turn signal NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 38 of 1659

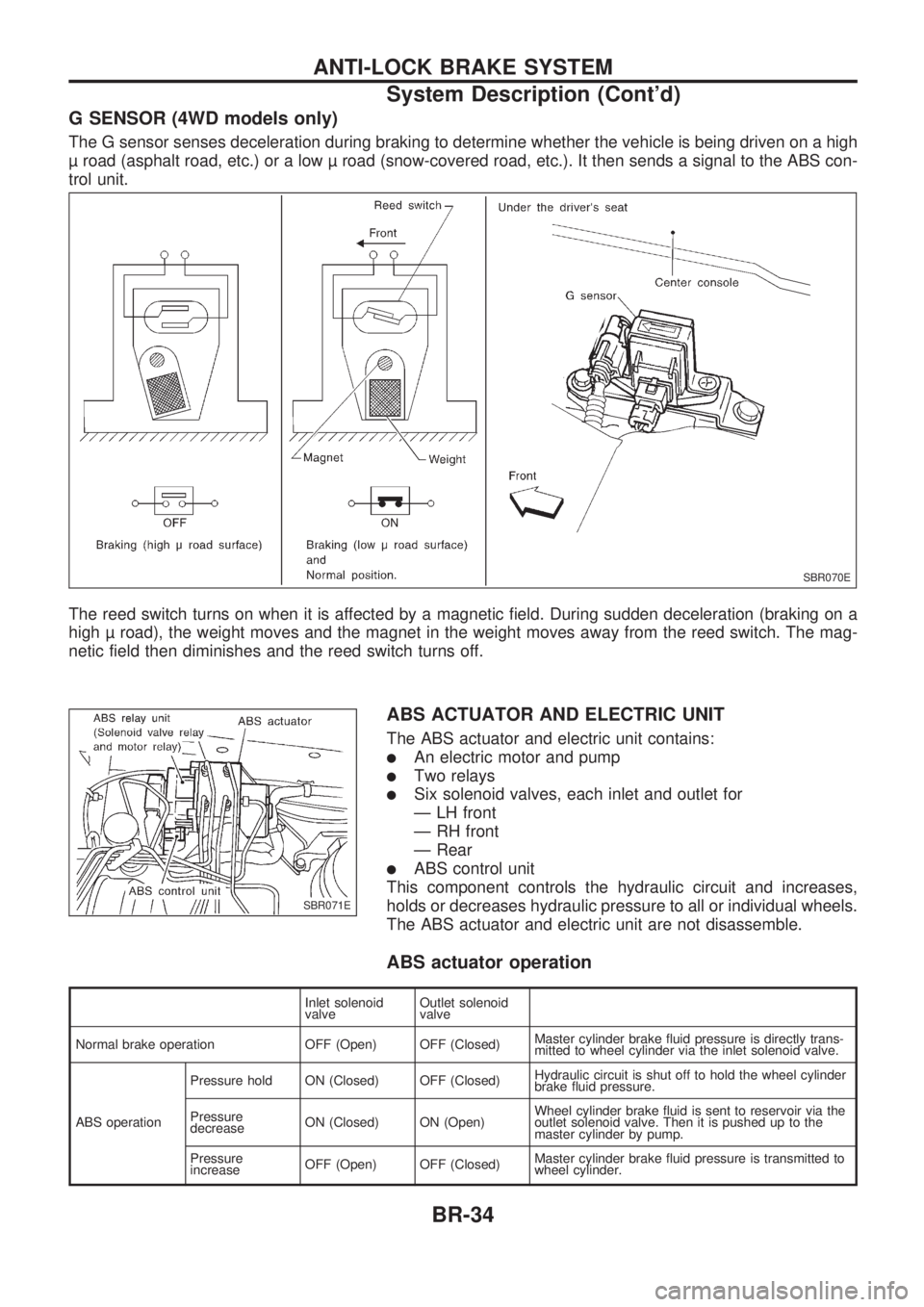

G SENSOR (4WD models only)

The G sensor senses deceleration during braking to determine whether the vehicle is being driven on a high

road (asphalt road, etc.) or a low road (snow-covered road, etc.). It then sends a signal to the ABS con-

trol unit.

The reed switch turns on when it is affected by a magnetic field. During sudden deceleration (braking on a

high road), the weight moves and the magnet in the weight moves away from the reed switch. The mag-

netic field then diminishes and the reed switch turns off.

ABS ACTUATOR AND ELECTRIC UNIT

The ABS actuator and electric unit contains:

lAn electric motor and pump

lTwo relays

lSix solenoid valves, each inlet and outlet for

Ð LH front

Ð RH front

Ð Rear

lABS control unit

This component controls the hydraulic circuit and increases,

holds or decreases hydraulic pressure to all or individual wheels.

The ABS actuator and electric unit are not disassemble.

ABS actuator operation

Inlet solenoid

valveOutlet solenoid

valve

Normal brake operation OFF (Open) OFF (Closed)Master cylinder brake fluid pressure is directly trans-

mitted to wheel cylinder via the inlet solenoid valve.

ABS operationPressure hold ON (Closed) OFF (Closed)Hydraulic circuit is shut off to hold the wheel cylinder

brake fluid pressure.

Pressure

decreaseON (Closed) ON (Open)Wheel cylinder brake fluid is sent to reservoir via the

outlet solenoid valve. Then it is pushed up to the

master cylinder by pump.

Pressure

increaseOFF (Open) OFF (Closed)Master cylinder brake fluid pressure is transmitted to

wheel cylinder.

SBR070E

SBR071E

ANTI-LOCK BRAKE SYSTEM

System Description (Cont'd)

BR-34

Page 62 of 1659

![NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when ...Diagnostic

procedure

FR RH SENSOR.1

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input vol NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when ...Diagnostic

procedure

FR RH SENSOR.1

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input vol](/img/5/57374/w960_57374-61.png)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when ...Diagnostic

procedure

FR RH SENSOR.1

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input voltage is entered.)1

FR LH SENSOR.1

[OPEN]

lCircuit for front left wheel sensor is open.

(An abnormally high input voltage is entered.)1

RR SENSOR.1,.2

[OPEN]

lCircuit for rear sensor is open.

(An abnormal high input voltage is entered.)1

RR RH SENSOR.1,.3

[OPEN]

lCircuit for rear right sensor is open.

