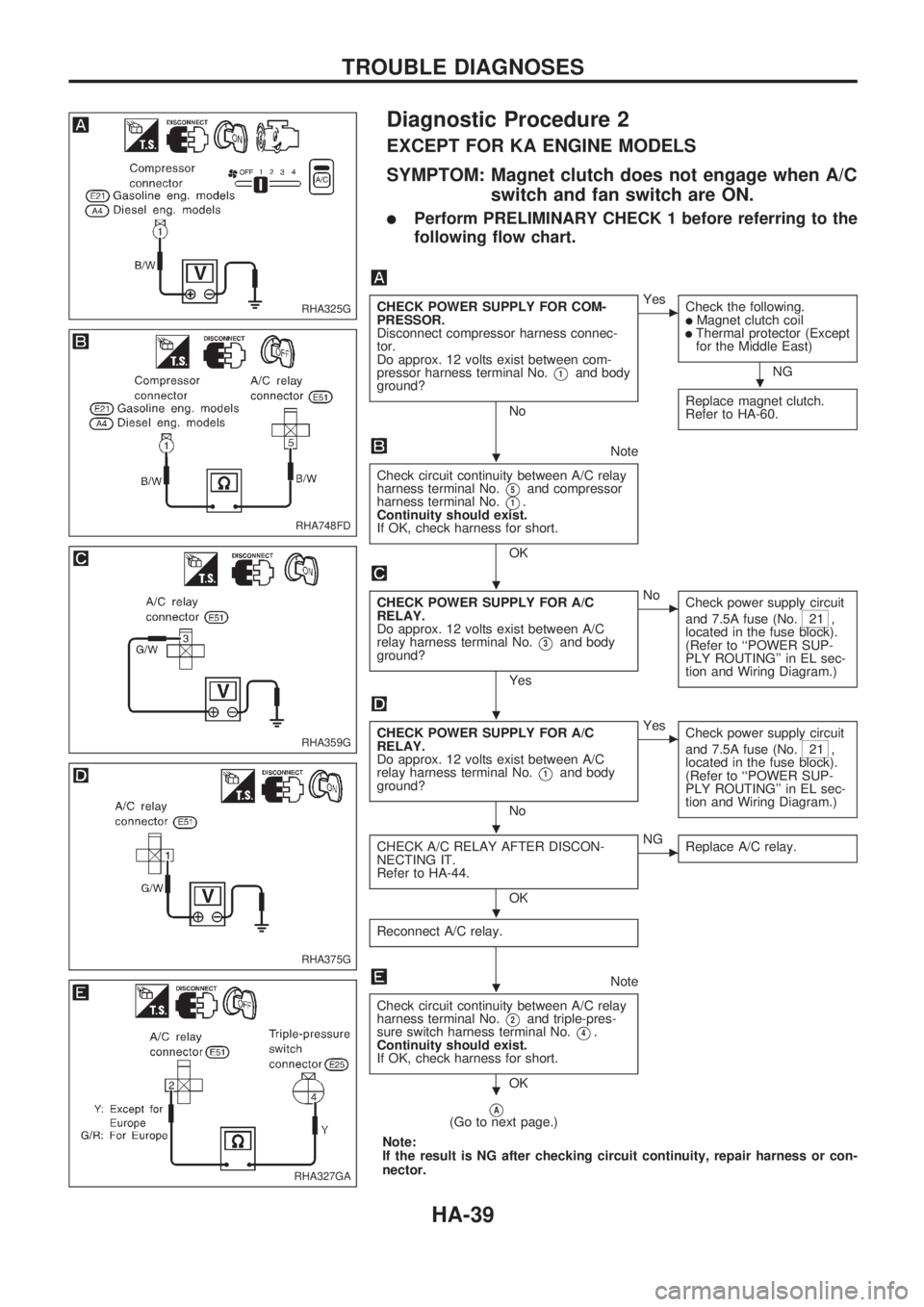

Diagnostic Procedure 2

EXCEPT FOR KA ENGINE MODELS

SYMPTOM: Magnet clutch does not engage when A/C

switch and fan switch are ON.

lPerform PRELIMINARY CHECK 1 before referring to the

following flow chart.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connec-

tor.

Do approx. 12 volts exist between com-

pressor harness terminal No.

V1and body

ground?

No

cYes

Check the following.

lMagnet clutch coillThermal protector (Except

for the Middle East)

NG

Replace magnet clutch.

Refer to HA-60.

Note

Check circuit continuity between A/C relay

harness terminal No.

V5and compressor

harness terminal No.

V1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx. 12 volts exist between A/C

relay harness terminal No.

V3and body

ground?

Yes

cNo

Check power supply circuit

and 7.5A fuse (No.

21 ,

located in the fuse block).

