warning light NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 37 of 1659

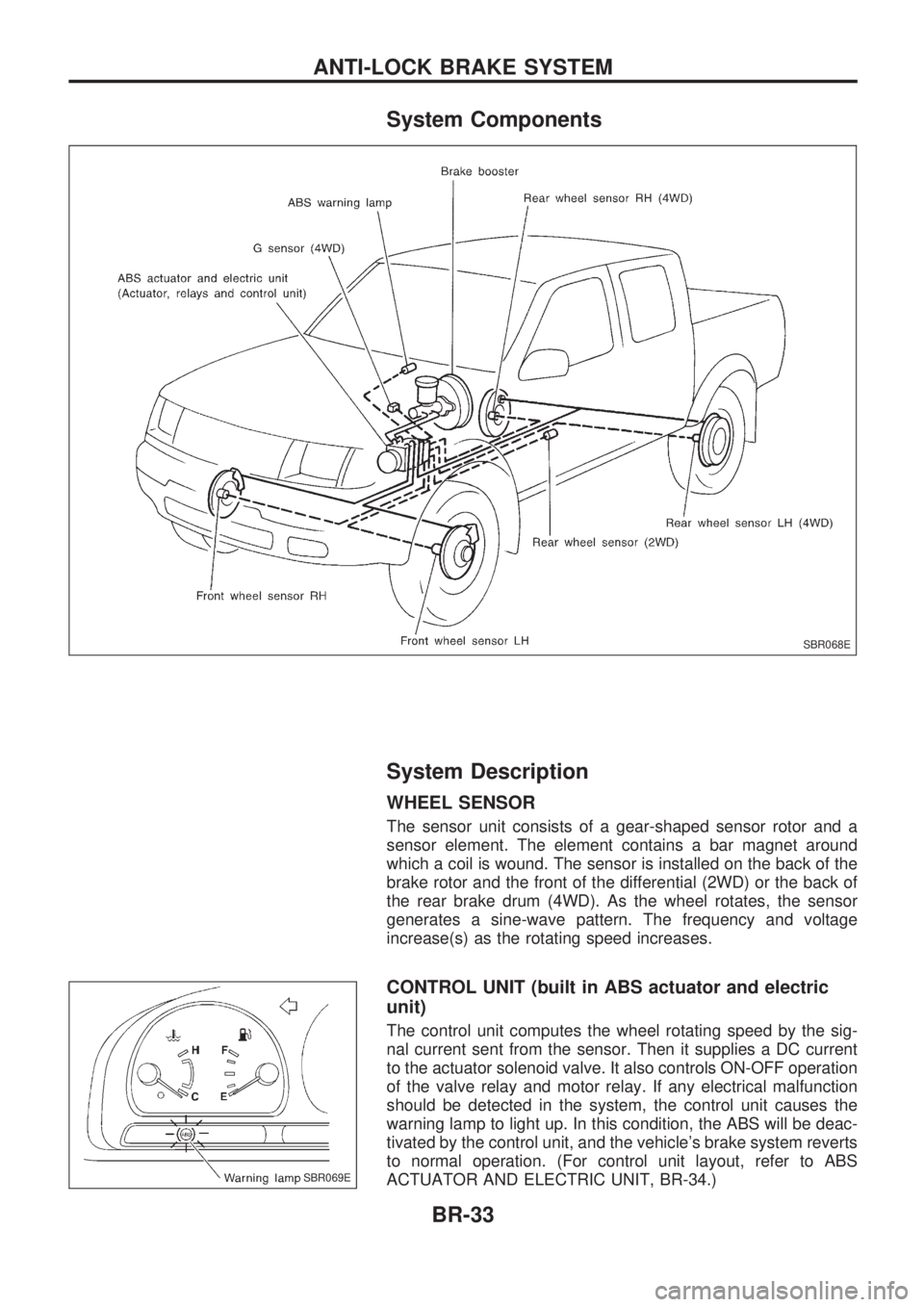

System Components

System Description

WHEEL SENSOR

The sensor unit consists of a gear-shaped sensor rotor and a

sensor element. The element contains a bar magnet around

which a coil is wound. The sensor is installed on the back of the

brake rotor and the front of the differential (2WD) or the back of

the rear brake drum (4WD). As the wheel rotates, the sensor

generates a sine-wave pattern. The frequency and voltage

increase(s) as the rotating speed increases.

CONTROL UNIT (built in ABS actuator and electric

unit)

The control unit computes the wheel rotating speed by the sig-

nal current sent from the sensor. Then it supplies a DC current

to the actuator solenoid valve. It also controls ON-OFF operation

of the valve relay and motor relay. If any electrical malfunction

should be detected in the system, the control unit causes the

warning lamp to light up. In this condition, the ABS will be deac-

tivated by the control unit, and the vehicle's brake system reverts

to normal operation. (For control unit layout, refer to ABS

ACTUATOR AND ELECTRIC UNIT, BR-34.)

