drain bolt NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 76 of 238

Cooling and Heating Systems

7. THERMOSTAT HOUSING

Special Equipment Required:

To Adjust Camshaft Drive Belt — Adjusting tool

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) On 1.6 liter models, remove the air cleaner

assembly from the engine. Refer to the Fuel and

Engine Management section if necessary. (3) Drain the cooling system as previously de-

scribed. (4) Remove the camshaft drive belt as described

in the Engine section under the heading Camshaft

Drive Belt. (5) Remove the bolts retaining the camshaft

drive belt rear cover to the cylinder block and remove

the rear cover.

\ COOLANT TEMPERATURE SENSOR TEMPERATURE SENDER SWITCH

View of the thermostat housing and

components.

(6) Disconnect the top radi ator hose, the heater

hose and the inlet manifold heater hose from the

thermostat housing.

(7) Disconnect the wire from the temperature

sender switch and the coolant temperature sensor. (8) Remove the bolts retaining the thermostat

housing to the cylinder head and remove the thermo-

stat housing and the O ring from the cylinder head. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all mounting faces are clean.

(2) Renew the O ring on installation.

NOTE; Ensure that the O ring is not

twisted. Do not use sealant.

(3) Tighten the thermostat housing retaining

bolts to the specified torque. (4) Adjust the camshaft drive belt tension as

described in the Engine section under the heading

Camshaft Drive Belt. (5) Fill the cooling system as previously de-

scribed and check for coolant leaks. 8. WATER PUMP

Special Equipment Required:

To Adjust Camshaft Drive Belt — Adjusting tool

TO REMOVE AND INSTAL

NOTE: The water pump is non-repairable

and if faulty must be renewed as a complete

assembly.

(1)

Drain the cooling system as previously de-

scribed.

(2) Remove the camshaft drive belt as described

in the Engine section under the heading Camshaft

Drive Belt. (3) Remove the water pump retaining bolts and

remove the water pump and the O ring from the

engine. Installation is a reversal of the removal procedure

with attention to the following points:

View of the water pump and components removed

from the vehicle.

(1) Ensure that all mounting faces are clean.

(2) Use a new O ring and smear it with a liberal

amount of silicone grease.

(3) Install the water pump to the engine but

do

not tighten the retaining bolts until the camshaft drive

belt has been installed and tensioned correctly as

described in the Engine section under the heading

Camshaft Drive Belt.

(4) Fill the cooling system as previously de-

scribed in this section and check for coolant leaks.

9. WELCH PLUGS

To facilitate the casting of the cylinder block and

cylinder head passages and water jackets, a number of

openings had to be ma de at manufacture.

Page 78 of 238

78 Cooling and Heating Systems

The air conditioner operates only when the engine

is running as the compressor is belt driven from the

engine.

Operating the air conditioner with the tempera-

ture control raised to a hot setting will produce

dehumidified hot air which is particularly useful for

demisting the vehicle glass.

Maximum cooling is achieved by operating the air

conditioner with the temperature control lowered

fully to the coldest setting . Operate the fan at high

speed when using the coldest temperature setting to

avoid forming ice on the evaporator.

