sensor NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 424 of 1306

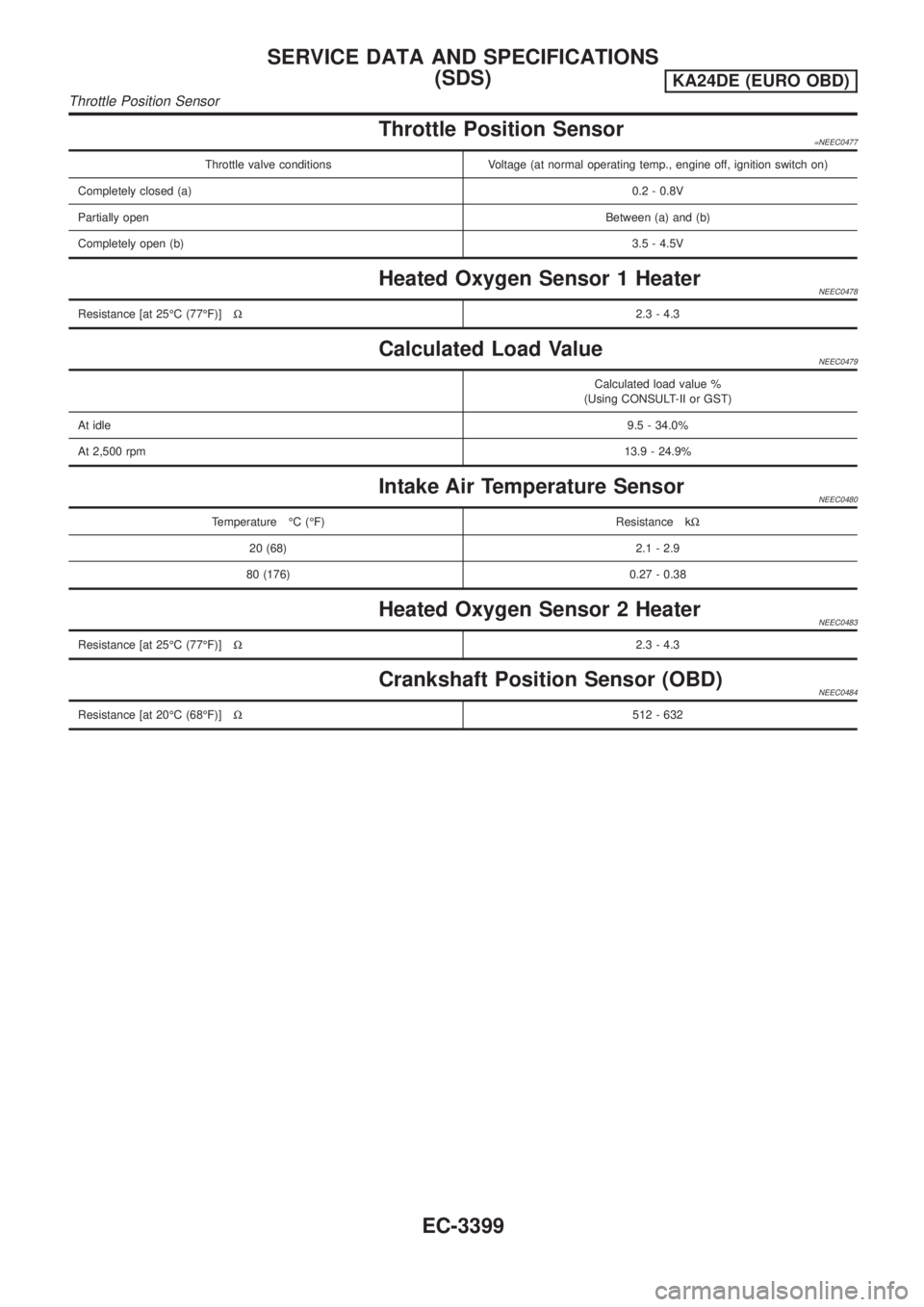

Throttle Position Sensor=NEEC0477

Throttle valve conditions Voltage (at normal operating temp., engine off, ignition switch on)

Completely closed (a)0.2 - 0.8V

Partially openBetween (a) and (b)

Completely open (b)3.5 - 4.5V

Heated Oxygen Sensor 1 HeaterNEEC0478

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Calculated Load ValueNEEC0479

Calculated load value %

(Using CONSULT-II or GST)

At idle9.5 - 34.0%

At 2,500 rpm13.9 - 24.9%

Intake Air Temperature SensorNEEC0480

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

80 (176) 0.27 - 0.38

Heated Oxygen Sensor 2 HeaterNEEC0483

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

Crankshaft Position Sensor (OBD)NEEC0484

Resistance [at 20ÉC (68ÉF)]W512 - 632

SERVICE DATA AND SPECIFICATIONS

(SDS)

KA24DE (EURO OBD)

