steering wheel adjustment NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 3 of 238

CONTENTS

INTRODUCTION........................................ 5

VEHICLE IDENTIFICATION AND

GENERAL SPECIFICATIONS................. 7

GENERAL INFORMATION...................... 8

Tools and equipment ............................................. 8 Safety .................................................................... 10

General repair procedures..................................... 11

LUBRICATION AND MAINTENANCE... 14

Specifications......................................................... 14

How to grease and oil change .............................. 14

Service schedule ................................................... 17

WHEELS AND TYRES............................. 21

Specifications......................................................... 21

How to change a road wheel ................................ 21

Tire wear troubl e shooting ..................................... 22

Care and main tenance ......................................... 23

ENGINE TUNE-UP.................................... 25

Tune-up specifications ........................................... 25

Tune-up operat ions............................................... 25

ROADSIDE TROUBLE SHOOTING....... 32

Trouble shoot ing.................................................... 32

To check ignition and el ectrical system ................ 33

To check fuel system ............................................ 34

To check mechani cal system ................................ 35

ENGINE....................................................... 37

Specifications ........................................................ 37

Engine mechanical tr ouble shooting ...................... 39

Description ............................................................ 41

Engine and transaxle assembly ........................... 42

Manifolds ............................................................... 44 Camshaft, rocker arms and tappets..................... 48

Cylinder head........................................................ 50

Engine sump and oil pum p pickup pipe................ 54

Oil pump ............................................................... 55

Pistons, connecting rods and cylinder bores ........ 57

Crankshaft and bearings ...................................... 60

Flywheel /drive plate............................................... 63

Engine mountings.................................................. 64

Exhaust system .................................................... 66

COOLING AND HEATING SYSTEMS.... 68

Specifications ........................................................ 68 Cooling system trouble shooting ........................... 68

Heater and air conditioner trouble shooting ......... 69 Description ............................................................ 70

Radiator ................................................................ 70

Cooling fan ............................................................ 73

Thermost at............................................................ 75

Thermostat housing .............................................. 76

Water pump .......................................................... 76

Welch plugs .......................................................... 76

Heater unit, water valv e and controls ................... 77

Blower fan ............................................................. 80

Air condition ing ..................................................... 80

FUEL AND ENGINE MANAGEMENT ... 82

Specifications ........................................................ 82 Fuel and engine management trouble shooting ... 82

Description ............................................................ 84

Service precautions and procedures

..................... 86

System diagnosis and adjustments ...................... 89

Fuel supply components ....................................... 92

Air flow components .............................................. 98

Electronic components .......................................... 104

EMISSION CONTROL............................. 117

Introduction ........................................................... 117

Crankcase ventilati on system............................... 117

Evaporate control system..................................... 117

Air preheat system — 1.6 liter engines ................ 119

Exhaust control system ........................................ 120

CLUTCH...................................................... 121

Specifications........................................................ 121

Clutch trouble shooting......................................... 121

Description ............................................................ 122

Clutch unit and release mechanism..................... 123

Clutch pedal ......................................................... 124

Clutch c able.......................................................... 124

Clutch adjustments ............................................... 125

MANUAL TRANSAXLE AND

DRIVE SHAFTS......................................... 126

Specifications ........................................................ 126

Manual transaxle and drive shaft trouble shooting 126

Description............................................................ 128

Transaxle assembly.............................................. 129

Differential and final drive assembly ..................... 135

Gear lever assembly ............................................ 136

Drive shafts .......................................................... 137

AUTOMATIC TRANSAXLE....................... 140

Specifications........................................................ 140

Automatic transaxle trouble shooting.................... 140

Description............................................................ 141

Transaxle fluid ...................................................... 141

Brake band........................................................... 142

Kickdown cable .................................................... 142

Transaxle select or linkage ................................... 142

Neutral safety switch ............................................ 142

Transaxle assembly .............................................. 143

STEERING................................................. 145

PART 1. STEERING TROUBLE SHOOTING....145

Faults, causes and remedies................................ 145

PART 2. MANUA L STEERING......................... 147

Specifications ........................................................ 147

Description............................................................ 147

Steering wheel ...................................................... 147

Steering column.................................................... 148

Steering gear assembly ....................................... 149

PART 3. POWE R STEERING .......................... 152

Specifications........................................................ 152

Description............................................................ 152

In car adjustments, checks and minor repairs ..... 152

Steering wheel ...................................................... 153

Steering column.................................................... 153 Power steering pump ........................................... 153

