set clock NISSAN PICK-UP 1999 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 454 of 666

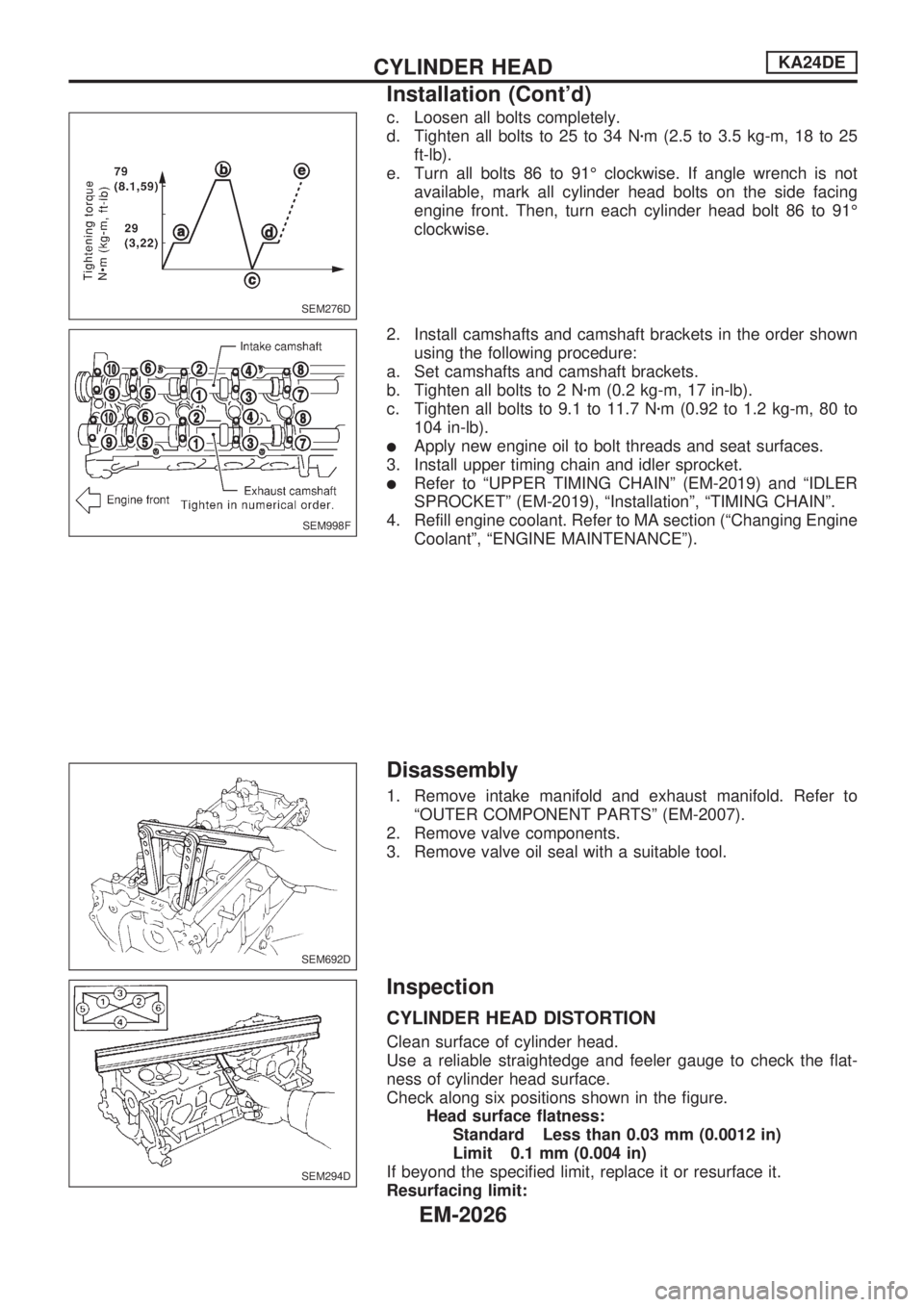

c. Loosen all bolts completely.

d. Tighten all bolts to 25 to 34 Nzm (2.5 to 3.5 kg-m, 18 to 25

ft-lb).

e. Turn all bolts 86 to 91É clockwise. If angle wrench is not

available, mark all cylinder head bolts on the side facing

engine front. Then, turn each cylinder head bolt 86 to 91É

clockwise.