Throttle Position Sensor

EC-3399

Page 425 of 1306

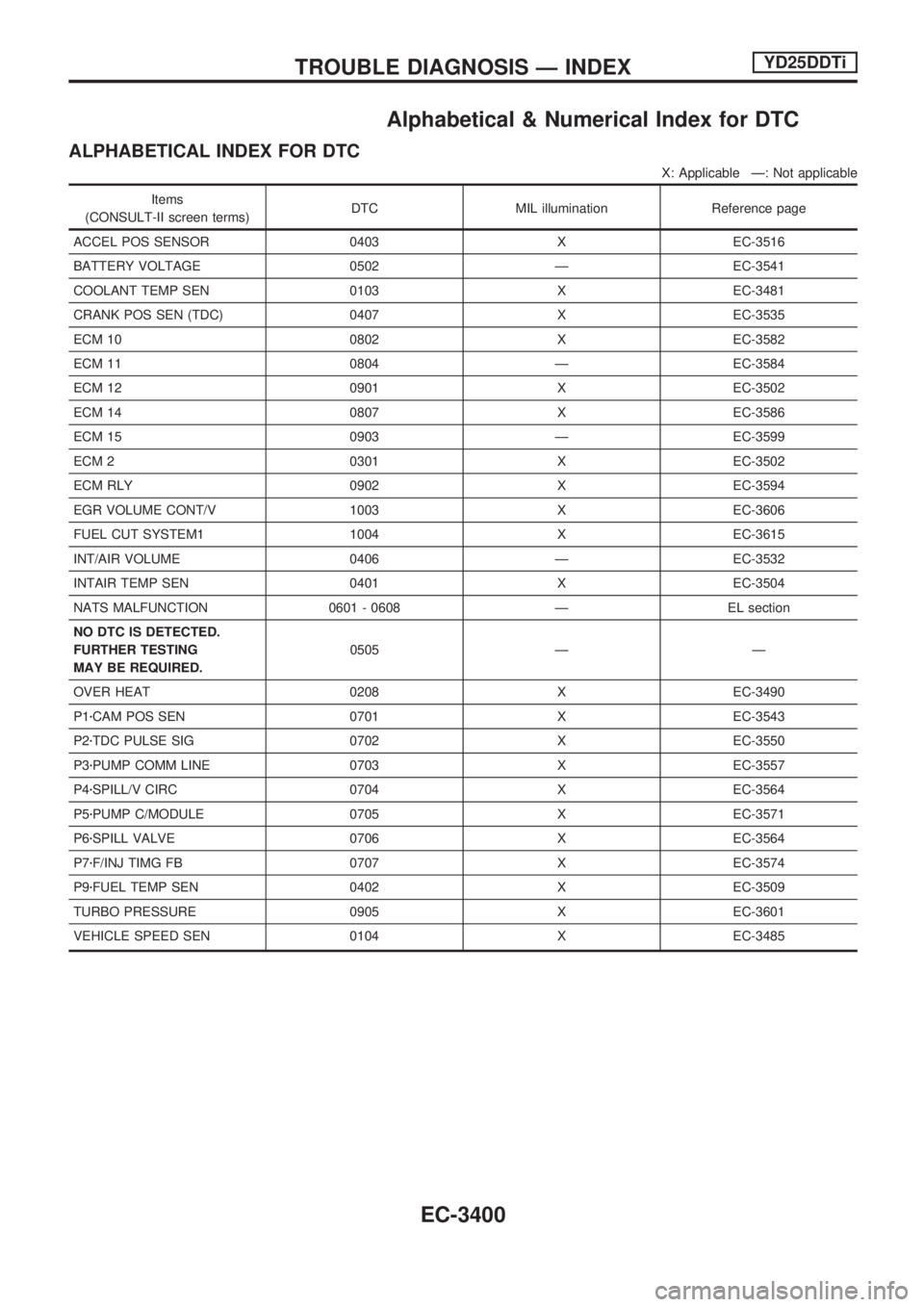

Alphabetical & Numerical Index for DTC

ALPHABETICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC MIL illumination Reference page