(Refer to ``POWER SUP-

PLY ROUTING'' in EL sec-

tion and Wiring Diagram.)

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx. 12 volts exist between A/C

relay harness terminal No.

V1and body

ground?

No

cYes

Check power supply circuit

and 7.5A fuse (No.

21 ,

located in the fuse block).

(Refer to ``POWER SUP-

PLY ROUTING'' in EL sec-

tion and Wiring Diagram.)

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-44.

OK

cNG

Replace A/C relay.

Reconnect A/C relay.

Note

Check circuit continuity between A/C relay

harness terminal No.

V2and triple-pres-

sure switch harness terminal No.

V4.

Continuity should exist.

If OK, check harness for short.

OK

VA(Go to next page.)

Note:

If the result is NG after checking circuit continuity, repair harness or con-

nector.

RHA325G

RHA748FD

RHA359G

RHA375G

RHA327GA

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

HA-39

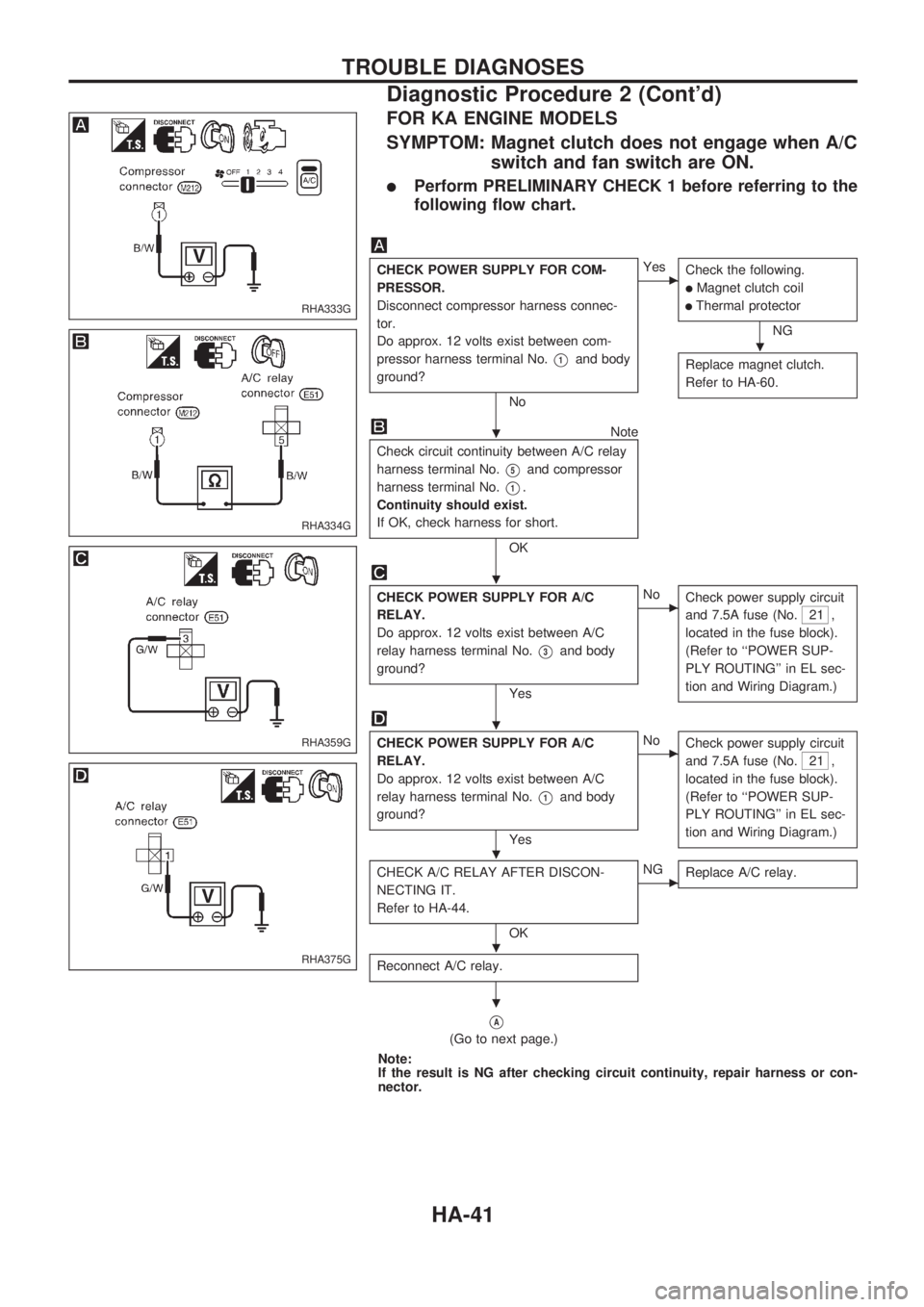

Page 912 of 1659

FOR KA ENGINE MODELS

SYMPTOM: Magnet clutch does not engage when A/C

switch and fan switch are ON.

lPerform PRELIMINARY CHECK 1 before referring to the

following flow chart.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connec-

tor.

