cooling NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 3 of 238

CONTENTS

INTRODUCTION........................................ 5

VEHICLE IDENTIFICATION AND

GENERAL SPECIFICATIONS................. 7

GENERAL INFORMATION...................... 8

Tools and equipment ............................................. 8 Safety .................................................................... 10

General repair procedures..................................... 11

LUBRICATION AND MAINTENANCE... 14

Specifications......................................................... 14

How to grease and oil change .............................. 14

Service schedule ................................................... 17

WHEELS AND TYRES............................. 21

Specifications......................................................... 21

How to change a road wheel ................................ 21

Tire wear troubl e shooting ..................................... 22

Care and main tenance ......................................... 23

ENGINE TUNE-UP.................................... 25

Tune-up specifications ........................................... 25

Tune-up operat ions............................................... 25

ROADSIDE TROUBLE SHOOTING....... 32

Trouble shoot ing.................................................... 32

To check ignition and el ectrical system ................ 33

To check fuel system ............................................ 34

To check mechani cal system ................................ 35

ENGINE....................................................... 37

Specifications ........................................................ 37

Engine mechanical tr ouble shooting ...................... 39

Description ............................................................ 41

Engine and transaxle assembly ........................... 42

Manifolds ............................................................... 44 Camshaft, rocker arms and tappets..................... 48

Cylinder head........................................................ 50

Engine sump and oil pum p pickup pipe................ 54

Oil pump ............................................................... 55

Pistons, connecting rods and cylinder bores ........ 57

Crankshaft and bearings ...................................... 60

Flywheel /drive plate............................................... 63

Engine mountings.................................................. 64

Exhaust system .................................................... 66

COOLING AND HEATING SYSTEMS.... 68

Specifications ........................................................ 68 Cooling system trouble shooting ........................... 68

Heater and air conditioner trouble shooting ......... 69 Description ............................................................ 70

Radiator ................................................................ 70

Cooling fan ............................................................ 73

Thermost at............................................................ 75

Thermostat housing .............................................. 76

Water pump .......................................................... 76

Welch plugs .......................................................... 76

Heater unit, water valv e and controls ................... 77

Blower fan ............................................................. 80

Air condition ing ..................................................... 80

FUEL AND ENGINE MANAGEMENT ... 82

Specifications ........................................................ 82 Fuel and engine management trouble shooting ... 82

Description ............................................................ 84

Service precautions and procedures

..................... 86

System diagnosis and adjustments ...................... 89

Fuel supply components ....................................... 92

Air flow components .............................................. 98

Electronic components .......................................... 104

EMISSION CONTROL............................. 117

Introduction ........................................................... 117

Crankcase ventilati on system............................... 117

Evaporate control system..................................... 117

Air preheat system — 1.6 liter engines ................ 119

Exhaust control system ........................................ 120

CLUTCH...................................................... 121

Specifications........................................................ 121

Clutch trouble shooting......................................... 121

Description ............................................................ 122

Clutch unit and release mechanism..................... 123

Clutch pedal ......................................................... 124

Clutch c able.......................................................... 124

Clutch adjustments ............................................... 125

MANUAL TRANSAXLE AND

DRIVE SHAFTS......................................... 126

Specifications ........................................................ 126

Manual transaxle and drive shaft trouble shooting 126

Description............................................................ 128

Transaxle assembly.............................................. 129

Differential and final drive assembly ..................... 135

Gear lever assembly ............................................ 136

Drive shafts .......................................................... 137

AUTOMATIC TRANSAXLE....................... 140

Specifications........................................................ 140

Automatic transaxle trouble shooting.................... 140

Description............................................................ 141

Transaxle fluid ...................................................... 141

Brake band........................................................... 142

Kickdown cable .................................................... 142

Transaxle select or linkage ................................... 142

Neutral safety switch ............................................ 142

Transaxle assembly .............................................. 143

STEERING................................................. 145

PART 1. STEERING TROUBLE SHOOTING....145

Faults, causes and remedies................................ 145

PART 2. MANUA L STEERING......................... 147

Specifications ........................................................ 147

Description............................................................ 147

Steering wheel ...................................................... 147

Steering column.................................................... 148

Steering gear assembly ....................................... 149

PART 3. POWE R STEERING .......................... 152

Specifications........................................................ 152

Description............................................................ 152

In car adjustments, checks and minor repairs ..... 152

Steering wheel ...................................................... 153

Steering column.................................................... 153 Power steering pump ........................................... 153

Power steering gear assembly............................. 154

Page 10 of 238

10 General Information

If tools are to be stored for any length of time, it is

good policy to wipe them with an oily cloth.

Bladed screwdrivers should be checked for dam-

age to the tip. If necessary, the tip can be returned to

its original profile by careful grinding. Do not grind

screwdriver tips to a sharp point.

Hammer heads should be secure on their handles

and should be regularly checked for cracking or other

damage.

Chisels and punches should be checked for dam-

age or 'mushrooming' of the head. Any faults should

be rectified by grinding.

Hydraulic jacks should be regularly checked for

fluid leaks. Chassis stands and car ramps should be

checked for damage and cracks. Any equipment that

is suspect should not be used.

STORES

For routine maintenance, stores of automotive

oils, greases and additives should be kept on hand.

The following is a suggested list.

Engine oil.

Brake fluid.

Manual transmission or automatic transmission

oil — automatic transmission oil is also used in

the power steering system.

Rear axle oil.

Cooling system corrosion inhibitor/antifreeze.

Chassis grease.

High melting point grease, for hub bearings etc.

Penetrating oil or spray.

Kerosene or similar cleaning solvent.

Methylated spirits.

Oils and greases are available in handy pack size for

do-it-yourself lube jobs.

2. SAFETY

PERSONAL SAFETY

Safety when working on a motor vehicle is basical-

ly a matter of commonsense. Some safety precautions

to prevent personal in juries are as follows.

Raising a Vehicle

Always jack a vehicle on firm, level ground and at

the specified jacking points . Ensure that the wheels

remaining on the ground are fully chocked.

After raising the vehicle, place chassis stands

underneath and allow the weight of the vehicle to rest

on them. Do not use bricks, blocks of wood or similar

material.

NOTE: Never work under a vehicle which is

only supported by a jack.

Electrical System

Always disconnect the negative battery terminal

when working on any electrical components. Avoid

wearing metal watches, rings and chains which may

short across live terminals.

As battery gases are explosive, keep naked flames

and sparks clear of the work area. When connecting

and disconnecting jumper leads, use extreme caution

to avoid sparking.

Electronic Ignition Systems

Electronic ignition systems produce dangerous

high tension voltages in bo th the primary and second-

ary circuits which can be fatal. Exercise extreme

caution when working on or near any ignition system

components. Do not disconnect high tension leads

while the engine is running.

Work Area

Do not run the engine in a confined space. Ensure

that the work area is adequately ventilated.

Spilt oil or water should be cleaned immediately

to avoid the possibility of slipping.

Fuel System

Always disconnect the negative battery terminal

when working on any fuel components. Do not smoke.

Keep naked flames and sparks clear of the work area.

Do not siphon fuel using the mouth. Use a hand

pump or suitable siphon.

