alternator belt NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 426 of 1659

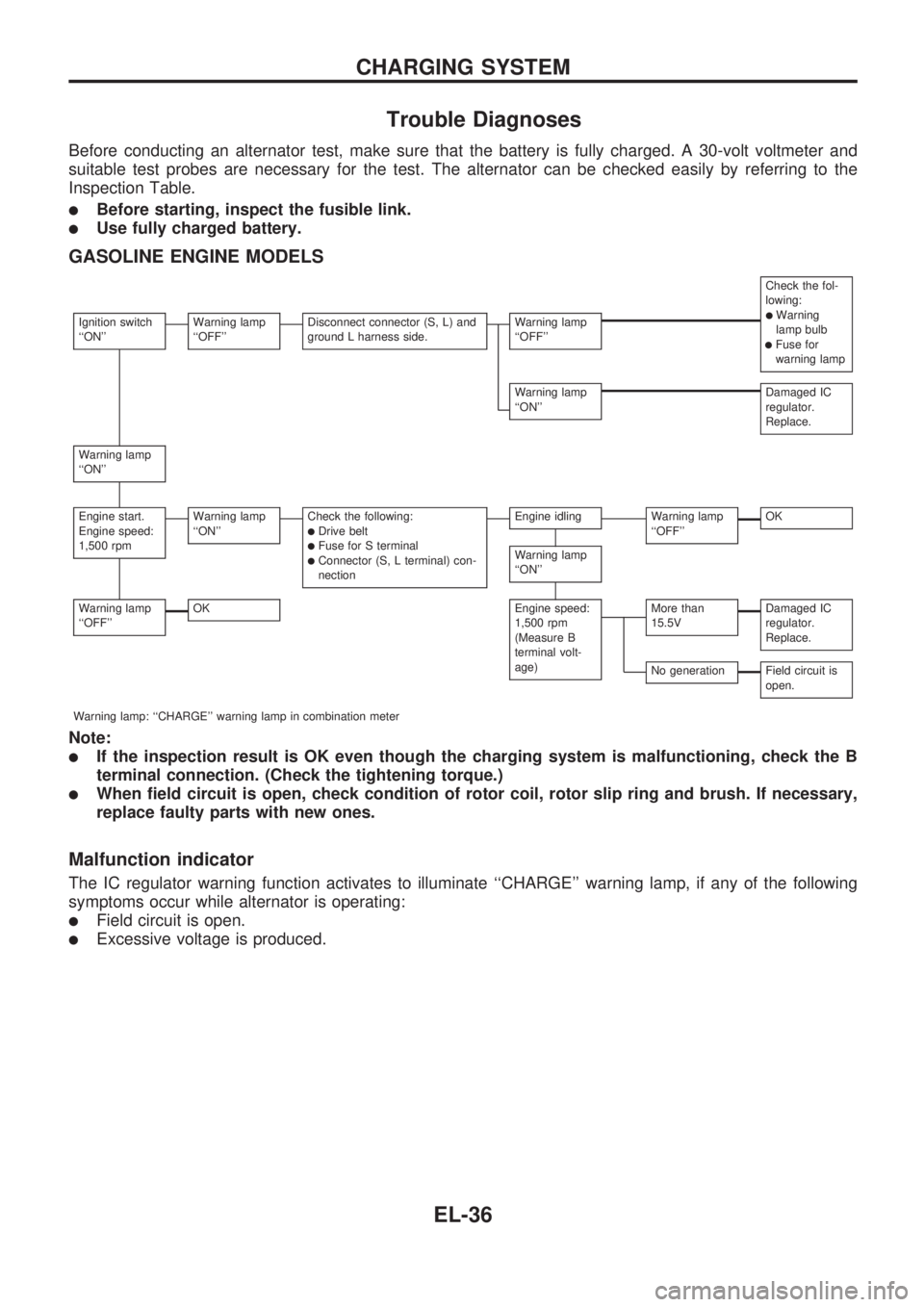

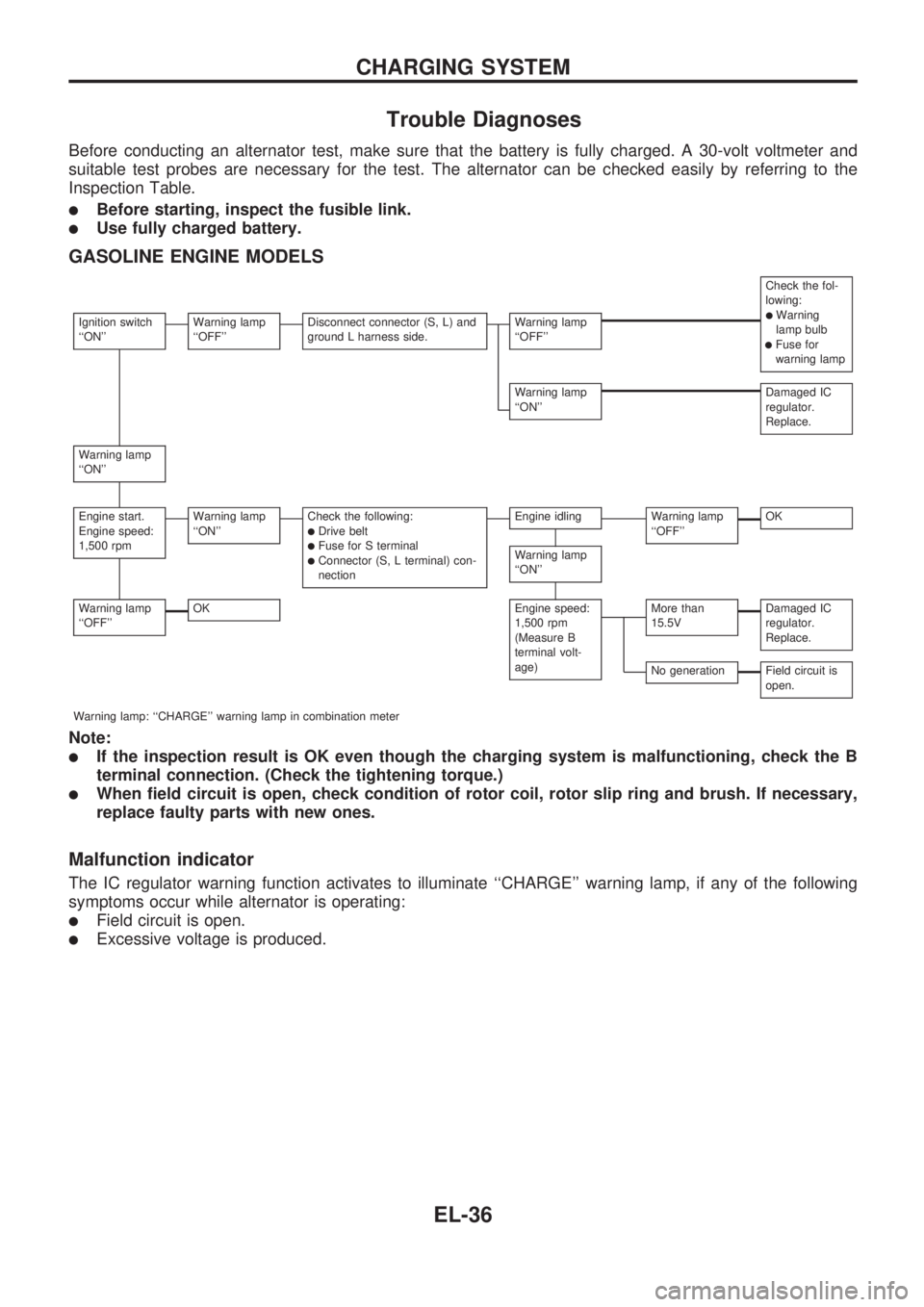

Trouble Diagnoses

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and

suitable test probes are necessary for the test. The alternator can be checked easily by referring to the

Inspection Table.

lBefore starting, inspect the fusible link.

lUse fully charged battery.

GASOLINE ENGINE MODELS

Check the fol-

lowing:

lWarning

lamp bulb

lFuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine start.

Engine speed:

1,500 rpmWarning lamp

``ON''Check the following:lDrive beltlFuse for S terminallConnector (S, L terminal) con-

nection

Engine idlingWarning lamp

``OFF''OK

Warning lamp

``ON''

Warning lamp

``OFF''OKEngine speed:

1,500 rpm

(Measure B

terminal volt-

age)More than

15.5VDamaged IC

regulator.

Replace.

No generationField circuit is

open.

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B

terminal connection. (Check the tightening torque.)

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

Malfunction indicator

The IC regulator warning function activates to illuminate ``CHARGE'' warning lamp, if any of the following

symptoms occur while alternator is operating:

lField circuit is open.

lExcessive voltage is produced.