(An abnormally high input voltage is entered.)1

RR LH SENSOR.1,.3

[OPEN]

lCircuit for rear left sensor is open.

(An abnormally high input voltage is entered.)1

FR RH SENSOR.1

[SHORT]

lCircuit for front right wheel sensor is shorted.

(An abnormally low input voltage is entered.)1

FR LH SENSOR.1

[SHORT]

lCircuit for front left wheel sensor is shorted.

(An abnormally low input voltage is entered.)1

RR SENSOR.1,.2

[SHORT]

lCircuit for rear sensor is shorted.

(An abnormal low input voltage is entered.)1

RR RH SENSOR.1,.3

[SHORT]

lCircuit for rear right sensor is shorted.

(An abnormally low input voltage is entered.)1

RR LH SENSOR.1,.3

[SHORT]

lCircuit for rear left sensor is shorted.

(An abnormally low input voltage is entered.)1

ABS SENSOR.1

[ABNORMAL SIGNAL]

lTeeth damage on sensor rotor or improper installation of wheel sensor.

(Abnormal wheel sensor signal is entered.)1

FR RH IN ABS SOL

[OPEN]

lCircuit for front right inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR LH IN ABS SOL

[OPEN]

lCircuit for front left inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR IN ABS SOL

[OPEN]

lCircuit for rear inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR RH IN ABS SOL

[SHORT]

lCircuit for front right inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR LH IN ABS SOL

[SHORT]

lCircuit for front left inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR IN ABS SOL

[SHORT]

lCircuit for rear inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR RH OUT ABS SOL

[OPEN]

lCircuit for front right outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR LH OUT ABS SOL

[OPEN]

lCircuit for front left outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR OUT ABS SOL

[OPEN]

lCircuit for rear outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR RH OUT ABS SOL

[SHORT]

lCircuit for front right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR LH OUT ABS SOL

[SHORT]

lCircuit for front left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR OUT ABS SOL

[SHORT]

lCircuit for rear outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

ABS ACTUATOR RELAY

[ABNORMAL]

lActuator solenoid valve relay is ON, even if control unit sends off signal.lActuator solenoid valve relay is OFF, even if control unit sends on signal.2

ABS MOTOR RELAY

[ABNORMAL]

lCircuit for ABS motor relay is open or shorted.lCircuit for actuator motor is open or shorted.lActuator motor relay is stuck.3

BATTERY VOLT

[VB-LOW]

lPower source voltage supplied to ABS control unit is abnormally low. 4

CONTROL UNIT

lFunction of calculation in ABS control unit has failed. 6

G-SENSOR.3

[ABNORMAL]

lG sensor circuit is open or shorted. 5

.1: If one or more wheels spin on a rough or slippery road for 40 seconds or more, the ABS warning lamp will illuminate. This

does not indicate a malfunction. Only in the case of the short-circuit (Code Nos. 26, 22, 32 and 36), after repair the ABS warn-

ing lamp also illuminates when the ignition switch is turned ``ON''. In this case, drive the vehicle at speeds greater than 30 km/h

(19 MPH) for approximately 1 minute as specified in ``SELF-DIAGNOSIS PROCEDURE'', BR-53. Check to ensure that the ABS

warning lamp goes out while the vehicle is being driven.

.2: 2WD model only

.3: 4WD model only

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-58

Page 65 of 1659

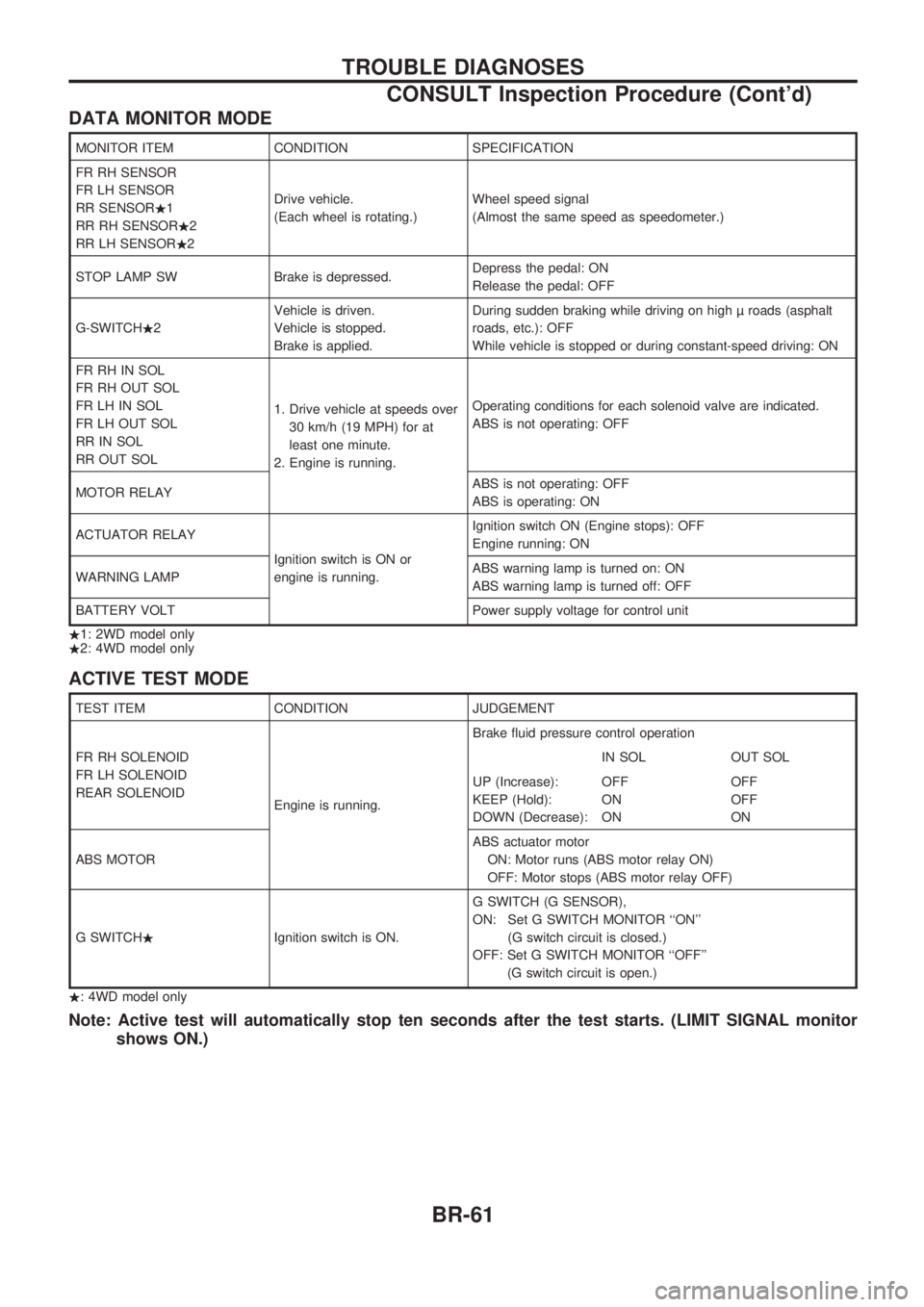

DATA MONITOR MODE

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR SENSOR.1

RR RH SENSOR.2

RR LH SENSOR.2Drive vehicle.