SBR068E

SBR069E

ANTI-LOCK BRAKE SYSTEM

BR-33

Page 190 of 1659

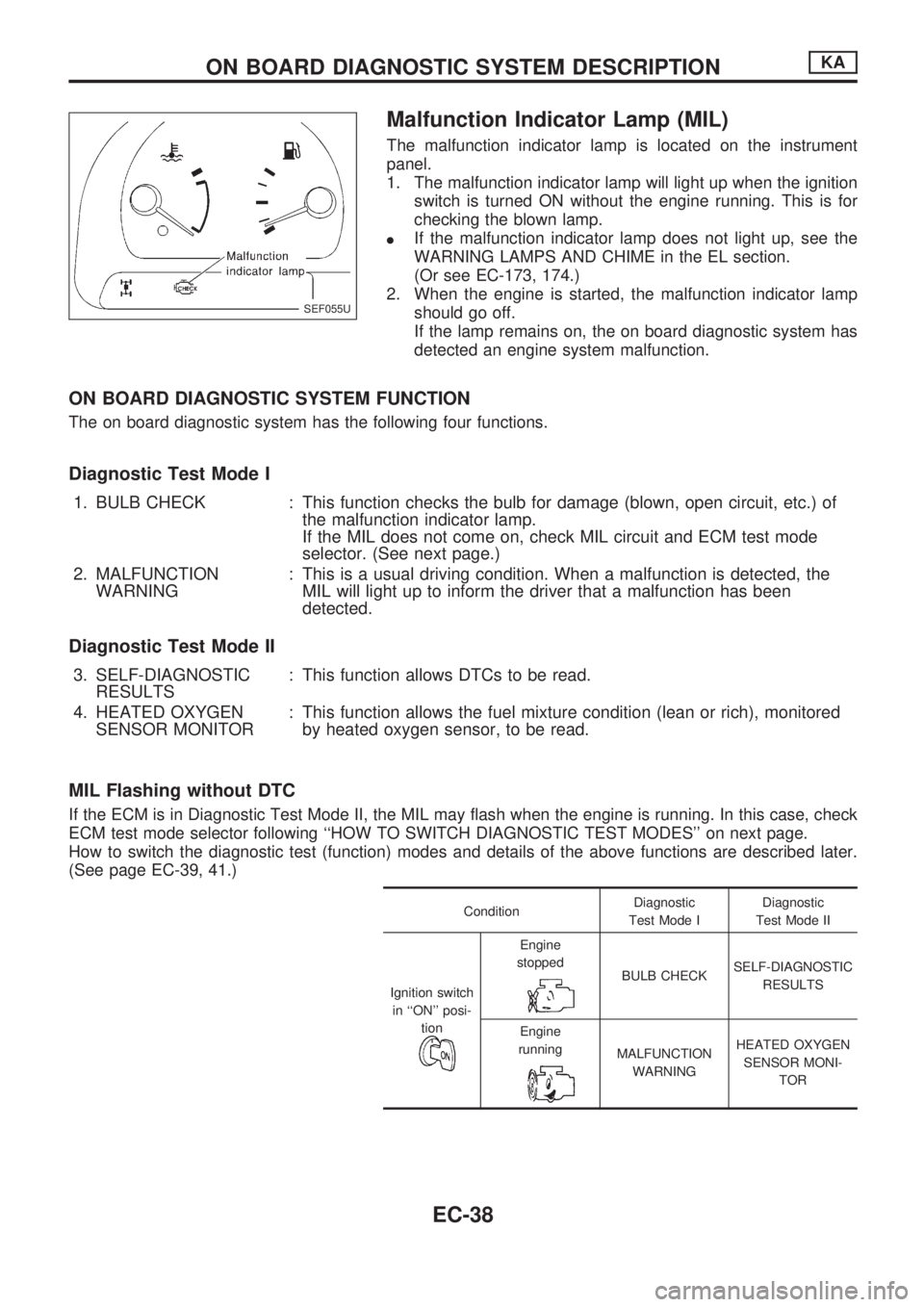

Malfunction Indicator Lamp (MIL)

The malfunction indicator lamp is located on the instrument

panel.

1. The malfunction indicator lamp will light up when the ignition

switch is turned ON without the engine running. This is for

checking the blown lamp.

lIf the malfunction indicator lamp does not light up, see the

WARNING LAMPS AND CHIME in the EL section.

(Or see EC-173, 174.)

2. When the engine is started, the malfunction indicator lamp

should go off.

If the lamp remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following four functions.

Diagnostic Test Mode I

1. BULB CHECK : This function checks the bulb for damage (blown, open circuit, etc.) of

the malfunction indicator lamp.

If the MIL does not come on, check MIL circuit and ECM test mode

selector. (See next page.)

2. MALFUNCTION

WARNING: This is a usual driving condition. When a malfunction is detected, the

MIL will light up to inform the driver that a malfunction has been

detected.

Diagnostic Test Mode II

3. SELF-DIAGNOSTIC

RESULTS: This function allows DTCs to be read.

4. HEATED OXYGEN

SENSOR MONITOR: This function allows the fuel mixture condition (lean or rich), monitored

by heated oxygen sensor, to be read.

MIL Flashing without DTC

If the ECM is in Diagnostic Test Mode II, the MIL may flash when the engine is running. In this case, check

ECM test mode selector following ``HOW TO SWITCH DIAGNOSTIC TEST MODES'' on next page.

How to switch the diagnostic test (function) modes and details of the above functions are described later.

(See page EC-39, 41.)