Power steering gear assembly............................. 154

Page 4 of 238

FRONT SUSPENSION............................ 156

Specifications......................................................... 156

Front suspension tr ouble shooting ........................ 156

Description ............................................................ 157

Steering knuckle.................................................... 157

Suspension unit..................................................... 159

Control arm ........................................................... 161

Stabiliser bar ........................................................ 162

Suspension and steering angles .......................... 163

REAR SUSPENSION................................ 164

Specifications ........................................................ 164

Rear suspension tr ouble shooting ........................ 164

Description ............................................................ 165

Rear hub ............................................................... 166

Suspension unit .................................................... 167

Control arm ........................................................... 169

Knuckle assembly.................................................. 170

Stabiliser bar ........................................................ 170

Rear wheel alignment ........................................... 171

BRAKES...................................................... 172

Specifications......................................................... 172

Brakes trouble shooting ........................................ 172

Description ............................................................ 174

Master cyli nder...................................................... 175

Brake servo unit .................................................... 177

Front brakes ......................................................... 178

Rear disc brakes................................................... 181

Rear drum brakes ................................................. 184

Handbrake cable and le ver assembly ................... 186

Brake adjustments ................................................ 187

Brake pedal ........................................................... 187

Hydraulic system................................................... 188

ELECTRICAL SYSTEM............................ 190

Specifications......................................................... 190

Battery and charging system trouble shooting ....... 190

Battery and starting system trouble shooting ........ 191

Lighting system trouble shooting ........................... 192

Turn signal lamp trouble shooting ........................ 192

Test equipment and so me applications................. 193

Battery ................................................................... 194

Alternator ............................................................... 196

Starter motor ......................................................... 201

Ignition system ...................................................... 206

Steering wheel ....................................................... 206

Switches and controls........................................... 206

Instrument cluster.................................................. 209

Blower fan .............................................................. 209

Radio/cassette...................................................... 209

lamp units ............................................................ 210

Windscreen wiper ................................................. 213

Fuses, fusible links and relays ............................. 215

Trailer wiring ......................................................... 216

Wiring diagrams ................................................... 218

BODY........................................................... 225

Windscreen and re ar glass .................................. 225

Front doors ........................................................... 225

Rear doors............................................................ 228

Engine bonnet...................................................... 231

Tailgate and lock — hatchback ............................ 231

Luggage compartment lid and lock — sedan ........ 233

Radiator grille.............................................................. 234

Centre console...................................................... 234 Dashboard ............................................................ 235

Scat belts ............................................................. 236

Seats .................................................................... 236

Vehicle cleaning ........................................................... 237

CONVERSION TABLES.......................... 238

Page 146 of 238

146 Steering — Part 1

STEERING PULLS TO ONE SIDE

(1) Uneven tire wear or pressures: Check the

condition of the tires and inflate to the recommended

pressures.

(2) Incorrect front wheel alignment: Check and

align the front end.

(3) Dragging brakes: Check each wheel for drag-

ging brakes. Overhaul the brakes as necessary. (4) Damaged suspension or crossmember: In-

spect and renew the damaged components. (5) Faulty power steering gear assembly: Re-

move the power steering gear for overhaul.

FRONT WHEEL WOBBLE OR SHIMMY

(1) Uneven tire wear or incorrect tire pressures;

Check the condition of the tires and inflate to the

recommended pressures. (2) Tire or wheel imbalance: Check and balance

as necessary (3) Worn or badly adjusted hub bearings: Check

the condition and adjust the front hub bearings.

(4) Faulty or worn suspension, units: Check and

overhaul or renew as a pair.

NOTE: Check the steering linkage as previ-

ously described. Raise the front of the vehi-

cle and check the adjustment of the hub

bearings by moving the road wheel in and

out at the top and bottom. No movement in

the bearings should be felt. Check the sus-

pension units as outlined in the Front Sus-

pension section.

STEERING ERRATIC OR WANDERING

(1) Incorrect or uneven wheel alignment setting:

Check and adjust th e steering geometry.

(2) Smooth front tires: Check and renew the

tires as necessary.

