sensor NISSAN PICK-UP 2001 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 50 of 1306

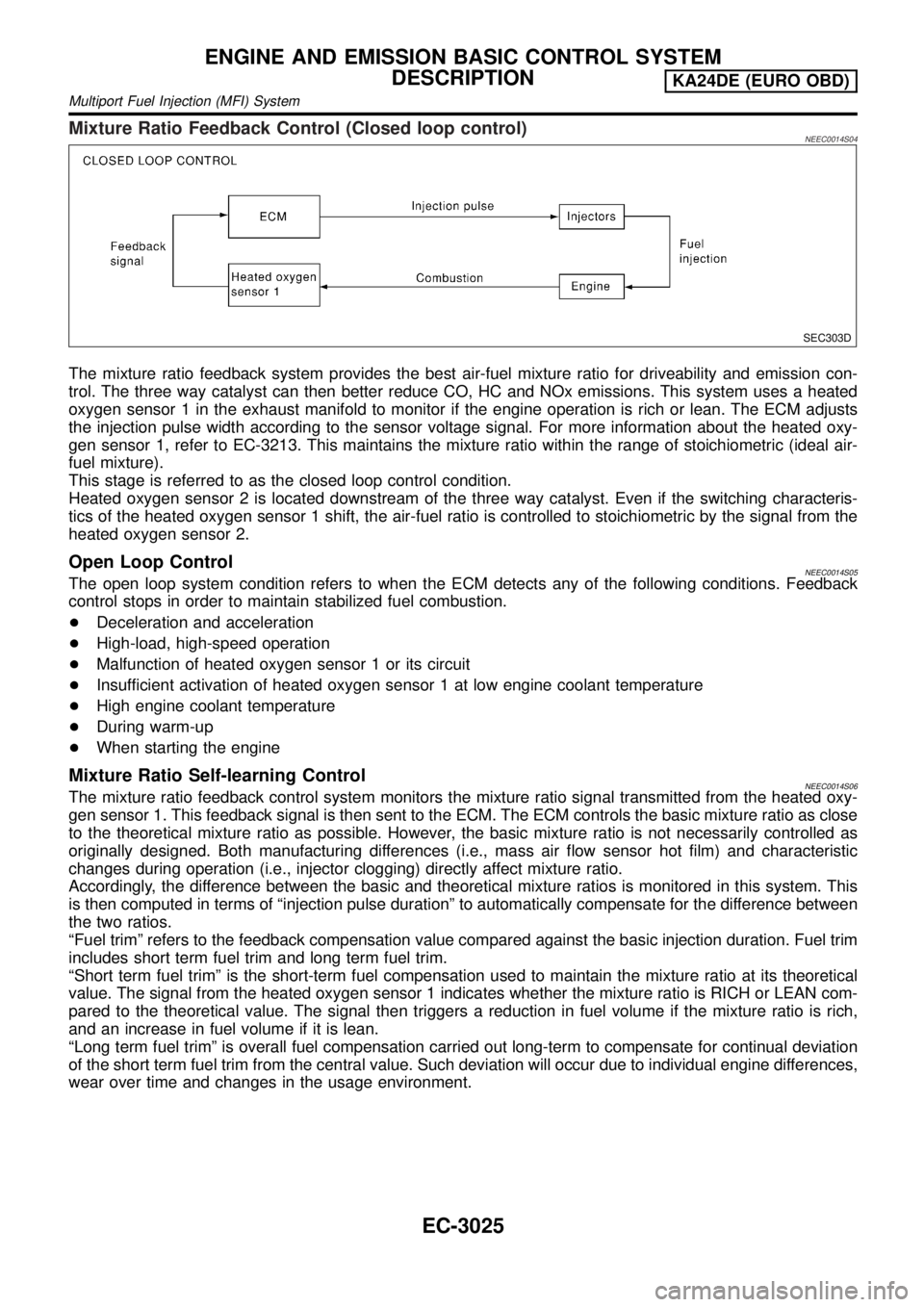

Mixture Ratio Feedback Control (Closed loop control)NEEC0014S04

SEC303D

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission con-

trol. The three way catalyst can then better reduce CO, HC and NOx emissions. This system uses a heated

oxygen sensor 1 in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM adjusts

the injection pulse width according to the sensor voltage signal. For more information about the heated oxy-

gen sensor 1, refer to EC-3213. This maintains the mixture ratio within the range of stoichiometric (ideal air-

fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst. Even if the switching characteris-

tics of the heated oxygen sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal from the

heated oxygen sensor 2.

Open Loop ControlNEEC0014S05The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

+Deceleration and acceleration

+High-load, high-speed operation

+Malfunction of heated oxygen sensor 1 or its circuit

+Insufficient activation of heated oxygen sensor 1 at low engine coolant temperature

+High engine coolant temperature

+During warm-up

+When starting the engine

Mixture Ratio Self-learning ControlNEEC0014S06The mixture ratio feedback control system monitors the mixture ratio signal transmitted from the heated oxy-

gen sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close

to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as

originally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic

changes during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This

is then computed in terms of ªinjection pulse durationº to automatically compensate for the difference between

the two ratios.