ConditionDiagnostic

Test Mode IDiagnostic

Test Mode II

Ignition switch

in ``ON'' posi-

tion

Engine

stopped

BULB CHECKSELF-DIAGNOSTIC

RESULTS

Engine

running

MALFUNCTION

WARNINGHEATED OXYGEN

SENSOR MONI-

TOR

SEF055U

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

EC-38

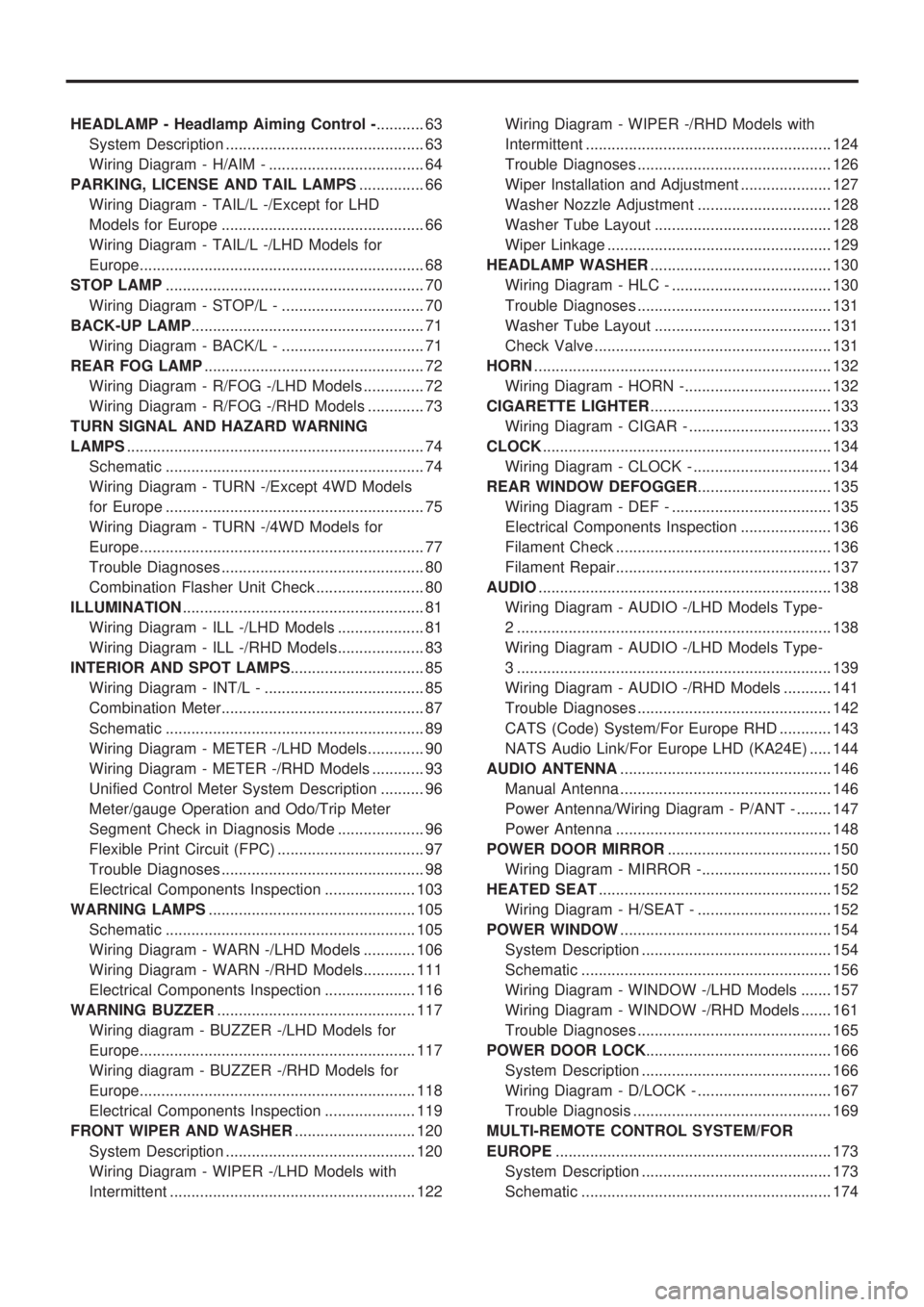

Page 389 of 1659

HEADLAMP - Headlamp Aiming Control -........... 63

System Description .............................................. 63

Wiring Diagram - H/AIM - .................................... 64

PARKING, LICENSE AND TAIL LAMPS............... 66

Wiring Diagram - TAIL/L -/Except for LHD

Models for Europe ............................................... 66

Wiring Diagram - TAIL/L -/LHD Models for

Europe.................................................................. 68

STOP LAMP............................................................ 70

Wiring Diagram - STOP/L - ................................. 70

BACK-UP LAMP...................................................... 71

Wiring Diagram - BACK/L - ................................. 71

REAR FOG LAMP................................................... 72

Wiring Diagram - R/FOG -/LHD Models .............. 72

Wiring Diagram - R/FOG -/RHD Models ............. 73

TURN SIGNAL AND HAZARD WARNING

LAMPS..................................................................... 74

Schematic ............................................................ 74

Wiring Diagram - TURN -/Except 4WD Models

for Europe ............................................................ 75

Wiring Diagram - TURN -/4WD Models for

Europe.................................................................. 77

Trouble Diagnoses ............................................... 80

Combination Flasher Unit Check ......................... 80

ILLUMINATION........................................................ 81

Wiring Diagram - ILL -/LHD Models .................... 81

Wiring Diagram - ILL -/RHD Models.................... 83

INTERIOR AND SPOT LAMPS............................... 85

Wiring Diagram - INT/L - ..................................... 85

Combination Meter............................................... 87

Schematic ............................................................ 89

Wiring Diagram - METER -/LHD Models............. 90

Wiring Diagram - METER -/RHD Models ............ 93

Unified Control Meter System Description .......... 96

Meter/gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode .................... 96

Flexible Print Circuit (FPC) .................................. 97

Trouble Diagnoses ............................................... 98

Electrical Components Inspection ..................... 103

WARNING LAMPS................................................ 105

Schematic .......................................................... 105

Wiring Diagram - WARN -/LHD Models ............ 106

Wiring Diagram - WARN -/RHD Models............ 111

Electrical Components Inspection ..................... 116

WARNING BUZZER.............................................. 117

Wiring diagram - BUZZER -/LHD Models for

Europe................................................................ 117

Wiring diagram - BUZZER -/RHD Models for

Europe................................................................ 118

Electrical Components Inspection ..................... 119

FRONT WIPER AND WASHER............................ 120

System Description ............................................ 120

Wiring Diagram - WIPER -/LHD Models with

Intermittent ......................................................... 122Wiring Diagram - WIPER -/RHD Models with