Do approx. 12 volts exist between com-

pressor harness terminal No.

V1and body

ground?

No

cYes

Check the following.

lMagnet clutch coil

lThermal protector

NG

Replace magnet clutch.

Refer to HA-60.

Note

Check circuit continuity between A/C relay

harness terminal No.

V5and compressor

harness terminal No.

V1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx. 12 volts exist between A/C

relay harness terminal No.

V3and body

ground?

Yes

cNo

Check power supply circuit

and 7.5A fuse (No.

21 ,

located in the fuse block).

(Refer to ``POWER SUP-

PLY ROUTING'' in EL sec-

tion and Wiring Diagram.)

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx. 12 volts exist between A/C

relay harness terminal No.

V1and body

ground?

Yes

cNo

Check power supply circuit

and 7.5A fuse (No.

21 ,

located in the fuse block).

(Refer to ``POWER SUP-

PLY ROUTING'' in EL sec-

tion and Wiring Diagram.)

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-44.

OK

cNG

Replace A/C relay.

Reconnect A/C relay.

VA

(Go to next page.)

Note:

If the result is NG after checking circuit continuity, repair harness or con-

nector.

RHA333G

RHA334G

RHA359G

RHA375G

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-41

Page 913 of 1659

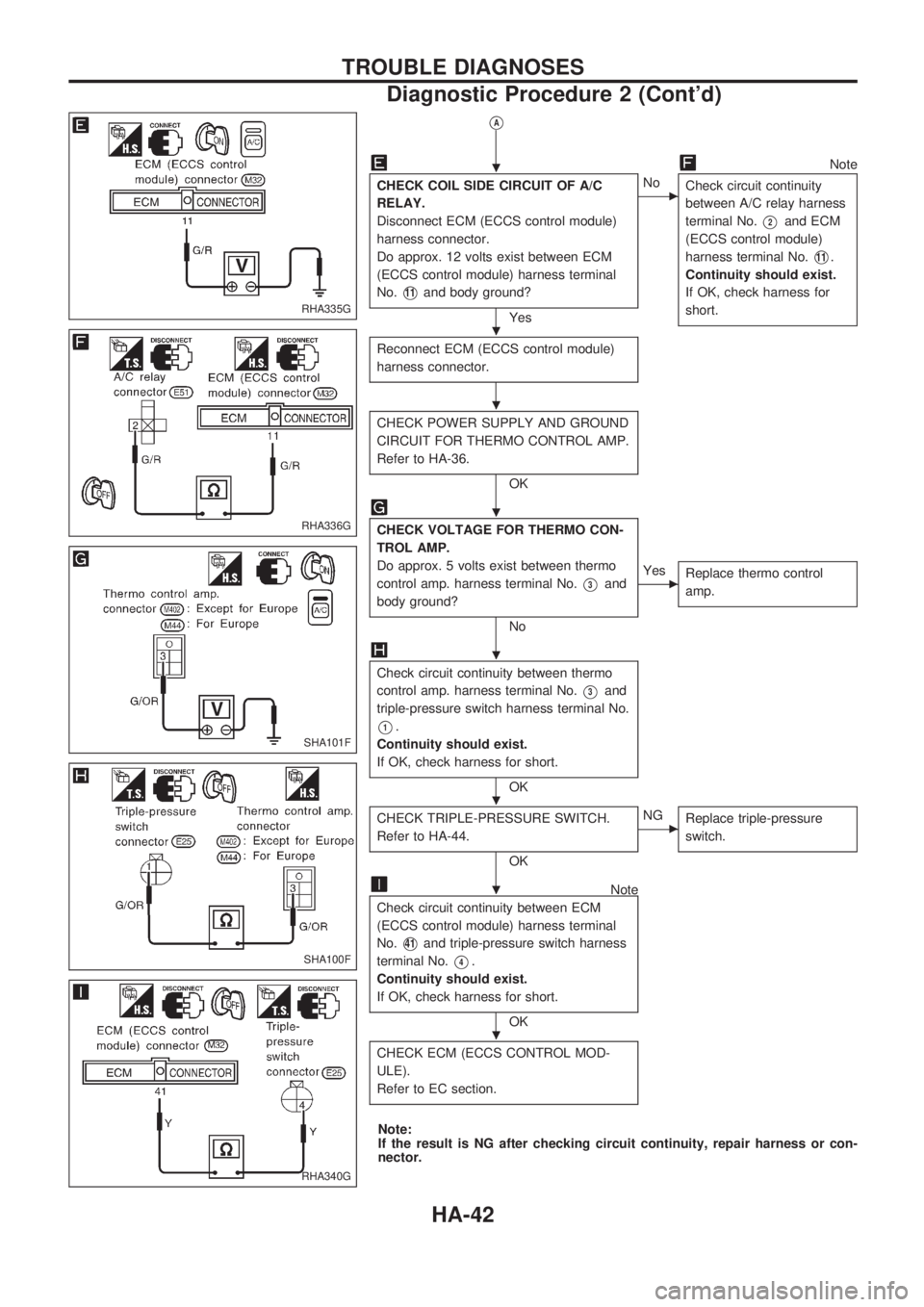

VA

Note

CHECK COIL SIDE CIRCUIT OF A/C

RELAY.