(Each wheel is rotating.)Wheel speed signal

(Almost the same speed as speedometer.)

STOP LAMP SW Brake is depressed.Depress the pedal: ON

Release the pedal: OFF

G-SWITCH.2Vehicle is driven.

Vehicle is stopped.

Brake is applied.During sudden braking while driving on high roads (asphalt

roads, etc.): OFF

While vehicle is stopped or during constant-speed driving: ON

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL1. Drive vehicle at speeds over

30 km/h (19 MPH) for at

least one minute.

2. Engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY

Ignition switch is ON or

engine is running.Ignition switch ON (Engine stops): OFF

Engine running: ON

WARNING LAMPABS warning lamp is turned on: ON

ABS warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

.1: 2WD model only

.2: 4WD model only

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

REAR SOLENOID

Engine is running.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase):

KEEP (Hold):

DOWN (Decrease):OFF

ON

ONOFF

OFF

ON

ABS MOTORABS actuator motor

ON: Motor runs (ABS motor relay ON)

OFF: Motor stops (ABS motor relay OFF)

G SWITCH.Ignition switch is ON.G SWITCH (G SENSOR),

ON: Set G SWITCH MONITOR ``ON''

(G switch circuit is closed.)

OFF: Set G SWITCH MONITOR ``OFF''

(G switch circuit is open.)

.: 4WD model only

Note: Active test will automatically stop ten seconds after the test starts. (LIMIT SIGNAL monitor

shows ON.)

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-61

Page 158 of 1659

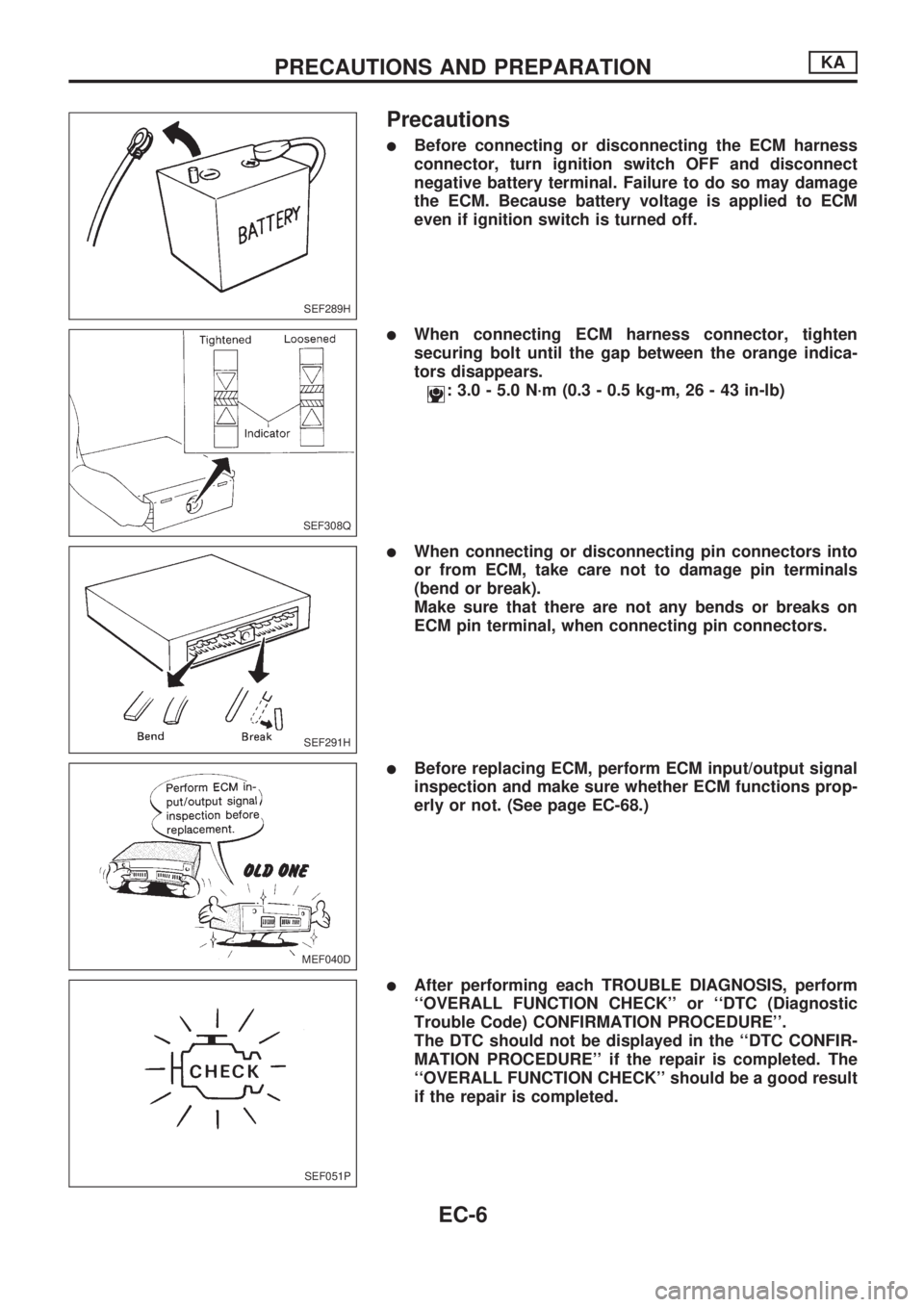

Precautions

lBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect

negative battery terminal. Failure to do so may damage

the ECM. Because battery voltage is applied to ECM

even if ignition switch is turned off.

lWhen connecting ECM harness connector, tighten

securing bolt until the gap between the orange indica-

tors disappears.