Do not attempt to repair a fuel tank by welding it.

This is an extremely hazardous procedure and should

be entrusted to a specialist.

Cooling System

To avoid scalding, use caution when releasing the

radiator cap on an engine wh ich is at normal operating

temperature. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to release.

When the pressure is released, remove the cap from

the radiator.

Brakes

As asbestos is used in some brake lining material,

avoid inhaling brake dust. Do not use compressed air

to remove the dust. Gentle brushing with a small

brush or using a vacuum cleaner with a hose attach-

ment are the safest methods of cleaning the brakes.

The above precautions also apply to the clutch plate

lining material.

Page 14 of 238

14

LUBRICATION AND MAINTENANCE

SPECIFICATIONS

CAPACITY AND GRADE

Engine:

Lubricant........................................... 15W-50 SF

Sump capacity including filter ........... 3.3 liters

Cooling system capacity............................ 6.0 liters

Manual transaxle:

Lubricant....................................... 80W-90 GL-4

Capacity ............................................... 2.7 liters

Automatic transaxle:

Lubricant.............................................. Dexron II

Capacity ............................................... 6.0 liters

Power steering:

Lubricant.............................................. Dexron II

Capacity ............................................... 1.0 liters

Manual steering lubricant ........ Castrol EPLl grease

Brake fluid type ................................................ Dot 4

1. HOW TO GREASE AND OIL CHANGE

(1) Run the front of the vehicle onto car ramps

and stop the engine. Chock the front wheels. (2) Raise the rear of the vehicle and place

chassis stands under the rear jacking points.

NOTE: It is best if the vehicle is kept as level

as possible to avoi d false readings when

checking the lubricant levels.

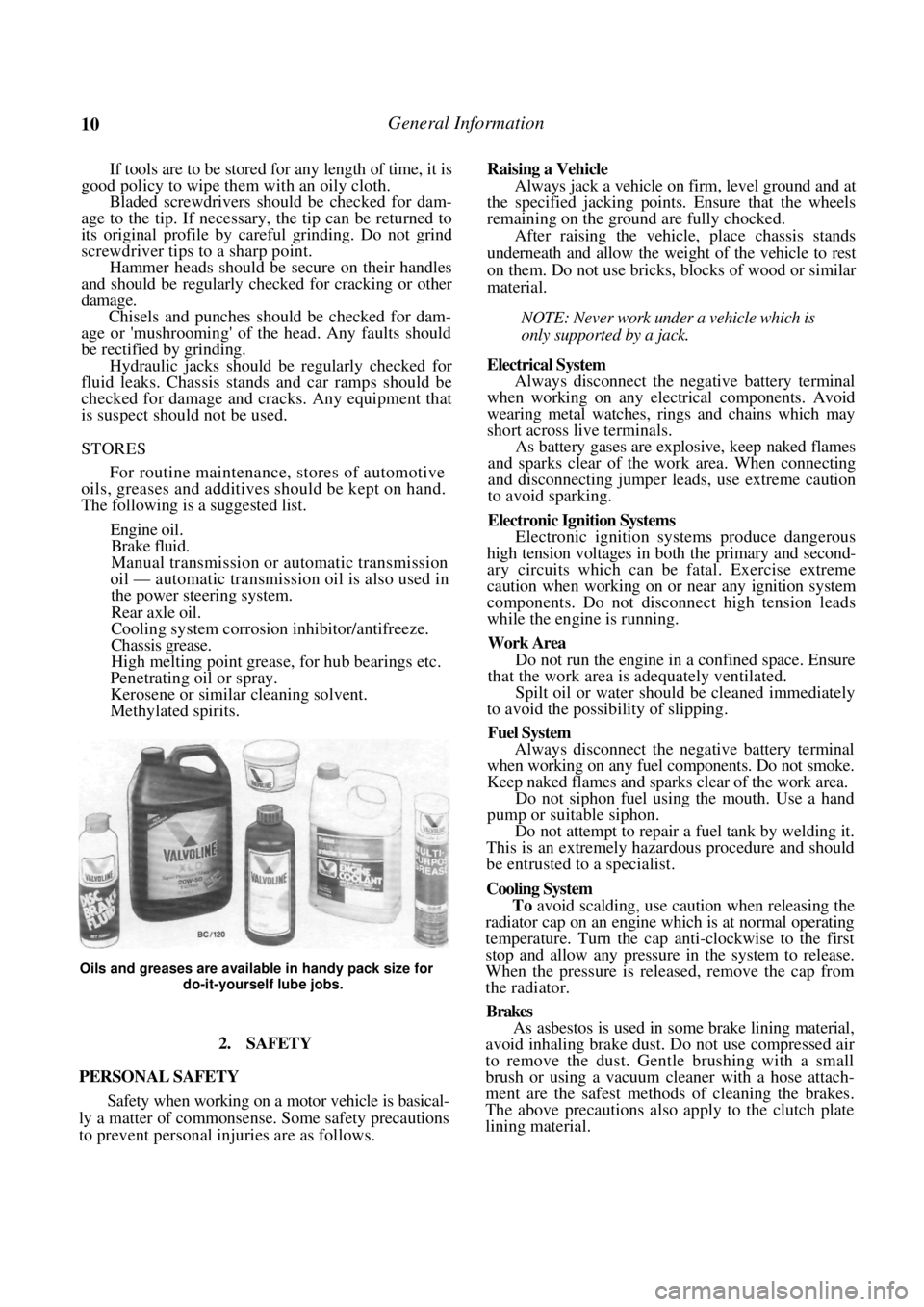

(3) Clean around the engine sump drain plug.

(4) Place a drain tin under the engine sump,

remove the engine sump drain plug and allow the

engine sump to completely drain.

NOTE: It is best to drain the engine sump

with the oil at operating temperature. How-

ever, if the oil is hot take care to avoid

scalding.

(5) Check that the sealing gasket on the sump

plug is in a serviceable condition. (6) When the engine sump has completely

drained, install and firmly tighten the sump drain plug.

Wipe around the plug after installation. (7) Place the drain tin under the oil filler,

remove the oil filter using a filter removal tool and

allow the residual engine oil to drain. Smear the

scaling ring of the new filter with engine oil and

lighten the filter by hand as per the instructions

supplied with the new filter.

NOTE: Before installing the new filter, en-

sure that the sealing gasket from the old

filter has not adhered to the filter sealing

surface on the engine.

(8) Remove the level checking plug from the

Location of the engine sump drain plug.

Removing the engine oil filter using a filter removal tool.