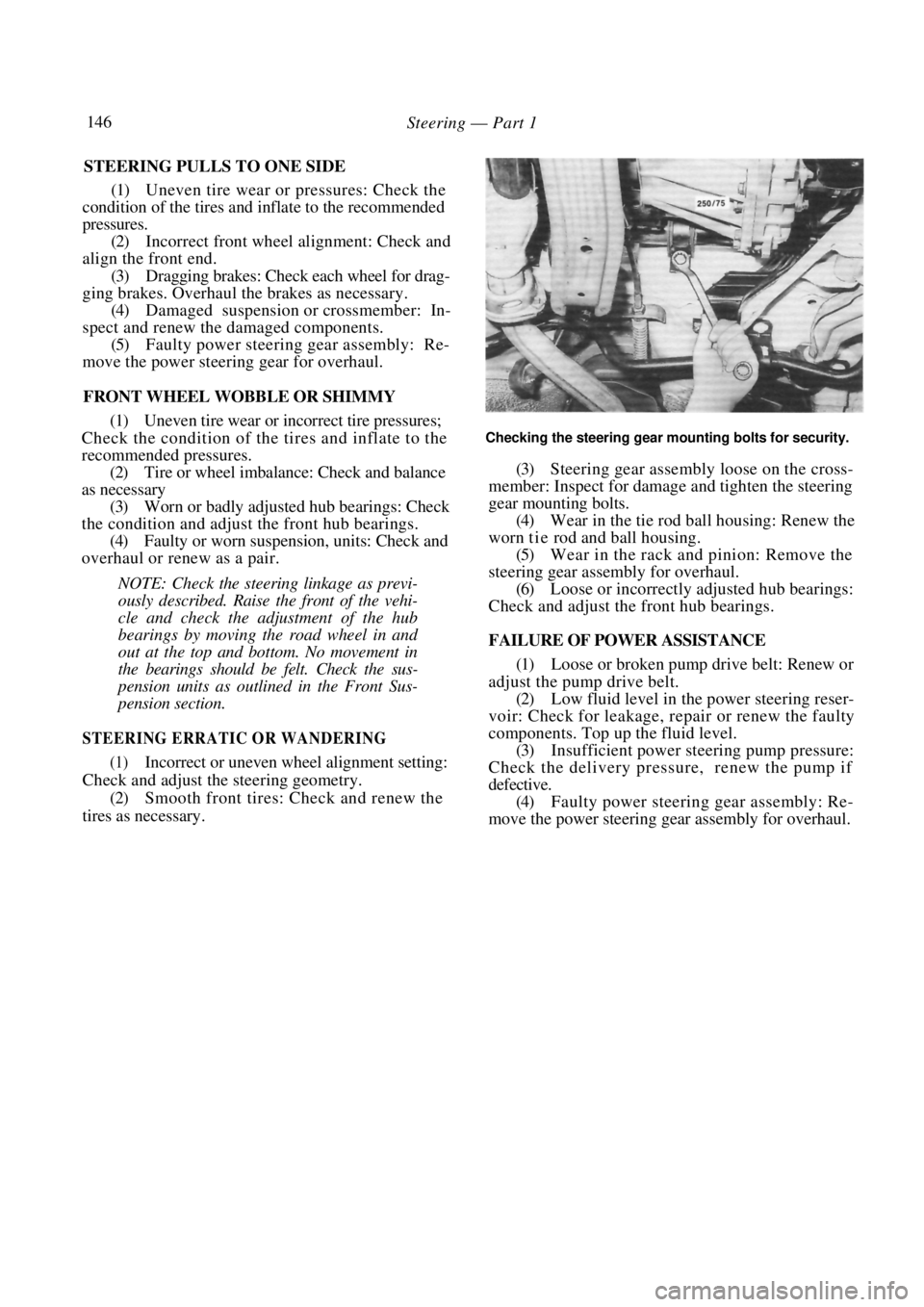

Checking the steering gear mounting bolts for security.

(3) Steering gear assembly loose on the cross-

member: Inspect for damage and tighten the steering

gear mounting bolts.

(4) Wear in the tie rod ball housing: Renew the

worn t i e rod and ball housing. (5) Wear in the rack and pinion: Remove the

steering gear assembly for overhaul. (6) Loose or incorrectly adjusted hub bearings:

Check and adjust the front hub bearings.

FAILURE OF POWER ASSISTANCE

(1) Loose or broken pump drive belt: Renew or

adjust the pump drive belt.