ªFuel trimº refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

ªShort term fuel trimº is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from the heated oxygen sensor 1 indicates whether the mixture ratio is RICH or LEAN com-

pared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich,

and an increase in fuel volume if it is lean.

ªLong term fuel trimº is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Multiport Fuel Injection (MFI) System

EC-3025

Page 51 of 1306

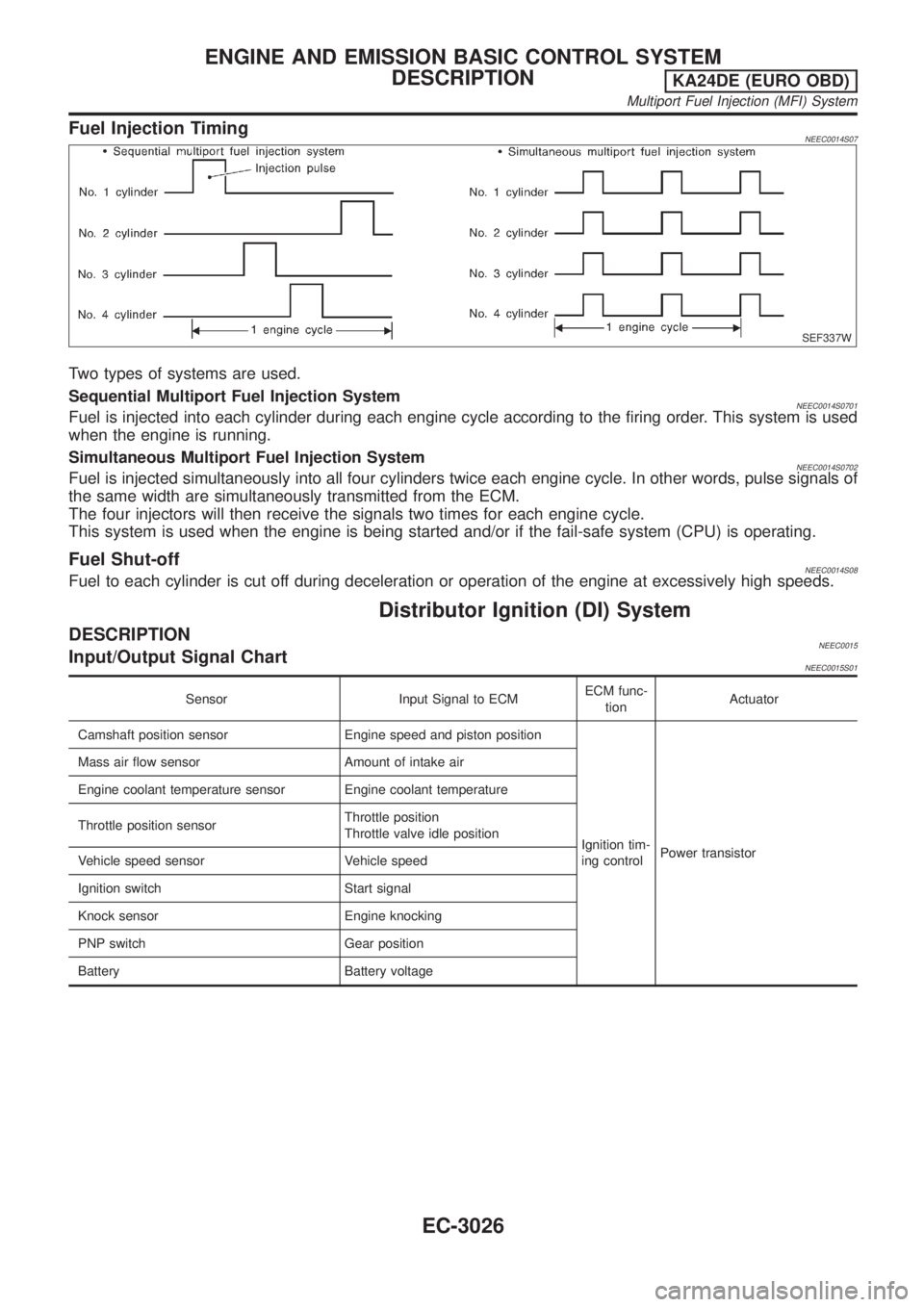

Fuel Injection TimingNEEC0014S07

SEF337W

Two types of systems are used.