Intermittent ......................................................... 124

Trouble Diagnoses ............................................. 126

Wiper Installation and Adjustment ..................... 127

Washer Nozzle Adjustment ............................... 128

Washer Tube Layout ......................................... 128

Wiper Linkage .................................................... 129

HEADLAMP WASHER.......................................... 130

Wiring Diagram - HLC - ..................................... 130

Trouble Diagnoses ............................................. 131

Washer Tube Layout ......................................... 131

Check Valve ....................................................... 131

HORN..................................................................... 132

Wiring Diagram - HORN -.................................. 132

CIGARETTE LIGHTER.......................................... 133

Wiring Diagram - CIGAR - ................................. 133

CLOCK................................................................... 134

Wiring Diagram - CLOCK - ................................ 134

REAR WINDOW DEFOGGER............................... 135

Wiring Diagram - DEF - ..................................... 135

Electrical Components Inspection ..................... 136

Filament Check .................................................. 136

Filament Repair.................................................. 137

AUDIO.................................................................... 138

Wiring Diagram - AUDIO -/LHD Models Type-

2 ......................................................................... 138

Wiring Diagram - AUDIO -/LHD Models Type-

3 ......................................................................... 139

Wiring Diagram - AUDIO -/RHD Models ........... 141

Trouble Diagnoses ............................................. 142

CATS (Code) System/For Europe RHD ............ 143

NATS Audio Link/For Europe LHD (KA24E) ..... 144

AUDIO ANTENNA................................................. 146

Manual Antenna ................................................. 146

Power Antenna/Wiring Diagram - P/ANT - ........ 147

Power Antenna .................................................. 148

POWER DOOR MIRROR...................................... 150

Wiring Diagram - MIRROR -.............................. 150

HEATED SEAT...................................................... 152

Wiring Diagram - H/SEAT - ............................... 152

POWER WINDOW................................................. 154

System Description ............................................ 154

Schematic .......................................................... 156

Wiring Diagram - WINDOW -/LHD Models ....... 157

Wiring Diagram - WINDOW -/RHD Models ....... 161

Trouble Diagnoses ............................................. 165

POWER DOOR LOCK........................................... 166

System Description ............................................ 166

Wiring Diagram - D/LOCK - ............................... 167

Trouble Diagnosis .............................................. 169

MULTI-REMOTE CONTROL SYSTEM/FOR