Page 35 of 238

Roadside Trouble Shooting 35

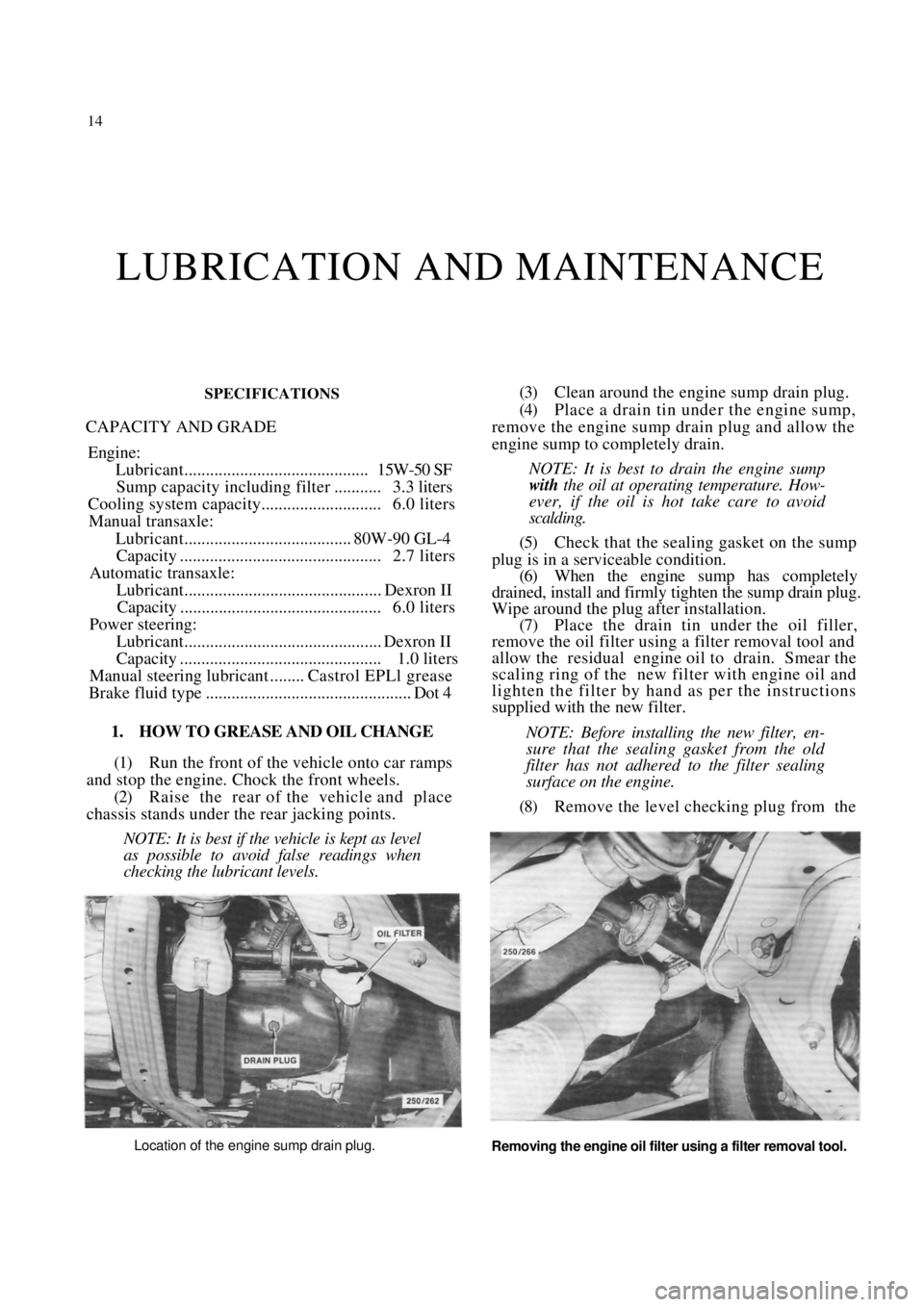

View showing the location of the fuel pump fuse and the EGI and fuel pump relays.

switch. When starting the engine, the fuel

pump will not operate until the oil pressure

is sufficient to extinguish the oil pressure

warning lamp. Therefore it will be necessary

to operate the starter motor for a longer

period than usual to start the engine.

(3) If the fuel pump cannot be felt operating,

check the fuel pump fuse located in the fuse panel

adjacent to the steering column.

If the fuel pump fuse is serviceable, refer to the

Fuel and Engine Management section for detailed

tests on the fuel pump.

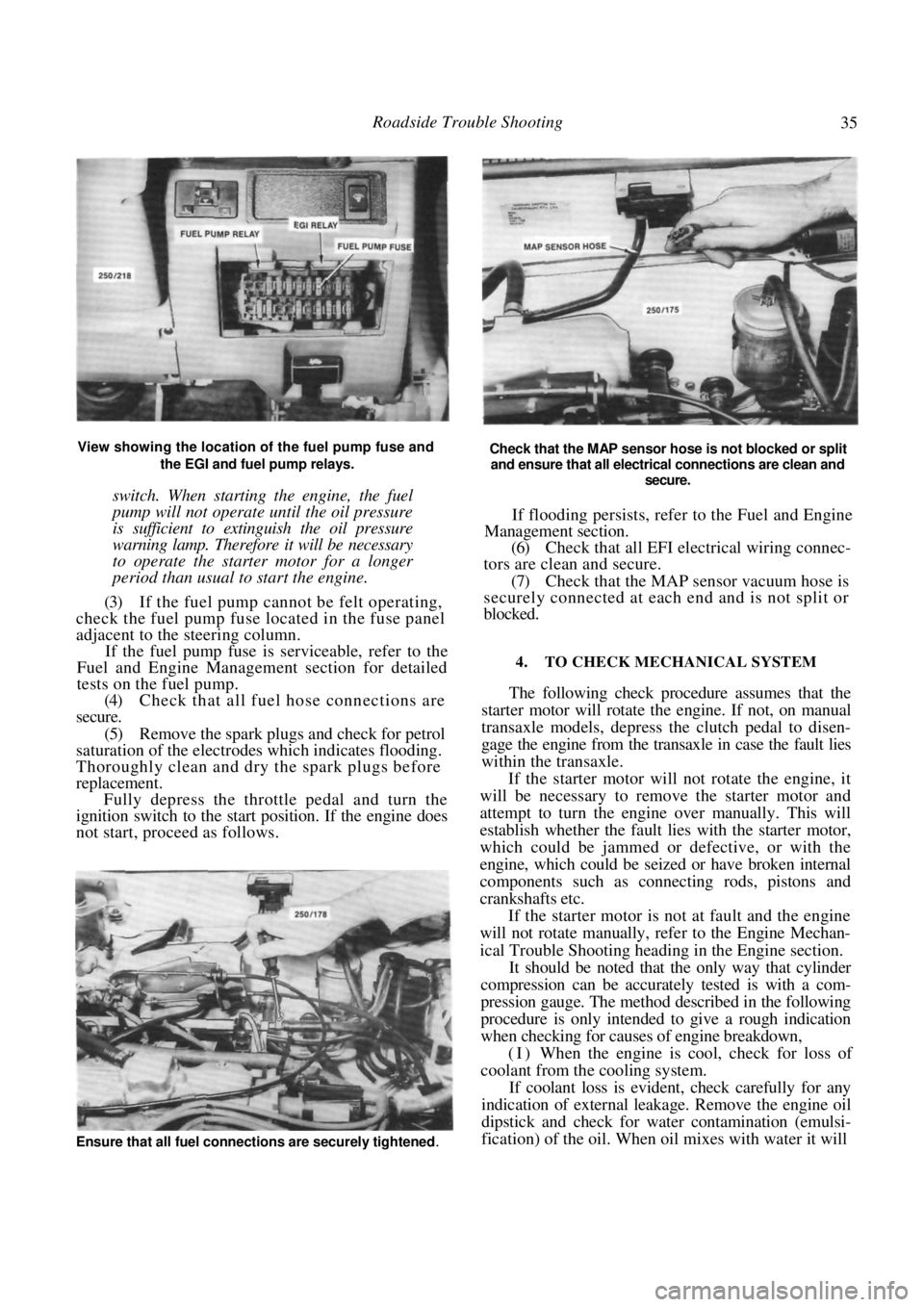

(4) Check that all fuel hose connections are

secure.