Disconnect ECM (ECCS control module)

harness connector.

Do approx. 12 volts exist between ECM

(ECCS control module) harness terminal

No.

V11and body ground?

Yes

cNo

Check circuit continuity

between A/C relay harness

terminal No.

V2and ECM

(ECCS control module)

harness terminal No.

V11.

Continuity should exist.

If OK, check harness for

short.

Reconnect ECM (ECCS control module)

harness connector.

CHECK POWER SUPPLY AND GROUND

CIRCUIT FOR THERMO CONTROL AMP.

Refer to HA-36.

OK

CHECK VOLTAGE FOR THERMO CON-

TROL AMP.

Do approx. 5 volts exist between thermo

control amp. harness terminal No.

V3and

body ground?

No

cYes

Replace thermo control

amp.

Check circuit continuity between thermo

control amp. harness terminal No.

V3and

triple-pressure switch harness terminal No.

V1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK TRIPLE-PRESSURE SWITCH.

Refer to HA-44.

OK

cNG

Replace triple-pressure

switch.

Note

Check circuit continuity between ECM

(ECCS control module) harness terminal

No.

V41and triple-pressure switch harness

terminal No.

V4.

Continuity should exist.

If OK, check harness for short.

OK

CHECK ECM (ECCS CONTROL MOD-

ULE).

Refer to EC section.

Note:

If the result is NG after checking circuit continuity, repair harness or con-

nector.

RHA335G

RHA336G

SHA101F

SHA100F

RHA340G

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

Diagnostic Procedure 2 (Cont'd)