: 3.0 - 5.0 N´m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

lWhen connecting or disconnecting pin connectors into

or from ECM, take care not to damage pin terminals

(bend or break).

Make sure that there are not any bends or breaks on

ECM pin terminal, when connecting pin connectors.

lBefore replacing ECM, perform ECM input/output signal

inspection and make sure whether ECM functions prop-

erly or not. (See page EC-68.)

lAfter performing each TROUBLE DIAGNOSIS, perform

``OVERALL FUNCTION CHECK'' or ``DTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDURE''.

The DTC should not be displayed in the ``DTC CONFIR-

MATION PROCEDURE'' if the repair is completed. The

``OVERALL FUNCTION CHECK'' should be a good result

if the repair is completed.

SEF289H

SEF308Q

SEF291H

MEF040D

SEF051P

PRECAUTIONS AND PREPARATIONKA

EC-6

Page 170 of 1659

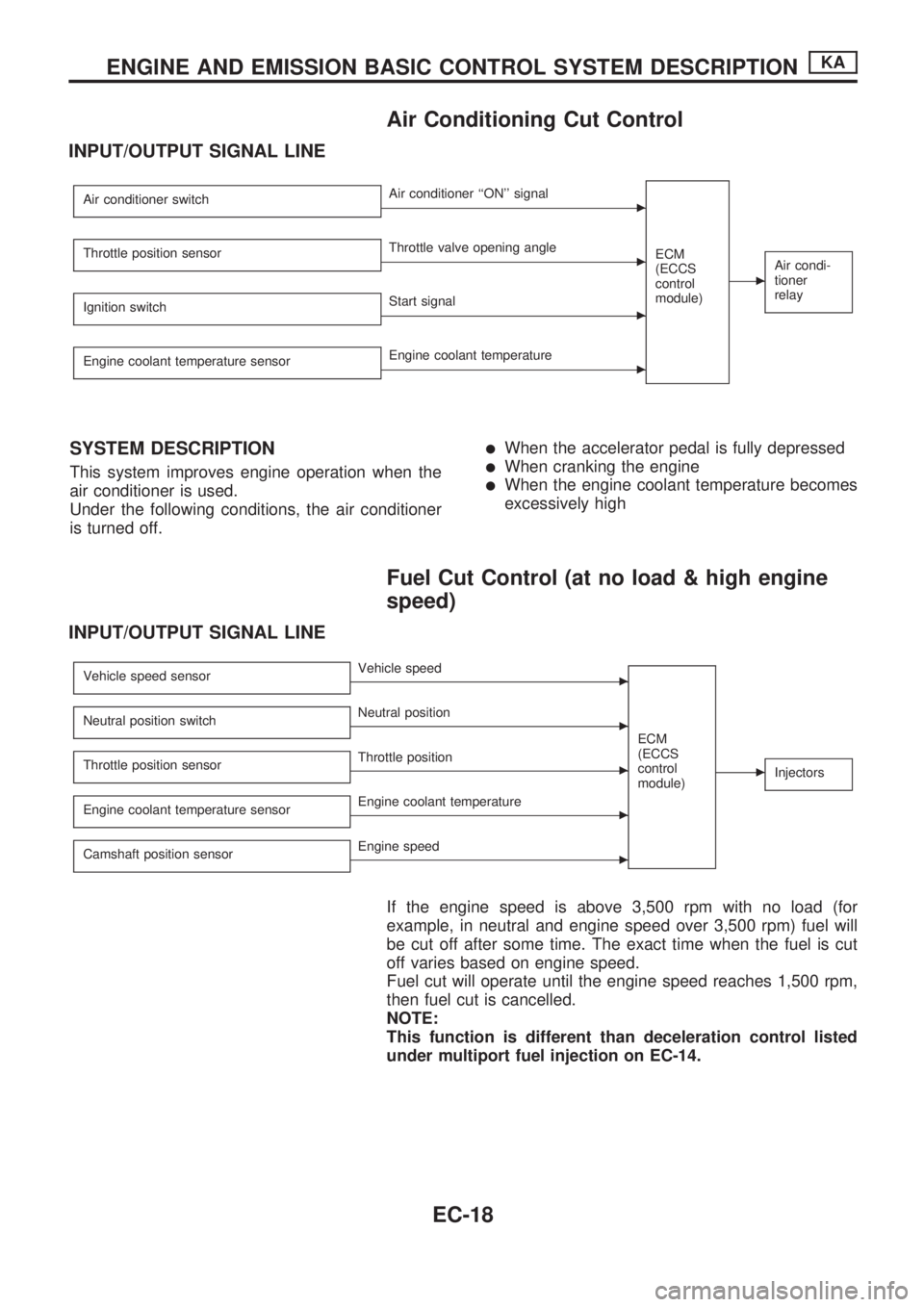

Air Conditioning Cut Control

INPUT/OUTPUT SIGNAL LINE

Air conditioner switchcAir conditioner ``ON'' signal

ECM

(ECCS

control

module)

cAir condi-

tioner

relayThrottle position sensorcThrottle valve opening angle

Ignition switch

cStart signal

Engine coolant temperature sensor

cEngine coolant temperature

SYSTEM DESCRIPTION

This system improves engine operation when the

air conditioner is used.

Under the following conditions, the air conditioner

is turned off.

lWhen the accelerator pedal is fully depressed

lWhen cranking the engine

lWhen the engine coolant temperature becomes

excessively high

Fuel Cut Control (at no load & high engine

speed)

INPUT/OUTPUT SIGNAL LINE

Vehicle speed sensorcVehicle speed

ECM

(ECCS

control

module)

cInjectors

Neutral position switchcNeutral position

Throttle position sensor

cThrottle position

Engine coolant temperature sensor

cEngine coolant temperature

Camshaft position sensor

cEngine speed

If the engine speed is above 3,500 rpm with no load (for

example, in neutral and engine speed over 3,500 rpm) fuel will

be cut off after some time. The exact time when the fuel is cut

off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm,

then fuel cut is cancelled.

NOTE:

This function is different than deceleration control listed

under multiport fuel injection on EC-14.