(5) Remove the spark plugs and check for petrol

saturation of the electrodes which indicates flooding.

Thoroughly clean and dry the spark plugs before

replacement. Fully depress the throttle pedal and turn the

ignition switch to the start position. If the engine does

not start, proceed as follows.

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.

If flooding persists, refer to the Fuel and Engine

Management section.

(6) Check that all EFI electrical wiring connec-

tors are clean and secure.

(7) Check that the MAP sensor vacuum hose is

securely connected at each end and is not split or

blocked.

4. TO CHECK MECHANICAL SYSTEM

The following check procedure assumes that the

starter motor will rotate the engine. If not, on manual

transaxle models, depress the clutch pedal to disen-

gage the engine from the tr ansaxle in case the fault lies

within the transaxle.

If the starter motor will not rotate the engine, it

will be necessary to remove the starter motor and

attempt to turn the engine over manually. This will

establish whether the fault lies with the starter motor,

which could be jammed or defective, or with the

engine, which could be seized or have broken internal

components such as connecting rods, pistons and

crankshafts etc.

If the starter motor is not at fault and the engine

will not rotate manually, refer to the Engine Mechan-

ical Trouble Shooting heading in the Engine section.

It should be noted that the only way that cylinder

compression can be accurately tested is with a com-

pression gauge. The method described in the following

procedure is only intended to give a rough indication

when checking for causes of engine breakdown,

(I) When the engine is cool, check for loss of

coolant from the cooling system.

If coolant loss is evident, check carefully for any

indication of external leakage. Remove the engine oil

dipstick and check for wate r contamination (emulsi-

fication) of the oil. When oil mixes with water it will

Ensure that all fuel connections are securely tightened.

Page 44 of 238

44 Engine

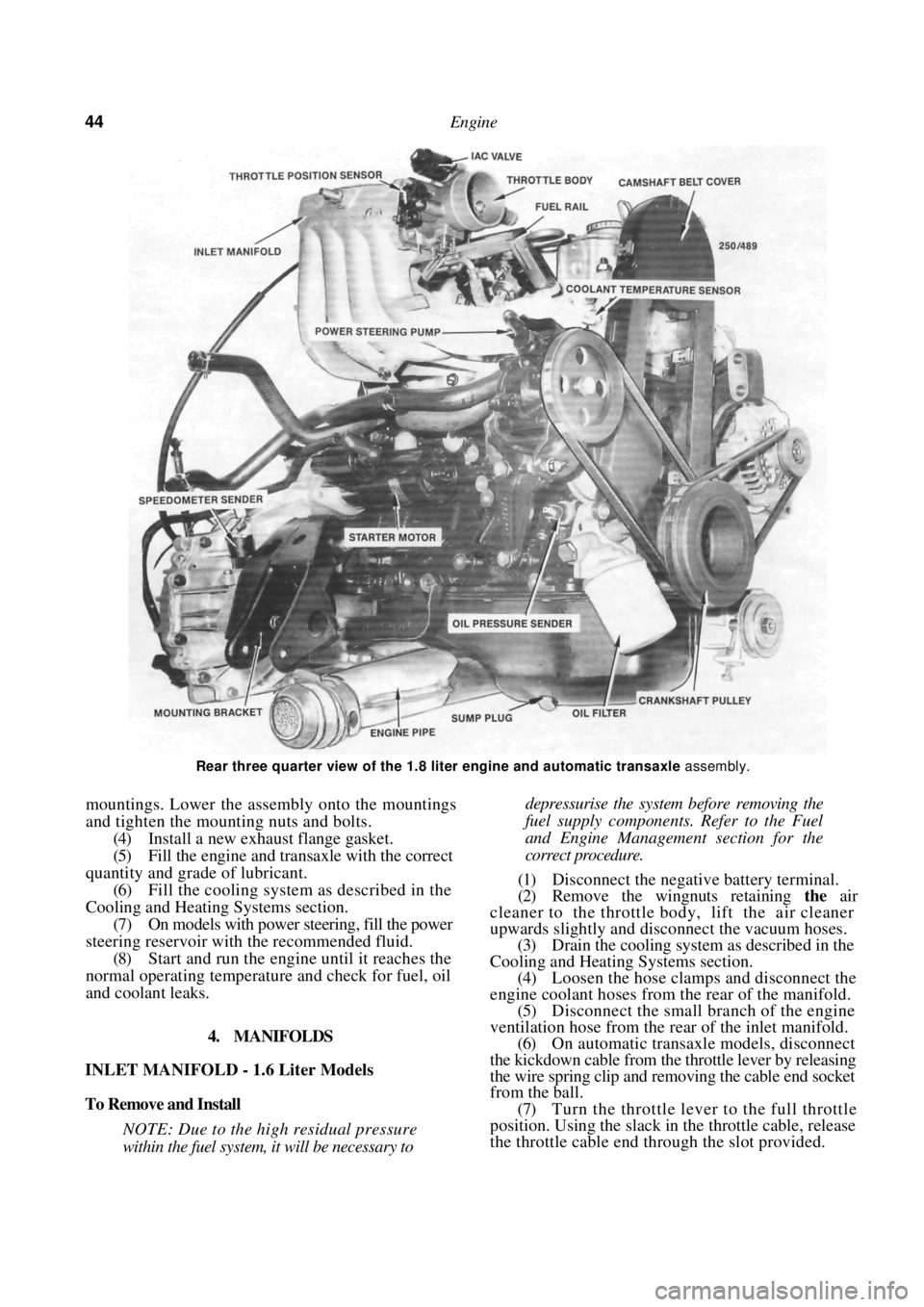

Rear three quarter view of the 1.8 liter engine and automatic transaxle assembly.

mountings. Lower the assembly onto the mountings

and tighten the mounting nuts and bolts.

(4) Install a new exhaust flange gasket.

(5) Fill the engine and transaxle with the correct

quantity and grade of lubricant. (6) Fill the cooling system as described in the

Cooling and Heating Systems section. (7) On models with power steering, fill the power

steering reservoir with the recommended fluid.

(8) Start and run the engine until it reaches the

normal operating temperatur e and check for fuel, oil

and coolant leaks.

4. MANIFOLDS

INLET MANIFOLD - 1.6 Liter Models

To Remove and Install

NOTE: Due to the high residual pressure

within the fuel system, it will be necessary to

depressurise the system before removing the

fuel supply components. Refer to the Fuel

and Engine Management section for the

correct procedure.

(1) Disconnect the negative battery terminal.

