recommended oil NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 515 of 1306

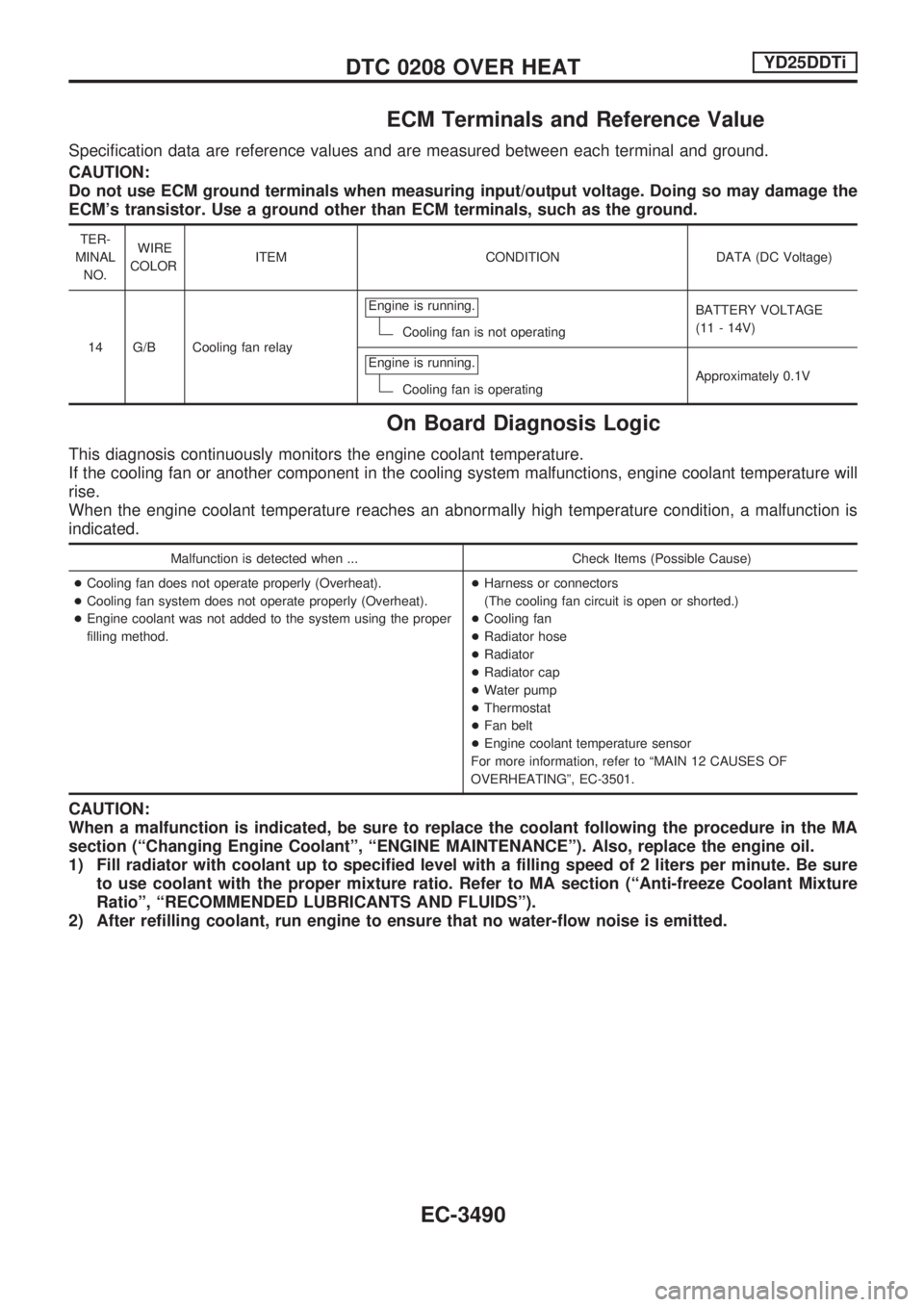

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

14 G/B Cooling fan relayEngine is running.

Cooling fan is not operatingBATTERY VOLTAGE

(11 - 14V)

Engine is running.