2. Install camshafts and camshaft brackets in the order shown

using the following procedure:

a. Set camshafts and camshaft brackets.

b. Tighten all bolts to 2 Nzm (0.2 kg-m, 17 in-lb).

c. Tighten all bolts to 9.1 to 11.7 Nzm (0.92 to 1.2 kg-m, 80 to

104 in-lb).

lApply new engine oil to bolt threads and seat surfaces.

3. Install upper timing chain and idler sprocket.

lRefer to ªUPPER TIMING CHAINº (EM-2019) and ªIDLER

SPROCKETº (EM-2019), ªInstallationº, ªTIMING CHAINº.

4. Refill engine coolant. Refer to MA section (ªChanging Engine

Coolantº, ªENGINE MAINTENANCEº).

Disassembly

1. Remove intake manifold and exhaust manifold. Refer to

ªOUTER COMPONENT PARTSº (EM-2007).

2. Remove valve components.

3. Remove valve oil seal with a suitable tool.

Inspection

CYLINDER HEAD DISTORTION

Clean surface of cylinder head.

Use a reliable straightedge and feeler gauge to check the flat-

ness of cylinder head surface.

Check along six positions shown in the figure.

Head surface flatness:

Standard Less than 0.03 mm (0.0012 in)

Limit 0.1 mm (0.004 in)

If beyond the specified limit, replace it or resurface it.

Resurfacing limit:

SEM276D

SEM998F

SEM692D

SEM294D

CYLINDER HEADKA24DE

Installation (Cont'd)