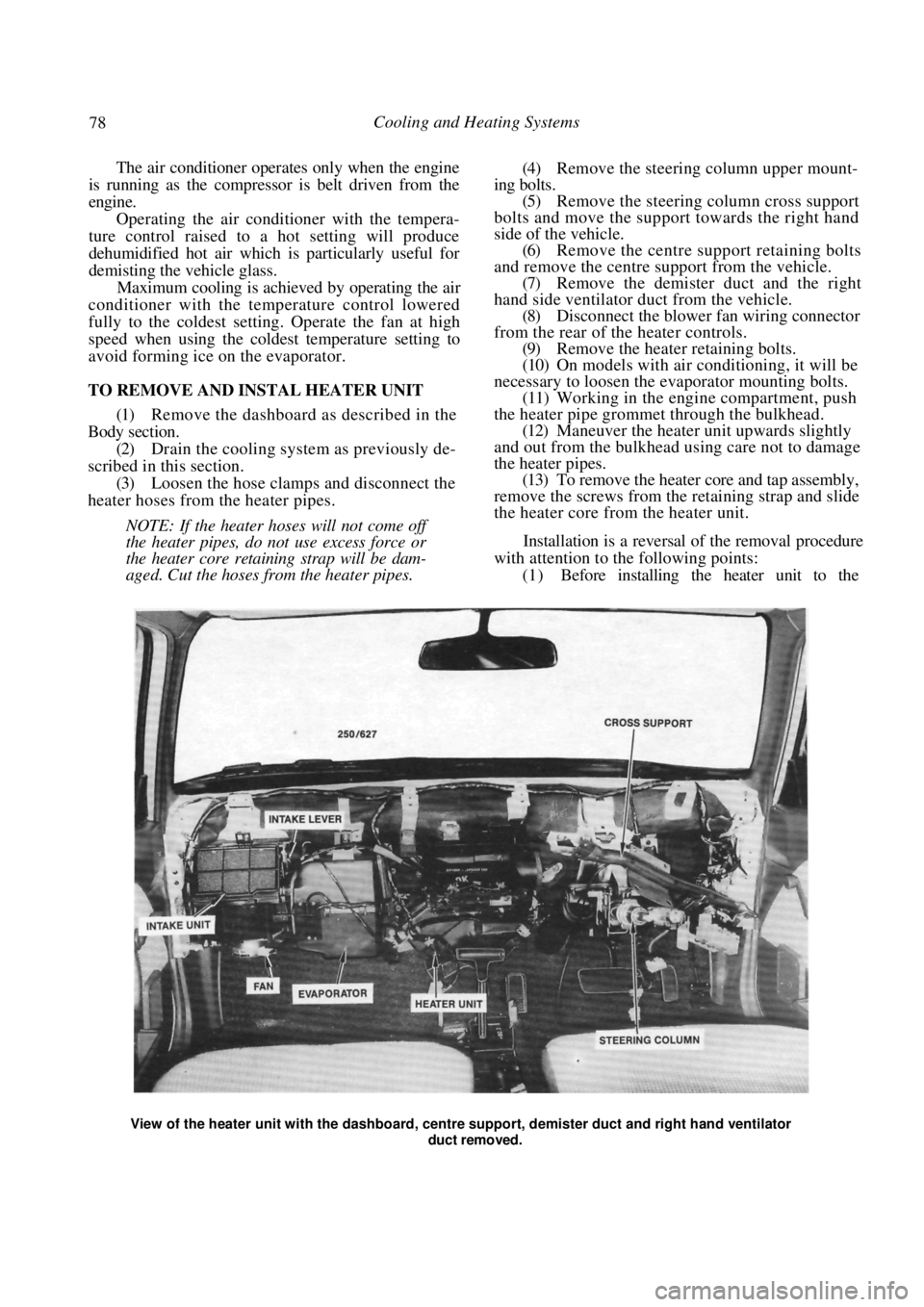

TO REMOVE AND INSTAL HEATER UNIT

(1) Remove the dashboard as described in the

Body section. (2) Drain the cooling system as previously de-

scribed in this section. (3) Loosen the hose clamps and disconnect the

heater hoses from the heater pipes.

NOTE: If the heater hos es will not come off

the heater pipes, do not use excess force or

the heater core retaining strap will be dam-

aged. Cut the hoses from the heater pipes.

(4) Remove the steering column upper mount-

ing bolts. (5) Remove the steering column cross support

bolts and move the support towards the right hand

side of the vehicle. (6) Remove the centre support retaining bolts

and remove the centre support from the vehicle.

(7) Remove the demister duct and the right

hand side ventilator duct from the vehicle. (8) Disconnect the blower fan wiring connector

from the rear of the heater controls. (9) Remove the heater retaining bolts.

(10) On models with air conditioning, it will be

necessary to loosen the evaporator mounting bolts. (11) Working in the engine compartment, push

the heater pipe grommet through the bulkhead. (12) Maneuver the heater unit upwards slightly

and out from the bulkhead using care not to damage

the heater pipes. (13) To remove the heater core and tap assembly,

remove the screws from the retaining strap and slide

the heater core from the heater unit.

Installation is a reversal of the removal procedure

with attention to the following points:

(1 ) Before installing the heater unit to the

View of the heater unit with the dashboard, centr e support, demister duct and right hand ventilator

duct removed.

Page 80 of 238

Cooling and Heating Systems

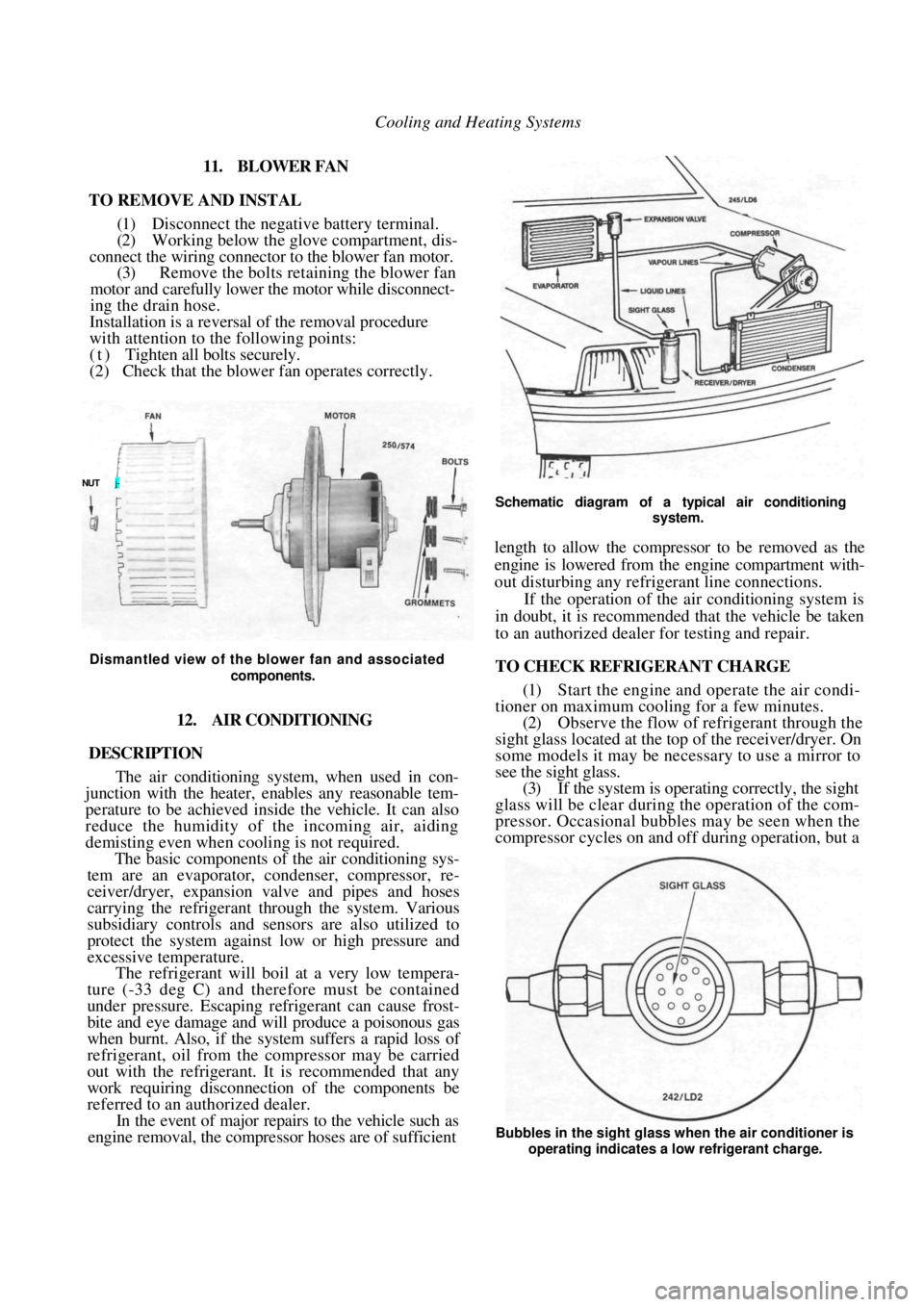

11. BLOWER FAN

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) Working below the glov e compartment, dis-

connect the wiring connector to the blower fan motor.