ACCEL POS SENSOR 0403 X EC-3516

BATTERY VOLTAGE 0502 Ð EC-3541

COOLANT TEMP SEN 0103 X EC-3481

CRANK POS SEN (TDC) 0407 X EC-3535

ECM 10 0802 X EC-3582

ECM 11 0804 Ð EC-3584

ECM 12 0901 X EC-3502

ECM 14 0807 X EC-3586

ECM 15 0903 Ð EC-3599

ECM 2 0301 X EC-3502

ECM RLY 0902 X EC-3594

EGR VOLUME CONT/V 1003 X EC-3606

FUEL CUT SYSTEM1 1004 X EC-3615

INT/AIR VOLUME 0406 Ð EC-3532

INTAIR TEMP SEN 0401 X EC-3504

NATS MALFUNCTION 0601 - 0608 Ð EL section

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.0505 Ð Ð

OVER HEAT 0208 X EC-3490

P1zCAM POS SEN 0701 X EC-3543

P2zTDC PULSE SIG 0702 X EC-3550

P3zPUMP COMM LINE 0703 X EC-3557

P4zSPILL/V CIRC 0704 X EC-3564

P5zPUMP C/MODULE 0705 X EC-3571

P6zSPILL VALVE 0706 X EC-3564

P7zF/INJ TIMG FB 0707 X EC-3574

P9zFUEL TEMP SEN 0402 X EC-3509

TURBO PRESSURE 0905 X EC-3601

VEHICLE SPEED SEN 0104 X EC-3485

TROUBLE DIAGNOSIS Ð INDEXYD25DDTi

EC-3400

Page 426 of 1306

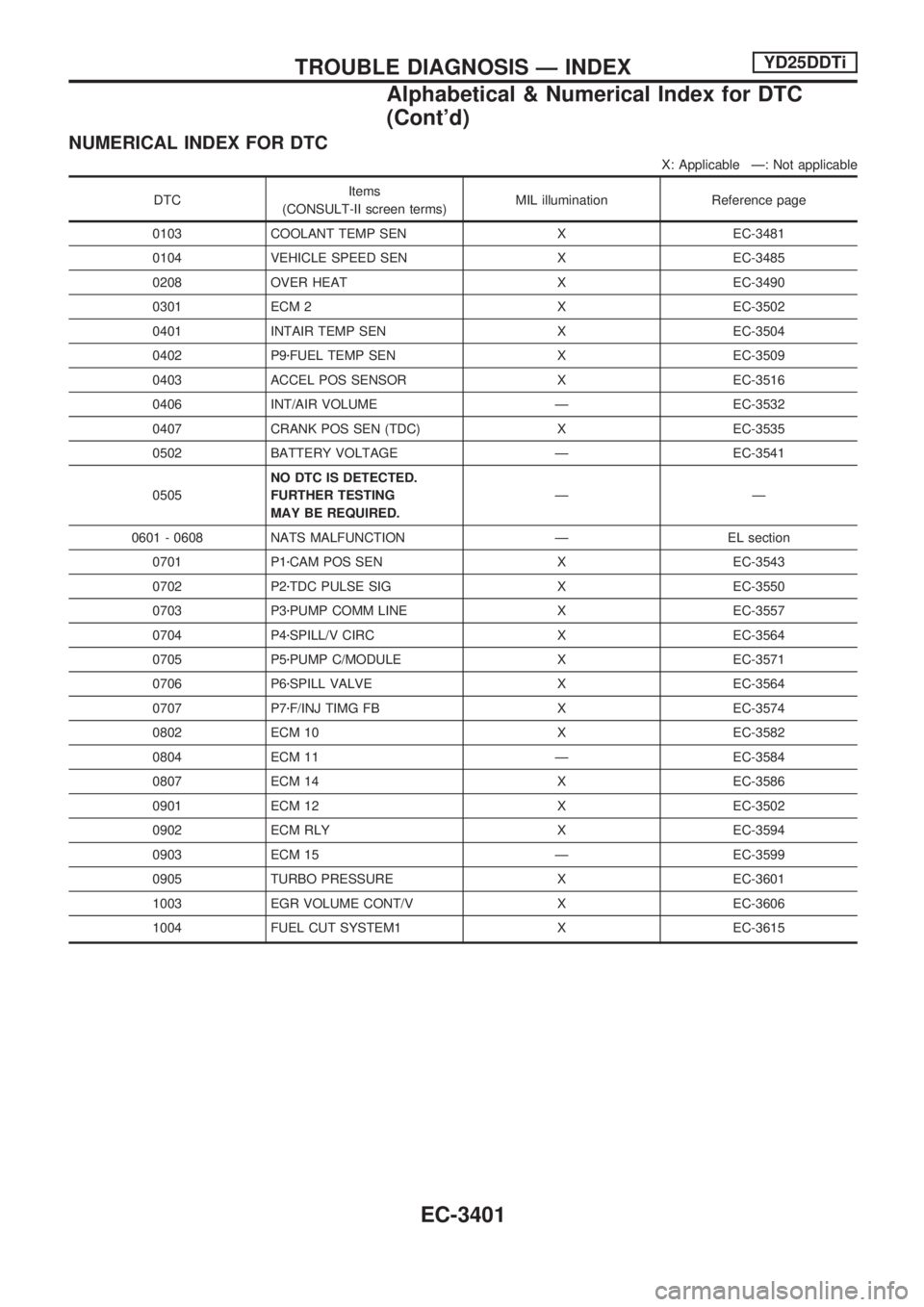

NUMERICAL INDEX FOR DTC

X: Applicable Ð: Not applicable

DTCItems

(CONSULT-II screen terms)MIL illumination Reference page

0103 COOLANT TEMP SEN X EC-3481

0104 VEHICLE SPEED SEN X EC-3485

0208 OVER HEAT X EC-3490

0301 ECM 2 X EC-3502

0401 INTAIR TEMP SEN X EC-3504

0402 P9zFUEL TEMP SEN X EC-3509

0403 ACCEL POS SENSOR X EC-3516

0406 INT/AIR VOLUME Ð EC-3532

0407 CRANK POS SEN (TDC) X EC-3535

0502 BATTERY VOLTAGE Ð EC-3541

0505NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.ÐÐ

0601 - 0608 NATS MALFUNCTION Ð EL section

0701 P1zCAM POS SEN X EC-3543

0702 P2zTDC PULSE SIG X EC-3550

0703 P3zPUMP COMM LINE X EC-3557

0704 P4zSPILL/V CIRC X EC-3564

0705 P5zPUMP C/MODULE X EC-3571

0706 P6zSPILL VALVE X EC-3564

0707 P7zF/INJ TIMG FB X EC-3574

0802 ECM 10 X EC-3582

0804 ECM 11 Ð EC-3584

0807 ECM 14 X EC-3586

0901 ECM 12 X EC-3502

0902 ECM RLY X EC-3594

0903 ECM 15 Ð EC-3599

0905 TURBO PRESSURE X EC-3601

1003 EGR VOLUME CONT/V X EC-3606

1004 FUEL CUT SYSTEM1 X EC-3615

TROUBLE DIAGNOSIS Ð INDEXYD25DDTi

Alphabetical & Numerical Index for DTC

(Cont'd)