Cooling fan is operatingApproximately 0.1V

On Board Diagnosis Logic

This diagnosis continuously monitors the engine coolant temperature.

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

Malfunction is detected when ... Check Items (Possible Cause)

+Cooling fan does not operate properly (Overheat).

+Cooling fan system does not operate properly (Overheat).

+Engine coolant was not added to the system using the proper

filling method.+Harness or connectors

(The cooling fan circuit is open or shorted.)

+Cooling fan

+Radiator hose

+Radiator

+Radiator cap

+Water pump

+Thermostat

+Fan belt

+Engine coolant temperature sensor

For more information, refer to ªMAIN 12 CAUSES OF

OVERHEATINGº, EC-3501.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant following the procedure in the MA

section (ªChanging Engine Coolantº, ªENGINE MAINTENANCEº). Also, replace the engine oil.

1) Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure

to use coolant with the proper mixture ratio. Refer to MA section (ªAnti-freeze Coolant Mixture

Ratioº, ªRECOMMENDED LUBRICANTS AND FLUIDSº).

2) After refilling coolant, run engine to ensure that no water-flow noise is emitted.

DTC 0208 OVER HEATYD25DDTi

EC-3490

Page 1023 of 1306

MAINTENANCE

SECTION

MA

MODIFICATION NOTICE:

+KA24DE engine information has been added. Refer to the Service Manual of D22 Supplement-II (SM9E-

D22BE0E) for the maintenance procedure not included here.

+YD25DDTi engine has been added.

CONTENTS

PERIODIC MAINTENANCE................................ 3002

Maintenance Schedule for Petrol Engines

(Annual Mileage < 30,000 km/year) ................ 3002

Maintenance Schedule for Diesel Engines

(Annual Mileage < 30,000 km/year) ................ 3003

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)... 3004

Maintenance Schedule for Petrol Engines

(Annual Mileage > 30,000 km/year) ................ 3005

Maintenance Schedule for Diesel Engines

(Annual Mileage > 30,000 km/year) ................ 3006

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km/year)... 3007

RECOMMENDED FLUIDS AND

LUBRICANTS...................................................... 3008

Fluids and Lubricants....................................... 3008

SAE Viscosity Number..................................... 3009

KA24DE

ENGINE MAINTENANCE.................................... 3010Changing Air Cleaner Filter ............................. 3010