(2) Remove the wingnuts retaining the air

cleaner to the throttle body, lift the air cleaner

upwards slightly and disconnect the vacuum hoses. (3) Drain the cooling system as described in the

Cooling and Heating Systems section. (4) Loosen the hose clamps and disconnect the

engine coolant hoses from the rear of the manifold.

(5) Disconnect the small branch of the engine

ventilation hose from the rear of the inlet manifold. (6) On automatic transaxle models, disconnect

the kickdown cable from the throttle lever by releasing

the wire spring clip and re moving the cable end socket

from the ball.

(7) Turn the throttle lever to the full throttle

position. Using the slack in the throttle cable, release

the throttle cable end thr ough the slot provided.

Page 45 of 238

Engine 45

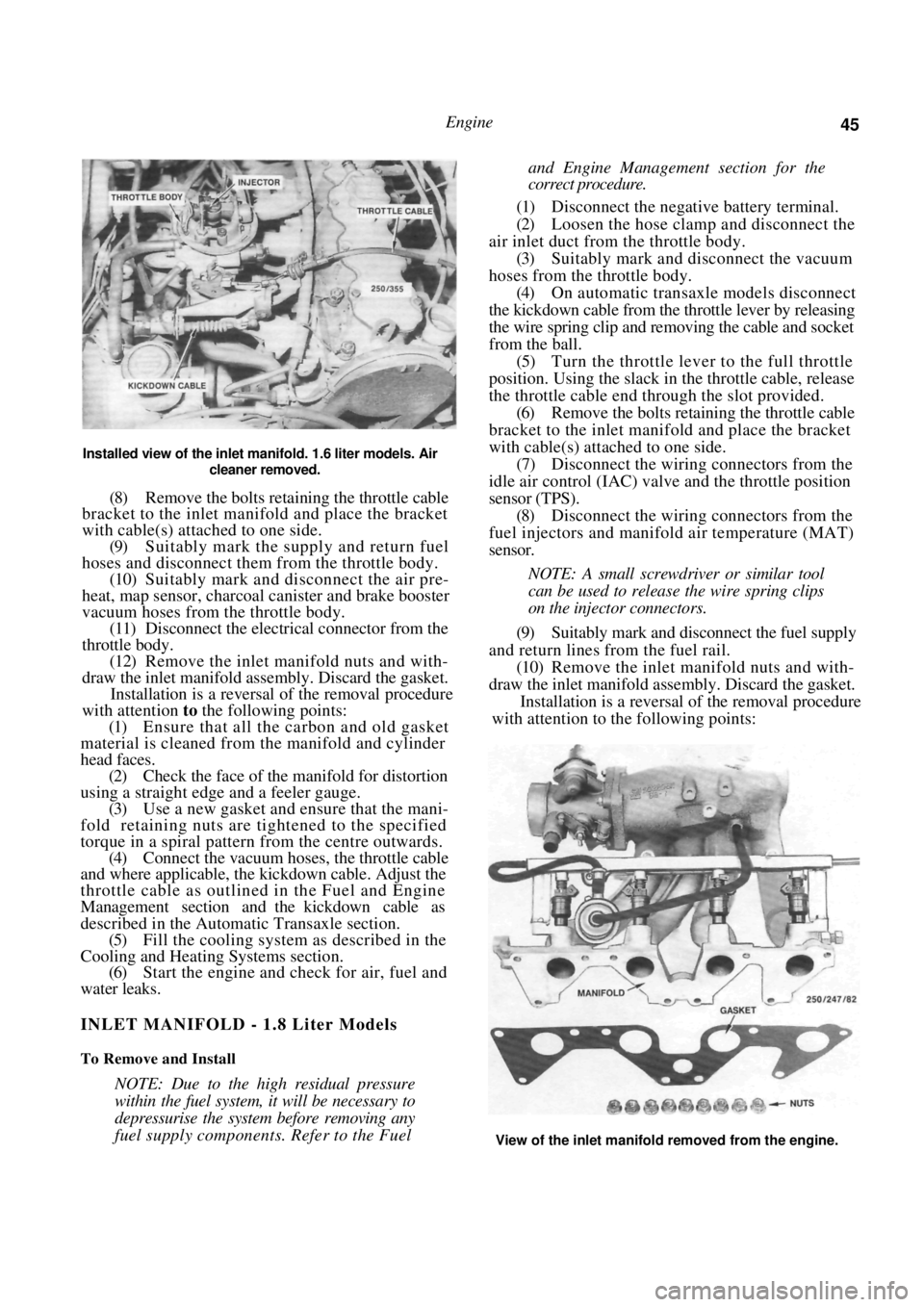

Installed view of the inlet manifold. 1.6 liter models. Air

cleaner removed.

(8) Remove the bolts retaining the throttle cable

bracket to the inlet manifold and place the bracket

with cable(s) attached to one side.

(9) Suitably mark the supply and return fuel

hoses and disconnect them from the throttle body.

(10) Suitably mark and disconnect the air pre-

heat, map sensor, charcoal canister and brake booster

vacuum hoses from the throttle body. (11) Disconnect the electrical connector from the

throttle body. (12) Remove the inlet manifold nuts and with-

draw the inlet manifold assembly. Discard the gasket. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all the carbon and old gasket

material is cleaned from the manifold and cylinder

head faces. (2) Check the face of the manifold for distortion

using a straight edge and a feeler gauge. (3) Use a new gasket and ensure that the mani-

fold retaining nuts are tightened to the specified

torque in a spiral pattern from the centre outwards. (4) Connect the vacuum hoses, the throttle cable

and where applicable, the kickdown cable. Adjust the

throttle cable as outlined in the Fuel and Engine

Management section and the kickdown cable as

described in the Automatic Transaxle section. (5) Fill the cooling system as described in the

Cooling and Heating Systems section. (6) Start the engine and check for air, fuel and

water leaks.

INLET MANIFOLD - 1.8 Liter Models

To Remove and Install

NOTE: Due to the high residual pressure

within the fuel system, it will be necessary to

depressurise the system before removing any

fuel supply components. Refer to the Fuel

and Engine Management section for the

correct procedure.

(1) Disconnect the negative battery terminal.

(2) Loosen the hose clamp and disconnect the

air inlet duct from the throttle body. (3) Suitably mark and disconnect the vacuum

hoses from the throttle body. (4) On automatic transaxle models disconnect

the kickdown cable from the throttle lever by releasing

the wire spring clip and re moving the cable and socket

from the ball. (5) Turn the throttle lever to the full throttle

position. Using the slack in the throttle cable, release

the throttle cable end thr ough the slot provided.

(6) Remove the bolts retaining the throttle cable

bracket to the inlet manifold and place the bracket

with cable(s) attached to one side. (7) Disconnect the wiring connectors from the

idle air control (IAC) valve and the throttle position

sensor (TPS).

(8) Disconnect the wiring connectors from the

fuel injectors and manifold air temperature (MAT)

sensor.

NOTE: A small screwdriver or similar tool

can be used to release the wire spring clips

on the injector connectors.

(9) Suitably mark and disconnect the fuel supply

and return lines from the fuel rail. (10) Remove the inlet manifold nuts and with-

draw the inlet manifold assembly. Discard the gasket. Installation is a reversal of the removal procedure

with attention to the following points:

View of the inlet manifold removed from the engine.