(3) Remove the bolts retaining the blower fan

motor and carefully lower the motor while disconnect-

ing the drain hose.

Installation is a reversal of the removal procedure

with attention to the following points:

( t ) Tighten all bolts securely.

(2) Check that the blow er fan operates correctly.

Dismantled view of the blower fan and associated

components.

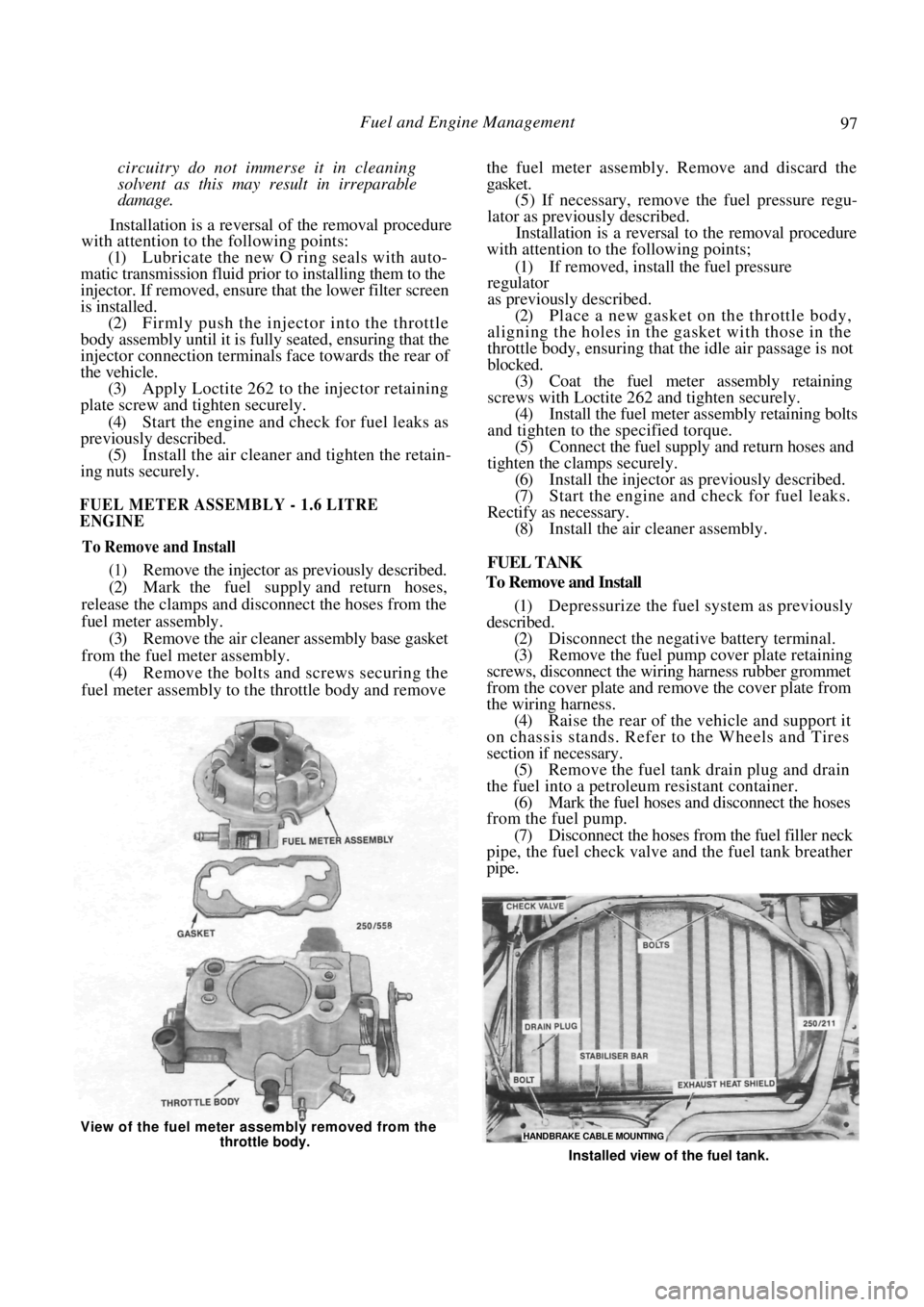

12. AIR CONDITIONING

DESCRIPTION

The air conditioning system, when used in con-

junction with the heater, enables any reasonable tem-

perature to be achieved inside the vehicle. It can also

reduce the humidity of the incoming air, aiding

demisting even when cooling is not required.

The basic components of the air conditioning sys-

tem are an evaporator, co ndenser, compressor, re-

ceiver/dryer, expansion valve and pipes and hoses

carrying the refrigerant through the system. Various

subsidiary controls and sensors are also utilized to

protect the system against low or high pressure and

excessive temperature.

The refrigerant will boil at a very low tempera-

ture (-33 deg C) and therefore must be contained

under pressure. Escaping refrigerant can cause frost-

bite and eye damage and will produce a poisonous gas

when burnt. Also, if the system suffers a rapid loss of

refrigerant, oil from the compressor may be carried

out with the refrigerant. It is recommended that any

work requiring disconnection of the components be

referred to an au thorized dealer.

In the event of major repair s to the vehicle such as

engine removal, the compress or hoses are of sufficient

Schematic diagram of a typical air conditioning

system.

length to allow the compressor to be removed as the

engine is lowered from the engine compartment with-

out disturbing any refrigerant line connections.

If the operation of the air conditioning system is

in doubt, it is recommended that the vehicle be taken

to an authorized dealer for testing and repair.