EUROPE................................................................ 173

System Description ............................................ 173

Schematic .......................................................... 174

Page 404 of 1659

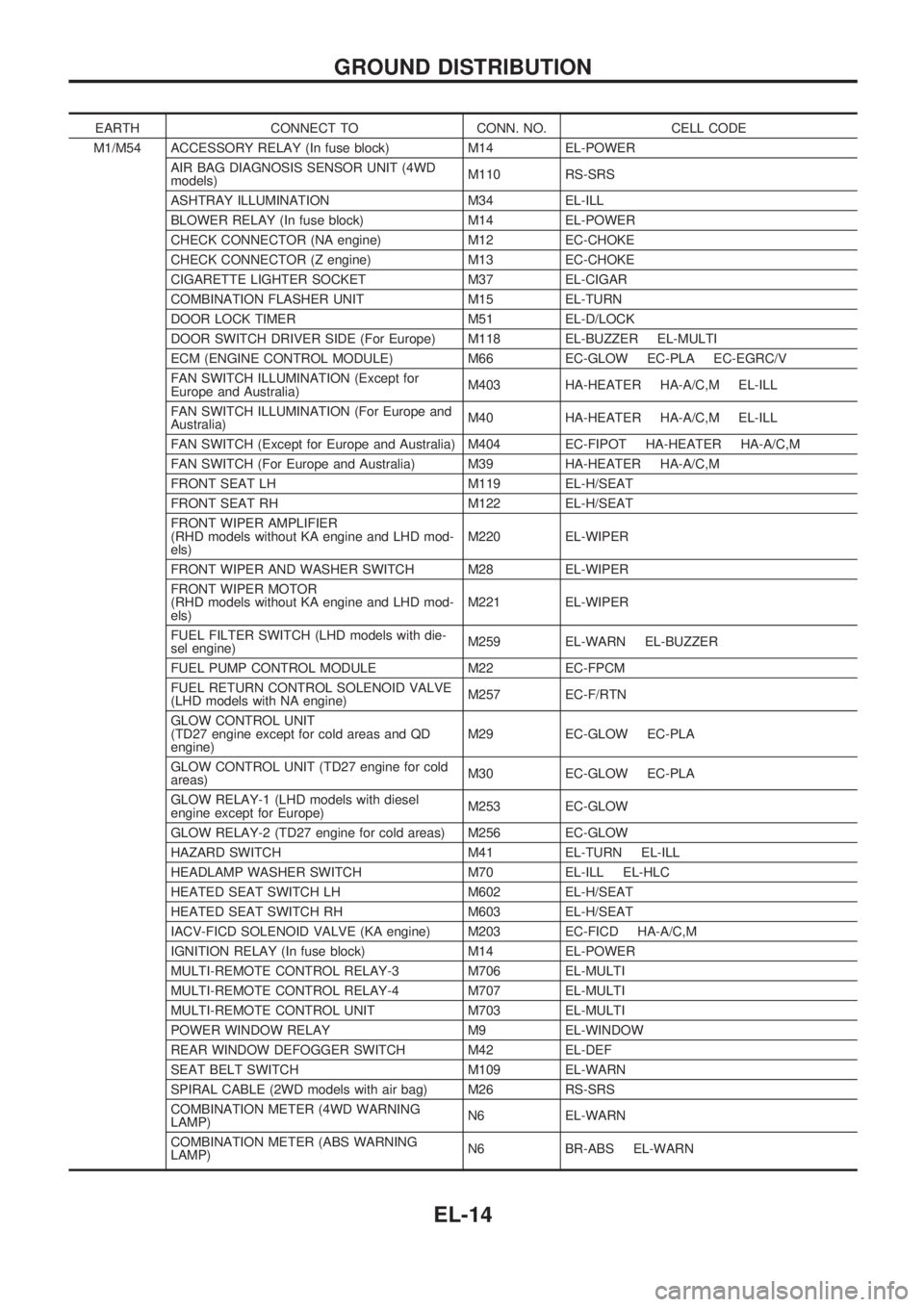

EARTH CONNECT TO CONN. NO. CELL CODE

M1/M54 ACCESSORY RELAY (In fuse block) M14 EL-POWER

AIR BAG DIAGNOSIS SENSOR UNIT (4WD

models)M110 RS-SRS

ASHTRAY ILLUMINATION M34 EL-ILL

BLOWER RELAY (In fuse block) M14 EL-POWER

CHECK CONNECTOR (NA engine) M12 EC-CHOKE

CHECK CONNECTOR (Z engine) M13 EC-CHOKE

CIGARETTE LIGHTER SOCKET M37 EL-CIGAR

COMBINATION FLASHER UNIT M15 EL-TURN

DOOR LOCK TIMER M51 EL-D/LOCK

DOOR SWITCH DRIVER SIDE (For Europe) M118 EL-BUZZER EL-MULTI

ECM (ENGINE CONTROL MODULE) M66 EC-GLOW EC-PLA EC-EGRC/V

FAN SWITCH ILLUMINATION (Except for

Europe and Australia)M403 HA-HEATER HA-A/C,M EL-ILL

FAN SWITCH ILLUMINATION (For Europe and

Australia)M40 HA-HEATER HA-A/C,M EL-ILL

FAN SWITCH (Except for Europe and Australia) M404 EC-FIPOT HA-HEATER HA-A/C,M

FAN SWITCH (For Europe and Australia) M39 HA-HEATER HA-A/C,M

FRONT SEAT LH M119 EL-H/SEAT

FRONT SEAT RH M122 EL-H/SEAT

FRONT WIPER AMPLIFIER

(RHD models without KA engine and LHD mod-

els)M220 EL-WIPER

FRONT WIPER AND WASHER SWITCH M28 EL-WIPER

FRONT WIPER MOTOR

(RHD models without KA engine and LHD mod-

els)M221 EL-WIPER

FUEL FILTER SWITCH (LHD models with die-

sel engine)M259 EL-WARN EL-BUZZER

FUEL PUMP CONTROL MODULE M22 EC-FPCM

FUEL RETURN CONTROL SOLENOID VALVE

(LHD models with NA engine)M257 EC-F/RTN

GLOW CONTROL UNIT

(TD27 engine except for cold areas and QD

engine)M29 EC-GLOW EC-PLA

GLOW CONTROL UNIT (TD27 engine for cold

areas)M30 EC-GLOW EC-PLA

GLOW RELAY-1 (LHD models with diesel

engine except for Europe)M253 EC-GLOW

GLOW RELAY-2 (TD27 engine for cold areas) M256 EC-GLOW

HAZARD SWITCH M41 EL-TURN EL-ILL

HEADLAMP WASHER SWITCH M70 EL-ILL EL-HLC

HEATED SEAT SWITCH LH M602 EL-H/SEAT

HEATED SEAT SWITCH RH M603 EL-H/SEAT

IACV-FICD SOLENOID VALVE (KA engine) M203 EC-FICD HA-A/C,M

IGNITION RELAY (In fuse block) M14 EL-POWER

MULTI-REMOTE CONTROL RELAY-3 M706 EL-MULTI

MULTI-REMOTE CONTROL RELAY-4 M707 EL-MULTI

MULTI-REMOTE CONTROL UNIT M703 EL-MULTI

POWER WINDOW RELAY M9 EL-WINDOW

REAR WINDOW DEFOGGER SWITCH M42 EL-DEF

SEAT BELT SWITCH M109 EL-WARN

SPIRAL CABLE (2WD models with air bag) M26 RS-SRS

COMBINATION METER (4WD WARNING

LAMP)N6 EL-WARN

COMBINATION METER (ABS WARNING

LAMP)N6 BR-ABS EL-WARN

GROUND DISTRIBUTION

EL-14

Page 506 of 1659

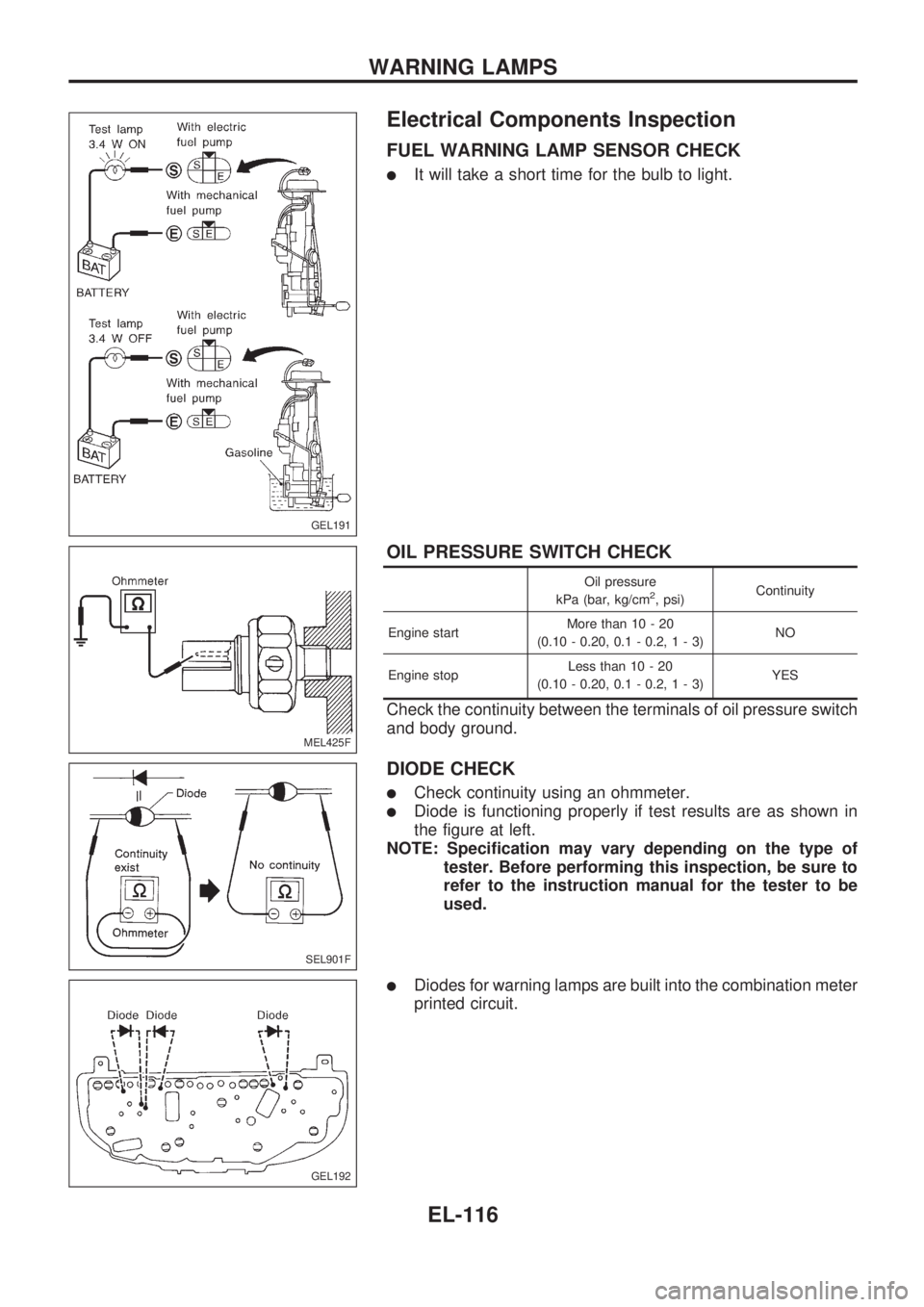

Electrical Components Inspection

FUEL WARNING LAMP SENSOR CHECK

lIt will take a short time for the bulb to light.

OIL PRESSURE SWITCH CHECK

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)NO

Engine stopLess than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

lCheck continuity using an ohmmeter.

lDiode is functioning properly if test results are as shown in

the figure at left.

NOTE: Specification may vary depending on the type of

tester. Before performing this inspection, be sure to

refer to the instruction manual for the tester to be

used.

lDiodes for warning lamps are built into the combination meter

printed circuit.