Sequential Multiport Fuel Injection System

NEEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NEEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNEEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Distributor Ignition (DI) System

DESCRIPTIONNEEC0015Input/Output Signal ChartNEEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speed and piston position

Ignition tim-

ing controlPower transistor Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Multiport Fuel Injection (MFI) System

EC-3026

Page 52 of 1306

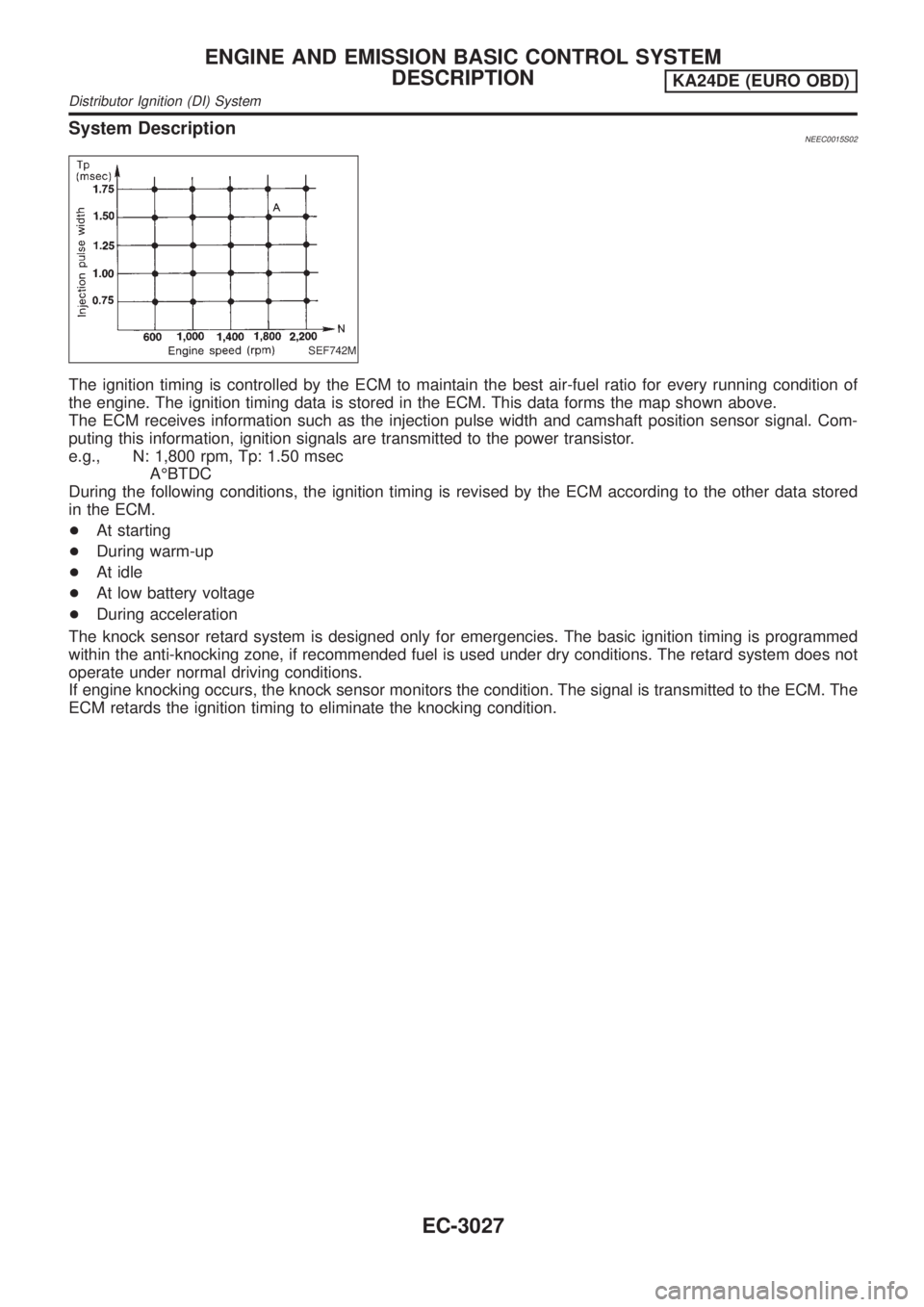

System DescriptionNEEC0015S02

SEF742M

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Com-

puting this information, ignition signals are transmitted to the power transistor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

+At starting

+During warm-up

+At idle

+At low battery voltage

+During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Distributor Ignition (DI) System

EC-3027

Page 53 of 1306

Air Conditioning Cut Control

DESCRIPTION=NEEC0016Input/Output Signal ChartNEEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Camshaft position sensor Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Vehicle speed sensor Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNEEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

+When the accelerator pedal is fully depressed.

+When cranking the engine.

+When the engine coolant temperature becomes excessively high.

+When operating power steering and air conditioner during low engine speed or when fully releasing accel-

erator pedal.