EM-2026

Page 534 of 666

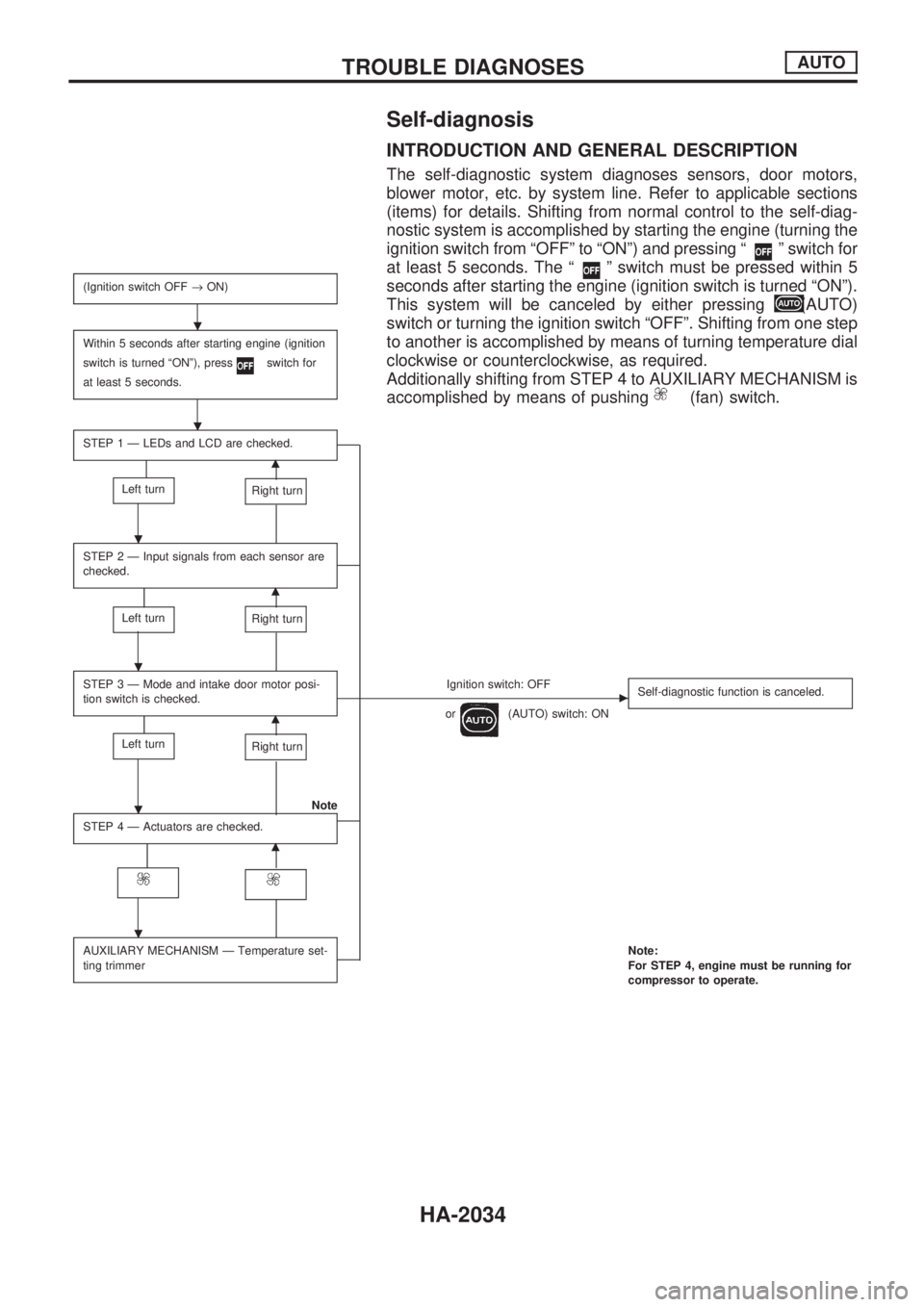

Self-diagnosis

INTRODUCTION AND GENERAL DESCRIPTION

The self-diagnostic system diagnoses sensors, door motors,

blower motor, etc. by system line. Refer to applicable sections

(items) for details. Shifting from normal control to the self-diag-

nostic system is accomplished by starting the engine (turning the

ignition switch from ªOFFº to ªONº) and pressing ª

º switch for

at least 5 seconds. The ª

º switch must be pressed within 5

seconds after starting the engine (ignition switch is turned ªONº).

This system will be canceled by either pressing

(AUTO)

switch or turning the ignition switch ªOFFº. Shifting from one step

to another is accomplished by means of turning temperature dial

clockwise or counterclockwise, as required.

Additionally shifting from STEP 4 to AUXILIARY MECHANISM is

accomplished by means of pushing

(fan) switch.

(Ignition switch OFF®ON)

Within 5 seconds after starting engine (ignition

switch is turned ªONº), press

switch for

at least 5 seconds.

STEP 1 Ð LEDs and LCD are checked.

m

Left turnRight turn

STEP 2 Ð Input signals from each sensor are

checked.

m

Left turnRight turn

STEP 3 Ð Mode and intake door motor posi-

tion switch is checked.Ignition switch: OFFc

or(AUTO) switch: ONSelf-diagnostic function is canceled.m

Left turnRight turn

Note

STEP 4 Ð Actuators are checked.

m

AUXILIARY MECHANISM Ð Temperature set-

ting trimmerNote:

For STEP 4, engine must be running for

compressor to operate.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

HA-2034

Page 535 of 666

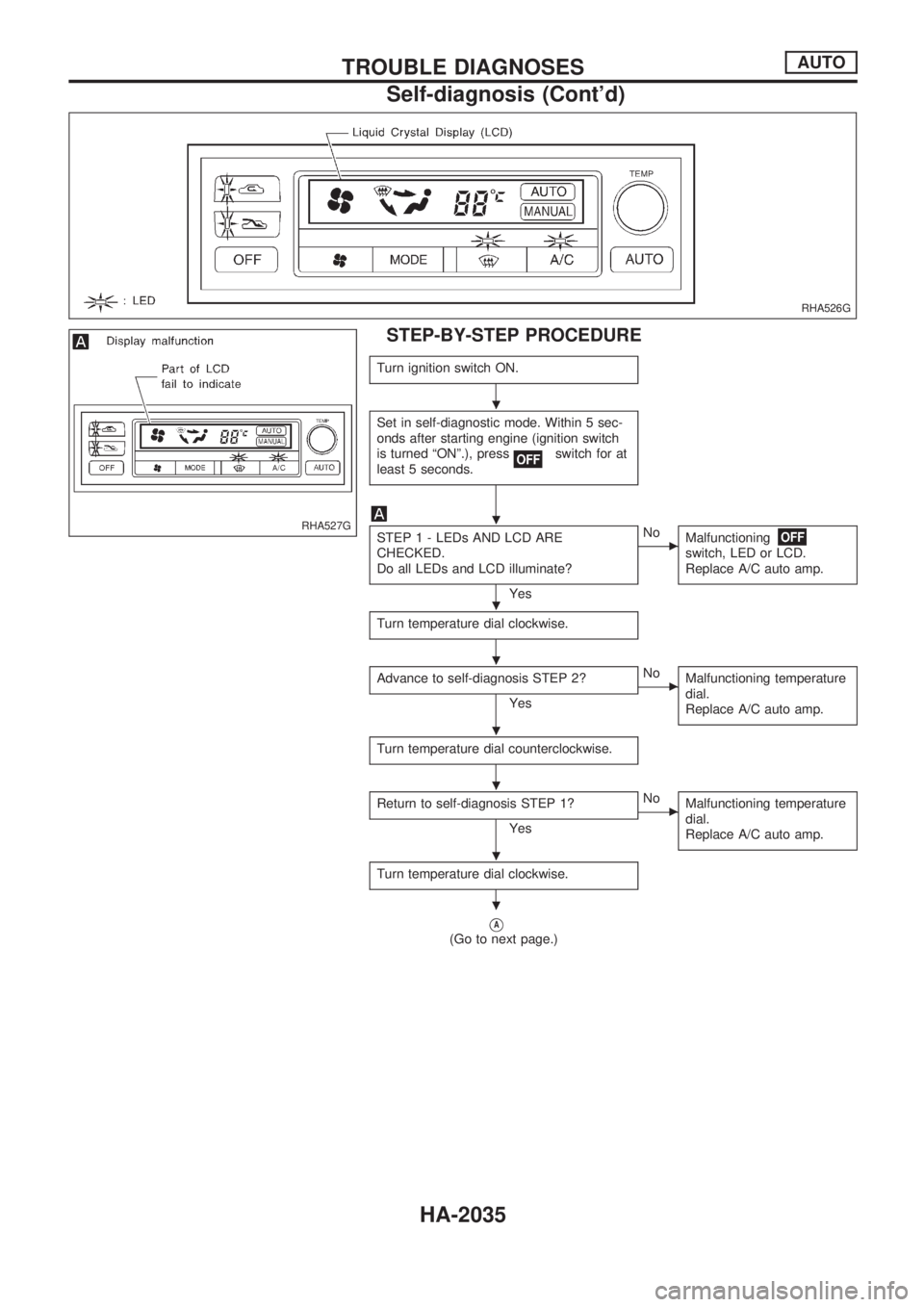

STEP-BY-STEP PROCEDURE

Turn ignition switch ON.

Set in self-diagnostic mode. Within 5 sec-

onds after starting engine (ignition switch

is turned ªONº.), press

switch for at

least 5 seconds.

STEP 1 - LEDs AND LCD ARE

CHECKED.

Do all LEDs and LCD illuminate?

Yes

cNo

Malfunctioning

switch, LED or LCD.

Replace A/C auto amp.

Turn temperature dial clockwise.

Advance to self-diagnosis STEP 2?

Yes

cNo

Malfunctioning temperature

dial.

Replace A/C auto amp.

Turn temperature dial counterclockwise.

Return to self-diagnosis STEP 1?

Yes

cNo

Malfunctioning temperature

dial.

Replace A/C auto amp.

Turn temperature dial clockwise.

VA(Go to next page.)