EC-3401

Page 429 of 1306

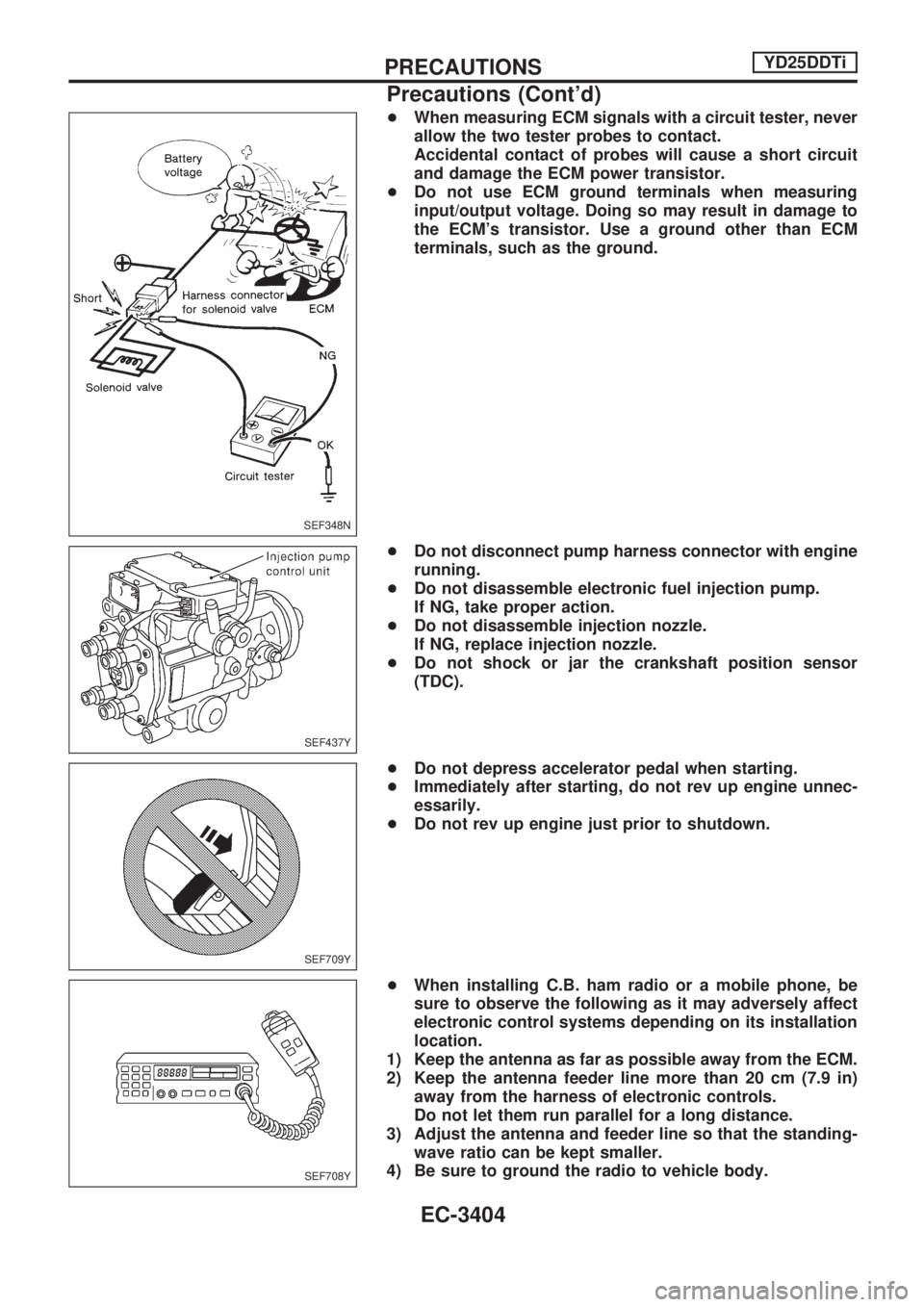

+When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit

and damage the ECM power transistor.

+Do not use ECM ground terminals when measuring

input/output voltage. Doing so may result in damage to

the ECM's transistor. Use a ground other than ECM

terminals, such as the ground.

+Do not disconnect pump harness connector with engine

running.

+Do not disassemble electronic fuel injection pump.

If NG, take proper action.

+Do not disassemble injection nozzle.

If NG, replace injection nozzle.

+Do not shock or jar the crankshaft position sensor

(TDC).

+Do not depress accelerator pedal when starting.

+Immediately after starting, do not rev up engine unnec-

essarily.

+Do not rev up engine just prior to shutdown.

+When installing C.B. ham radio or a mobile phone, be

sure to observe the following as it may adversely affect

electronic control systems depending on its installation

location.

1) Keep the antenna as far as possible away from the ECM.

2) Keep the antenna feeder line more than 20 cm (7.9 in)

away from the harness of electronic controls.

Do not let them run parallel for a long distance.

3) Adjust the antenna and feeder line so that the standing-

wave ratio can be kept smaller.

4) Be sure to ground the radio to vehicle body.

SEF348N

SEF437Y

SEF709Y

SEF708Y

PRECAUTIONSYD25DDTi

Precautions (Cont'd)