+When engine speed is excessively low.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTIONNEEC0017Input/Output Signal ChartNEEC0017S01

Sensor Input Signal to ECMECM func-

tionActuator

Vehicle speed sensor Vehicle speed

Fuel cut

controlInjectors PNP switch Neutral position

Throttle position sensor Throttle position

Camshaft position sensor Engine speed

If the engine speed is above 3,000 rpm with no load, (for example, in Neutral and engine speed over 3,000

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªMultiport Fuel Injection (MFI) Systemº,

EC-3024.

ENGINE AND EMISSION BASIC CONTROL SYSTEM

DESCRIPTION

KA24DE (EURO OBD)

Air Conditioning Cut Control

EC-3028

Page 62 of 1306

INSPECTION PROCEDURE=NEEC0028S02

1 INSPECTION START

1. Visually check the following:

+Air cleaner clogging

+Hoses and duct for leaks

+Electrical connectors

+Gasket (intake manifold, cylinder head, exhaust system)

+Throttle valve and throttle position sensor operation

2. Start engine and warm it up until engine coolant temperature indicator points to the middle of gauge.

Ensure engine speed stays below 1,000 rpm.

SEF810K

3. Open engine hood and run engine at about 2,000 rpm for about 2 minutes under no-load.

4. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK©+GO TO 2. (With CONSULT-II)

+GO TO 3. (Without CONSULT-II)

NG©1. Repair or replace components as necessary.

2. GO TO 2. (With CONSULT-II)

3. GO TO 3. (Without CONSULT-II)

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3037

Page 64 of 1306

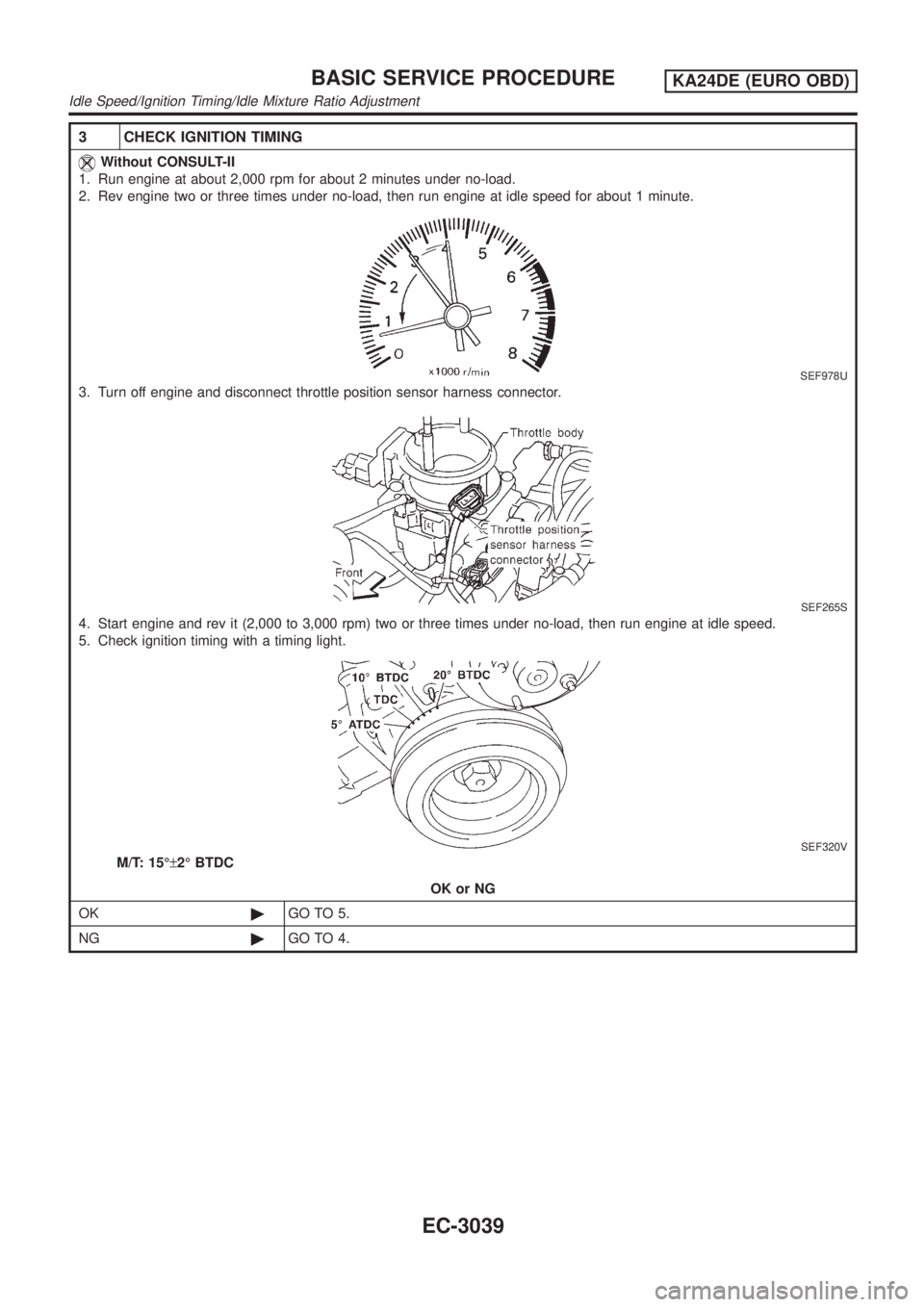

3 CHECK IGNITION TIMING

Without CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Rev engine two or three times under no-load, then run engine at idle speed for about 1 minute.