Changing Positive Crankcase Ventilation

(PCV) Filter ...................................................... 3010

YD25DDTi

ENGINE MAINTENANCE.................................... 3011

Checking Tightening Torque............................ 3011

Checking Drive Belts ....................................... 3011

Changing Engine Oil ........................................ 3012

Changing Oil Filter ........................................... 3013

Changing Engine Coolant ................................ 3014

Checking Cooling System................................ 3016

Checking and Replacing Fuel Filter and

Draining Water ................................................. 3018

Checking Fuel Lines ........................................ 3019

Cleaning and Replacing Air Cleaner Filter ...... 3019

Checking Cyclone Pre-air Cleaner .................. 3019

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 3020

Engine Maintenance ........................................ 3020

MA

Page 1030 of 1306

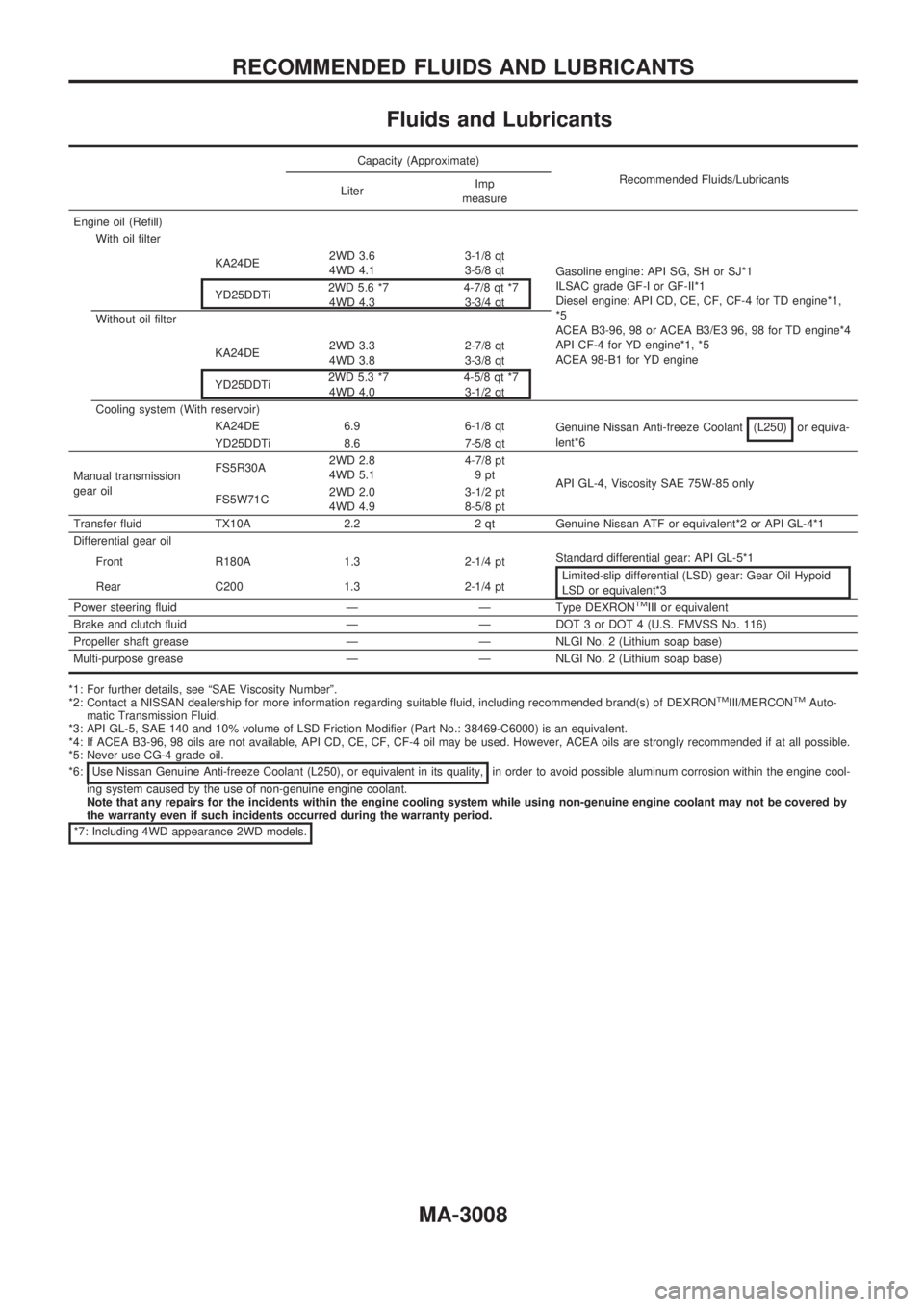

Fluids and Lubricants

Capacity (Approximate)

Recommended Fluids/Lubricants

LiterImp

measure

Engine oil (Refill)

With oil filter

Gasoline engine: API SG, SH or SJ*1

ILSAC grade GF-I or GF-II*1

Diesel engine: API CD, CE, CF, CF-4 for TD engine*1,

*5

ACEA B3-96, 98 or ACEA B3/E3 96, 98 for TD engine*4

API CF-4 for YD engine*1, *5

ACEA 98-B1 for YD engine KA24DE2WD 3.6

4WD 4.13-1/8 qt

3-5/8 qt

YD25DDTi2WD 5.6 *7

4WD 4.34-7/8 qt *7

3-3/4 qt

Without oil filter

KA24DE2WD 3.3

4WD 3.82-7/8 qt

3-3/8 qt

YD25DDTi2WD 5.3 *7

4WD 4.04-5/8 qt *7

3-1/2 qt

Cooling system (With reservoir)