EC-3404

Page 435 of 1306

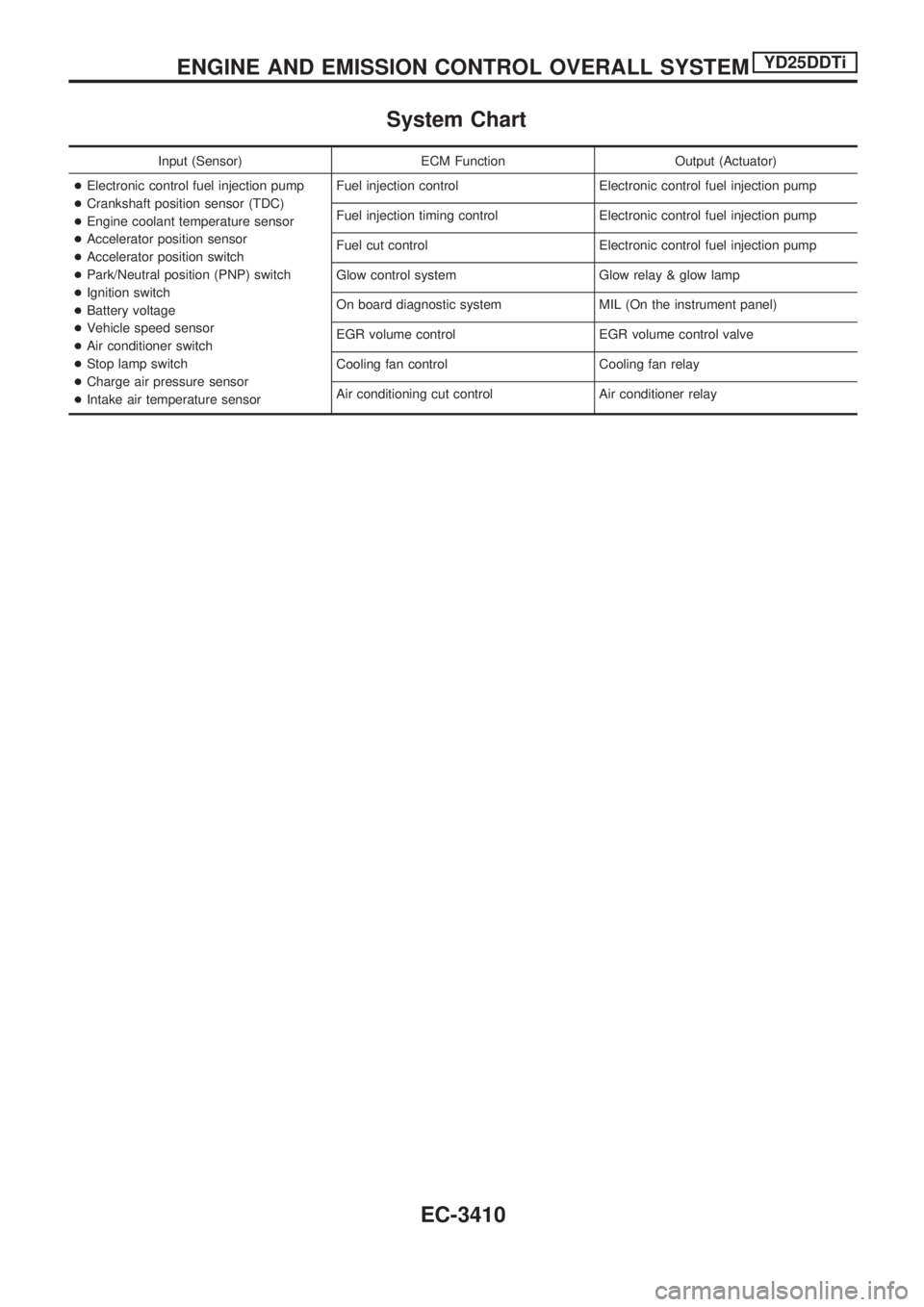

System Chart

Input (Sensor) ECM Function Output (Actuator)

+Electronic control fuel injection pump

+Crankshaft position sensor (TDC)

+Engine coolant temperature sensor

+Accelerator position sensor

+Accelerator position switch

+Park/Neutral position (PNP) switch

+Ignition switch

+Battery voltage

+Vehicle speed sensor

+Air conditioner switch

+Stop lamp switch

+Charge air pressure sensor

+Intake air temperature sensorFuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

ENGINE AND EMISSION CONTROL OVERALL SYSTEMYD25DDTi

EC-3410

Page 436 of 1306

Fuel Injection Control System

DESCRIPTION

System description

Three types of fuel injection control are provided to accommodate engine operating conditions; normal

control, idle control and start control. The ECM determines the appropriate fuel injection control. Under each

control, the amount of fuel injected is compensated to improve engine performance.

Pulse signals are exchanged between ECM and electronic control fuel injection pump (control unit is built-

in). The fuel injection pump control unit performs duty control on the spill valve (built into the fuel injection

pump) according to the input signals to compensate the amount of fuel injected to the preset value.

Start control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (start control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Ignition switch Start signal

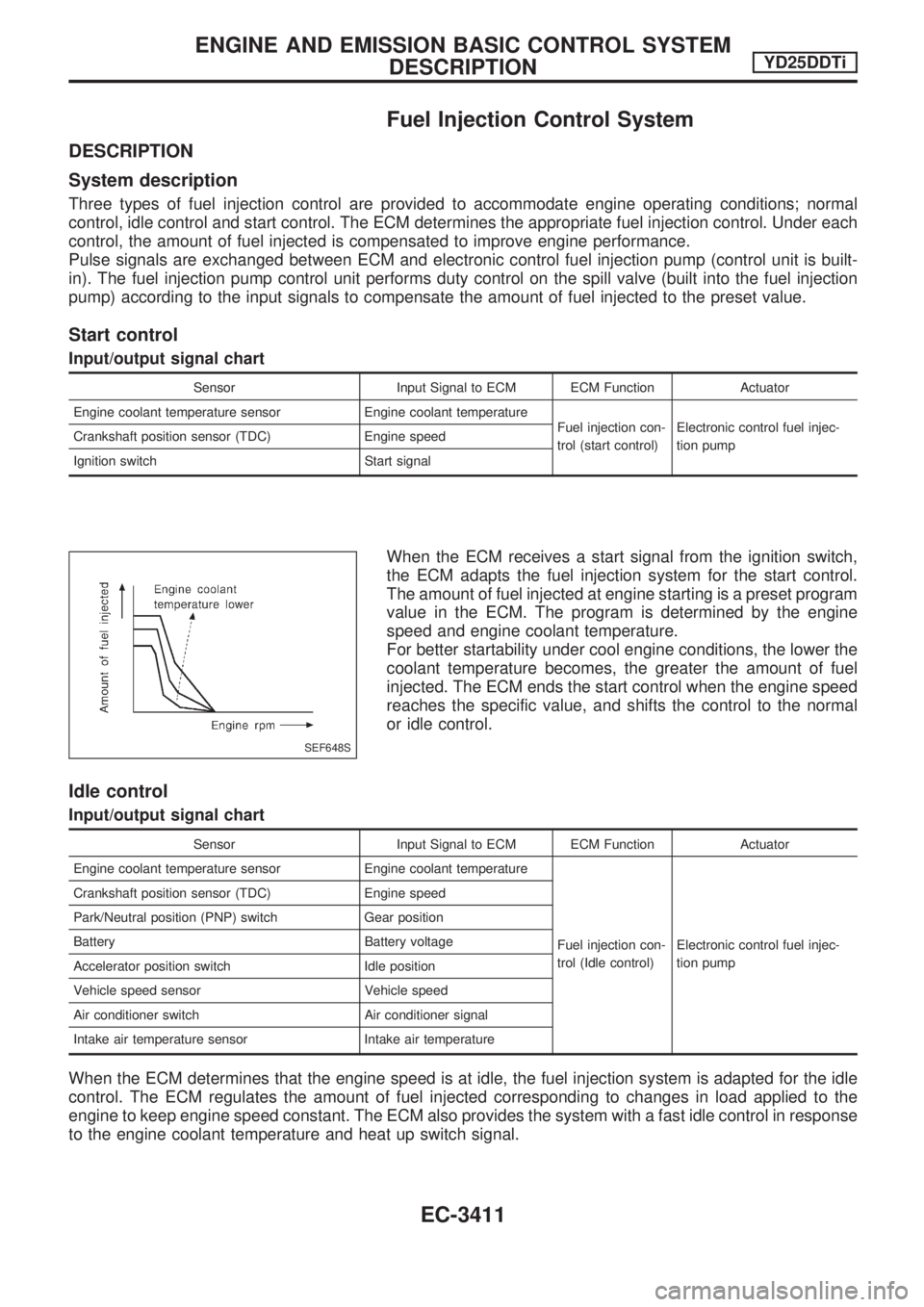

When the ECM receives a start signal from the ignition switch,

the ECM adapts the fuel injection system for the start control.