Page 47 of 238

Engine 47

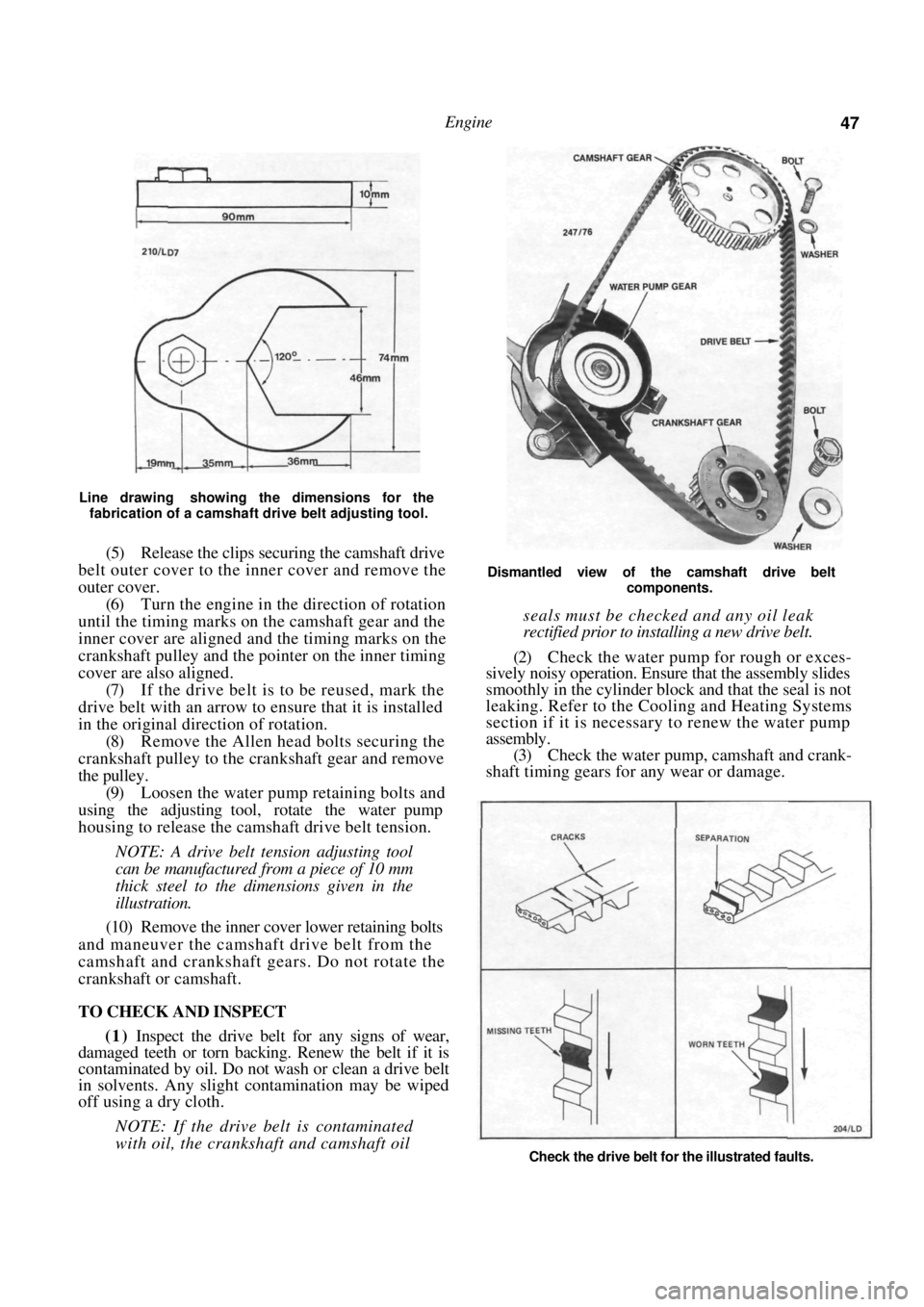

Line drawing showing the dimensions for the fabrication of a camshaft drive belt adjusting tool.

(5) Release the clips securing the camshaft drive

belt outer cover to the inner cover and remove the

outer cover.

(6) Turn the engine in the direction of rotation

until the timing marks on the camshaft gear and the

inner cover are aligned and the timing marks on the

crankshaft pulley and the pointer on the inner timing

cover are also aligned.

(7) If the drive belt is to be reused, mark the

drive belt with an arrow to ensure that it is installed

in the original direction of rotation. (8) Remove the Allen head bolts securing the

crankshaft pulley to the crankshaft gear and remove

the pulley. (9) Loosen the water pump retaining bolts and

using the adjusting tool, rotate the water pump

housing to release the camsh aft drive belt tension.

NOTE: A drive belt tension adjusting tool

can be manufactured from a piece of 10 mm

thick steel to the dimensions given in the

illustration.

(10) Remove the inner cover lower retaining bolts

and maneuver the camshaft drive belt from the

camshaft and crankshaft gears. Do not rotate the

crankshaft or camshaft.

TO CHECK AND INSPECT

(1) Inspect the drive belt for any signs of wear,

damaged teeth or torn backing. Renew the belt if it is

contaminated by oil. Do not wash or clean a drive belt

in solvents. Any slight contamination may be wiped

off using a dry cloth.

NOTE: If the drive belt is contaminated

with oil, the crankshaft and camshaft oil

Dismantled view of the camshaft drive belt

components.

seals must be checked and any oil leak

rectified prior to installing a new drive belt.

(2) Check the water pump for rough or exces-

sively noisy operation. Ensure that the assembly slides

smoothly in the cylinder bloc k and that the seal is not

leaking. Refer to the Cooling and Heating Systems

section if it is necessary to renew the water pump

assembly. (3) Check the water pump, camshaft and crank-

shaft timing gears for any wear or damage.

Check the drive belt for the illustrated faults.