(2) Low fluid level in the power steering reser-

voir: Check for leakage, repair or renew the faulty

components. Top up the fluid level. (3) Insufficient power steering pump pressure:

Check the delivery pressure, renew the pump if

defective. (4) Faulty power steering gear assembly: Re-

move the power steering gear assembly for overhaul.

Page 151 of 238

Steering — Part 2 151

(8) Slide the rack out of the housing slightly so

that an adjustable spanner can be used to hold the

rack. (9) Using a Stillsons wrench, unscrew the ball

housings in turn using care not to allow the rack to

rotate. Keep all the tie rod parts in order. (10) Inspect the rack boots for cracks and deteri-

oration and renew as necessary. (11) Inspect the tie rod ends for wear and damage

and renew as necessary.

Dismantled view of the tie rod ball housing and the tie

rod end assemblies removed from the steering gear.

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Using large Stillsons and a large adjustable

spanner, install the tie rod and ball housing

assemblies

to the rack. Tighten the ball housings to the specified

torque.

NOTE: To avoid damage to the rack or

pinion the adjustable spanner must be

firmly tightened over the rack teeth and the

rack must not be allowed to rotate when

installing the ball housings.

(2) Measure a point 9 mm in from the rear face

of the ball housing of the rack and at 90 deg to the

rack teeth. Centre punch this point.

(3) At this point drill a 4 mm hole, 10 mm deep

through the rack and into the ball housing thread.

(4) Place a locking pin above the hole and drive

it into position.

(5) Lubricate the rack, rack teeth and t i e rod

boot groove with suitable EPL 1 grease. (6) Install the rack boots and secure with the

clamps. Renew the clamps if necessary. (7) Install the tie rod end locknuts and then the

tie rod ends, ensuring that they are screwed on the

same number of turns as was necessary to remove

them.

(8) Tighten the locknuts to the specified torque.

(9) Install the mounting rubbers and brackets

to

the steering gear as noted on removal. (10) Install the steering gear assembly to

the

vehicle as previously described. (11) Check and if necessary adjust the front wheel toe in as described in the Front Suspension section

under the appropriate heading.

TO RENEW TIE ROD END

(1)

Raise the front of the vehicle and support it

on chassis stands. (2) Remove the relevant front wheel.

(3) Loosen the tie rod end locknut and remove

the tie rod end castellated nut. Disconnect the tie rod

from the steering arm by plac ing a suitable dolly or

hammer against one side of the steering arm eye and

striking the opposite side with a hammer. (4) Unscrew the tie rod end from the tie rod,

noting the number of turns necessary to remove it.

(5) Screw the new tie rod end onto the t i e rod

the same number of turn s noted during removal.

(6) Connect the t i e rod to the steering arm and

install the castellated nut. Tighten the nut to the

specified torque and secure it with a new split pin.

(7) Install the front wheel and lower the vehicle

to the ground. (8) Check and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. Ensure that the rubber boots are not distorted

or twisted on the tie rod when the adjustment is

completed.

TO RENEW RUBBER BOOT

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the relevant t i e rod end as previ-

ously described. (3) Release the clamps securi ng the boot to the

tie rod and steering gear housing. (4) Unscrew and remove the locknut from the

tie rod. (5) Remove the rubber boot together with the

outer retaining clamp from the t i e rod. (6) Sparingly lubricate th e tie rod boot groove

with EPL 1 grease, install the new boot to the t i e

rod

and push it onto the steering gear rack housing. Install

and secure the inner and outer retaining clamps.

(7) Install the tie rod end locknut and screw

the

tie rod end onto the tie ro d the same number of turns

noted during removal. (8) Connect the tie rod to the steering arm and

install the castellated nut. Tighten the nut to the

specified torque and secure it with a new split pin. (9) Install the wheel and lower the vehicle to the

ground. (10) Check and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. Ensure that the rubber boots are not distorted

or twisted when the adjustment is completed.

Page 152 of 238

152

PART 3. POWER STEERING

SPECIFICATIONS

Steering gear type ................Rack and pinion with

integral power cylinder

Steering column type .................... Energy absorbing

collapsible and lilt adjustable

Steering wheel free play ................................. 35 mm

Number of turns lock to lock:

TRW ...............................................................2.82

PR24SA ........................................................... 2.7

Linkage.....................................Direct from rack ends

to ti e rods and steering knuckles

Power steering pump

maximum pr essure.................................... 6 865 kPa

Lubricant ...................................................... Dexron II

TORQUE WRENCH SETTINGS

Steering gear to bulkhead mounting bolts... 108 Nm

Tie rod to steering knuckle nut ...................... 98 Nm

Tie rod to tie rod end locknut....................... 98 Nm

Tie rod ball housing to rack............................ 88 Nm

Power steering pump pulley nut ..................... 68 Nm

1. DESCRIPTION

The vehicles covered by this manual are equipped

with either a TRW power steering system or a

Japanese PR24SA power steering system.