The amount of fuel injected at engine starting is a preset program

value in the ECM. The program is determined by the engine

speed and engine coolant temperature.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal

or idle control.

Idle control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Idle control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Park/Neutral position (PNP) switch Gear position

Battery Battery voltage

Accelerator position switch Idle position

Vehicle speed sensor Vehicle speed

Air conditioner switch Air conditioner signal

Intake air temperature sensor Intake air temperature

When the ECM determines that the engine speed is at idle, the fuel injection system is adapted for the idle

control. The ECM regulates the amount of fuel injected corresponding to changes in load applied to the

engine to keep engine speed constant. The ECM also provides the system with a fast idle control in response

to the engine coolant temperature and heat up switch signal.

SEF648S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONYD25DDTi

EC-3411

Page 437 of 1306

Normal control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (TDC) Engine speed

Fuel injection con-

trol (Normal con-

trol)Electronic control fuel injec-

tion pump Accelerator position sensor Accelerator position

Vehicle speed sensor Vehicle speed

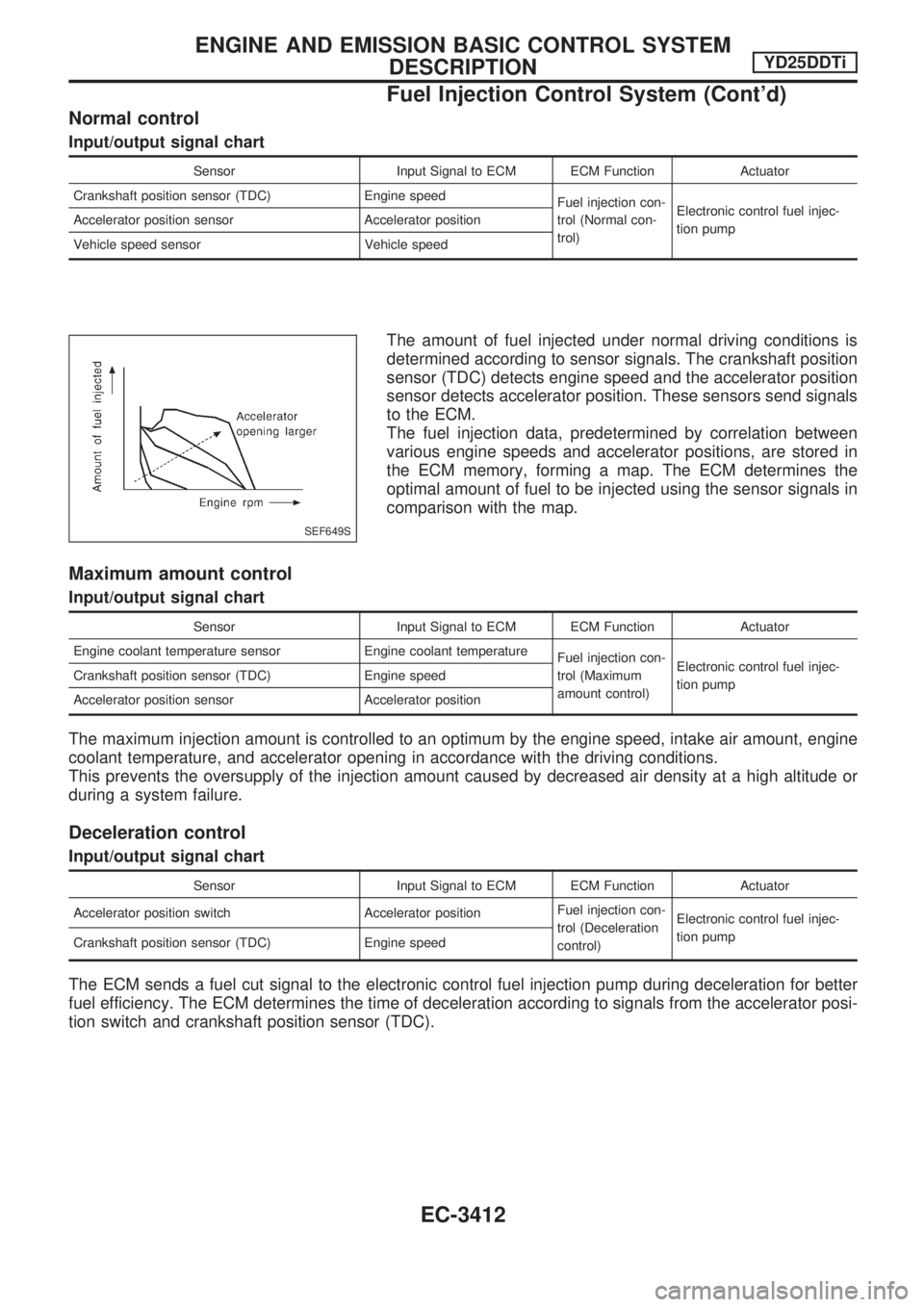

The amount of fuel injected under normal driving conditions is

determined according to sensor signals. The crankshaft position

sensor (TDC) detects engine speed and the accelerator position

sensor detects accelerator position. These sensors send signals

to the ECM.

The fuel injection data, predetermined by correlation between

various engine speeds and accelerator positions, are stored in

the ECM memory, forming a map. The ECM determines the

optimal amount of fuel to be injected using the sensor signals in

comparison with the map.

Maximum amount control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection con-

trol (Maximum

amount control)Electronic control fuel injec-

tion pump Crankshaft position sensor (TDC) Engine speed

Accelerator position sensor Accelerator position

The maximum injection amount is controlled to an optimum by the engine speed, intake air amount, engine

coolant temperature, and accelerator opening in accordance with the driving conditions.