RHA526G

RHA527G

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-2035

Page 539 of 666

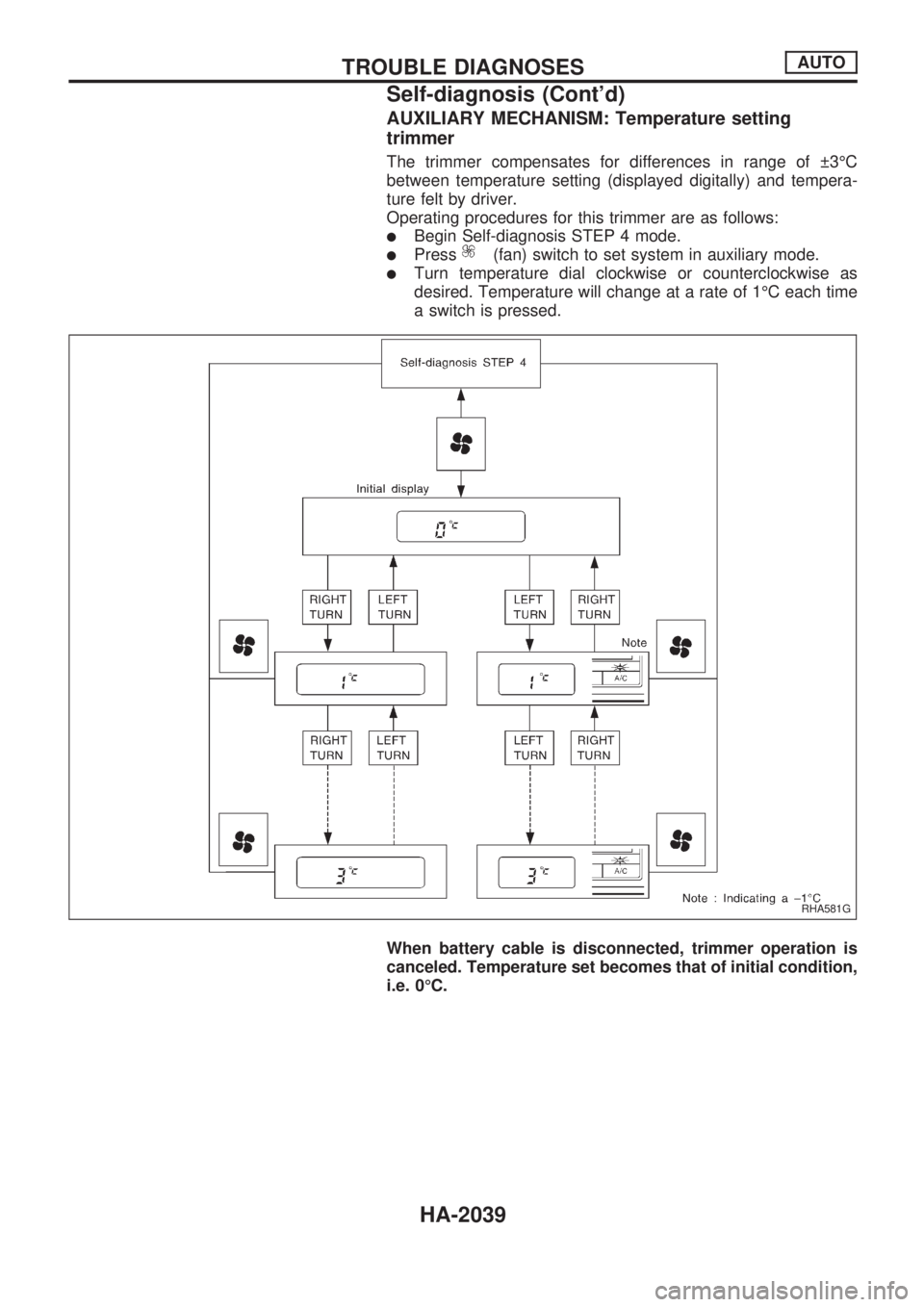

AUXILIARY MECHANISM: Temperature setting

trimmer

The trimmer compensates for differences in range of 3ÉC

between temperature setting (displayed digitally) and tempera-

ture felt by driver.

Operating procedures for this trimmer are as follows:

lBegin Self-diagnosis STEP 4 mode.

lPress(fan) switch to set system in auxiliary mode.

lTurn temperature dial clockwise or counterclockwise as

desired. Temperature will change at a rate of 1ÉC each time

a switch is pressed.

When battery cable is disconnected, trimmer operation is

canceled. Temperature set becomes that of initial condition,

i.e. 0ÉC.

