ECU NISSAN PICK-UP 2004 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: PICK-UP, Model: NISSAN PICK-UP 2004Pages: 53, PDF Size: 1.01 MB

Page 27 of 53

Adjustments

NOTE:

Adjust valve clearance while engine is cold.

+Remove the adjusting shim for parts which are outside the

specified valve clearance.

1. Remove the spill tube. Refer to ªBASIC SERVICE PROCE-

DUREº in EC section.

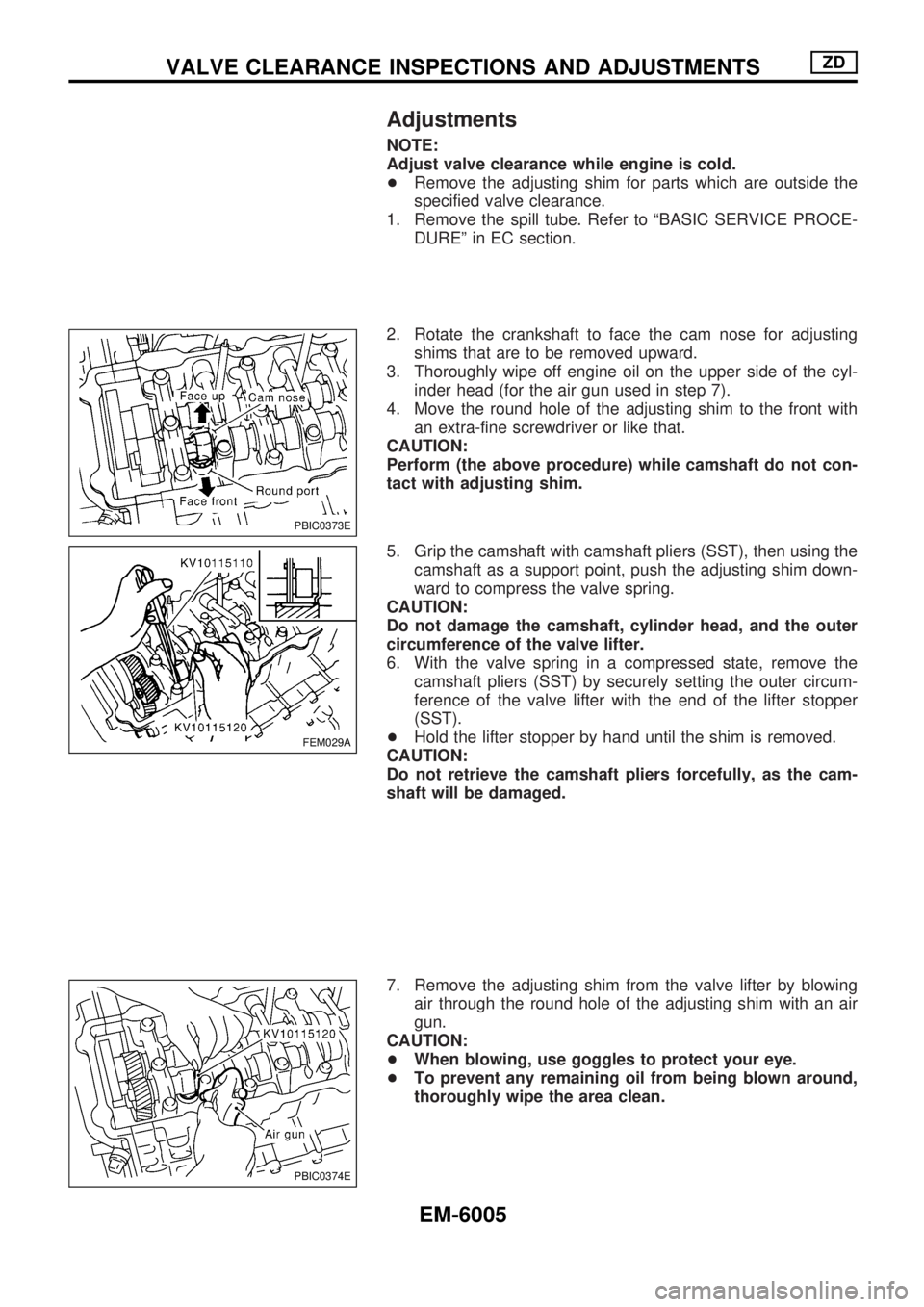

2. Rotate the crankshaft to face the cam nose for adjusting

shims that are to be removed upward.

3. Thoroughly wipe off engine oil on the upper side of the cyl-

inder head (for the air gun used in step 7).

4. Move the round hole of the adjusting shim to the front with

an extra-fine screwdriver or like that.

CAUTION:

Perform (the above procedure) while camshaft do not con-

tact with adjusting shim.

5. Grip the camshaft with camshaft pliers (SST), then using the

camshaft as a support point, push the adjusting shim down-

ward to compress the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head, and the outer

circumference of the valve lifter.

6. With the valve spring in a compressed state, remove the

camshaft pliers (SST) by securely setting the outer circum-

ference of the valve lifter with the end of the lifter stopper

(SST).

+Hold the lifter stopper by hand until the shim is removed.

CAUTION:

Do not retrieve the camshaft pliers forcefully, as the cam-

shaft will be damaged.

7. Remove the adjusting shim from the valve lifter by blowing

air through the round hole of the adjusting shim with an air

gun.

CAUTION:

+When blowing, use goggles to protect your eye.