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONKA

EC-18

Page 198 of 1659

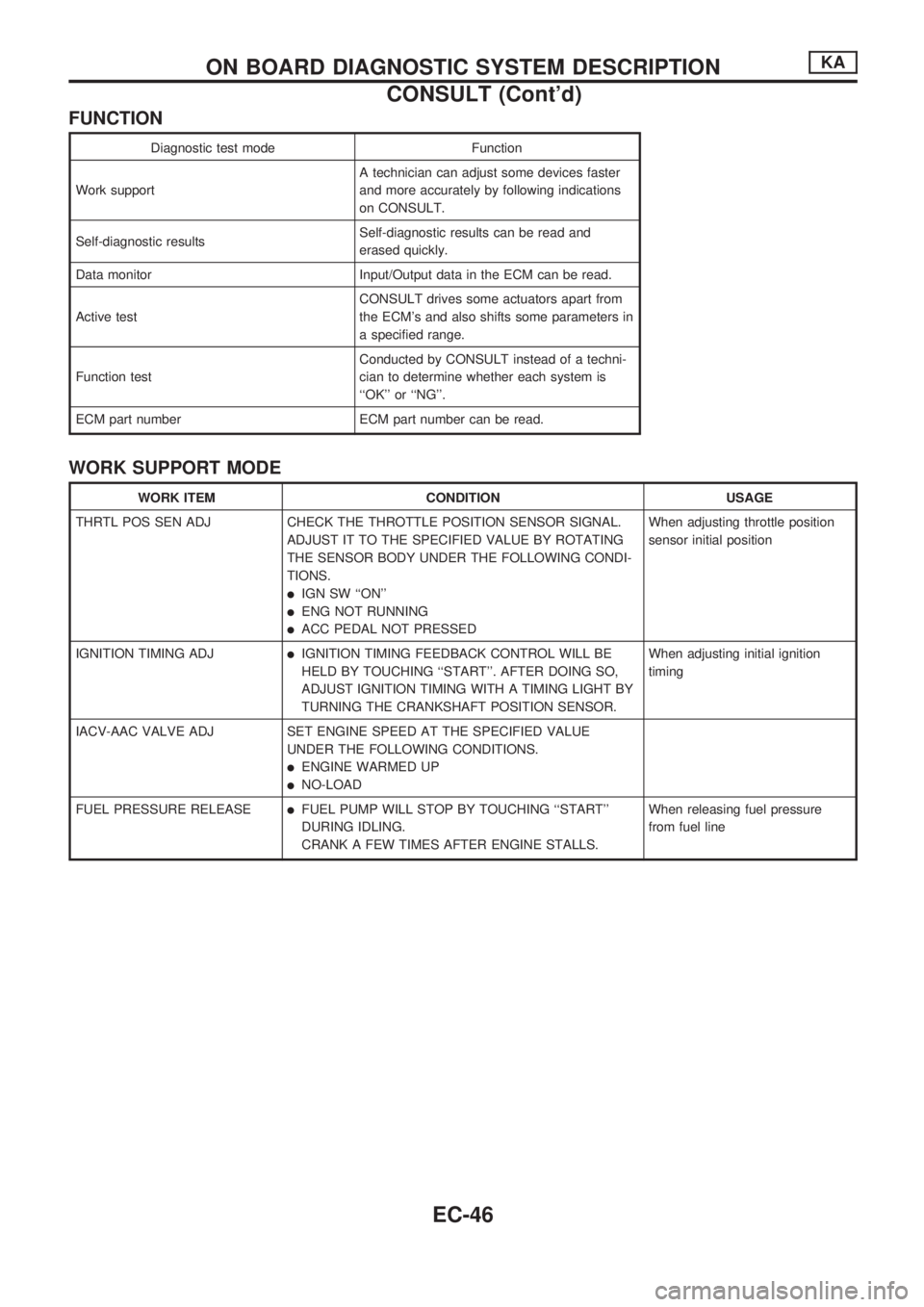

FUNCTION

Diagnostic test mode Function

Work supportA technician can adjust some devices faster

and more accurately by following indications

on CONSULT.

Self-diagnostic resultsSelf-diagnostic results can be read and

erased quickly.

Data monitor Input/Output data in the ECM can be read.

Active testCONSULT drives some actuators apart from

the ECM's and also shifts some parameters in

a specified range.

Function testConducted by CONSULT instead of a techni-

cian to determine whether each system is

``OK'' or ``NG''.

ECM part number ECM part number can be read.

WORK SUPPORT MODE

WORK ITEM CONDITION USAGE

THRTL POS SEN ADJ CHECK THE THROTTLE POSITION SENSOR SIGNAL.

ADJUST IT TO THE SPECIFIED VALUE BY ROTATING

THE SENSOR BODY UNDER THE FOLLOWING CONDI-

TIONS.

lIGN SW ``ON''

lENG NOT RUNNING

lACC PEDAL NOT PRESSEDWhen adjusting throttle position

sensor initial position

IGNITION TIMING ADJ

lIGNITION TIMING FEEDBACK CONTROL WILL BE

HELD BY TOUCHING ``START''. AFTER DOING SO,

ADJUST IGNITION TIMING WITH A TIMING LIGHT BY

TURNING THE CRANKSHAFT POSITION SENSOR.When adjusting initial ignition

timing

IACV-AAC VALVE ADJ SET ENGINE SPEED AT THE SPECIFIED VALUE

UNDER THE FOLLOWING CONDITIONS.

lENGINE WARMED UP

lNO-LOAD

FUEL PRESSURE RELEASE

lFUEL PUMP WILL STOP BY TOUCHING ``START''

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure

from fuel line

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-46

Page 200 of 1659

![NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr](/img/5/57374/w960_57374-199.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS'' mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX'', EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CMPSRPM

(POS) [rpm]

jj

lIndicates the engine speed computed

from the POS signal (1É signal) of the

camshaft position sensor.

MAS AIR/FL SE [V]

jjlThe signal voltage of the mass air flow

sensor is displayed.lWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj

lThe engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.lWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine coolant

temperature determined by the ECM is

displayed.

O2 SEN [V]

jjlThe signal voltage of the heated oxygen

sensor is displayed.lLHD models only

M/R F/C MNT

[RICH/LEAN]

jj

lDisplay of heated oxygen sensor signal

during air-fuel ratio feedback control:

RICH ... means the mixture became

``rich'', and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

``lean'', and control is being affected

toward a rich mixture.lAfter turning ON the ignition switch,

``RICH'' is displayed until air-fuel mixture

ratio feedback control begins.

lWhen the air-fuel ratio feedback is

clamped, the value just before the clamp-

ing is displayed continuously.

lLHD models only

VHCL SPEED SE

[km/h] or [mph]

jjlThe vehicle speed computed from the

vehicle speed sensor signal is displayed.