TO CHECK REFRIGERANT CHARGE

(1) Start the engine and operate the air condi-

tioner on maximum cooling for a few minutes.

(2) Observe the flow of refrigerant through the

sight glass located at the top of the receiver/dryer. On

some models it may be necessary to use a mirror to

see the sight glass. (3) If the system is operating correctly, the sight

glass will be clear during the operation of the com-

pressor. Occasional bubbles may be seen when the

compressor cycles on and off during operation, but a

NUT j-

Bubbles in the sight glass when the air conditioner is

operating indicates a low refrigerant charge.

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

Page 97 of 238

Fuel and Engine Management 97

circuitry do not immerse it in cleaning

solvent as this may result in irreparable

damage.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Lubricate the new O ring seals with auto-

matic transmission fluid prior to installing them to the

injector. If removed, ensure that the lower filter screen

is installed. (2) Firmly push the injector into the throttle

body assembly until it is fully seated, ensuring that the

injector connection terminals face towards the rear of

the vehicle.

(3) Apply Loctite 262 to the injector retaining

plate screw and tighten securely.

(4) Start the engine and check for fuel leaks as

previously described.

(5) Install the air cleaner and tighten the retain-

ing nuts securely.

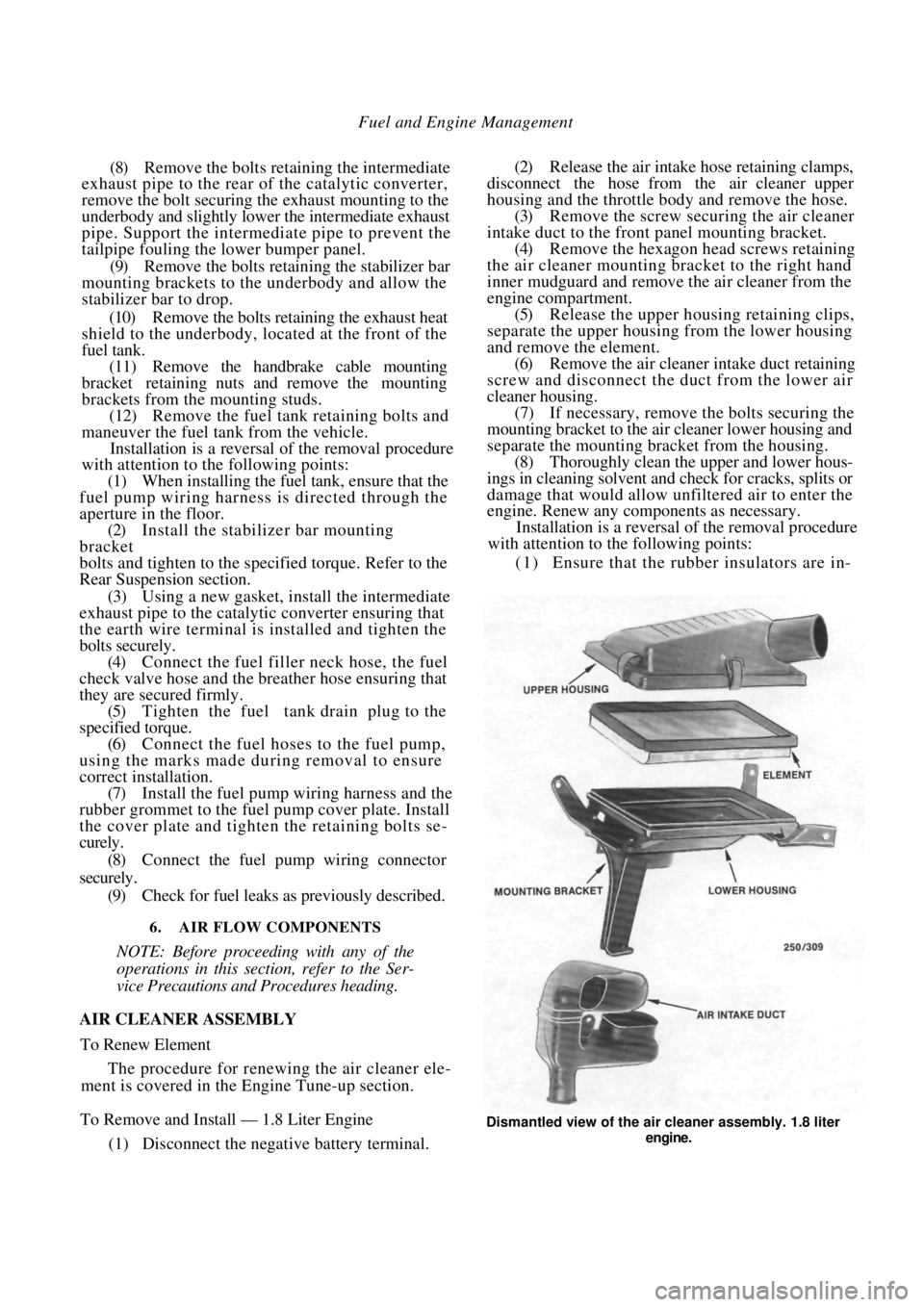

FUEL METER ASSEMBLY - 1.6 LITRE

ENGINE

To Remove and Install

(1) Remove the injector as previously described.

(2) Mark the fuel supp ly and return hoses,

release the clamps and disconnect the hoses from the

fuel meter assembly.

(3) Remove the air cleaner assembly base gasket

from the fuel meter assembly. (4) Remove the bolts and screws securing the

fuel meter assembly to the throttle body and remove the fuel meter assembly. Remove and discard the

gasket.

(5) If necessary, remove the fuel pressure regu-

lator as previously described.

Installation is a reversal to the removal procedure

with attention to the following points;

(1) If removed, install the fuel pressure

regulator

as previously described.

(2) Place a new gasket on the throttle body,

aligning the holes in the gasket with those in the

throttle body, ensuring that the idle air passage is not

blocked. (3) Coat the fuel meter assembly retaining

screws with Loctite 26 2 and tighten securely.