+To prevent any remaining oil from being blown around,

thoroughly wipe the area clean.

PBIC0373E

FEM029A

PBIC0374E

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

EM-6005

Page 33 of 53

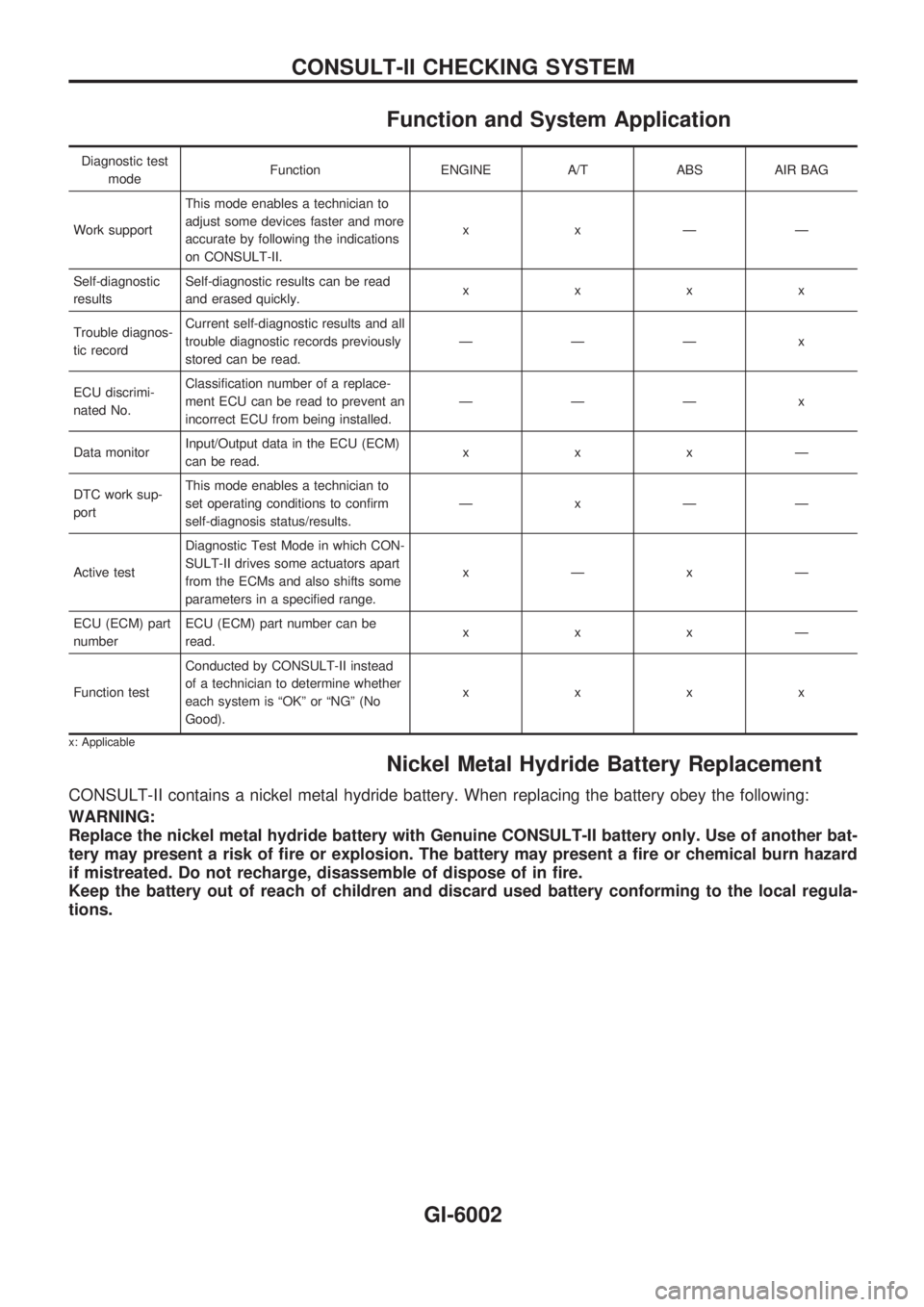

Function and System Application

Diagnostic test

modeFunction ENGINE A/T ABS AIR BAG

Work supportThis mode enables a technician to

adjust some devices faster and more

accurate by following the indications

on CONSULT-II.xxÐÐ

Self-diagnostic

resultsSelf-diagnostic results can be read

and erased quickly.xxxx

Trouble diagnos-

tic recordCurrent self-diagnostic results and all

trouble diagnostic records previously

stored can be read.ÐÐÐ x

ECU discrimi-

nated No.Classification number of a replace-

ment ECU can be read to prevent an

incorrect ECU from being installed.ÐÐÐ x

Data monitorInput/Output data in the ECU (ECM)

can be read.xxxÐ

DTC work sup-

portThis mode enables a technician to

set operating conditions to confirm

self-diagnosis status/results.ÐxÐÐ

Active testDiagnostic Test Mode in which CON-

SULT-II drives some actuators apart

from the ECMs and also shifts some

parameters in a specified range.xÐxÐ

ECU (ECM) part

numberECU (ECM) part number can be

read.xxxÐ

Function testConducted by CONSULT-II instead

of a technician to determine whether

each system is ªOKº or ªNGº (No

Good).xxxx

x: Applicable

Nickel Metal Hydride Battery Replacement

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

if mistreated. Do not recharge, disassemble of dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regula-

tions.

CONSULT-II CHECKING SYSTEM

GI-6002