Page 49 of 238

Engine 49

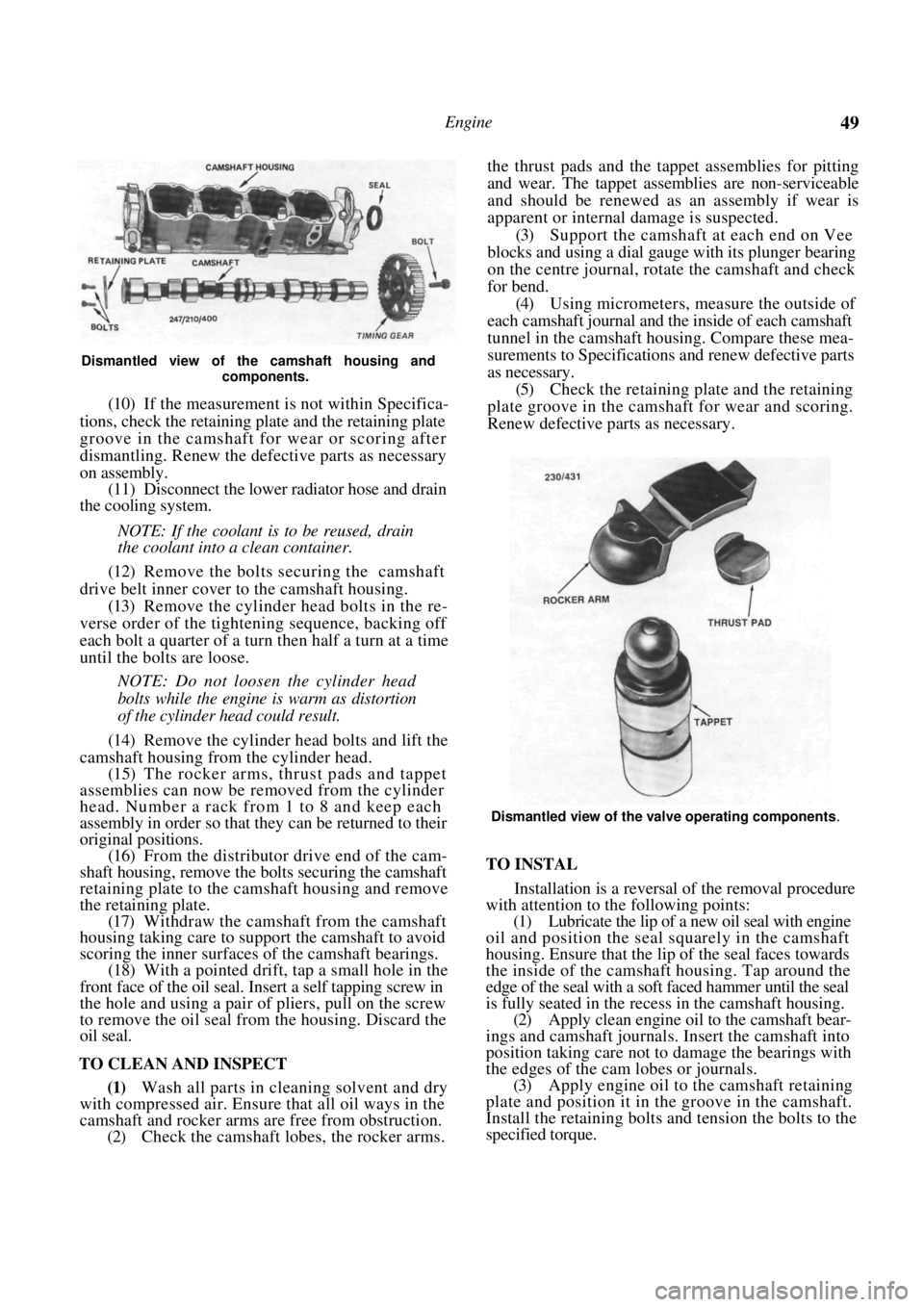

Dismantled view of the camshaft housing and components.

(10) If the measurement is not within Specifica-

tions, check the retaining plate and the retaining plate

groove in the camshaft for wear or scoring after

dismantling. Renew the defective parts as necessary

on assembly. (11) Disconnect the lower radiator hose and drain

the cooling system.

NOTE: If the coolant is to be reused, drain

the coolant into a clean container.

(12) Remove the bolts securing the camshaft

drive belt inner cover to the camshaft housing. (13) Remove the cylinder head bolts in the re-

verse order of the tighten ing sequence, backing off

each bolt a quarter of a turn then half a turn at a time

until the bolts are loose.

NOTE: Do not loosen the cylinder head

bolts while the engine is warm as distortion

of the cylinder head could result.

(14) Remove the cylinder head bolts and lift the

camshaft housing from the cylinder head. (15) The rocker arms, thrust pads and tappet

assemblies can now be removed from the cylinder

head. Number a rack from 1 to 8 and keep each

assembly in order so that they can be returned to their

original positions.

(16) From the distributor drive end of the cam-

shaft housing, remove the bolts securing the camshaft

retaining plate to the camshaft housing and remove

the retaining plate. (17) Withdraw the camshaft from the camshaft

housing taking care to supp ort the camshaft to avoid

scoring the inner surfaces of the camshaft bearings.

(18) With a pointed drift, tap a small hole in the

front face of the oil seal. Insert a self tapping screw in

the hole and using a pair of pliers, pull on the screw

to remove the oil seal from the housing. Discard the

oil seal.

TO CLEAN AND INSPECT

(1) Wash all parts in cleaning solvent and dry

with compressed air. Ensure that all oil ways in the

camshaft and rocker arms are free from obstruction.

(2) Check the camshaft lobes, the rocker arms. the thrust pads and the ta

ppet assemblies for pitting

and wear. The tappet assemblies are non-serviceable

and should be renewed as an assembly if wear is

apparent or internal damage is suspected.

(3) Support the camshaft at each end on Vee

blocks and using a dial gauge with its plunger bearing

on the centre journal, rotate the camshaft and check

for bend. (4) Using micrometers, measure the outside of

each camshaft journal and the inside of each camshaft

tunnel in the camshaft housing. Compare these mea-

surements to Specifications and renew defective parts

as necessary. (5) Check the retaining plate and the retaining

plate groove in the camshaft for wear and scoring.

Renew defective parts as necessary.

Dismantled view of the valve operating components.

TO INSTAL

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Lubricate the lip of a new oil seal with engine

oil and position the seal squarely in the camshaft

housing. Ensure that the li p of the seal faces towards

the inside of the camshaft housing. Tap around the

edge of the seal with a soft faced hammer until the seal

is fully seated in the recess in the camshaft housing. (2) Apply clean engine oil to the camshaft bear-

ings and camshaft journals. Insert the camshaft into

position taking care not to damage the bearings with

the edges of the cam lobes or journals. (3) Apply engine oil to the camshaft retaining

plate and position it in the groove in the camshaft.

Install the retaining bolts and tension the bolts to the

specified torque.

Page 50 of 238

50 Engine

(4) Ensure that the tappet assemblies are full of

clean engine oil and insert the tappets in their

respective bores in the cylinde r head. Install the thrust

pads to the top of each valve assembly ensuring that

they are returned to their original location.

(5) Coat the contact surfaces of the rocker arms

with molybdenum disulphide grease and install the

rocker arms to their origin al locations on the cylinder

head. (6) Clean the mating surfaces of the camshaft

housing and cylinder head. Apply a bead of Loctite

515 to the cylinder head and camshaft housing mating

surfaces. Take care that no sea lant is forced into the

oil passages and install the camshaft housing to the

cylinder head.

(7) Install new cylinder head bolts and lubricate

the bolts and washers with oil.

(8) Apply an initial torque to the cylinder head

bolts of 25 Nm in the corr ect sequence as shown in

the illustration under the Cylinder Head heading.

Further tighten the head bolts in the correct sequence,

in three separate 60 degree stages. Refer to Specifica-

tions. (9) Install the bolts securing the camshaft

drive

belt inner cover to the camshaft housing. (10) Install the camshaft timing gear to the cam-

shaft ensuring that it is correctly located. Tighten the

camshaft timing gear retain ing boll to the specified

torque. (11) Install and adjust the camshaft drive belt as

described under the previous heading. (12) Install the distributor. Refer to the Fuel and

Engine Management section.