SEF978U

3. Turn off engine and disconnect throttle position sensor harness connector.

SEF265S

4. Start engine and rev it (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

5. Check ignition timing with a timing light.

SEF320V

M/T: 15ɱ2É BTDC

OK or NG

OK©GO TO 5.

NG©GO TO 4.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3039

Page 65 of 1306

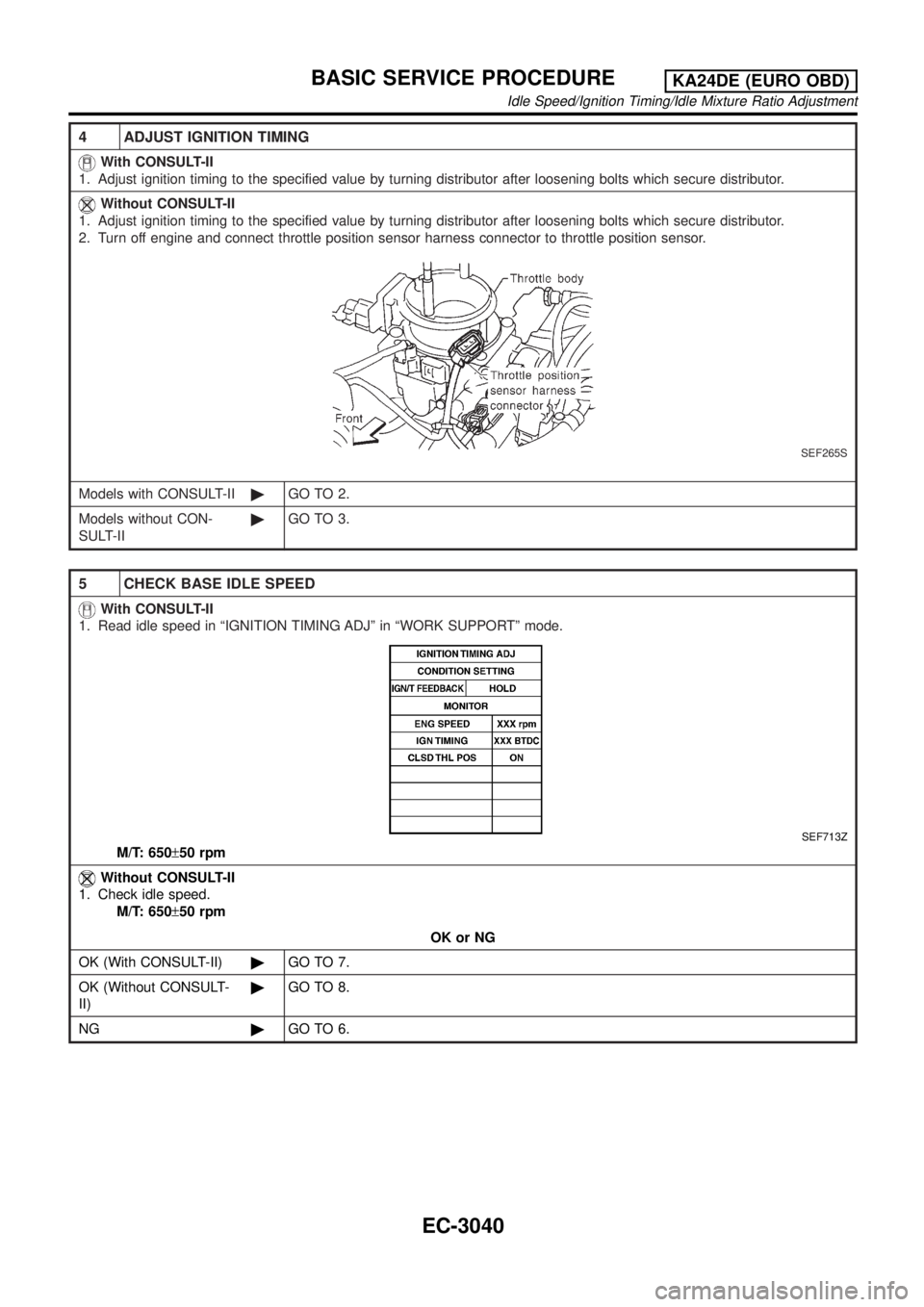

4 ADJUST IGNITION TIMING

With CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

Without CONSULT-II

1. Adjust ignition timing to the specified value by turning distributor after loosening bolts which secure distributor.

2. Turn off engine and connect throttle position sensor harness connector to throttle position sensor.

SEF265S

Models with CONSULT-II©GO TO 2.