(4) Install the fuel meter assembly retaining bolts

and tighten to the specified torque.

(5) Connect the fuel supply and return hoses and

tighten the clamps securely. (6) Install the injector as previously described.

(7) Start the engine and check for fuel leaks.

Rectify as necessary. (8) Install the air cleaner assembly.

FUEL TANK

To Remove and Install

(1) Depressurize the fuel system as previously

described.

(2) Disconnect the negative battery terminal.

(3) Remove the fuel pump cover plate retaining

screws, disconnect the wi ring harness rubber grommet

from the cover plate and remove the cover plate from

the wiring harness. (4) Raise the rear of the vehicle and support it

on chassis stands. Refer to the Wheels and Tires

section if necessary. (5) Remove the fuel tank drain plug and drain

the fuel into a petroleum resistant container. (6) Mark the fuel hoses and disconnect the hoses

from the fuel pump.

(7) Disconnect the hoses from the fuel filler neck

pipe, the fuel check valve and the fuel tank breather

pipe.

View of the fuel meter assembly removed from the

throttle body. HANDBRAKE CABLE MOUNTING

Installed view of the fuel tank.

Page 98 of 238

Fuel and Engine Management

(8) Remove the bolts retaining the intermediate

exhaust pipe to the rear of the catalytic converter,

remove the bolt securing the exhaust mounting to the

underbody and slightly lower the intermediate exhaust

pipe. Support the intermediate pipe to prevent the

tailpipe fouling the lower bumper panel.

(9) Remove the bolts retaining the stabilizer bar

mounting brackets to the underbody and allow the

stabilizer bar to drop.

(10) Remove the bolts retaining the exhaust heat

shield to the underbody, located at the front of the

fuel tank. (11) Remove the handbrake cable mounting

bracket retaining nuts and remove the mounting

brackets from the mounting studs. (12) Remove the fuel tank retaining bolts and

maneuver the fuel tank from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing the fuel tank, ensure that the

fuel pump wiring harness is directed through the

aperture in the floor. (2) Install the stabilizer bar mounting

bracket

bolts and tighten to the specified torque. Refer to the

Rear Suspension section.

(3) Using a new gasket, install the intermediate

exhaust pipe to the catalyti c converter ensuring that

the earth wire terminal is installed and tighten the

bolts securely. (4) Connect the fuel filler neck hose, the fuel

check valve hose and the breat her hose ensuring that

they are secured firmly. (5) Tighten the fuel tank drain plug to the

specified torque. (6) Connect the fuel hoses to the fuel pump,

using the marks made during removal to ensure

correct installation. (7) Install the fuel pump wiring harness and the

rubber grommet to the fuel pump cover plate. Install

the cover plate and tighten the retaining bolts se-

curely.

(8) Connect the fuel pump wiring connector

securely. (9) Check for fuel leaks as previously described.

6. AIR FLOW COMPONENTS

NOTE: Before proceeding with any of the

operations in this section, refer to the Ser-

vice Precautions and Procedures heading.

AIR CLEANER ASSEMBLY

To Renew Element

The procedure for renewing the air cleaner ele-

ment is covered in the Engine Tune-up section.

To Remove and Install — 1.8 Liter Engine

(1) Disconnect the negative battery terminal.

(2) Release the air intake hose retaining clamps,

disconnect the hose from the air cleaner upper

housing and the throttle body and remove the hose. (3) Remove the screw securing the air cleaner

intake duct to the front panel mounting bracket. (4) Remove the hexagon head screws retaining

the air cleaner mounting bracket to the right hand

inner mudguard and remove the air cleaner from the

engine compartment. (5) Release the upper housing retaining clips,

separate the upper housing from the lower housing

and remove the element. (6) Remove the air cleaner intake duct retaining

screw and disconnect the duct from the lower air

cleaner housing. (7) If necessary, remove the bolts securing the

mounting bracket to the ai r cleaner lower housing and

separate the mounting bracket from the housing. (8) Thoroughly clean the upper and lower hous-

ings in cleaning solvent and check for cracks, splits or

damage that would allow unfiltered air to enter the

engine. Renew any components as necessary.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the r ubber insulators are in-

Dismantled view of the ai r cleaner assembly. 1.8 liter

engine.

Page 126 of 238

126

MANUAL TRANSAXLE AND DRIVE SHAFTS

SPECIFICATIONS

TRANSAXLE

Type .....................................Five speed, synchromesh

on all forward gears

Model .......................................................... RS5F31A

Gear ratios: 1.6 liter -

First .......................................................... 3.333:1

Second...................................................... 1.955:1

Third......................................................... 1.286:1

Fourth....................................................... 0.975:1

Fifth.......................................................... 0.810:1

Reverse .................................................... 3.417:1

1.8 liter -

First .......................................................... 3.063:1

Second...................................................... 1.826:1

Third......................................................... 1.286:1

Fourth ....................................................... 0.975:1

Fifth.......................................................... 0.810:1

Reverse .................................................... 3.417:1

Gear end float:

Fifth...............................................0.18-0.41 mm

Second, third and fourth................0.20-0.40 mm

First ...............................................0.18-0.31 mm

Synchro ring to gear clearance:

Standard ............................................ 1.0-1.3 mm

Minimum ................................................. 0.7 mm

Turning torque (new bearings):

Differential assembly ........................ 3.9-7.8 Nm

Total differential and mainshaft __ 5.9-13.7 Nm

Differential and final drive:

Type ........................ Helical ring gear and pinion

Ratio......................................................... 4.167:1

Lubricant:

Grade ............................................. 80W-90 GL-4

Capacity ..................................................2.7 liters

DRIVE SHAFTS

C.V. joint lubrication:

Lubricant ........ Valvoline Special Moly EP grease

Amount ................................................. 40 grams

TORQUE WRENCH SETTINGS

Transaxle case retaining bolts ........