KA24DE 6.9 6-1/8 qt

Genuine Nissan Anti-freeze Coolant (L250)

or equiva-

lent*6

YD25DDTi 8.6 7-5/8 qt

Manual transmission

gear oilFS5R30A2WD 2.8

4WD 5.14-7/8 pt

9pt

API GL-4, Viscosity SAE 75W-85 only

FS5W71C2WD 2.0

4WD 4.93-1/2 pt

8-5/8 pt

Transfer fluid TX10A 2.2 2 qt Genuine Nissan ATF or equivalent*2 or API GL-4*1

Differential gear oil

Front R180A 1.3 2-1/4 pt

Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear: Gear Oil Hypoid

LSD or equivalent*3 Rear C200 1.3 2-1/4 pt

Power steering fluid Ð Ð Type DEXRON

TMIII or equivalent

Brake and clutch fluid Ð Ð DOT 3 or DOT 4 (U.S. FMVSS No. 116)

Propeller shaft grease Ð Ð NLGI No. 2 (Lithium soap base)

Multi-purpose grease Ð Ð NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Contact a NISSAN dealership for more information regarding suitable fluid, including recommended brand(s) of DEXRONTMIII/MERCONTMAuto-

matic Transmission Fluid.

*3: API GL-5, SAE 140 and 10% volume of LSD Friction Modifier (Part No.: 38469-C6000) is an equivalent.

*4: If ACEA B3-96, 98 oils are not available, API CD, CE, CF, CF-4 oil may be used. However, ACEA oils are strongly recommended if at all possible.

*5: Never use CG-4 grade oil.

*6: Use Nissan Genuine Anti-freeze Coolant (L250), or equivalent in its quality,

in order to avoid possible aluminum corrosion within the engine cool-

ing system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be covered by

the warranty even if such incidents occurred during the warranty period.

*7: Including 4WD appearance 2WD models.