BATTERY VOLT [V]

jjlThe power supply voltage of ECM is dis-

played.

THRTL POS SEN [V]

jjlThe throttle position sensor signal volt-

age is displayed.

INT/A TEMP SE

[ÉC] or [ÉF]

j

lThe intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

START SIGNAL

[ON/OFF]

jjlIndicates [ON/OFF] condition from the

starter signal.lAfter starting the engine, [OFF] is

displayed regardless of the starter signal.

CLSD THL/POSI

[ON/OFF]

jj

lIndicates [ON/OFF] condition from the

throttle position sensor signal.

AIR COND SIG

[ON/OFF]

jj

lIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]

jj

lIndicates [ON/OFF] condition from the

park/neutral position switch signal.

PW/ST SIGNAL

[ON/OFF]

jj

l[ON/OFF] condition of the power steering

oil pressure switch determined by the

power steering oil pressure signal is indi-

cated.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-48

Page 202 of 1659

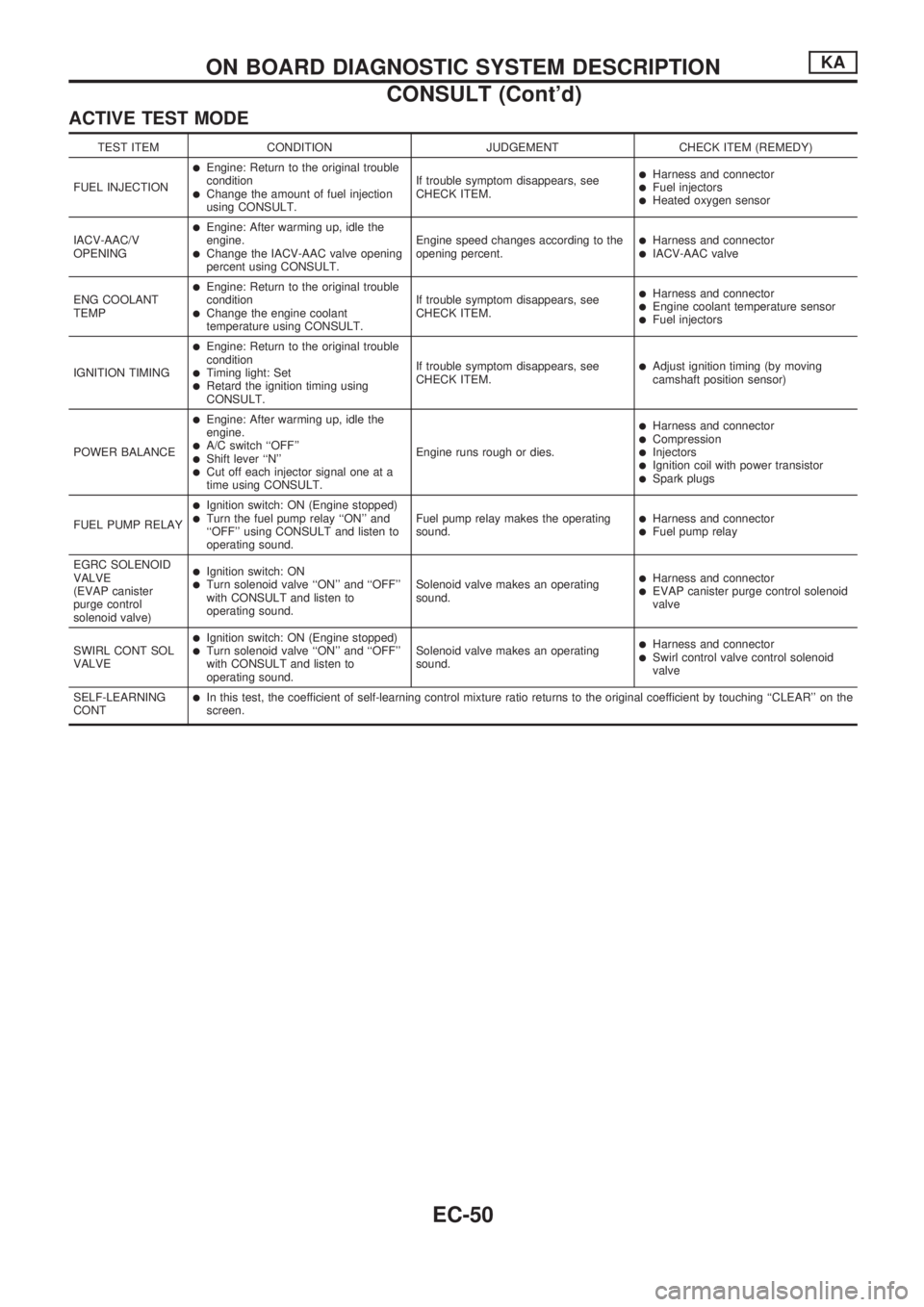

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTION

lEngine: Return to the original trouble

condition

lChange the amount of fuel injection

using CONSULT.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectorlFuel injectorslHeated oxygen sensor

IACV-AAC/V

OPENING

lEngine: After warming up, idle the

engine.

lChange the IACV-AAC valve opening

percent using CONSULT.Engine speed changes according to the

opening percent.lHarness and connectorlIACV-AAC valve

ENG COOLANT

TEMP

lEngine: Return to the original trouble

condition

lChange the engine coolant

temperature using CONSULT.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectorlEngine coolant temperature sensorlFuel injectors

IGNITION TIMING

lEngine: Return to the original trouble

condition

lTiming light: SetlRetard the ignition timing using

CONSULT.If trouble symptom disappears, see

CHECK ITEM.

lAdjust ignition timing (by moving

camshaft position sensor)

POWER BALANCE

lEngine: After warming up, idle the

engine.

lA/C switch ``OFF''lShift lever ``N''lCut off each injector signal one at a

time using CONSULT.Engine runs rough or dies.

lHarness and connectorlCompressionlInjectorslIgnition coil with power transistorlSpark plugs