GEL191

MEL425F

SEL901F

GEL192

WARNING LAMPS

EL-116

Page 507 of 1659

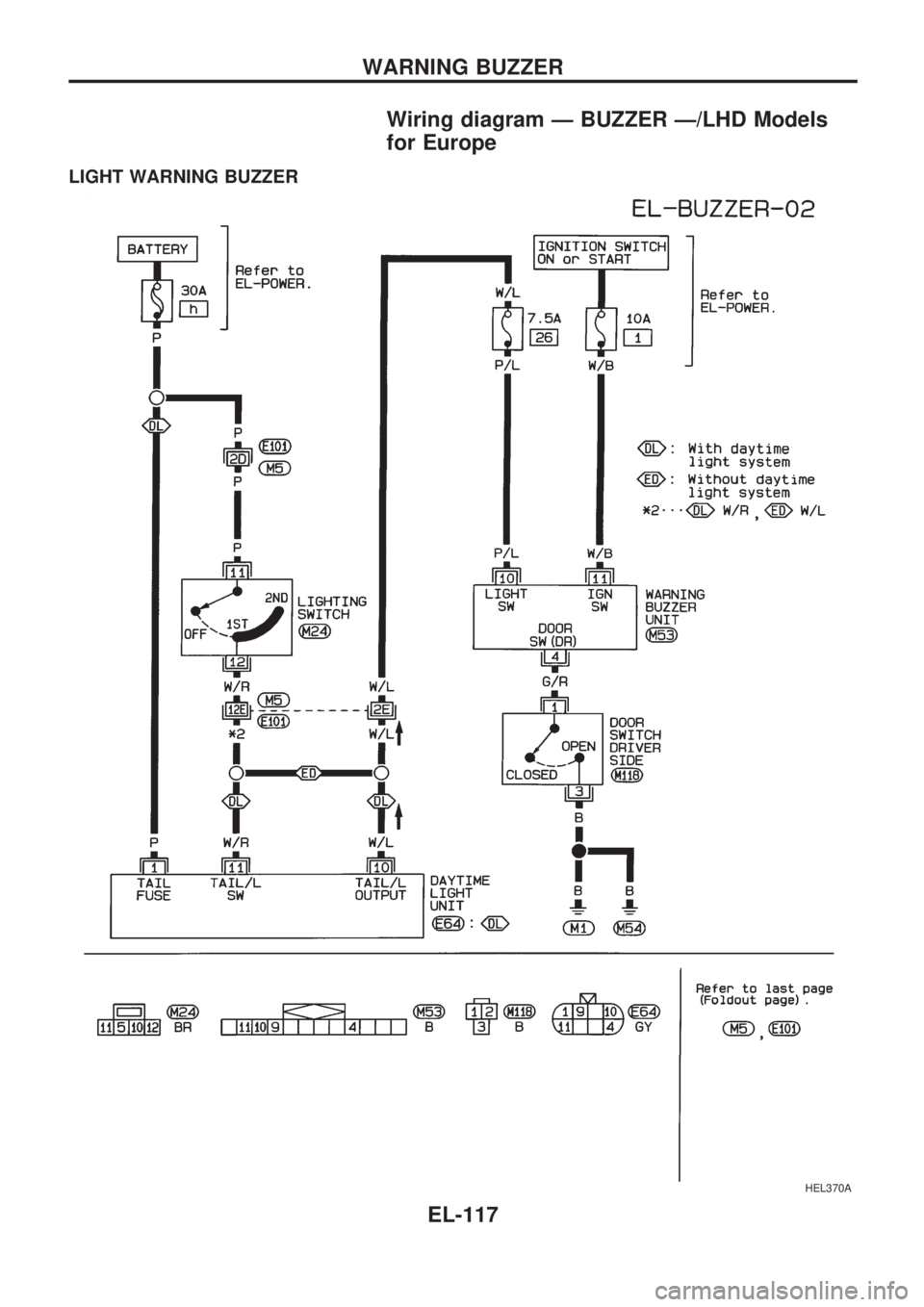

Wiring diagram Ð BUZZER Ð/LHD Models

for Europe

LIGHT WARNING BUZZER

HEL370A

WARNING BUZZER

EL-117

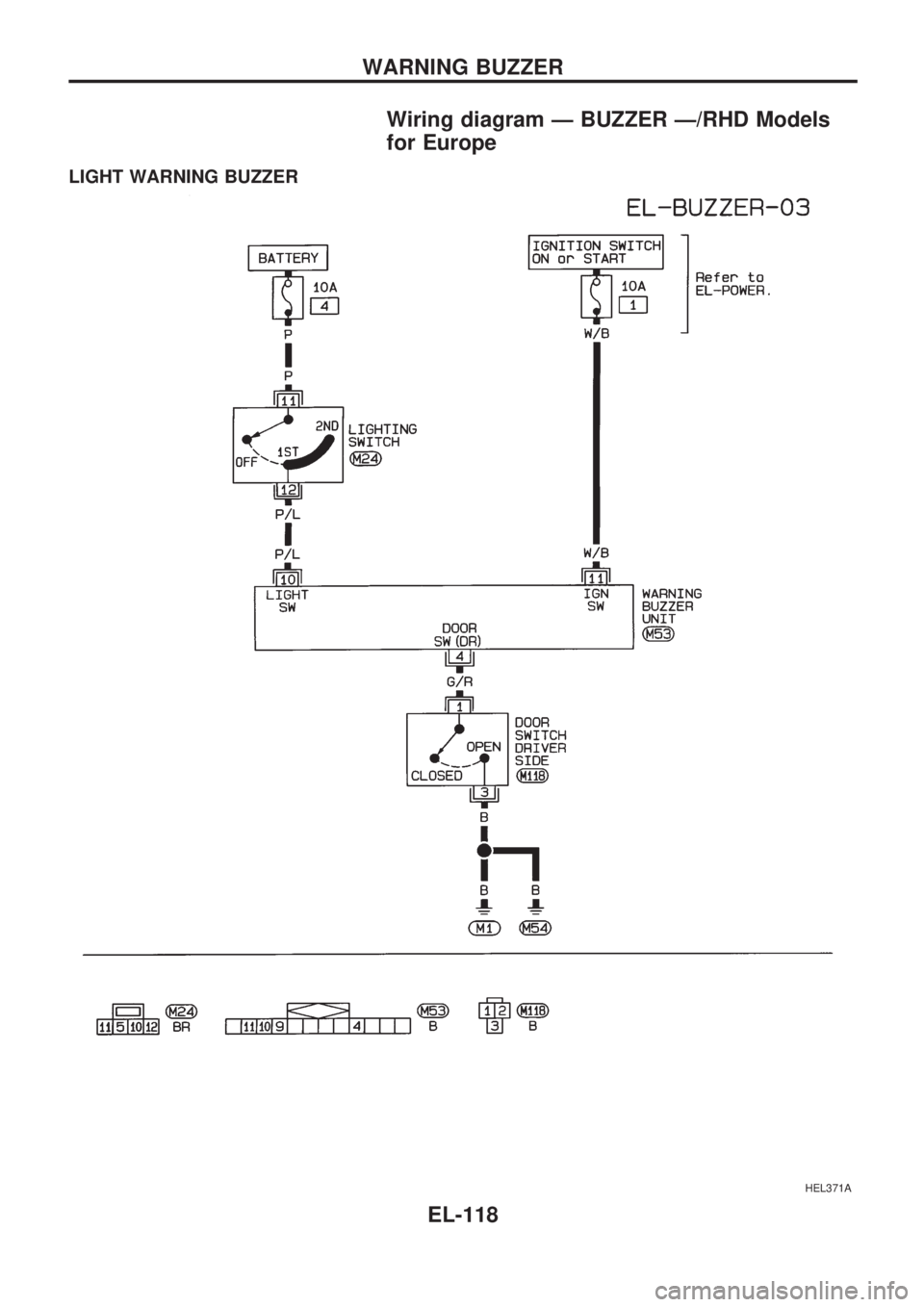

Page 508 of 1659

Wiring diagram Ð BUZZER Ð/RHD Models

for Europe

LIGHT WARNING BUZZER

HEL371A

WARNING BUZZER

EL-118

Page 509 of 1659

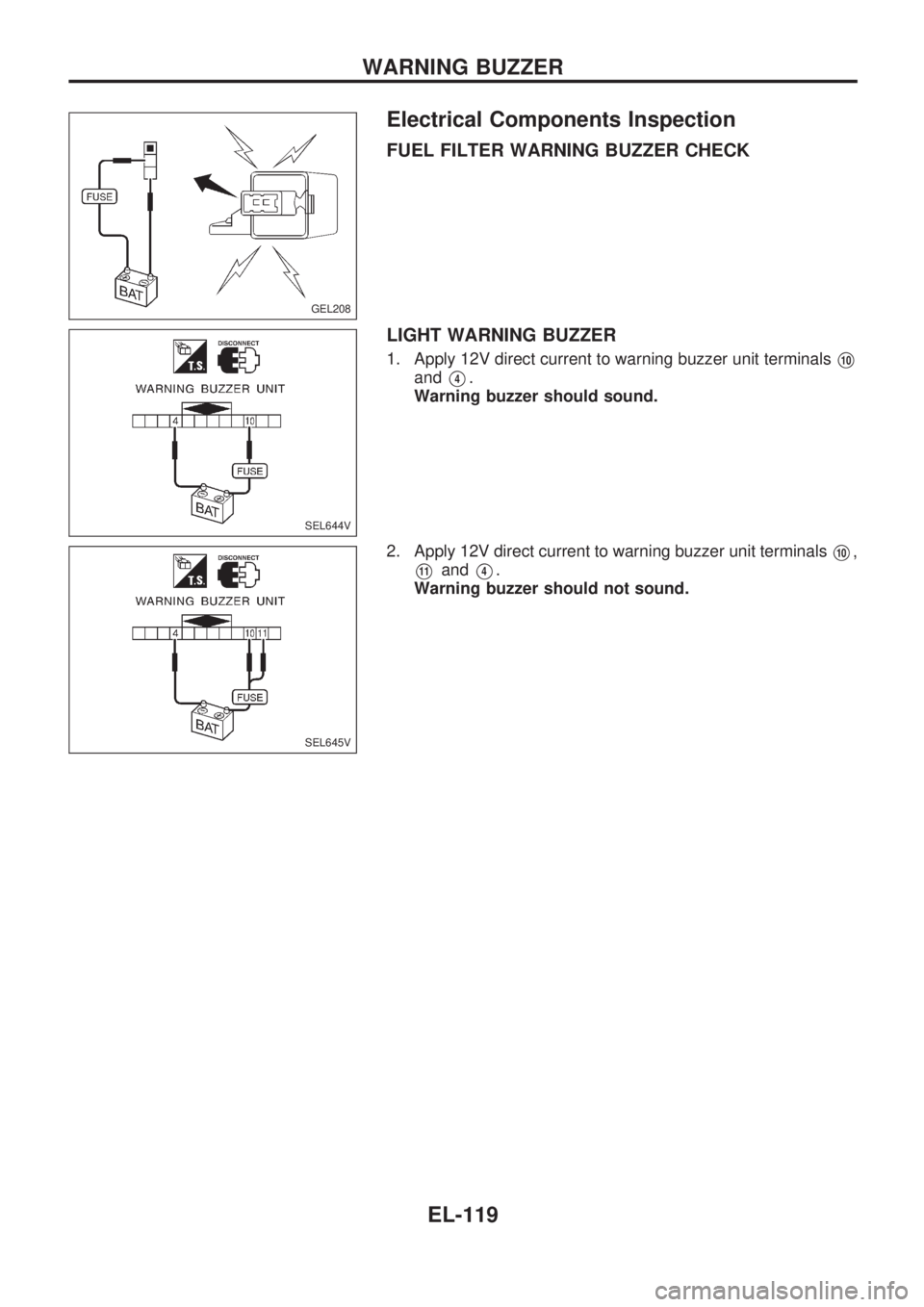

Electrical Components Inspection