Models without CON-

SULT-II©GO TO 3.

5 CHECK BASE IDLE SPEED

With CONSULT-II

1. Read idle speed in ªIGNITION TIMING ADJº in ªWORK SUPPORTº mode.

SEF713Z

M/T: 650±50 rpm

Without CONSULT-II

1. Check idle speed.

M/T: 650±50 rpm

OK or NG

OK (With CONSULT-II)©GO TO 7.

OK (Without CONSULT-

II)©GO TO 8.

NG©GO TO 6.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3040

Page 67 of 1306

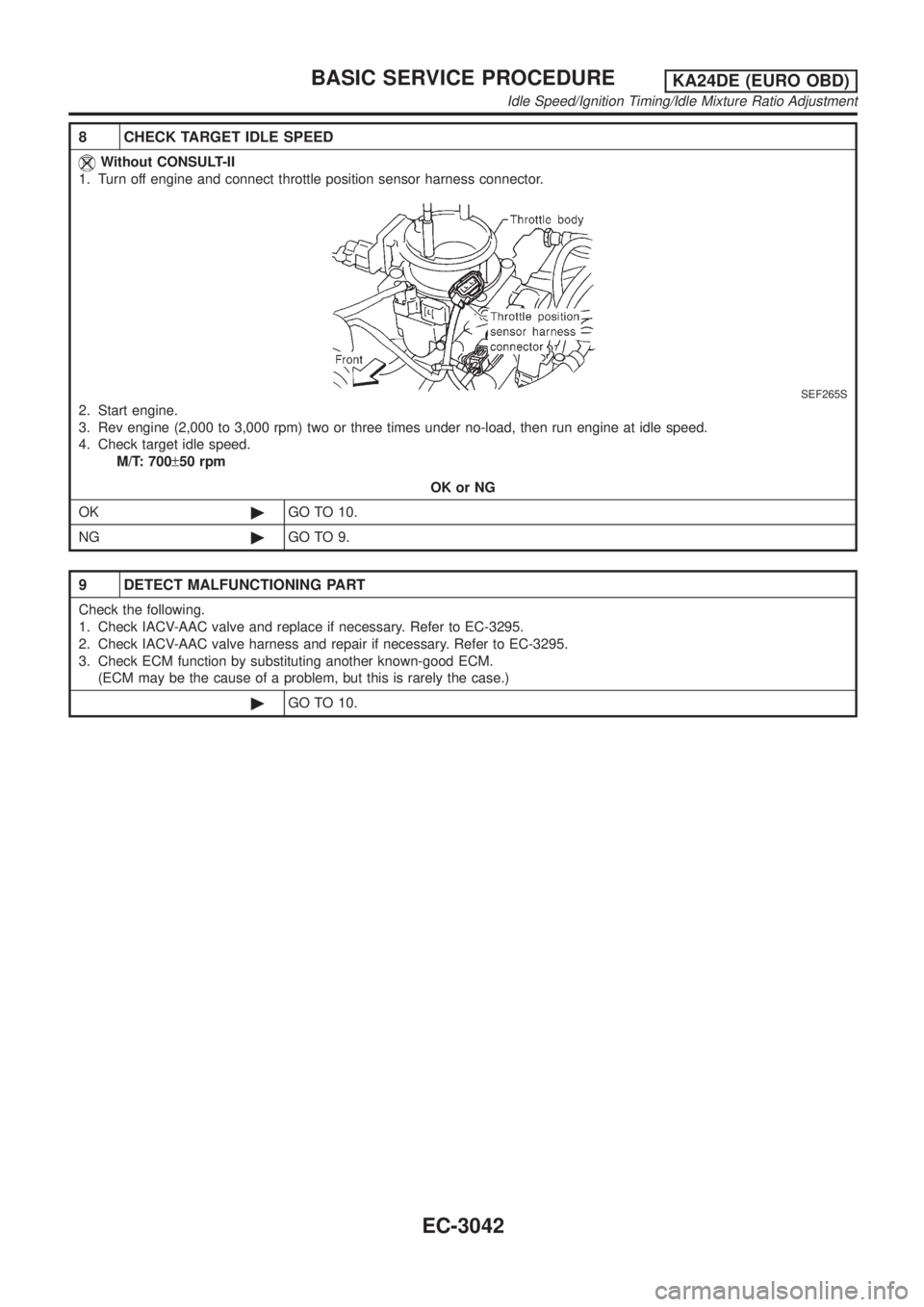

8 CHECK TARGET IDLE SPEED

Without CONSULT-II

1. Turn off engine and connect throttle position sensor harness connector.

SEF265S

2. Start engine.

3. Rev engine (2,000 to 3,000 rpm) two or three times under no-load, then run engine at idle speed.

4. Check target idle speed.

M/T: 700±50 rpm

OK or NG

OK©GO TO 10.