HA-42

Page 921 of 1659

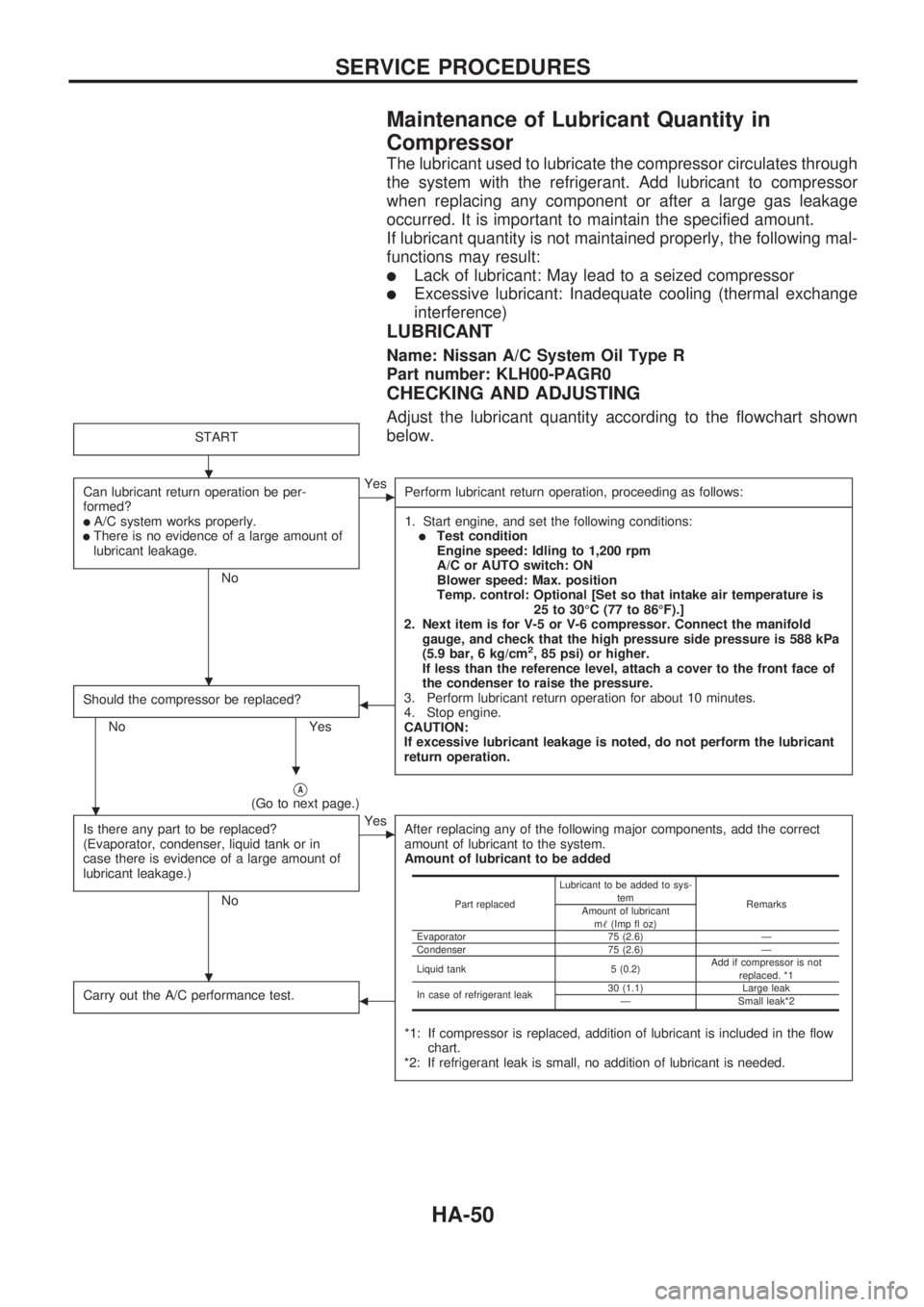

Maintenance of Lubricant Quantity in

Compressor

The lubricant used to lubricate the compressor circulates through

the system with the refrigerant. Add lubricant to compressor

when replacing any component or after a large gas leakage

occurred. It is important to maintain the specified amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANT

Name: Nissan A/C System Oil Type R

Part number: KLH00-PAGR0

CHECKING AND ADJUSTING

Adjust the lubricant quantity according to the flowchart shown

below.

START

Can lubricant return operation be per-

formed?

lA/C system works properly.lThere is no evidence of a large amount of

lubricant leakage.

No

cYes

Perform lubricant return operation, proceeding as follows:

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

lTest condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is

25 to 30ÉC (77 to 86ÉF).]

2. Next item is for V-5 or V-6 compressor. Connect the manifold

gauge, and check that the high pressure side pressure is 588 kPa

(5.9 bar, 6 kg/cm

2, 85 psi) or higher.

If less than the reference level, attach a cover to the front face of

the condenser to raise the pressure.

3. Perform lubricant return operation for about 10 minutes.

4. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant

return operation.

Should the compressor be replaced?

No Yes

b

VA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount of

lubricant leakage.)

No

cYes

After replacing any of the following major components, add the correct

amount of lubricant to the system.

Amount of lubricant to be added

*1: If compressor is replaced, addition of lubricant is included in the flow

chart.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Carry out the A/C performance test.b

Part replacedLubricant to be added to sys-

tem

Remarks

Amount of lubricant

m!(Imp fl oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is not

replaced. *1

In case of refrigerant leak30 (1.1) Large leak

Ð Small leak*2

.

.

.

.

.

SERVICE PROCEDURES

HA-50

Page 972 of 1659

MAINTENANCE

SECTION

MA

CONTENTS

PRECAUTIONS AND PREPARATION..................... 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 1

Special Service Tools ............................................ 2

Commercial Service Tools ..................................... 2

PRE-DELIVERY INSPECTION ITEMS...................... 3

GENERAL MAINTENANCE...................................... 4

PERIODIC MAINTENANCE...................................... 5

Basic Schedule for Gasoline Engine Models ........ 5

Basic Schedule for Diesel Engine Models ............ 8

Maintenance Under Severe Driving Conditions .. 10

RECOMMENDED FLUIDS AND LUBRICANTS..... 12

Fluids and Lubricants........................................... 12

SAE Viscosity Number......................................... 13

Anti-freeze Coolant Mixture Ratio........................ 14

KA

ENGINE MAINTENANCE........................................ 15

Checking Drive Belts ........................................... 15

Changing Engine Coolant .................................... 16

Checking Cooling System.................................... 17

Checking Fuel Lines ............................................ 18

Changing Fuel Filter ............................................ 18

Changing Air Cleaner Filter (Viscous paper

type) ..................................................................... 19

Changing Engine Oil ............................................ 19

Changing Oil Filter ............................................... 20

Checking and Changing Spark Plugs.................. 20

Checking Ignition Wires ....................................... 21Checking Positive Crankcase Ventilation