RHA581G

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-2039

Page 551 of 666

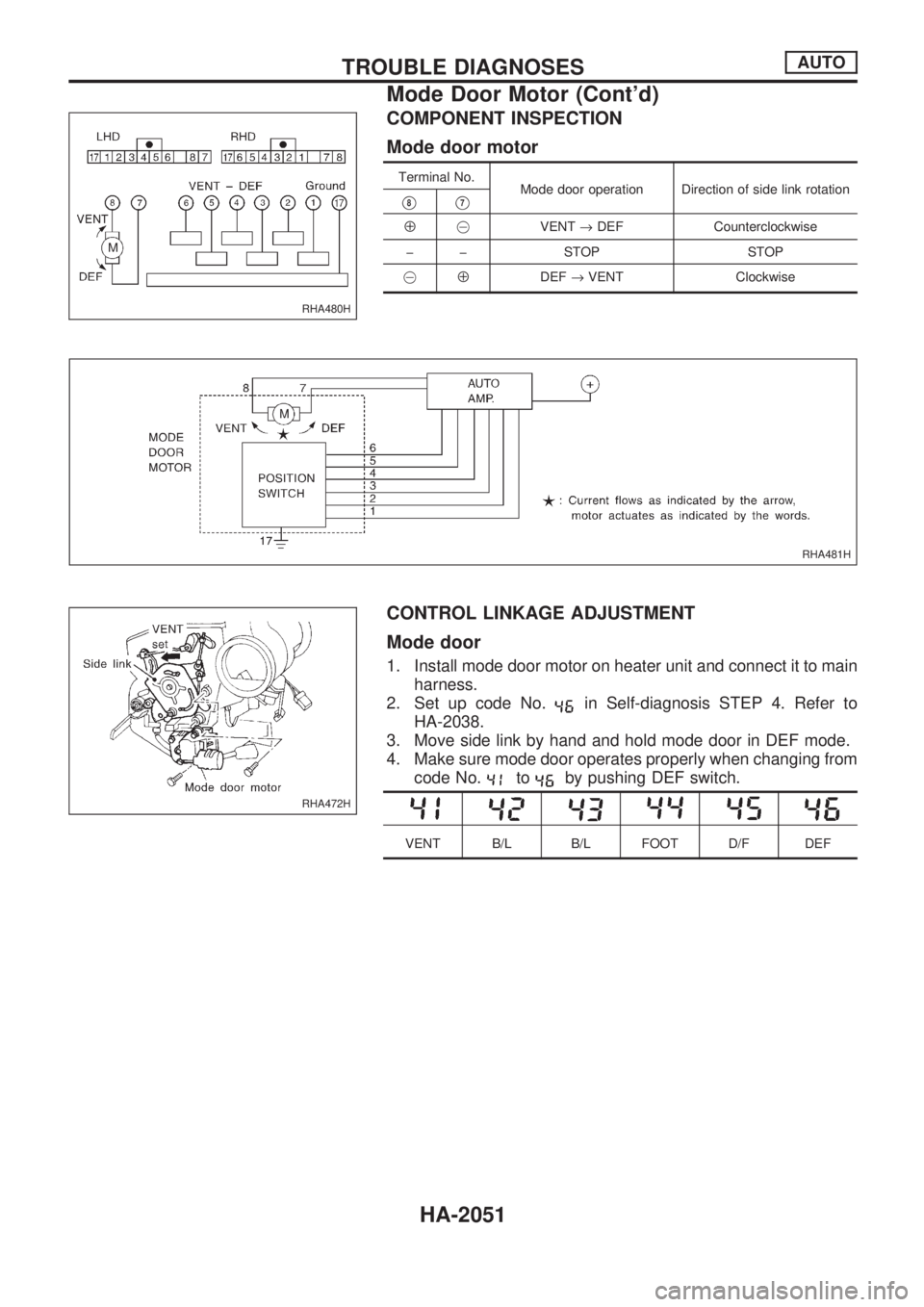

COMPONENT INSPECTION

Mode door motor

Terminal No.

Mode door operation Direction of side link rotation

V8V7

Å@VENT®DEF Counterclockwise

þ þ STOP STOP

@

ÅDEF®VENT Clockwise

CONTROL LINKAGE ADJUSTMENT

Mode door

1. Install mode door motor on heater unit and connect it to main

harness.

2. Set up code No.

in Self-diagnosis STEP 4. Refer to

HA-2038.

3. Move side link by hand and hold mode door in DEF mode.

4. Make sure mode door operates properly when changing from

code No.

toby pushing DEF switch.

VENT B/L B/L FOOT D/F DEF

RHA480H

RHA481H

RHA472H

TROUBLE DIAGNOSESAUTO

Mode Door Motor (Cont'd)