This prevents the oversupply of the injection amount caused by decreased air density at a high altitude or

during a system failure.

Deceleration control

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Accelerator position switch Accelerator positionFuel injection con-

trol (Deceleration

control)Electronic control fuel injec-

tion pump

Crankshaft position sensor (TDC) Engine speed

The ECM sends a fuel cut signal to the electronic control fuel injection pump during deceleration for better

fuel efficiency. The ECM determines the time of deceleration according to signals from the accelerator posi-

tion switch and crankshaft position sensor (TDC).

SEF649S

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONYD25DDTi

Fuel Injection Control System (Cont'd)

EC-3412

Page 438 of 1306

Fuel Injection Timing Control System

DESCRIPTION

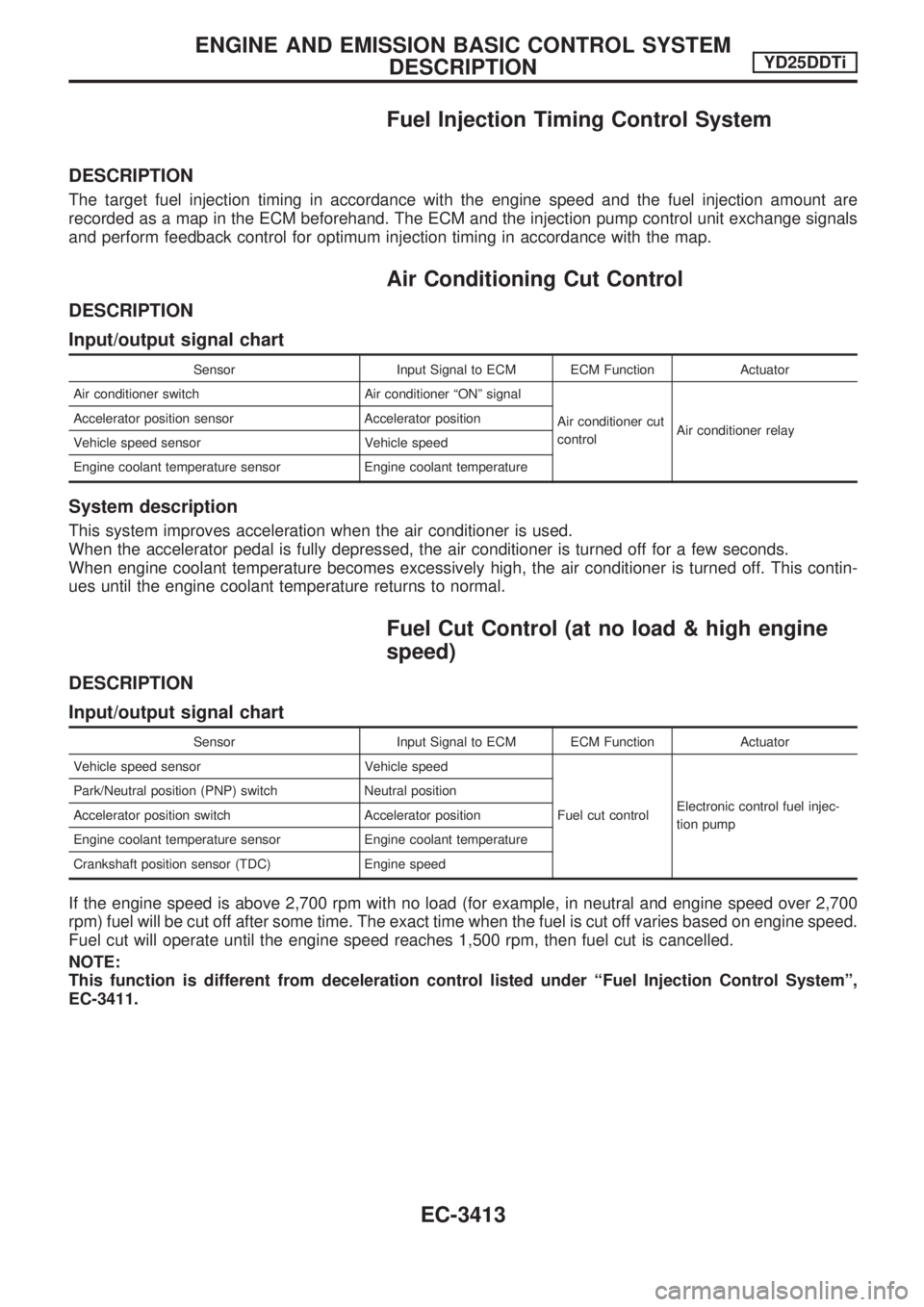

The target fuel injection timing in accordance with the engine speed and the fuel injection amount are

recorded as a map in the ECM beforehand. The ECM and the injection pump control unit exchange signals

and perform feedback control for optimum injection timing in accordance with the map.

Air Conditioning Cut Control

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Air conditioner switch Air conditioner ªONº signal

Air conditioner cut

controlAir conditioner relay Accelerator position sensor Accelerator position

Vehicle speed sensor Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

System description

This system improves acceleration when the air conditioner is used.

When the accelerator pedal is fully depressed, the air conditioner is turned off for a few seconds.

When engine coolant temperature becomes excessively high, the air conditioner is turned off. This contin-

ues until the engine coolant temperature returns to normal.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTION

Input/output signal chart

Sensor Input Signal to ECM ECM Function Actuator

Vehicle speed sensor Vehicle speed

Fuel cut controlElectronic control fuel injec-

tion pump Park/Neutral position (PNP) switch Neutral position

Accelerator position switch Accelerator position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (TDC) Engine speed

If the engine speed is above 2,700 rpm with no load (for example, in neutral and engine speed over 2,700

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªFuel Injection Control Systemº,

EC-3411.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTIONYD25DDTi

EC-3413

Page 452 of 1306

2. Bleed air of the fuel filter. Refer to EC-3426.

Accelerator Position Sensor Idle Position

Learning

DESCRIPTION

ªAccelerator Position Sensor Idle Position Learningº is an opera-

tion to clear the self-learning fully closed accelerator position.