(PCV) System ...................................................... 21

Changing Positive Crankcase Ventilation

(PCV) Filter .......................................................... 21

Checking Vacuum Hoses and Connections ........ 22

Checking Vapor Lines.......................................... 22

Checking Heated Oxygen Sensor ....................... 22

TD

ENGINE MAINTENANCE........................................ 23

Checking Manifold Tightening Torque ................. 23

Adjusting Intake and Exhaust Valve Clearance .. 23

Checking Drive Belt ............................................. 23

Changing Engine Oil ............................................ 24

Changing Engine Oil Filter................................... 24

Changing Engine Coolant .................................... 25

Checking Cooling System.................................... 26

Checking and Replacing Fuel Filter and

Draining Water ..................................................... 27

Checking Fuel Lines ............................................ 28

Cleaning and Replacing Air Cleaner Filter .......... 29

Checking Injection Nozzle ................................... 29

Checking Idle Speed............................................ 30

CHASSIS AND BODY MAINTENANCE................. 32

Checking Exhaust System ................................... 32

Checking Clutch Fluid Level and Leaks .............. 32

Checking Clutch System...................................... 32

Checking M/T Oil ................................................. 32

Changing M/T Oil ................................................. 32

Checking Water Entry - For 4WD models ........... 33

MA

Page 973 of 1659

Checking Transfer Fluid....................................... 33

Changing Transfer Fluid ...................................... 33

Checking Propeller Shaft ..................................... 33

Greasing Propeller Shaft ..................................... 33

Checking Differential Gear Oil ............................. 34

Changing Differential Gear Oil............................. 34

Balancing Wheels ................................................ 34

Tire Rotation ........................................................ 35

Checking Brake Fluid Level and Leaks ............... 35

Checking Brake System ...................................... 35

Changing Brake Fluid .......................................... 35

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve ............................ 36Checking Disc Brake ........................................... 36

Checking Drum Brake.......................................... 36

Checking Steering Gear and Linkage ................. 37

Checking Power Steering Fluid and Lines .......... 37

Checking Steering Gear Oil Level and Leaks ..... 38

Lubricating Hood Latches, Locks and Hinges ..... 39

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters......................................... 40