CHARGING SYSTEM

EL-36

Page 658 of 1659

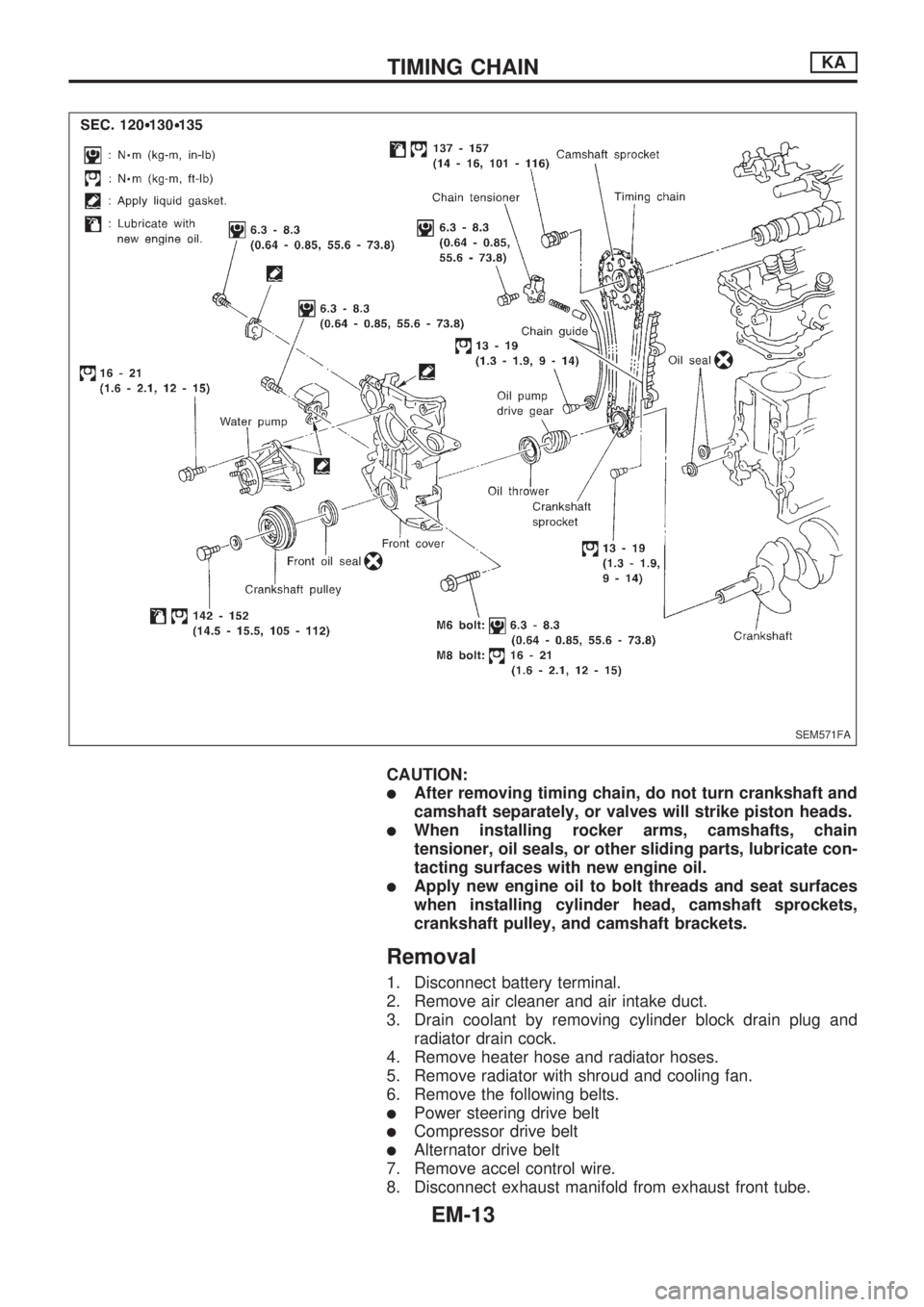

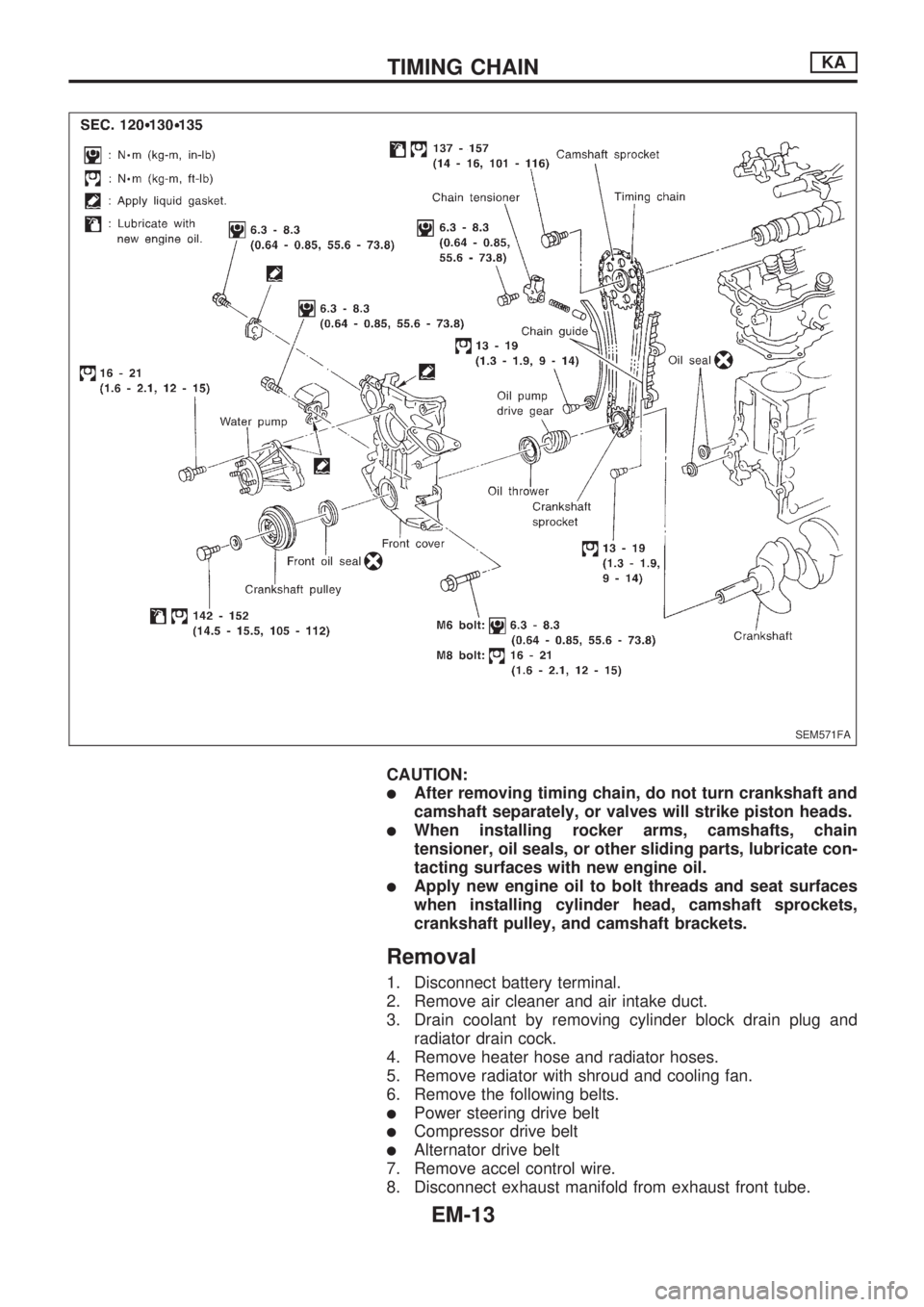

CAUTION:

lAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

lWhen installing rocker arms, camshafts, chain

tensioner, oil seals, or other sliding parts, lubricate con-

tacting surfaces with new engine oil.

lApply new engine oil to bolt threads and seat surfaces

when installing cylinder head, camshaft sprockets,

crankshaft pulley, and camshaft brackets.