FUEL PUMP RELAY

lIgnition switch: ON (Engine stopped)lTurn the fuel pump relay ``ON'' and

``OFF'' using CONSULT and listen to

operating sound.Fuel pump relay makes the operating

sound.lHarness and connectorlFuel pump relay

EGRC SOLENOID

VALVE

(EVAP canister

purge control

solenoid valve)

lIgnition switch: ONlTurn solenoid valve ``ON'' and ``OFF''

with CONSULT and listen to

operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlEVAP canister purge control solenoid

valve

SWIRL CONT SOL

VALVE

lIgnition switch: ON (Engine stopped)lTurn solenoid valve ``ON'' and ``OFF''

with CONSULT and listen to

operating sound.Solenoid valve makes an operating

sound.lHarness and connectorlSwirl control valve control solenoid

valve

SELF-LEARNING

CONT

lIn this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching ``CLEAR'' on the

screen.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-50

Page 214 of 1659

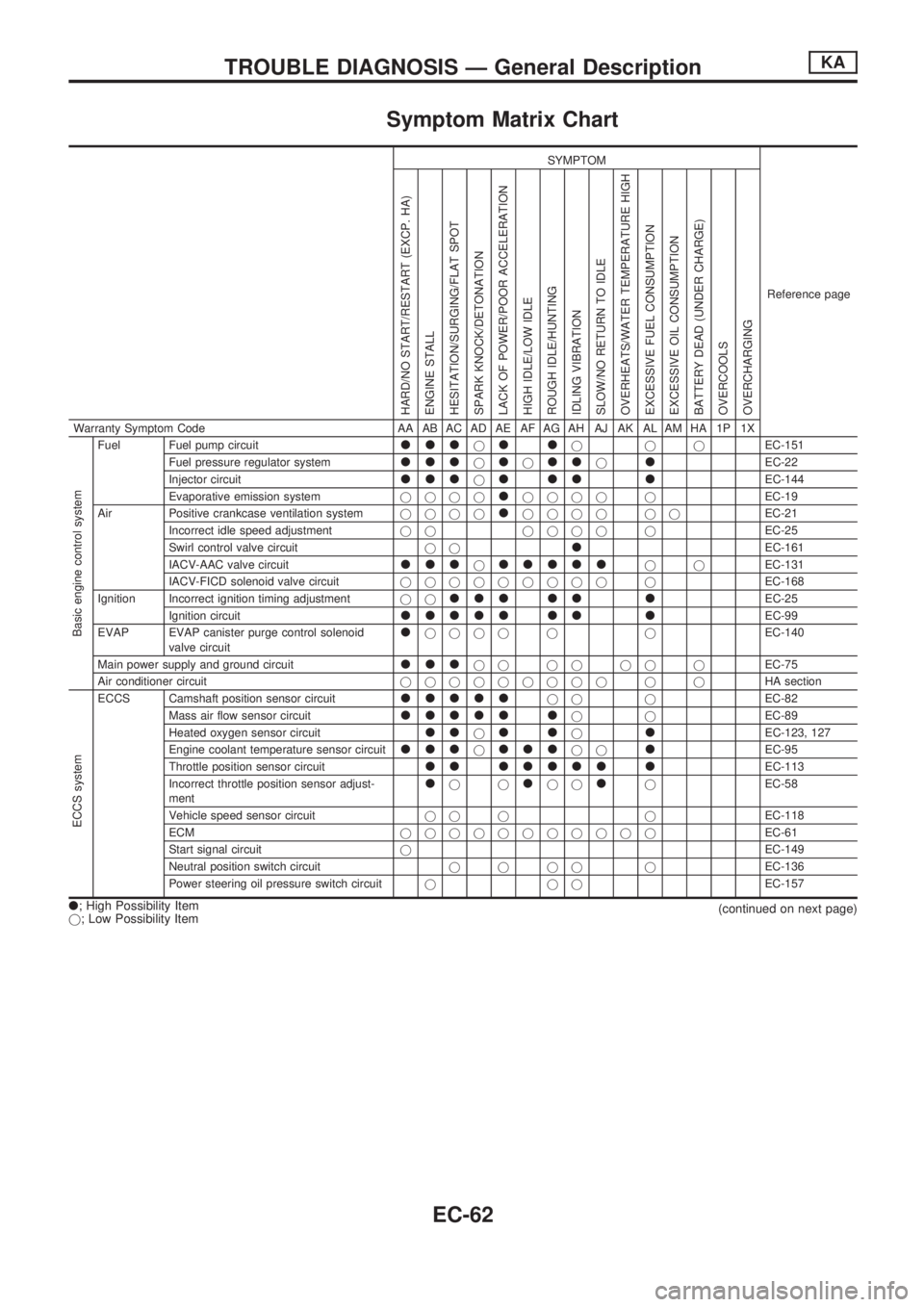

Symptom Matrix Chart

SYMPTOM

Reference page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

OVERCOOLS

OVERCHARGING

Warranty Symptom Code AA AB AC AD AE AF AG AH AJ AK AL AM HA 1P 1X

Basic engine control system

Fuel Fuel pump circuitllljlljjjEC-151

Fuel pressure regulator system

llljljlljlEC-22

Injector circuit

llljlll lEC-144

Evaporative emission systemjjjj

ljjjj jEC-19

Air Positive crankcase ventilation systemjjjj

ljjjj jjEC-21

Incorrect idle speed adjustmentjj jjjj jEC-25

Swirl control valve circuitjj

lEC-161

IACV-AAC valve circuit

llljllllljjEC-131

IACV-FICD solenoid valve circuitjjjjjjjjj jEC-168

Ignition Incorrect ignition timing adjustmentjj

lll ll lEC-25

Ignition circuit

lllll ll lEC-99

EVAP EVAP canister purge control solenoid

valve circuit

ljjjj j jEC-140

Main power supply and ground circuit

llljj jj jj jEC-75

Air conditioner circuitjjjjjjjjj j jHA section

ECCS system

ECCS Camshaft position sensor circuitllllljj jEC-82

Mass air flow sensor circuit

lllll ljjEC-89

Heated oxygen sensor circuit

lljlljlEC-123, 127

Engine coolant temperature sensor circuit

llljllljjlEC-95

Throttle position sensor circuit

ll lllll lEC-113

Incorrect throttle position sensor adjust-

ment

ljjljjljEC-58

Vehicle speed sensor circuitjj j jEC-118

ECMjjjjjjjjjjjEC-61

Start signal circuitjEC-149

Neutral position switch circuitjjjj jEC-136

Power steering oil pressure switch circuitjjjEC-157

l; High Possibility Item

j; Low Possibility Item(continued on next page)