It must be performed each time harness connector of accelera-

tor position sensor or ECM is disconnected.

OPERATION PROCEDURE

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with

CONSULT-II.

3. Touch ªCLEARº.

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

BASIC SERVICE PROCEDUREYD25DDTi

EC-3427

Page 460 of 1306

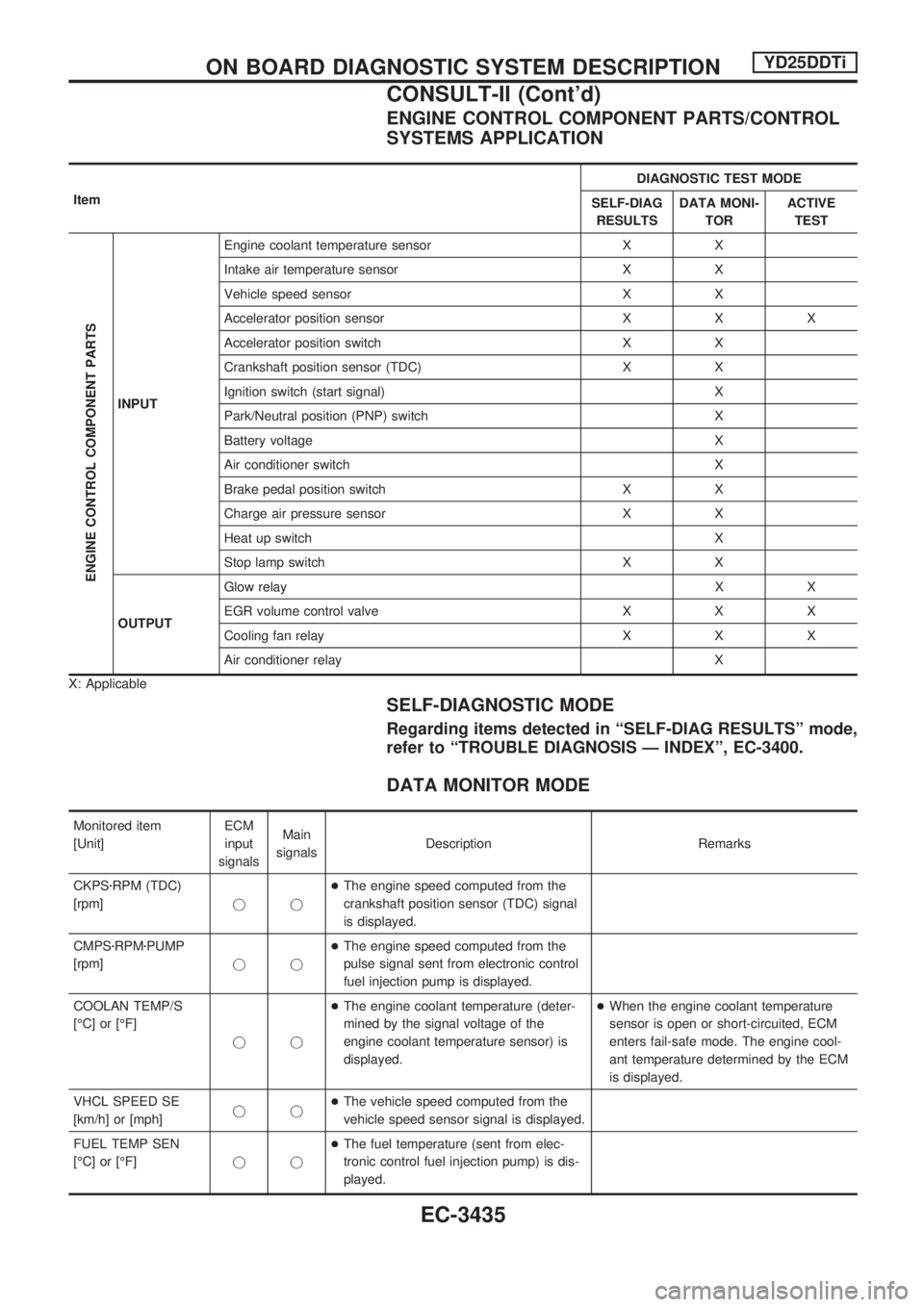

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

ItemDIAGNOSTIC TEST MODE

SELF-DIAG

RESULTSDATA MONI-

TORACTIVE

TEST

ENGINE CONTROL COMPONENT PARTS

INPUTEngine coolant temperature sensor X X

Intake air temperature sensor X X

Vehicle speed sensor X X

Accelerator position sensor X X X

Accelerator position switch X X

Crankshaft position sensor (TDC) X X

Ignition switch (start signal) X

Park/Neutral position (PNP) switch X

Battery voltage X

Air conditioner switch X

Brake pedal position switch X X

Charge air pressure sensor X X

Heat up switch X

Stop lamp switch X X

OUTPUTGlow relayXX

EGR volume control valve X X X

Cooling fan relay X X X

Air conditioner relay X

X: Applicable

SELF-DIAGNOSTIC MODE

Regarding items detected in ªSELF-DIAG RESULTSº mode,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-3400.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CKPSzRPM (TDC)

[rpm]jj+The engine speed computed from the

crankshaft position sensor (TDC) signal

is displayed.

CMPSzRPMzPUMP

[rpm]jj+The engine speed computed from the

pulse signal sent from electronic control

fuel injection pump is displayed.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj+The engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.+When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

VHCL SPEED SE

[km/h] or [mph]jj+The vehicle speed computed from the

vehicle speed sensor signal is displayed.

FUEL TEMP SEN

[ÉC] or [ÉF]jj+The fuel temperature (sent from elec-

tronic control fuel injection pump) is dis-

played.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD25DDTi

CONSULT-II (Cont'd)

EC-3435