Removal

1. Disconnect battery terminal.

2. Remove air cleaner and air intake duct.

3. Drain coolant by removing cylinder block drain plug and

radiator drain cock.

4. Remove heater hose and radiator hoses.

5. Remove radiator with shroud and cooling fan.

6. Remove the following belts.

lPower steering drive belt

lCompressor drive belt

lAlternator drive belt

7. Remove accel control wire.

8. Disconnect exhaust manifold from exhaust front tube.

SEM571FA

TIMING CHAINKA

EM-13

Page 682 of 1659

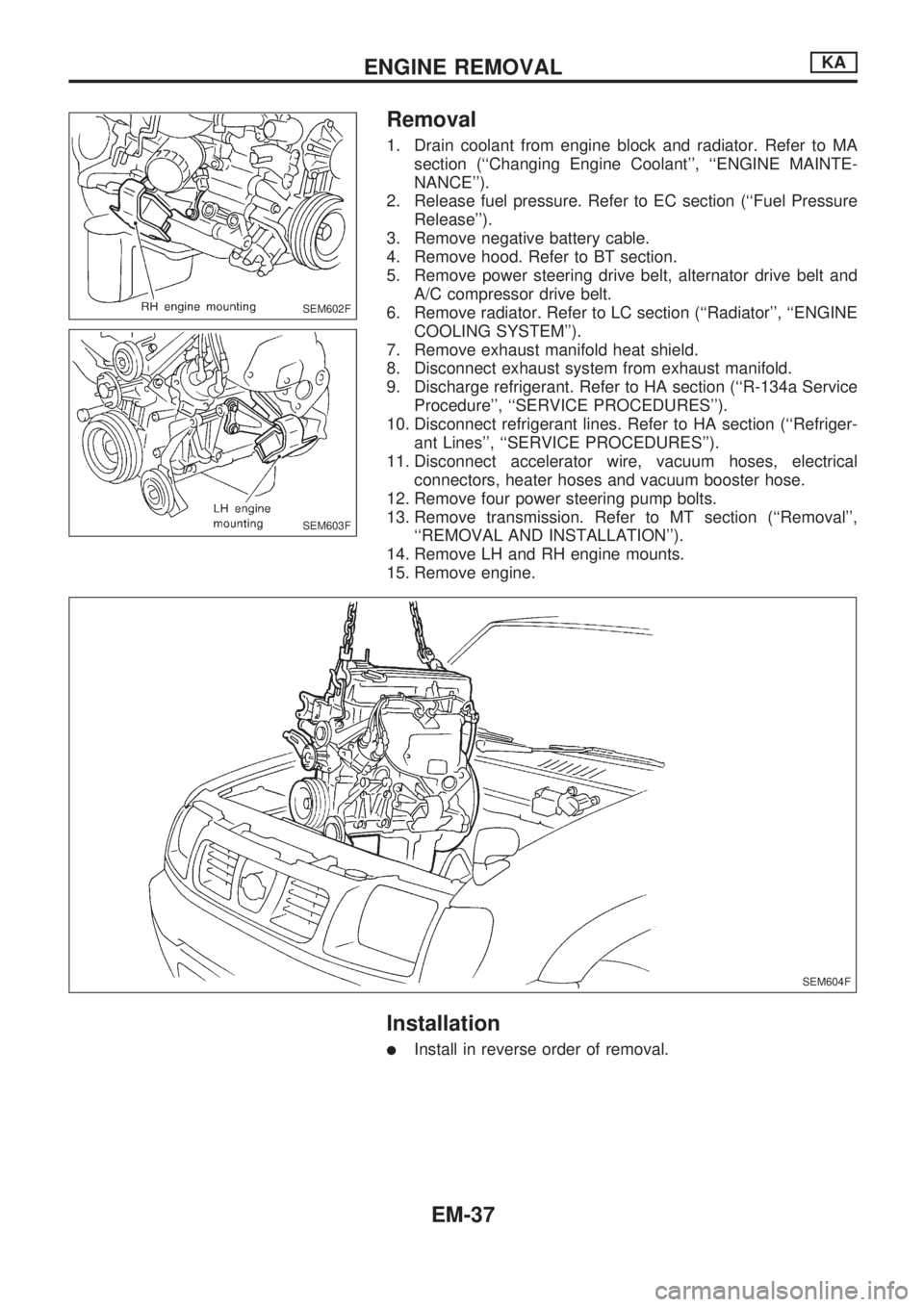

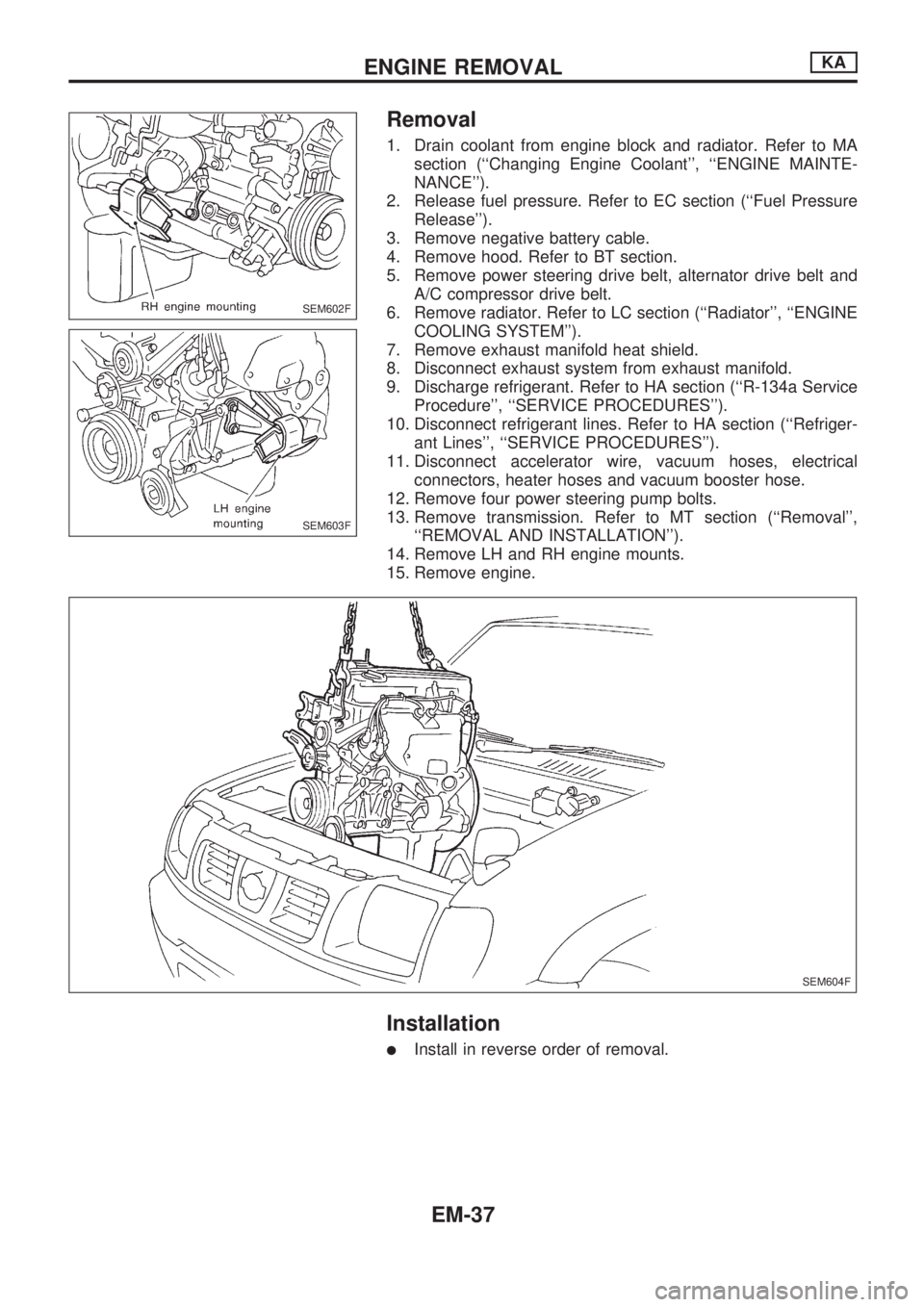

Removal

1. Drain coolant from engine block and radiator. Refer to MA

section (``Changing Engine Coolant'', ``ENGINE MAINTE-

NANCE'').

2. Release fuel pressure. Refer to EC section (``Fuel Pressure

Release'').

3. Remove negative battery cable.

4. Remove hood. Refer to BT section.

5. Remove power steering drive belt, alternator drive belt and

A/C compressor drive belt.

6. Remove radiator. Refer to LC section (``Radiator'', ``ENGINE

COOLING SYSTEM'').

7. Remove exhaust manifold heat shield.

8. Disconnect exhaust system from exhaust manifold.

9. Discharge refrigerant. Refer to HA section (``R-134a Service

Procedure'', ``SERVICE PROCEDURES'').

10. Disconnect refrigerant lines. Refer to HA section (``Refriger-

ant Lines'', ``SERVICE PROCEDURES'').

11. Disconnect accelerator wire, vacuum hoses, electrical

connectors, heater hoses and vacuum booster hose.

12. Remove four power steering pump bolts.

13. Remove transmission. Refer to MT section (``Removal'',

``REMOVAL AND INSTALLATION'').

14. Remove LH and RH engine mounts.

15. Remove engine.

Installation

lInstall in reverse order of removal.