Cover plate to transaxle case .......................... 8.3 Nm

Input shaft bearing retainer bolts ..................... 21 Nm

Control bracket bolts ...................................... 8.3 Nm

Reverse check plug.......................................... 25 Nm

Ring gear to differential case........................... 88 Nm

Filler and drain plugs....................................... 34 Nm

Reverse lamps switch ...................................... 29 Nm

Upper and centre clutch housing to engine…...49 Nm

Lower clutch housing to engine ...................... 21 Nm

1. MANUAL TRANSAXLE AND DRIVE

SHAFT

TROUBLE SHOOTING

DIFFICULT GEAR CHANGE

(1) Faulty clutch or clutch release mechanism:

Check and adjust or overhaul the clutch or the clutch

release mechanism. (2) Loose control bracket retaining bolts: Dis-

mantle the transaxle and tighten the control bracket

retaining bolts. Apply Loctite or an equivalent to the

bolt threads to prevent a repeat of the problem.

(3) Faulty gear lever assembly: Check and

renew

or repair the gear lever assembly. (4) Bent or worn gear lever control rod: Repair

or renew the faulty components. (5) Worn transaxle selector mechanism: Over-

haul the transaxle assembly. Renew components as

necessary.

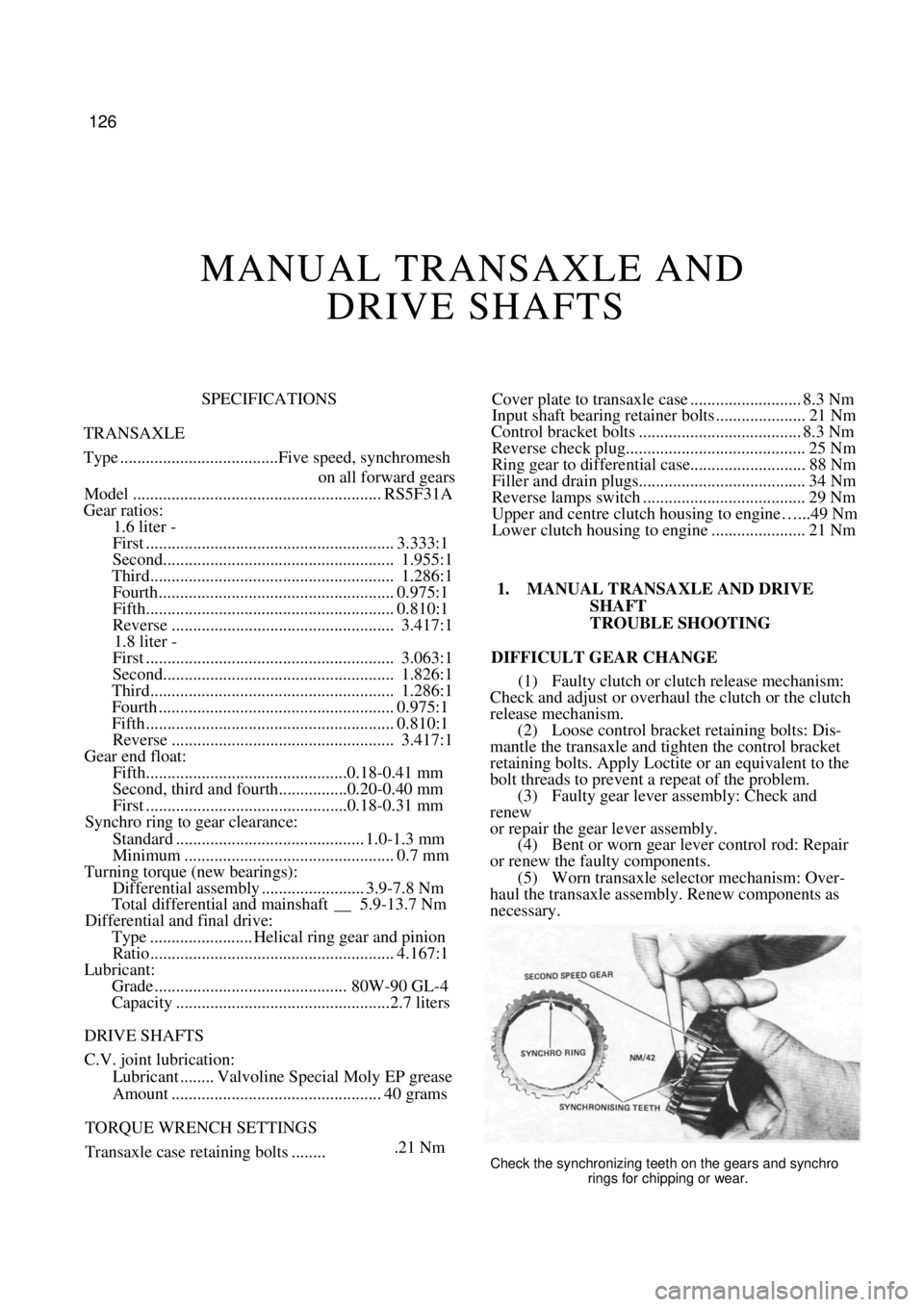

.21 NmCheck the synchronizing teeth on the gears and synchro

rings for chipping or wear.

Page 140 of 238

140

AUTOMATIC TRANSAXLE

SPECIFICATIONS

Make .............................................. JATCO RL3F01A

Type .....................3 speed and reverse epicyclic gear

train with lock up torque converter

Operation .................................... Automatic hydraulic

Lubricant:

Type....................................................... Dexron IT

Capacity................................................. 6.3 liters

TORQUE WRENCH SETTINGS

Drive plate to crankshaft bolls ........................60 Nm

Drive plate to torque converter bolts ..............49 Nm

Convener housing to engine ...........................22 Nm

Converter housing to transaxle ........................23 Nm

Transaxle sump to transaxle ............................. 7 Nm

Oil cooler pipe to transaxle .............................49 Nm

Selector shaft locknut .......................................42 Nm

Transaxle filter bolts.........................................12 Nm

1. AUTOMATIC TRANSAXLE TROUBLE SHOOTING

NO DRIVE IN D RANGE

{1) Low fluid level in transaxle: Check the fluid

level in the transaxle and top up if required.