Both types are similar in construction and appear-

ance.

The power steering is a rack and pinion type

which is mounted on the lower section of the engine

compartment bulkhead by rubber mountings and

brackets.

Hydraulic pressure is supplied to the power

steering gear by a pump driven by a drive belt from

the engine.

The power steering pump has a separate fluid

reservoir located on the righ t side of the bulkhead.

No lubrication of the steering gear or steering

pump is required in service and in the event of the

loss of power assistance, the steering will continue to

operate but will require a greatly increased effort.

However, as the steering gear and pump are lubricated

by the power steering fluid, the cause of the loss of

power steering or fluid loss must be determined and

repaired promptly to prevent damage to the steering

pump and to a lesser extent, the steering gear.

The t i e rod ends and rubb er boots can be renewed

without removing the steering gear from the vehicle.

To renew the integral t i e rod and tie rod ball housings,

the steering gear must be removed.

As specialist knowledge and equipment are re-

quired to overhaul the power steering gear and the

hydraulic pump, it is recommended that these op-

erations be carried out by an authorized dealer.

However, procedures for the removal and installa-

tion of the steering gear and pump are fully de-

scribed in this section.

The steering column is of the energy absorbing

type and is designed to collapse in the event of a

severe front end collision. The energy absorbing com-

ponents are the column tu bes, steering shaft and tilt

bracket breakaway capsules. All these components

should be handled with extr eme care if service opera-

tions are to be carried out on the steering column

assembly.

2. IN CAR ADJUSTMENTS, CHECKS AND

MINOR REPAIRS

If the power steering system becomes partially or

fully inoperative it is most important that the follow-

ing preliminary inspection and testing procedure be

performed prior to undertaking any trouble shooting

or repair operations.

PUMP DRIVE BELT

Inspect the pump drive belt for breakage, glazing

or wear. If any of these characteristics are evident,

renew the belt using only a genuine replacement.

If the belt is loose but still serviceable, adjust it

using the procedure outlined in the Engine Tune-up

section.

NOTE: In most cases a loose drive belt can

be heard squealing when a load is placed on

the pump as the steering wheel is turned or

as the engine speed is increased.

Checking the power steering pump drive belt for

deterioration.

Page 154 of 238

154 Steering —

(2) Remove the air inlet duct from the air

cleaner and throttle body. (3) Position a container or a piece of cloth

beneath the steering pump reservoir and disconnect

the fluid return and power steering pump supply hose

from the reservoir.

(4) Loosen the steering pump drive belt as

described in the Engi ne Tune-up section.

(5) Loosen the return hose clamp and the supply

union and disconnect the hoses from the power

steering pump. Plug the hoses to prevent the loss of

fluid.

(6) Loosen the retaining bolts and withdraw the

pump. (7) Thoroughly clean the exterior of the steering

pump and inspect it for cracks, damage and signs of

leakage.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pump and retaining bolts.

(2) Install the drive belt and adjust it as de-

scribed in the Engine Tune-up section. (3) Install the hoses to the power steering pump

and tighten securely. (4) Top up the pump reservoir and purge the

power steering system of air as previously described.

TO OVERHAUL

As specialist knowledge and equipment arc re-

quired to overhaul the power steering pump, it is

recommended that this operation be performed by an

authorized dealer or steering specialist.

6. POWER STEERING GEAR ASSEMBLY

Special Equipment Required:

To Renew Tie Rod Ball Housings — Large Still-

sons

TO REMOVE AND INSTAL

The procedures for removing and installing the

power steering gear are similar to those carried out in

the Manual Steering section under the Steering Gear

Assembly heading except fo r the following differences.

(1) Place a container under the pressure and

return pipes that are conn ected to the steering gear

valve housing. Remove the pipes and allow the fluid

to drain into the container. (2) Suitably seal the pipes and the steering gear

to prevent the entry of di rt whilst the pipes are

removed.