FUEL FILTER WARNING BUZZER CHECK

LIGHT WARNING BUZZER

1. Apply 12V direct current to warning buzzer unit terminalsV10

andV4.

Warning buzzer should sound.

2. Apply 12V direct current to warning buzzer unit terminals

V10,

V11andV4.

Warning buzzer should not sound.

GEL208

SEL644V

SEL645V

WARNING BUZZER

EL-119

Page 643 of 1659

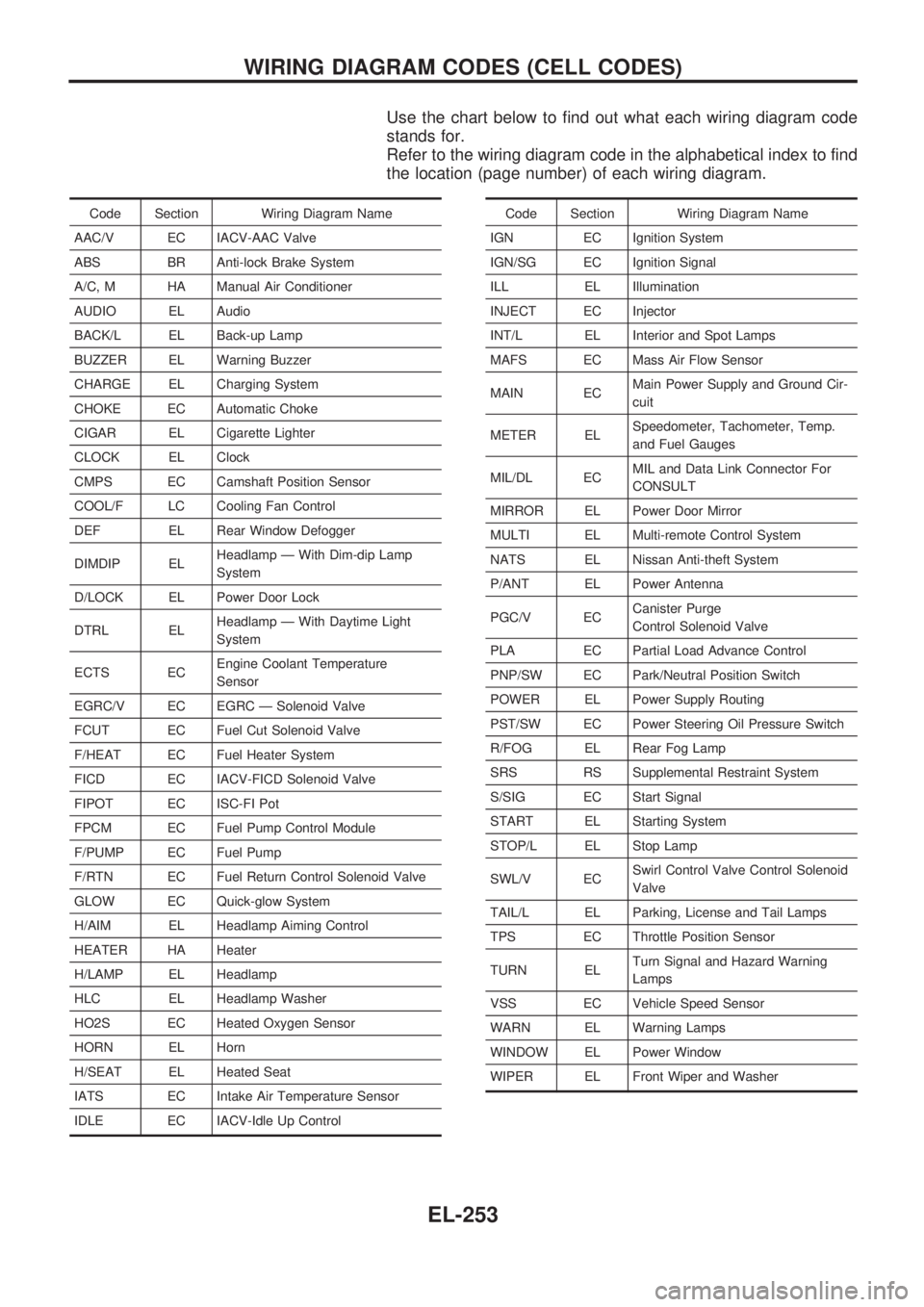

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, M HA Manual Air Conditioner