SEM602F

SEM603F

SEM604F

ENGINE REMOVALKA

EM-37

Page 988 of 1659

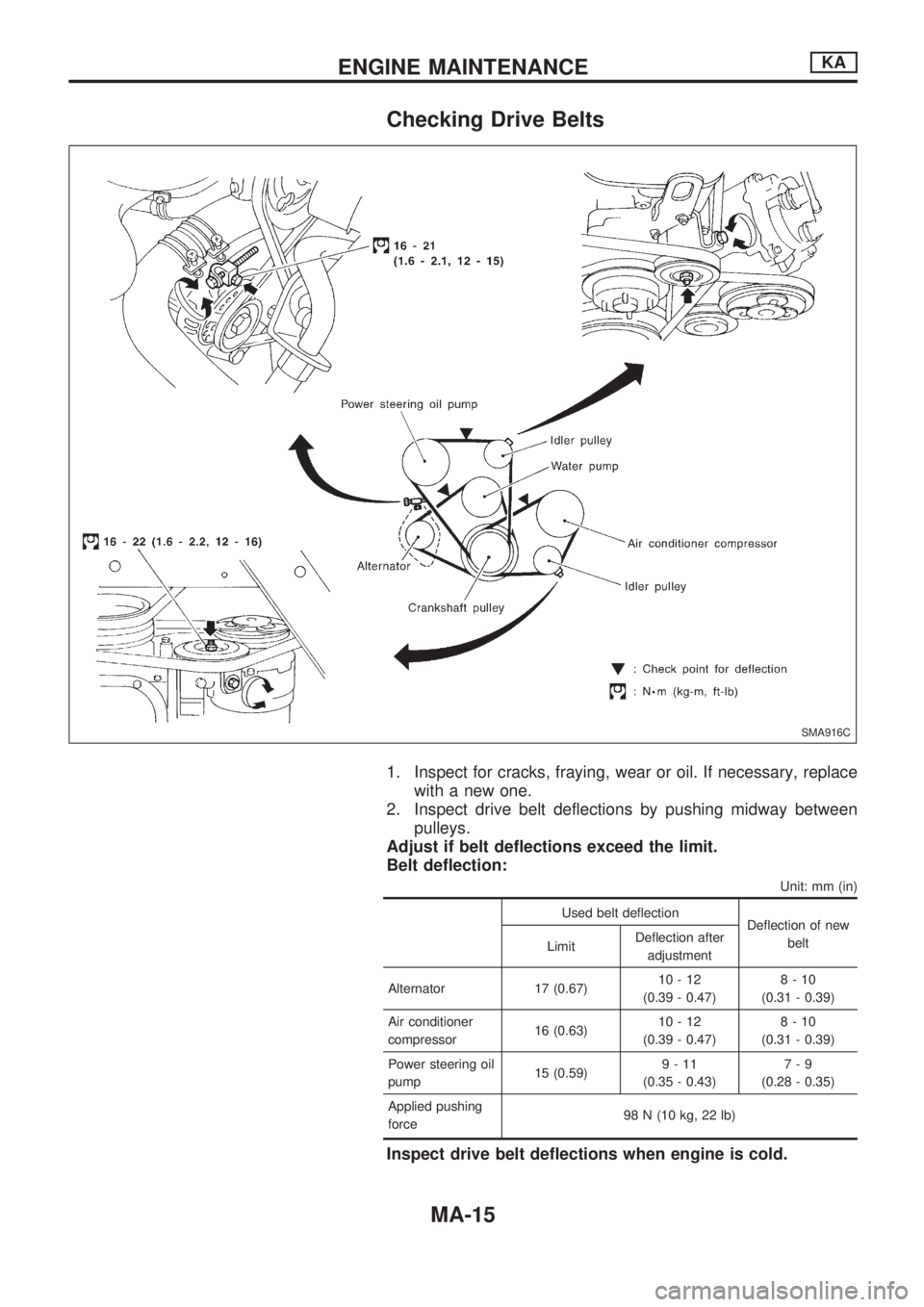

Checking Drive Belts

1. Inspect for cracks, fraying, wear or oil. If necessary, replace

with a new one.

2. Inspect drive belt deflections by pushing midway between

pulleys.

Adjust if belt deflections exceed the limit.

Belt deflection:

Unit: mm (in)

Used belt deflection

Deflection of new

belt

LimitDeflection after

adjustment

Alternator 17 (0.67)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Air conditioner

compressor16 (0.63)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Power steering oil

pump15 (0.59)9-11

(0.35 - 0.43)7-9

(0.28 - 0.35)

Applied pushing

force98 N (10 kg, 22 lb)

Inspect drive belt deflections when engine is cold.

SMA916C

ENGINE MAINTENANCEKA

MA-15

Page 996 of 1659

![NISSAN PICK-UP 1998 Repair Manual Checking Manifold Tightening Torque

Checking should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Manifold bolts and nuts:

Intake

: 13 - 19 N´m (1.3 - 1.9 kg-m,9-14ft-lb)

Exhaust

: NISSAN PICK-UP 1998 Repair Manual Checking Manifold Tightening Torque

Checking should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Manifold bolts and nuts:

Intake

: 13 - 19 N´m (1.3 - 1.9 kg-m,9-14ft-lb)

Exhaust

:](/img/5/57374/w960_57374-995.png)

Checking Manifold Tightening Torque

Checking should be performed while engine is cold

[approximately 20ÉC (68ÉF)].

Manifold bolts and nuts:

Intake

: 13 - 19 N´m (1.3 - 1.9 kg-m,9-14ft-lb)

Exhaust

: 25 - 29 N´m (2.5 - 3.0 kg-m, 18 - 22 ft-lb)

Exhaust tube nuts:

: 41.2 - 48.0 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

Adjusting Intake and Exhaust Valve

Clearance

Adjustment should be made while engine is warm but not

running.

1. Set No. 1 cylinder in top dead center on its compression

stroke, and adjust valve clearance

V1,V2,V3andV6.

2. Set No. 4 cylinder at top dead center on its compression

stroke, and adjust valve clearance

V4,V5,V7andV8.

Valve clearance:

Intake

V1,V3,V5andV7

0.30 - 0.40 mm (0.012 - 0.016 in)

Exhaust

V2,V4,V6andV8

0.30 - 0.40 mm (0.012 - 0.016 in)

Adjusting screw lock nuts:

: 15 - 20 N´m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

lTighten lock nuts, by fixing the adjusting screws using a

minus driver.