Checking Body Corrosion .................................... 41

SERVICE DATA AND SPECIFICATIONS (SDS)... 42

Engine Maintenance (KA) .................................... 42

Engine Maintenance (TD) .................................... 42

Chassis and Body Maintenance .......................... 42

Page 988 of 1659

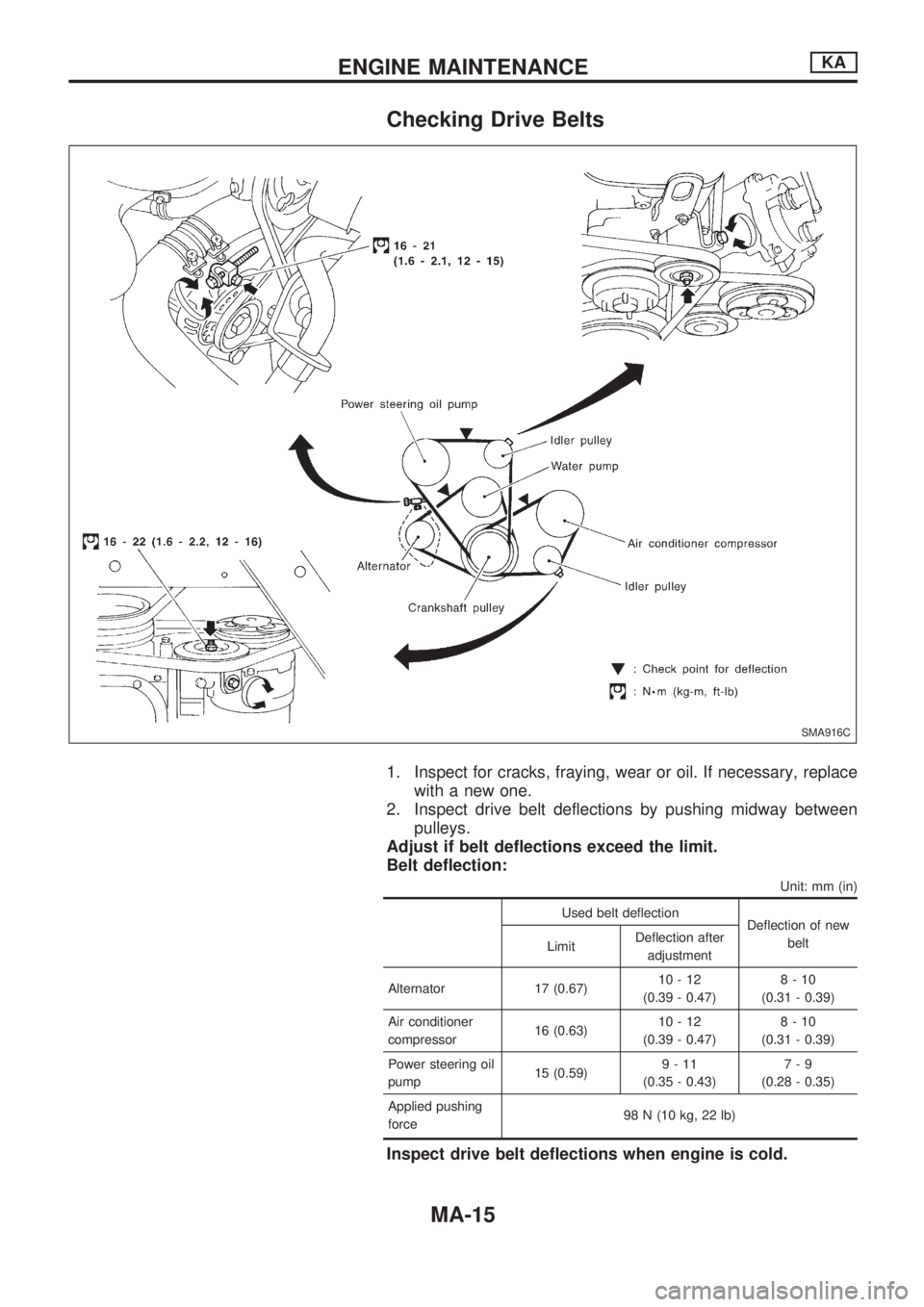

Checking Drive Belts

1. Inspect for cracks, fraying, wear or oil. If necessary, replace

with a new one.

2. Inspect drive belt deflections by pushing midway between

pulleys.

Adjust if belt deflections exceed the limit.

Belt deflection:

Unit: mm (in)

Used belt deflection

Deflection of new

belt

LimitDeflection after

adjustment

Alternator 17 (0.67)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Air conditioner

compressor16 (0.63)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Power steering oil

pump15 (0.59)9-11

(0.35 - 0.43)7-9

(0.28 - 0.35)

Applied pushing

force98 N (10 kg, 22 lb)

Inspect drive belt deflections when engine is cold.