RECOMMENDED FLUIDS AND LUBRICANTS

MA-3008

Page 1034 of 1306

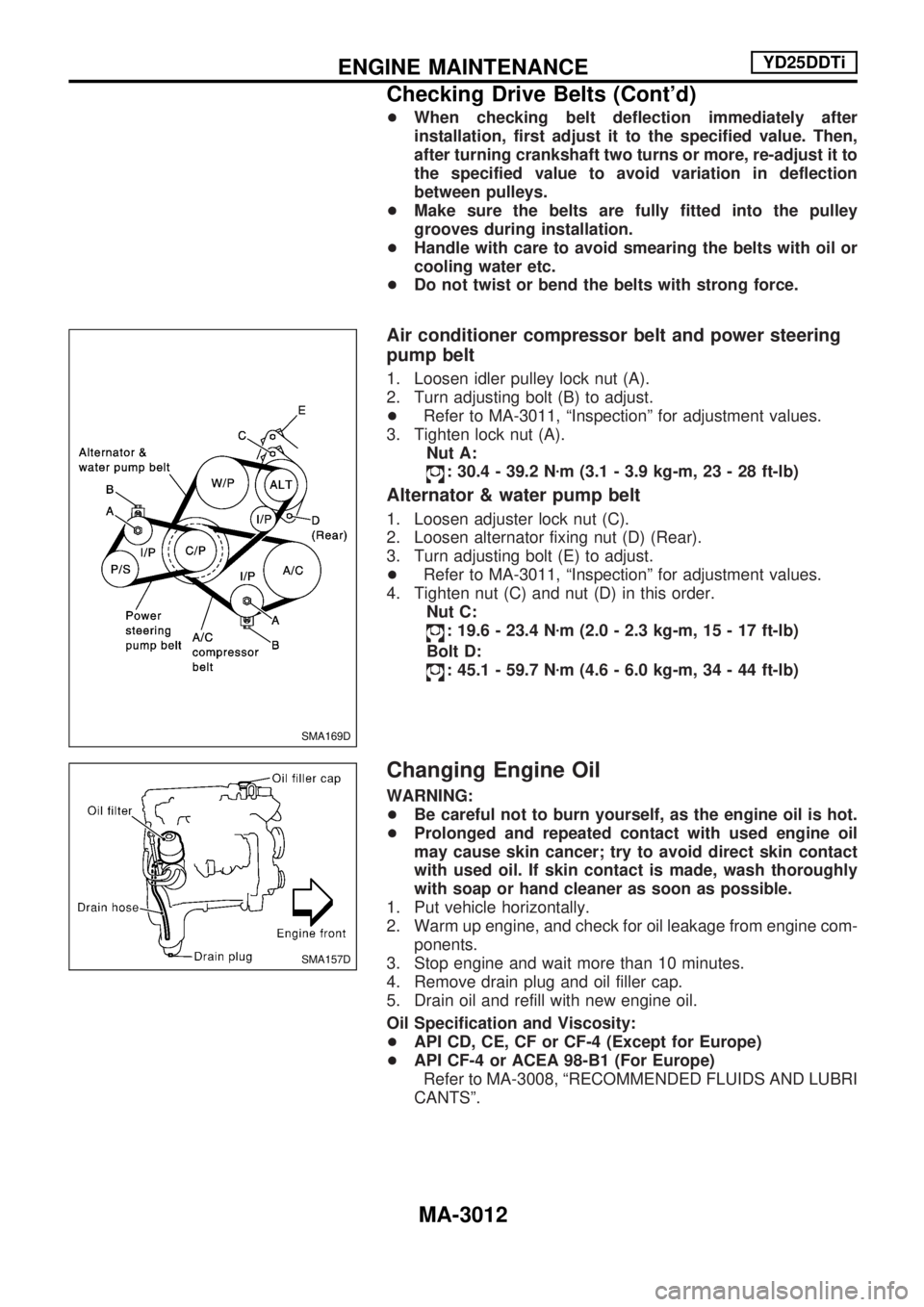

+When checking belt deflection immediately after

installation, first adjust it to the specified value. Then,

after turning crankshaft two turns or more, re-adjust it to

the specified value to avoid variation in deflection

between pulleys.

+Make sure the belts are fully fitted into the pulley

grooves during installation.

+Handle with care to avoid smearing the belts with oil or

cooling water etc.

+Do not twist or bend the belts with strong force.

Air conditioner compressor belt and power steering

pump belt

1. Loosen idler pulley lock nut (A).

2. Turn adjusting bolt (B) to adjust.

+Refer to MA-3011, ªInspectionº for adjustment values.

3. Tighten lock nut (A).

Nut A:

: 30.4 - 39.2 Nzm (3.1 - 3.9 kg-m, 23 - 28 ft-lb)

Alternator & water pump belt

1. Loosen adjuster lock nut (C).

2. Loosen alternator fixing nut (D) (Rear).

3. Turn adjusting bolt (E) to adjust.

+Refer to MA-3011, ªInspectionº for adjustment values.

4. Tighten nut (C) and nut (D) in this order.

Nut C:

: 19.6 - 23.4 Nzm (2.0 - 2.3 kg-m, 15 - 17 ft-lb)

Bolt D:

: 45.1 - 59.7 Nzm (4.6 - 6.0 kg-m, 34 - 44 ft-lb)

Changing Engine Oil

WARNING:

+Be careful not to burn yourself, as the engine oil is hot.

+Prolonged and repeated contact with used engine oil

may cause skin cancer; try to avoid direct skin contact

with used oil. If skin contact is made, wash thoroughly

with soap or hand cleaner as soon as possible.

1. Put vehicle horizontally.

2. Warm up engine, and check for oil leakage from engine com-

ponents.

3. Stop engine and wait more than 10 minutes.

4. Remove drain plug and oil filler cap.

5. Drain oil and refill with new engine oil.

Oil Specification and Viscosity:

+API CD, CE, CF or CF-4 (Except for Europe)

+API CF-4 or ACEA 98-B1 (For Europe)

Refer to MA-3008, ªRECOMMENDED FLUIDS AND LUBRI

CANTSº.

SMA169D

SMA157D

ENGINE MAINTENANCEYD25DDTi

Checking Drive Belts (Cont'd)

MA-3012