NG©GO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

1. Check IACV-AAC valve and replace if necessary. Refer to EC-3295.

2. Check IACV-AAC valve harness and repair if necessary. Refer to EC-3295.

3. Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 10.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3042

Page 68 of 1306

10 CHECK HEATED OXYGEN SENSOR 1 SIGNAL

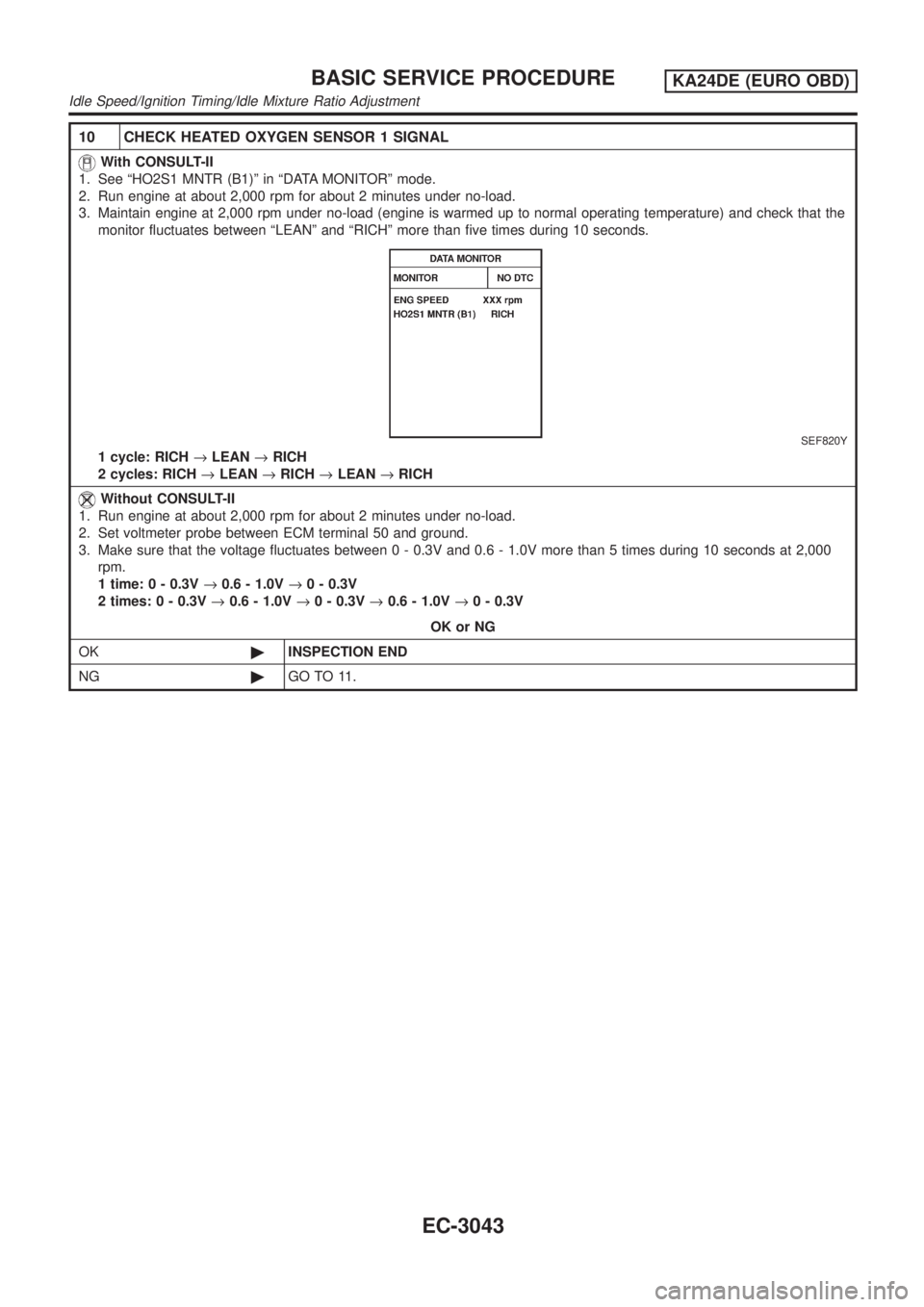

With CONSULT-II

1. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

2. Run engine at about 2,000 rpm for about 2 minutes under no-load.

3. Maintain engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature) and check that the

monitor fluctuates between ªLEANº and ªRICHº more than five times during 10 seconds.

SEF820Y

1 cycle: RICH®LEAN®RICH

2 cycles: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no-load.