(2) Incorrectly adjusted selector cable: Check

and adjust the selector cable as detailed. (3) Incorrect or contaminated transaxle fluid:

Drain and refill with the recommend type and quan-

tity of transaxle fluid.

NOTE: Check the possible causes in the

order given.

NO REVERSE IN R RANGE

(1) Low fluid level in transaxle: Check the fluid

level and top up if required. (2) Incorrectly adjusted selector linkage: Check

the condition of the selector cable, selector quadrant

and selector arm for wear and damage. Adjust as

required.

Check the drive shaft oil seals as a likely leak source.

SLIPPING OR ROUGH UPSHIFT

(1) Incorrectly adjusted selector linkage: Check

and adjust the selector linkage. (2) Low fluid level in transaxle: Check the fluid

level and top up if required.

NO TRANSAXLE KICKDOWN

(1) Incorrectly adjusted throttle cable: Check

and adjust the cable as detailed in the Fuel and Engine

Management section.

Check the oil cooler hose connections for leaks if the

fluid level is low.

Page 154 of 238

154 Steering —

(2) Remove the air inlet duct from the air

cleaner and throttle body. (3) Position a container or a piece of cloth

beneath the steering pump reservoir and disconnect

the fluid return and power steering pump supply hose

from the reservoir.

(4) Loosen the steering pump drive belt as

described in the Engi ne Tune-up section.

(5) Loosen the return hose clamp and the supply

union and disconnect the hoses from the power

steering pump. Plug the hoses to prevent the loss of

fluid.

(6) Loosen the retaining bolts and withdraw the

pump. (7) Thoroughly clean the exterior of the steering

pump and inspect it for cracks, damage and signs of

leakage.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pump and retaining bolts.

(2) Install the drive belt and adjust it as de-

scribed in the Engine Tune-up section. (3) Install the hoses to the power steering pump

and tighten securely. (4) Top up the pump reservoir and purge the

power steering system of air as previously described.

TO OVERHAUL

As specialist knowledge and equipment arc re-

quired to overhaul the power steering pump, it is

recommended that this operation be performed by an

authorized dealer or steering specialist.

6. POWER STEERING GEAR ASSEMBLY

Special Equipment Required:

To Renew Tie Rod Ball Housings — Large Still-

sons

TO REMOVE AND INSTAL

The procedures for removing and installing the

power steering gear are similar to those carried out in

the Manual Steering section under the Steering Gear

Assembly heading except fo r the following differences.

(1) Place a container under the pressure and

return pipes that are conn ected to the steering gear

valve housing. Remove the pipes and allow the fluid

to drain into the container. (2) Suitably seal the pipes and the steering gear

to prevent the entry of di rt whilst the pipes are

removed.

(3) Upon removal of the power steering gear,

thoroughly clean the steering gear except the tie rod

ends in a suitable solvent. Be careful not to allow the

solvent to enter the apertu res where the pressure and

return pipes were removed. (4) Check the pipes and co nnections for cracks,

damage or obstructions and renew as necessary.

Installed view of the power steering gear with the

engine removed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pressure and return pipes to the

steering gear valve housing and tighten securely. (2) Fill the power steering reservoir to the cor-

rect level and bleed the system as described previously

under the heading In Car Adjustments. Checks and

Minor Repairs. (3) Check all power steering pipe connections

for leaks and repair as necessary. (4) Check, and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. After adjustment ensure that the rubber boots

are not distorted or twisted and the rubber boot

clamps and clips are facing downward.

TO OVERHAUL

As specialist knowledge and equipment are re-

quired to overhaul the power steering gear, it is rec-

ommended that this opera tion be performed by an

authorized dealer or steering specialist.

TO RENEW TIE ROD BALL HOUSINGS

TRW Steering Gear

The renewal of the tie rod ball housings is the

same as for the manual steering gear. Refer to Part 2.

Manual Steering section.

PR24SA Steering Gear

(1) Remove the power steering gear assembly

from the vehicle as previously described.

(2) Carefully mount the power steering gear in a

vice equipped with soft jaws. Loosen the tie rod end

locknuts without disturbing the location of the tie rod

ends and unscrew the tie rod ends, taking note of the

number of turns required to remove them. Unscrew

and remove the locknuts from the tie rod. (3) Remove the clamps from the rubber boots

and remove the boots.

Page 175 of 238

Brakes 175

A pressure proportioning valve is incorporated in

each circuit to prevent premature locking of the rear

wheels during severe braking.

The four wheel hydraulically operated brakes

utilize disc brakes on each front wheel and disc brakes

or leading and trailing drum brake shoes on each rear

wheel.

The front disc brakes comprise a disc attached to

the hub assembly and a caliper bolted to the steering

knuckle.

The rear disc brakes comprise a disc and hub

assembly attached to the rear stub axle and a caliper

and anchor plate bolted to the backing plate.

The front and rear calipers are of the sliding type.

As pad wear takes place, the caliper piston is allowed

to slide outwards through the seal to take up a new

position in the caliper bore. Elastic deformation of the

seal takes place when the brakes are applied, which

returns the piston slightly when the brakes are re-

leased. Thus a constant clearance is maintained

between the pads and the disc when the brakes are in

the off position.

The disc brakes do not require periodical adjust-

ment in service to compensate for pad wear as they

are self adjusting.

The leading and trailing shoe drum brakes on the

rear wheels use a double ended wheel cylinder to

operate both brake shoes at the top. The lower end of

each brake shoe abuts a fixed anchor point. The brake

shoes are automatically adju sted when the brakes are

operated.

The handbrake operates the rear brakes via a

cable arrangement.