(3) Upon removal of the power steering gear,

thoroughly clean the steering gear except the tie rod

ends in a suitable solvent. Be careful not to allow the

solvent to enter the apertu res where the pressure and

return pipes were removed. (4) Check the pipes and co nnections for cracks,

damage or obstructions and renew as necessary.

Installed view of the power steering gear with the

engine removed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pressure and return pipes to the

steering gear valve housing and tighten securely. (2) Fill the power steering reservoir to the cor-

rect level and bleed the system as described previously

under the heading In Car Adjustments. Checks and

Minor Repairs. (3) Check all power steering pipe connections

for leaks and repair as necessary. (4) Check, and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. After adjustment ensure that the rubber boots

are not distorted or twisted and the rubber boot

clamps and clips are facing downward.

TO OVERHAUL

As specialist knowledge and equipment are re-

quired to overhaul the power steering gear, it is rec-

ommended that this opera tion be performed by an

authorized dealer or steering specialist.

TO RENEW TIE ROD BALL HOUSINGS

TRW Steering Gear

The renewal of the tie rod ball housings is the

same as for the manual steering gear. Refer to Part 2.

Manual Steering section.

PR24SA Steering Gear

(1) Remove the power steering gear assembly

from the vehicle as previously described.

(2) Carefully mount the power steering gear in a

vice equipped with soft jaws. Loosen the tie rod end

locknuts without disturbing the location of the tie rod

ends and unscrew the tie rod ends, taking note of the

number of turns required to remove them. Unscrew

and remove the locknuts from the tie rod. (3) Remove the clamps from the rubber boots

and remove the boots.

Page 163 of 238

Front Suspension 163

(2) Ensure that the stabilizer bar links are in

good condition. Renew if necessary.

(3) When installing the stabilizer bar ensure that

the links are installed perpendicular to the control arm

with the ball joint socket face parallel to the end of the

stabilizer bar. (4) Ensure that the brackets are installed with

the flat portion facing towards the front of the vehicle.

Tighten the retaining bolts securely.

7. SUSPENSION AND STEERING ANGLES

ADJUSTMENT

NOTE: Extensive knowledge and special-

ised equipment are required to measure and

correct the suspension and steering angles

with the exception of the front wheel toe in.

Therefore, as it is not a viable proposition

for the average person to carry out a com-

plete wheel alignment, the vehicle should be

taken to a wheel alignment specialist.

Prior to carrying out a wheel alignment, a thor-

ough inspection of the steering linkage, front hub

bearings, ball joints and suspension units should be

carried out. Faulty components should be renewed or

repaired as necessary.

The tread of the front ti res should be examined

for excessive or uneven wear as certain conditions of

tire wear are indicative of damaged or worn compo-

nents in the suspension, stee ring linkage and/or wheels

and bearings. Refer to the heading Tire Wear Trouble

Shooting in the Wheels and Tires section. If the tires

are found to be defective, renew them with serviceable

lyres.

TO CHECK AND ADJUST TOE IN/OUT

NOTE: The vehicle s hould be unladen ex-

cept for the normal amount of fuel and with

the tires inflated to the correct pressures.

(1) With the vehicle on a level floor, raise the

front of the vehicle and s upport it on chassis stands.

(2) Spin each front wheel in turn and using a

piece of chalk, mark a line around the periphery of

each tire as near to the centre as possible. (3) Lower the vehicle to the ground and bounce

the front several times to stabilize the suspension. (4) Set the wheels in the straight ahead position.

(5) Mark the centre chalk line on both tires at a

point approximately 200 mm above the floor and

forward of the suspension. (6) Using a tape measure, measure and record

the distance between the two marked points on the

tire centers.