TROUBLE DIAGNOSIS Ð General DescriptionKA

EC-62

Page 216 of 1659

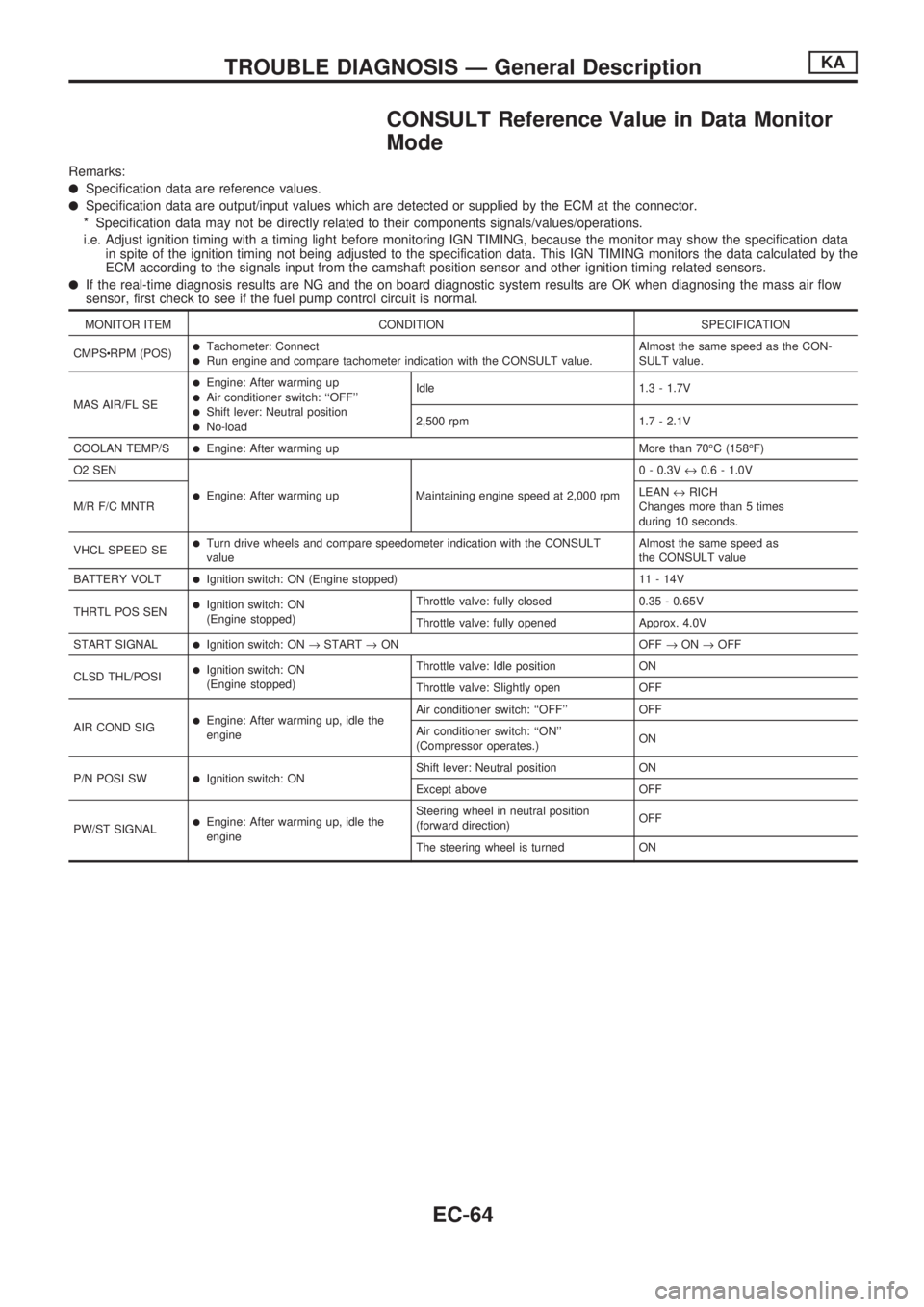

CONSULT Reference Value in Data Monitor

Mode

Remarks:

lSpecification data are reference values.

lSpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data

in spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the

ECM according to the signals input from the camshaft position sensor and other ignition timing related sensors.

lIf the real-time diagnosis results are NG and the on board diagnostic system results are OK when diagnosing the mass air flow

sensor, first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

CMPScRPM (POS)

lTachometer: ConnectlRun engine and compare tachometer indication with the CONSULT value.Almost the same speed as the CON-

SULT value.

MAS AIR/FL SE

lEngine: After warming uplAir conditioner switch: ``OFF''lShift lever: Neutral positionlNo-loadIdle 1.3 - 1.7V

2,500 rpm 1.7 - 2.1V

COOLAN TEMP/S

lEngine: After warming up More than 70ÉC (158ÉF)

O2 SEN

lEngine: After warming up Maintaining engine speed at 2,000 rpm0 - 0.3V«0.6 - 1.0V

M/R F/C MNTRLEAN«RICH

Changes more than 5 times

during 10 seconds.

VHCL SPEED SE

lTurn drive wheels and compare speedometer indication with the CONSULT

valueAlmost the same speed as

the CONSULT value

BATTERY VOLT

lIgnition switch: ON (Engine stopped) 11 - 14V

THRTL POS SEN

lIgnition switch: ON

(Engine stopped)Throttle valve: fully closed 0.35 - 0.65V

Throttle valve: fully opened Approx. 4.0V

START SIGNAL

lIgnition switch: ON®START®ON OFF®ON®OFF

CLSD THL/POSI

lIgnition switch: ON

(Engine stopped)Throttle valve: Idle position ON

Throttle valve: Slightly open OFF

AIR COND SIG

lEngine: After warming up, idle the

engineAir conditioner switch: ``OFF'' OFF

Air conditioner switch: ``ON''

(Compressor operates.)ON

P/N POSI SW

lIgnition switch: ONShift lever: Neutral position ON

Except above OFF

PW/ST SIGNAL

lEngine: After warming up, idle the

engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is turned ON

TROUBLE DIAGNOSIS Ð General DescriptionKA

EC-64