SMA916C

ENGINE MAINTENANCEKA

MA-15

Page 993 of 1659

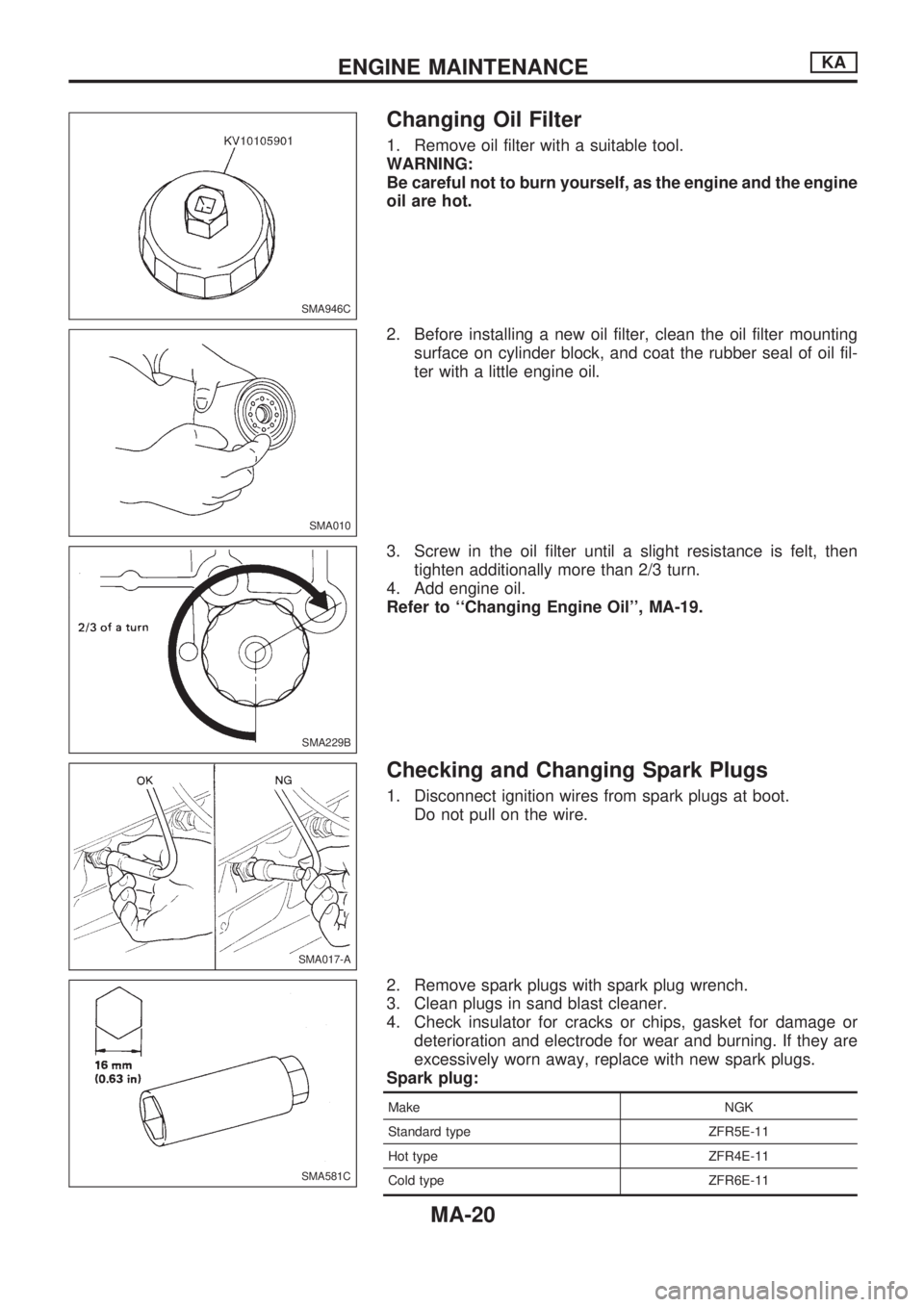

Changing Oil Filter

1. Remove oil filter with a suitable tool.

WARNING:

Be careful not to burn yourself, as the engine and the engine

oil are hot.

2. Before installing a new oil filter, clean the oil filter mounting

surface on cylinder block, and coat the rubber seal of oil fil-

ter with a little engine oil.

3. Screw in the oil filter until a slight resistance is felt, then

tighten additionally more than 2/3 turn.

4. Add engine oil.

Refer to ``Changing Engine Oil'', MA-19.

Checking and Changing Spark Plugs

1. Disconnect ignition wires from spark plugs at boot.

Do not pull on the wire.

2. Remove spark plugs with spark plug wrench.

3. Clean plugs in sand blast cleaner.

4. Check insulator for cracks or chips, gasket for damage or

deterioration and electrode for wear and burning. If they are

excessively worn away, replace with new spark plugs.

Spark plug:

Make NGK

Standard type ZFR5E-11

Hot type ZFR4E-11

Cold type ZFR6E-11

SMA946C

SMA010

SMA229B

SMA017-A

SMA581C

ENGINE MAINTENANCEKA

MA-20

Page 996 of 1659

![NISSAN PICK-UP 1998 User Guide Checking Manifold Tightening Torque

Checking should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Manifold bolts and nuts:

Intake

: 13 - 19 N´m (1.3 - 1.9 kg-m,9-14ft-lb)

Exhaust

: NISSAN PICK-UP 1998 User Guide Checking Manifold Tightening Torque

Checking should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Manifold bolts and nuts:

Intake

: 13 - 19 N´m (1.3 - 1.9 kg-m,9-14ft-lb)

Exhaust

:](/img/5/57374/w960_57374-995.png)

Checking Manifold Tightening Torque

Checking should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Manifold bolts and nuts:

Intake

: 13 - 19 N´m (1.3 - 1.9 kg-m,9-14ft-lb)

Exhaust

: 25 - 29 N´m (2.5 - 3.0 kg-m, 18 - 22 ft-lb)

Exhaust tube nuts:

: 41.2 - 48.0 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

Adjusting Intake and Exhaust Valve

Clearance

Adjustment should be made while engine is warm but not

running.

1. Set No. 1 cylinder in top dead center on its compression

stroke, and adjust valve clearance

V1,V2,V3andV6.

2. Set No. 4 cylinder at top dead center on its compression

stroke, and adjust valve clearance

V4,V5,V7andV8.

Valve clearance:

Intake

V1,V3,V5andV7

0.30 - 0.40 mm (0.012 - 0.016 in)

Exhaust

V2,V4,V6andV8

0.30 - 0.40 mm (0.012 - 0.016 in)

Adjusting screw lock nuts:

: 15 - 20 N´m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

lTighten lock nuts, by fixing the adjusting screws using a

minus driver.

Checking Drive Belt

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if

necessary.

The belts should not touch the bottom of the pulley groove.

2. Check drive belt deflection by pushing on the belt midway

between pulleys.

Adjust if belt deflections exceed the limit.

Unit: mm (in)

Used belt deflection

Deflection of new belt

LimitDeflection after

adjustment

Alternator 20 (0.79) 11 - 13 (0.43 - 0.51) 9 - 11 (0.35 - 0.43)

Air conditioner

compressor12 (0.47) 6 - 7.5 (0.236 - 0.295) 5 - 6.5 (0.197 - 0.256)

Power steering oil

pump15 (0.59) 8 - 9.5 (0.315 - 0.374) 7 - 8.5 (0.276 - 0.335)

Applied pushing

force98 N (10 kg, 22 lb)

Check drive belt deflections when engine is cold.

SMA653C

SMA613C

ENGINE MAINTENANCETD

MA-23