AUDIO EL Audio

BACK/L EL Back-up Lamp

BUZZER EL Warning Buzzer

CHARGE EL Charging System

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC Cooling Fan Control

DEF EL Rear Window Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

FCUT EC Fuel Cut Solenoid Valve

F/HEAT EC Fuel Heater System

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel Pump

F/RTN EC Fuel Return Control Solenoid Valve

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IDLE EC IACV-Idle Up ControlCode Section Wiring Diagram Name

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior and Spot Lamps

MAFS EC Mass Air Flow Sensor

MAIN ECMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL ECMIL and Data Link Connector For

CONSULT

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

P/ANT EL Power Antenna

PGC/V ECCanister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

Valve

TAIL/L EL Parking, License and Tail Lamps

TPS EC Throttle Position Sensor

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

WARN EL Warning Lamps

WINDOW EL Power Window

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-253

Page 697 of 1659

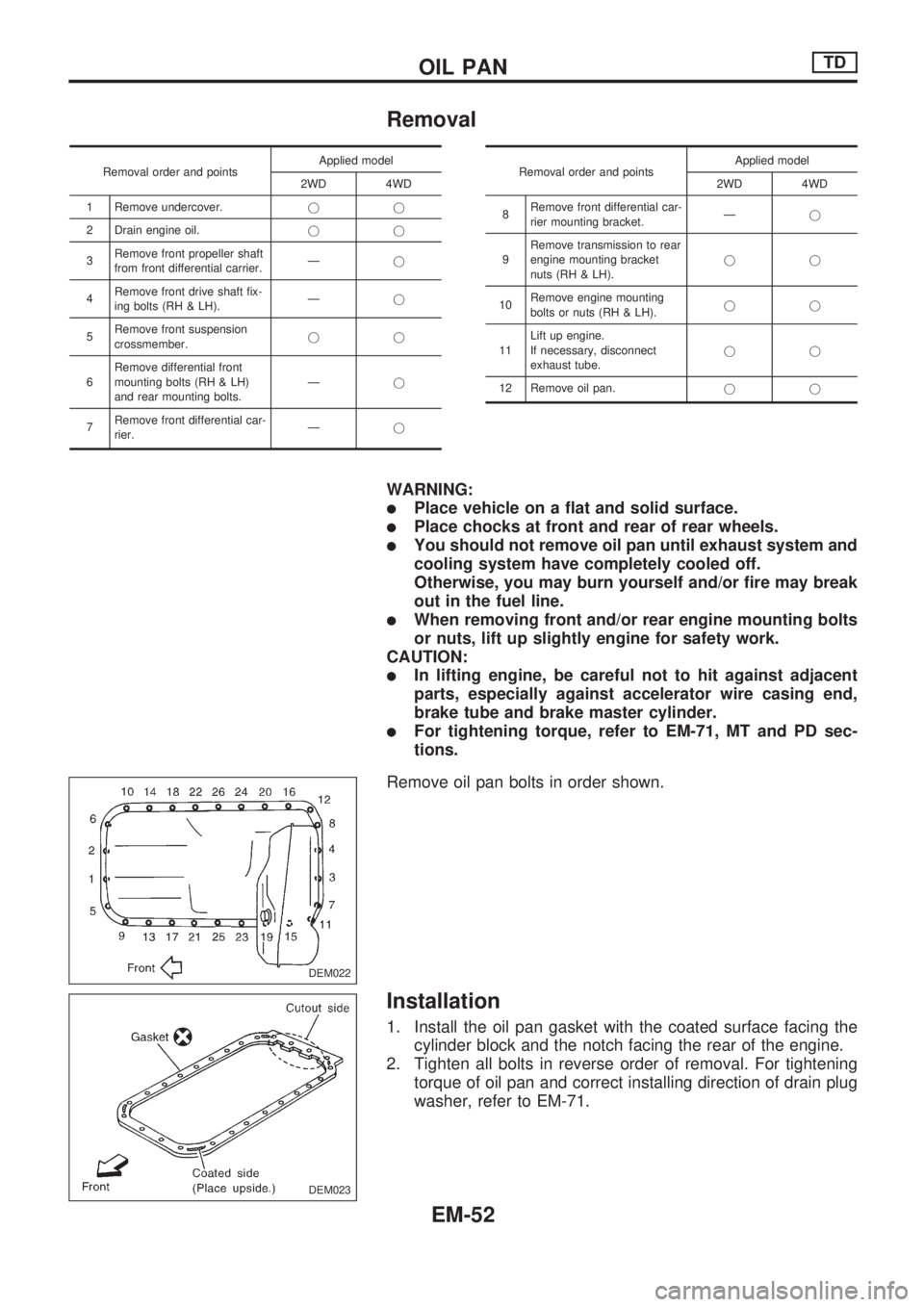

Removal

Removal order and pointsApplied model

2WD 4WD

1 Remove undercover.jj

2 Drain engine oil.jj

3Remove front propeller shaft

from front differential carrier.Ðj

4Remove front drive shaft fix-

ing bolts (RH & LH).Ðj

5Remove front suspension

crossmember.jj

6Remove differential front

mounting bolts (RH & LH)

and rear mounting bolts.Ðj

7Remove front differential car-

rier.ÐjRemoval order and pointsApplied model

2WD 4WD

8Remove front differential car-

rier mounting bracket.Ðj

9Remove transmission to rear

engine mounting bracket

nuts (RH & LH).jj

10Remove engine mounting

bolts or nuts (RH & LH).jj

11Lift up engine.

If necessary, disconnect

exhaust tube.jj

12 Remove oil pan.jj

WARNING:

lPlace vehicle on a flat and solid surface.

lPlace chocks at front and rear of rear wheels.

lYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

lWhen removing front and/or rear engine mounting bolts

or nuts, lift up slightly engine for safety work.

CAUTION:

lIn lifting engine, be careful not to hit against adjacent

parts, especially against accelerator wire casing end,

brake tube and brake master cylinder.

lFor tightening torque, refer to EM-71, MT and PD sec-

tions.

Remove oil pan bolts in order shown.

Installation

1. Install the oil pan gasket with the coated surface facing the

cylinder block and the notch facing the rear of the engine.

2. Tighten all bolts in reverse order of removal. For tightening

torque of oil pan and correct installing direction of drain plug

washer, refer to EM-71.

DEM022

DEM023

OIL PANTD

EM-52