Checking Drive Belt

1. Inspect for cracks, fraying, wear or oil adhesion. Replace if

necessary.

The belts should not touch the bottom of the pulley groove.

2. Check drive belt deflection by pushing on the belt midway

between pulleys.

Adjust if belt deflections exceed the limit.

Unit: mm (in)

Used belt deflection

Deflection of new belt

LimitDeflection after

adjustment

Alternator 20 (0.79) 11 - 13 (0.43 - 0.51) 9 - 11 (0.35 - 0.43)

Air conditioner

compressor12 (0.47) 6 - 7.5 (0.236 - 0.295) 5 - 6.5 (0.197 - 0.256)

Power steering oil

pump15 (0.59) 8 - 9.5 (0.315 - 0.374) 7 - 8.5 (0.276 - 0.335)

Applied pushing

force98 N (10 kg, 22 lb)

Check drive belt deflections when engine is cold.

SMA653C

SMA613C

ENGINE MAINTENANCETD

MA-23

Page 1015 of 1659

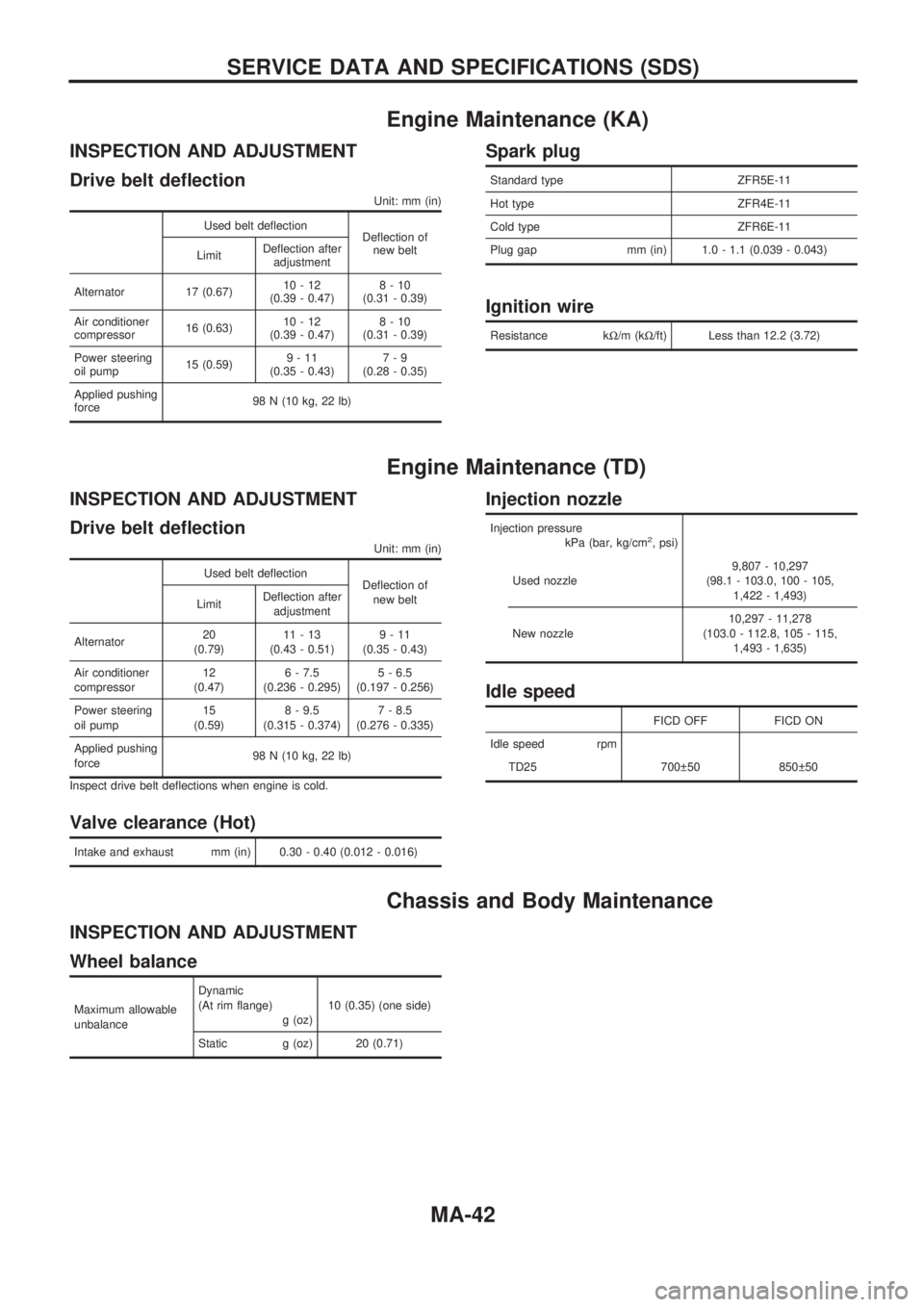

Engine Maintenance (KA)

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflection

Deflection of

new belt

LimitDeflection after

adjustment

Alternator 17 (0.67)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Air conditioner

compressor16 (0.63)10-12

(0.39 - 0.47)8-10

(0.31 - 0.39)

Power steering

oil pump15 (0.59)9-11

(0.35 - 0.43)7-9

(0.28 - 0.35)

Applied pushing

force98 N (10 kg, 22 lb)

Spark plug

Standard type ZFR5E-11

Hot type ZFR4E-11

Cold type ZFR6E-11

Plug gap mm (in) 1.0 - 1.1 (0.039 - 0.043)