2. Set voltmeter probe between ECM terminal 50 and ground.

3. Make sure that the voltage fluctuates between 0 - 0.3V and 0.6 - 1.0V more than 5 times during 10 seconds at 2,000

rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©INSPECTION END

NG©GO TO 11.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3043

Page 69 of 1306

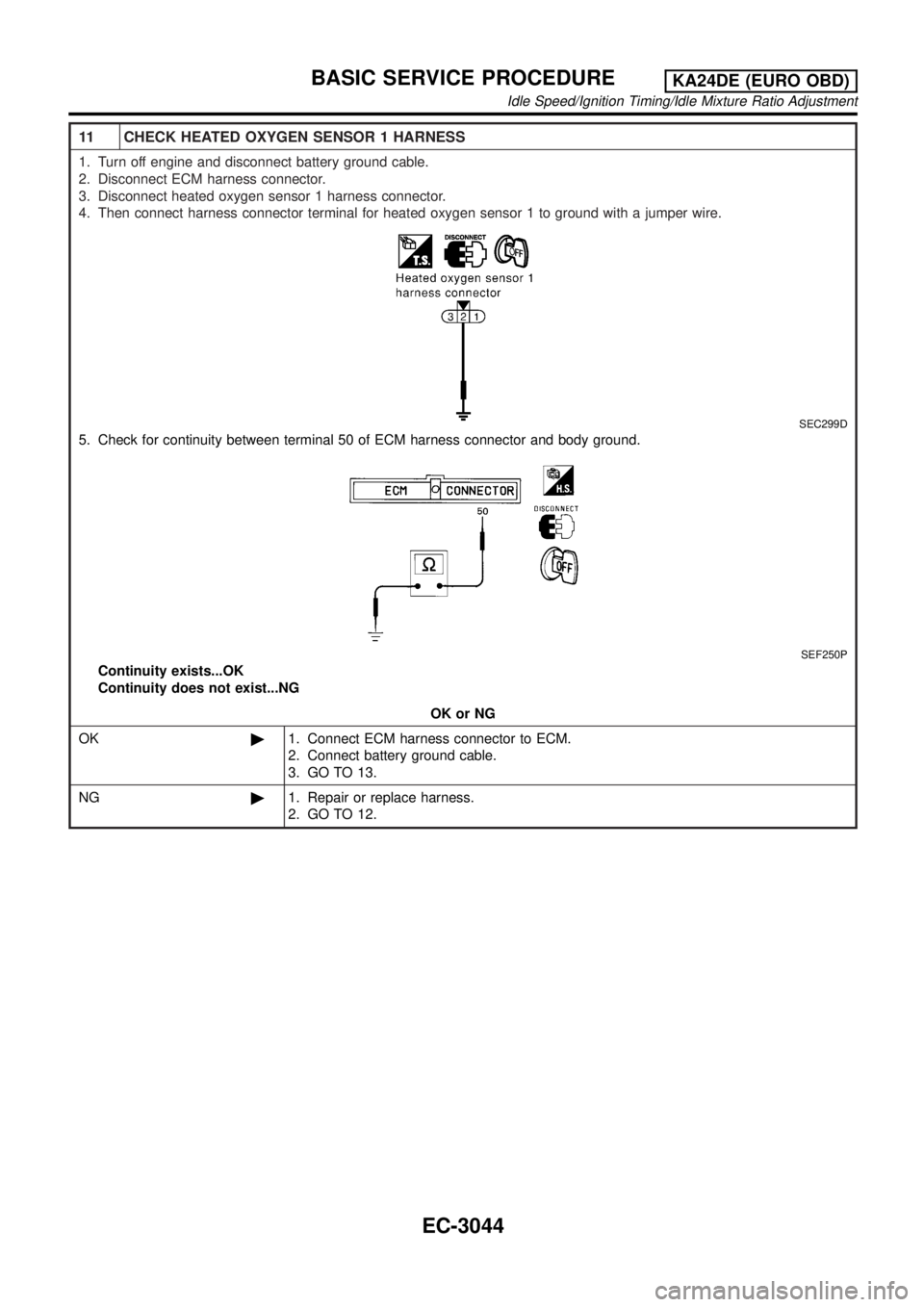

11 CHECK HEATED OXYGEN SENSOR 1 HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 harness connector.

4. Then connect harness connector terminal for heated oxygen sensor 1 to ground with a jumper wire.

SEC299D

5. Check for continuity between terminal 50 of ECM harness connector and body ground.

SEF250P

Continuity exists...OK

Continuity does not exist...NG

OK or NG

OK©1. Connect ECM harness connector to ECM.

2. Connect battery ground cable.

3. GO TO 13.

NG©1. Repair or replace harness.

2. GO TO 12.

BASIC SERVICE PROCEDUREKA24DE (EURO OBD)

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment

EC-3044