(13) Connect the lower radiat or hose and fill the

cooling system with the required coolant. Refer to the

Cooling and Heating Systems section if necessary. (14) Start and run the engine until normal oper-

ating temperature is attained and tighten the cylinder

head bolts another 30-50 degrees in the correct

sequence, ensuring that the tension does not exceed

135 Nm.

TO RENEW CAMSHAFT OIL SEAL,

CAMSHAFT INSTALLED

(1) Remove the camshaft drive belt from the

camshaft timing gear as described under the previous

heading.

(2) Remove the camshaft housing top cover

retaining bolts, remove the cover and discard the

gasket.

(3) Use an open end spanner to hold the cam-

shaft between the inlet and exhaust lobes of number

four cylinder and remove the camshaft timing gear

retaining bolt and the camshaft timing gear. (4) With a pointed drift, tap a small hole in the

front face of the oil seal. Insert a self tapping screw in

the hole and using a pair of pliers, pull on the screw

to remove the oil seal from the housing.

(5) Clean the seal recess and the camshaft sea!

running surface. (6) Lubricate the lip of a new oil seal with engine

oil and slide the seal over the camshaft. Ensure that

the lip of the seal faces to wards the inside of the

camshaft housing. Tap evenly around the edges of the

seal until it is fully seated in the camshaft housing.

(7) Install the camshaft timing gear to the cam-

shaft, ensuring that it is co rrectly located. Tighten the

camshaft timing gear retain ing bolt to the specified

torque. Do not allow the camshaft to rotate while

tightening the bolt. (8) Install and adjust the drive belt as described

under the previous heading. Ensure that the timing

marks are aligned. (9) Install the camshaft hou sing top cover using a

new gasket. Tighten the retaining bolts to the specified

torque.

7. CYLINDER HEAD

Special Equipment Required:

To Dismantle and Assemble — Valve spring com-

pressor

To Inspect — Dial gauge and straight edge

To Install — Drive belt adjusting tool

TO REMOVE AND INSTAL

NOTE: Due to the high residua! pressure

within the fuel system, it will be necessary to

depressurize the system before removing any

fuel supply components. Refer to the Fuel

and Engine Management section for the

correct procedure.

Allow the engine to cool prior to the

removal of the cylinder head to prevent

possible distortion of the cylinder head.

(1) Disconnect the negative battery terminal and

remove the nuts securing the earth wires to the

cylinder head bolts.

(2) Remove the camshaft drive belt as previ-

ously described.

(3) Disconnect the lower radiator hose and drain

the cooling system. Refer to the Cooling and Heating

Systems section if necessary. (4) Remove the alternator adjusting bracket

mounting bolt and insulating washers from the inlet

manifold. Loosen the adjusting bolt at the alternator

and slide the bracket away from the cylinder head. (5) Disconnect the upper radiator hose, coolant

by-pass hose and the heater hose from the thermostat

housing and on 1.6 liter m odels, the coolant hoses

from the inlet manifold. (6) Disconnect the electrica l connectors from the

throttle body, fuel injectors, coil, distributor and on

1.8 liter models, the MAT sensor. (7) Disconnect the oxygen sensor wiring connec-

tor and remove the wiring connectors from the

Page 51 of 238

Engine 51

coolant temperature sensor and temperature sender

switch located in the thermostat housing.

(8) Remove the bolt securing the wiring clamp

to the rear of the manifold and maneuver the wiring

away from the cylinder head and the inlet manifold.

(9) Disconnect the throttle cable and on auto-

matic transaxle models, the kickdown cable from the

throttle body linkage. (10) Remove the bolls securing the throttle cable

bracket to the inlet manifold and place the bracket

and cable(s) to one side.

(11) Mark the fuel supply and return hoses to

ensure correct installation and disconnect the hoses

from the fuel rail or throttle body. Plug the hoses to

prevent the loss of fuel or the entry of dirt. (12) Mark the vacuum hoses connected to the

inlet manifold and throttle body to ensure correct

installation and disconnect the hoses. (13) Remove the nuts securing the engine pipe to

the exhaust manifold and separate the pipe from the

manifold. (14) Remove the oxygen sensor from the exhaust

manifold. Refer to the Fuel and Engine Management

section if necessary. (15) Remove the distributor and coil as described

in the Fuel and Engine Management section. (16) Disconnect the engine breather hoses from

the camshaft housing and cams haft housing top cover.

(17) Remove the bolts retaining the top cover to

the camshaft housing and remove the top cover. (18) Using an open end spanner, hold the cam-

shaft between the inlet and exhaust lobes of number

four cylinder and remove the camshaft timing gear

retaining bolt and the camshaft timing gear.

(19) Remove the bolts securing the camshaft

drive belt inner cover to the camshaft housing. (20) Loosen the cylinder head bolts in the reverse

order of the tightening sequence, backing off each bolt

a quarter turn then half a turn at a time until the bolts

are loose.

NOTE: Do not loosen the head bolts while

the engine is warm as distortion of the

cylinder head could result.

(21) Remove the cylinder head bolts and lift the

camshaft housing from the cylinder head. (22) Remove the cylinder head and gasket from

the cylinder block. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Thoroughly clean the gasket surfaces of the

cylinder head, cylinder block and camshaft housing

and check all mating surfaces with a straight edge.

Ensure that all the oilways are clean and free of any

foreign material and lightly oil all operating parts with

engine oil.

(2) Install new gaskets throughout during

assem-

bly.

View of the cylinder head showing the bolt tightening

sequence.

(3) Ensure that the cylinde r head and gasket are

located correctly on the dowels on the cylinder block

face. The head gasket is marked TOP to aid in correct

installation. (4) With the cylinder head and gasket in posi-

tion on the cylinder block, apply an even smear of

Loctite 515 to the cylinder head and camshaft housing

mating surfaces. Take care that no sealant is forced

into the oil passages. (5) Install new cylinder head bolts and lubricate

the bolts and washers with engine oil,

(6) Apply an initial torque to the cylinder head

bolts of 25 Nm in the sequence shown in the

illustration. Further tighten the head bolts in the same

sequence in three separate 60 degree stages. Refer to

Specifications. (7) Install the bolts secur ing the camshaft drive

belt inner cover to the camshaft housing. Install the

camshaft timing gear and tighten the retaining bolt to

the specified torque. (8) Install and adjust the camshaft drive belt as

previously described. (9) Install the distributor, coil and oxygen sensor

as described in the Fuel and Engine Management

section.

(10) Using a new gasket, connect the engine pipe

to the exhaust manifold flange, coat the nuts with an

anti-seize compound and install and tighten the nuts

to

the specified torque. (11) Connect all hoses and electrical wiring dis-

connected during the removal of the cylinder head.

Ensure that all the hoses are returned to their original

locations. (12) Connect the throttle cable and where appli-

cable, the kickdown cable. Adjust the cables as

described in the Fuel and Engine Management section

and the Automatic Transaxle section. (13) Check the engine oil fo r correct level on the

dipstick and for dilution. Change the engine oil and

filter if necessary. (14) Fill the cooling system as described in the

Cooling and Heating Systems section. (15) Start the engine and check for oil or water