Ignition wire

Resistance kW/m (kW/ft) Less than 12.2 (3.72)

Engine Maintenance (TD)

INSPECTION AND ADJUSTMENT

Drive belt deflection

Unit: mm (in)

Used belt deflection

Deflection of

new belt

LimitDeflection after

adjustment

Alternator20

(0.79)11-13

(0.43 - 0.51)9-11

(0.35 - 0.43)

Air conditioner

compressor12

(0.47)6 - 7.5

(0.236 - 0.295)5 - 6.5

(0.197 - 0.256)

Power steering

oil pump15

(0.59)8 - 9.5

(0.315 - 0.374)7 - 8.5

(0.276 - 0.335)

Applied pushing

force98 N (10 kg, 22 lb)

Inspect drive belt deflections when engine is cold.

Valve clearance (Hot)

Intake and exhaust mm (in) 0.30 - 0.40 (0.012 - 0.016)

Injection nozzle

Injection pressure

kPa (bar, kg/cm2, psi)

Used nozzle9,807 - 10,297

(98.1 - 103.0, 100 - 105,

1,422 - 1,493)

New nozzle10,297 - 11,278

(103.0 - 112.8, 105 - 115,

1,493 - 1,635)

Idle speed

FICD OFF FICD ON

Idle speed rpm

TD25 700 50 850 50

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Wheel balance

Maximum allowable

unbalanceDynamic

(At rim flange)

g (oz)10 (0.35) (one side)

Static g (oz) 20 (0.71)

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-42

Page 1334 of 1659

Trouble Diagnoses

Before conducting an alternator test, make sure that the battery is fully charged. A 30-volt voltmeter and

suitable test probes are necessary for the test. The alternator can be checked easily by referring to the

Inspection Table.

lBefore starting, inspect the fusible link.

lUse fully charged battery.

GASOLINE ENGINE MODELS

Check the fol-

lowing:

lWarning

lamp bulb

lFuse for

warning lamp

Ignition switch

``ON''Warning lamp

``OFF''Disconnect connector (S, L) and

ground L harness side.Warning lamp

``OFF''

Warning lamp

``ON''Damaged IC

regulator.

Replace.

Warning lamp

``ON''

Engine start.

Engine speed:

1,500 rpmWarning lamp

``ON''Check the following:lDrive beltlFuse for S terminallConnector (S, L terminal) con-

nection

Engine idlingWarning lamp

``OFF''OK

Warning lamp

``ON''

Warning lamp

``OFF''OKEngine speed:

1,500 rpm

(Measure B

terminal volt-

age)More than

15.5VDamaged IC

regulator.

Replace.

No generationField circuit is

open.

Warning lamp: ``CHARGE'' warning lamp in combination meter

Note:

lIf the inspection result is OK even though the charging system is malfunctioning, check the B

terminal connection. (Check the tightening torque.)

lWhen field circuit is open, check condition of rotor coil, rotor slip ring and brush. If necessary,

replace faulty parts with new ones.

Malfunction indicator

The IC regulator warning function activates to illuminate ``CHARGE'' warning lamp, if any of the following

symptoms occur while alternator is operating:

lField circuit is open.

lExcessive voltage is produced.

CHARGING SYSTEM

EL-36

Page 1566 of 1659

CAUTION:

lAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

lWhen installing rocker arms, camshafts, chain

tensioner, oil seals, or other sliding parts, lubricate con-

tacting surfaces with new engine oil.

lApply new engine oil to bolt threads and seat surfaces

when installing cylinder head, camshaft sprockets,

crankshaft pulley, and camshaft brackets.

Removal

1. Disconnect battery terminal.

2. Remove air cleaner and air intake duct.

3. Drain coolant by removing cylinder block drain plug and

radiator drain cock.

4. Remove heater hose and radiator hoses.

5. Remove radiator with shroud and cooling fan.

6. Remove the following belts.

lPower steering drive belt

lCompressor drive belt

lAlternator drive belt

7. Remove accel control wire.

8. Disconnect exhaust manifold from exhaust front tube.

SEM571FA

TIMING CHAINKA

EM-13

Page 1590 of 1659

Removal

1. Drain coolant from engine block and radiator. Refer to MA

section (``Changing Engine Coolant'', ``ENGINE MAINTE-

NANCE'').

2. Release fuel pressure. Refer to EC section (``Fuel Pressure

Release'').

3. Remove negative battery cable.

4. Remove hood. Refer to BT section.

5. Remove power steering drive belt, alternator drive belt and

A/C compressor drive belt.

6. Remove radiator. Refer to LC section (``Radiator'', ``ENGINE

COOLING SYSTEM'').

7. Remove exhaust manifold heat shield.

8. Disconnect exhaust system from exhaust manifold.

9. Discharge refrigerant. Refer to HA section (``R-134a Service

Procedure'', ``SERVICE PROCEDURES'').

10. Disconnect refrigerant lines. Refer to HA section (``Refriger-

ant Lines'', ``SERVICE PROCEDURES'').

11. Disconnect accelerator wire, vacuum hoses, electrical

connectors, heater hoses and vacuum booster hose.

12. Remove four power steering pump bolts.

13. Remove transmission. Refer to MT section (``Removal'',

``REMOVAL AND INSTALLATION'').

14. Remove LH and RH engine mounts.

15. Remove engine.

Installation

lInstall in reverse order of removal.

SEM602F

SEM603F

SEM604F

ENGINE REMOVALKA

EM-37