HA-2051

Page 557 of 666

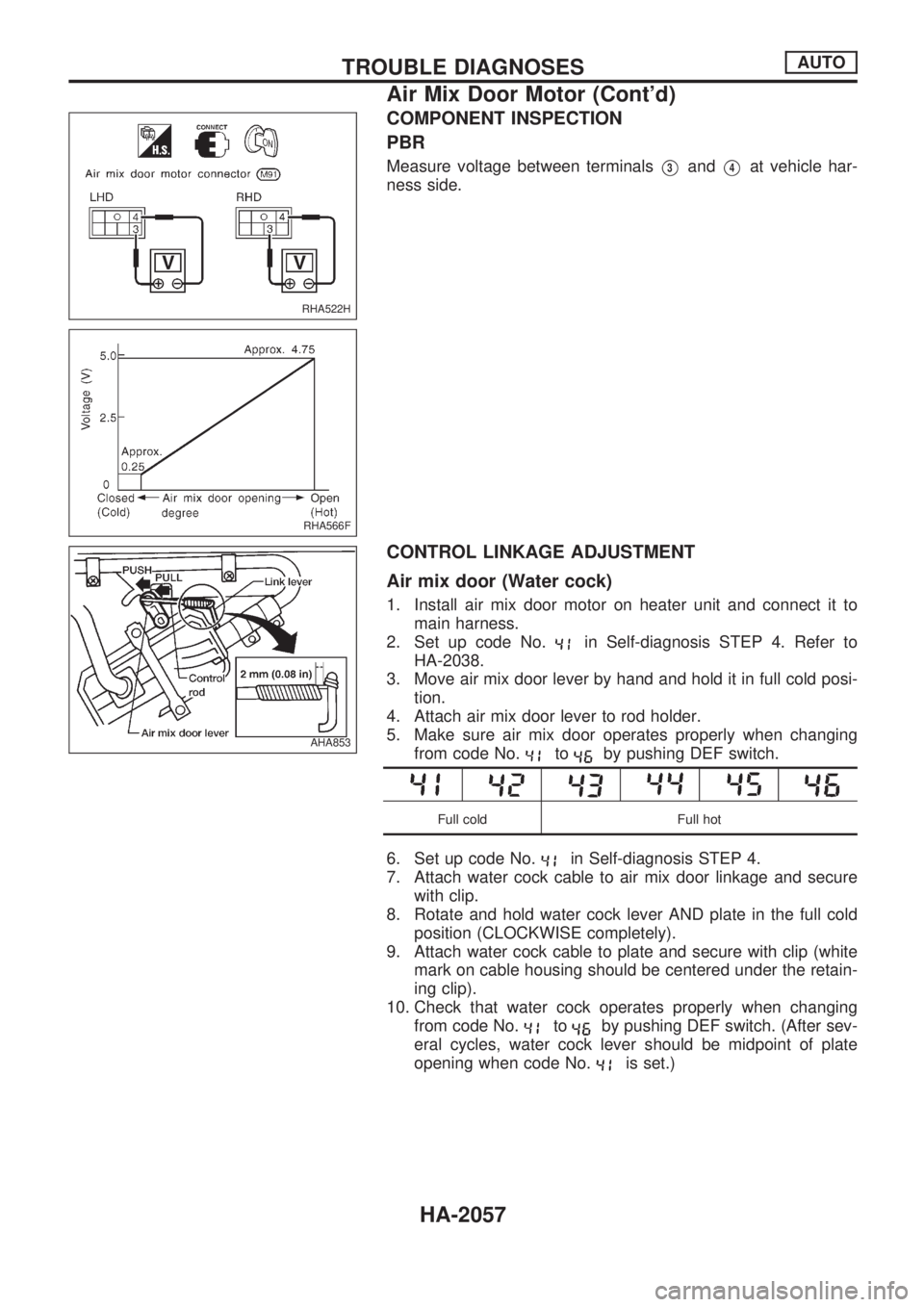

COMPONENT INSPECTION

PBR

Measure voltage between terminalsV3andV4at vehicle har-

ness side.

CONTROL LINKAGE ADJUSTMENT

Air mix door (Water cock)

1. Install air mix door motor on heater unit and connect it to

main harness.

2. Set up code No.

in Self-diagnosis STEP 4. Refer to

HA-2038.

3. Move air mix door lever by hand and hold it in full cold posi-

tion.

4. Attach air mix door lever to rod holder.

5. Make sure air mix door operates properly when changing

from code No.

toby pushing DEF switch.

Full cold Full hot

6. Set up code No.in Self-diagnosis STEP 4.

7. Attach water cock cable to air mix door linkage and secure

with clip.

8. Rotate and hold water cock lever AND plate in the full cold

position (CLOCKWISE completely).

9. Attach water cock cable to plate and secure with clip (white

mark on cable housing should be centered under the retain-

ing clip).

10. Check that water cock operates properly when changing

from code No.

toby pushing DEF switch. (After sev-

eral cycles, water cock lever should be midpoint of plate

opening when code No.

is set.)

RHA522H

RHA566F

AHA853

TROUBLE DIAGNOSESAUTO

Air Mix Door Motor (Cont'd)

HA-2057