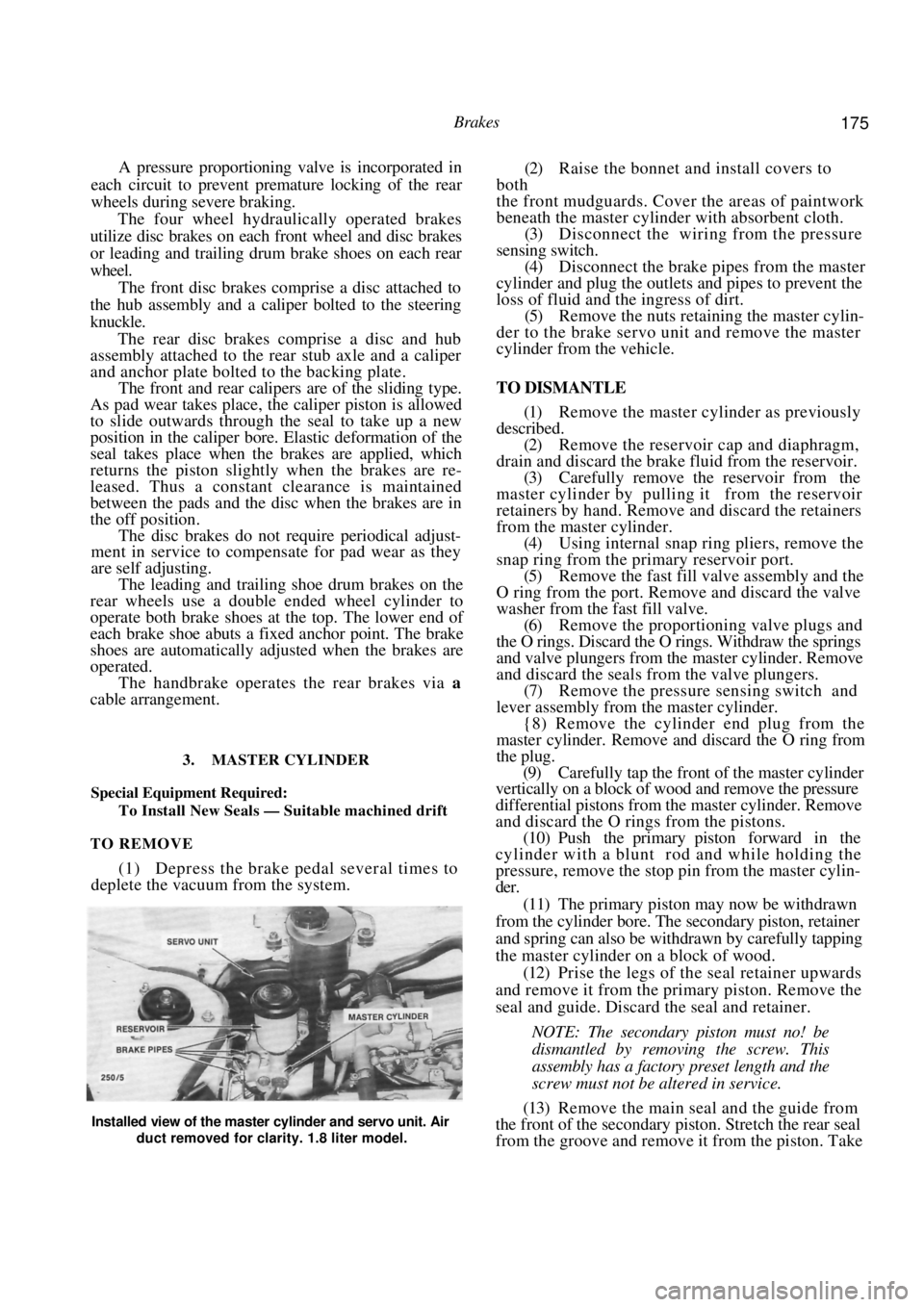

3. MASTER CYLINDER

Special Equipment Required:

To Install New Seals — Suitable machined drift

TO REMOVE

(1) Depress the brake pedal several times to

deplete the vacuum from the system.

(2) Raise the bonnet and install covers to

both

the front mudguards. Cover the areas of paintwork

beneath the master cylinder with absorbent cloth.

(3) Disconnect the wiring from the pressure

sensing switch. (4) Disconnect the brake pipes from the master

cylinder and plug the outlets and pipes to prevent the

loss of fluid and the ingress of dirt.

(5) Remove the nuts retaining the master cylin-

der to the brake servo unit and remove the master

cylinder from the vehicle.

TO DISMANTLE

(1) Remove the master cylinder as previously

described. (2) Remove the reservoir cap and diaphragm,

drain and discard the brake fluid from the reservoir. (3) Carefully remove the reservoir from the

master cylinder by pulling it from the reservoir

retainers by hand. Remove and discard the retainers

from the master cylinder. (4) Using internal snap ring pliers, remove the

snap ring from the primary reservoir port. (5) Remove the fast fill valve assembly and the

O ring from the port. Remove and discard the valve

washer from the fast fill valve.

(6) Remove the proportioning valve plugs and

the O rings. Discard the O rings. Withdraw the springs

and valve plungers from the master cylinder. Remove

and discard the seals from the valve plungers. (7) Remove the pressure sensing switch and

lever assembly from the master cylinder. {8) Remove the cylinder end plug from the

master cylinder. Remove and discard the O ring from

the plug.

(9) Carefully tap the front of the master cylinder

vertically on a block of wo od and remove the pressure

differential pistons from the master cylinder. Remove

and discard the O rings from the pistons. (10) Push the primary piston forward in the

cylinder with a blunt rod and while holding the

pressure, remove the stop pin from the master cylin-

der.

(11) The primary piston may now be withdrawn

from the cylinder bore. The secondary piston, retainer

and spring can also be withdrawn by carefully tapping

the master cylinder on a block of wood. (12) Prise the legs of the seal retainer upwards

and remove it from the primary piston. Remove the

seal and guide. Discard the seal and retainer.

NOTE: The secondary piston must no! be

dismantled by removing the screw. This

assembly has a factory p reset length and the

screw must not be altered in service.

(13) Remove the main seal and the guide from

the front of the secondary piston. Stretch the rear seal

from the groove and remove it from the piston. Take

Installed view of the master cylinder and servo unit. Air

duct removed for clarity. 1.8 liter model.