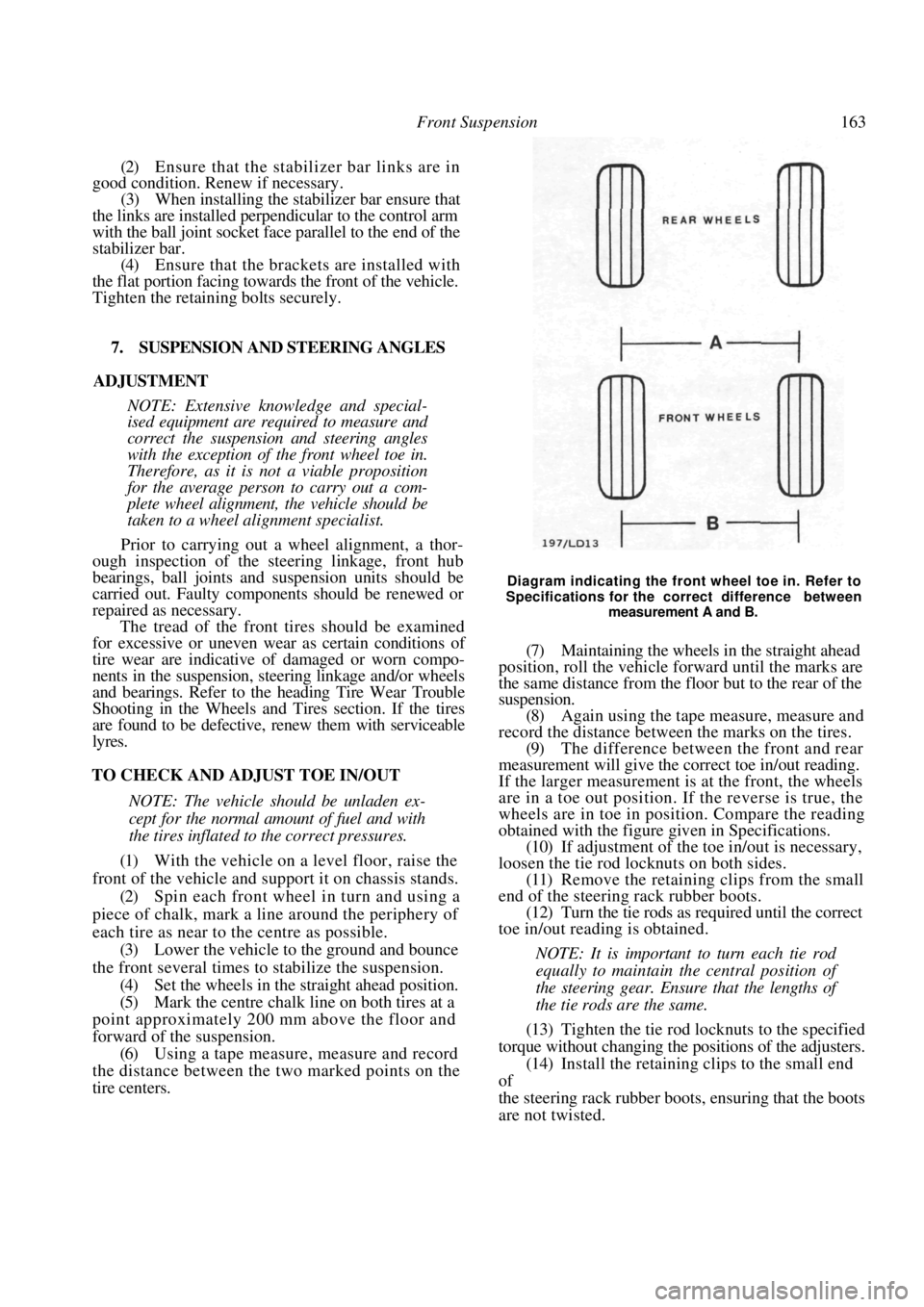

Diagram indicating the front wheel toe in. Refer to

Specifications for the correct difference between

measurement A and B.

(7) Maintaining the wheels in the straight ahead

position, roll the vehicle forward until the marks are

the same distance from the floor but to the rear of the

suspension. (8) Again using the tape measure, measure and

record the distance between the marks on the tires.

(9) The difference between the front and rear

measurement will give the correct toe in/out reading.

If the larger measurement is at the front, the wheels

are in a toe out position. If the reverse is true, the

wheels are in toe in position. Compare the reading

obtained with the figure given in Specifications.

(10) If adjustment of the to e in/out is necessary,

loosen the tie rod locknuts on both sides. (11) Remove the retaining clips from the small

end of the steering rack rubber boots. (12) Turn the tie rods as required until the correct

toe in/out reading is obtained.

NOTE: It is important to turn each tie rod

equally to maintain the central position of

the steering gear. Ensure that the lengths of

the tie rods are the same.

(13) Tighten the tie rod locknuts to the specified

torque without changing the positions of the adjusters.

(14) Install the retaining clips to the small end

of

the steering rack rubber boots, ensuring that the boots

are not twisted.