warning NISSAN QASHQAI 2014 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: QASHQAI, Model: NISSAN QASHQAI 2014Pages: 338, PDF Size: 4.87 MB

Page 249 of 338

4. Loosen each wheel bolt by one or two turns

anticlockwise with the wheel wrench.

Do not remove the wheel bolts until the tyre is

off the ground.

Models with wheel lock bolts (where fitted):

If the wheel is equipped with a wheel lock bolt,

insert the wheel lock key

j1 and loosen it as pre-

viously described.

The wheel lock bolt can only be removed with the

wheel lock key. A key number is necessary if you

need to duplicate the wheel lock key.

Record the key number as shown on the key

code card on the “Security information” page at

the end of this manual and keep it in a safe place,

not in the vehicle. If you loose the wheel lock key,

see your NISSAN dealer for a duplicate with the

original wheel lock key code.Make sure to keep the lock key in the vehicle.

Otherwise, wheels cannot be removed and the

service cannot be performed.

5. To lift the vehicle, securely hold and turn the

handle clockwise as shown.

6. Carefully raise the vehicle until the tyre clears the

ground.

7. Remove the wheel bolts, then remove the wheel

with the flat tyre.

CAUTION

The wheel is heavy. Be sure that your feet are

clear of the wheel and use gloves as necessary

to avoid injury.

Installing the wheel

WARNING

•The temporary use spare tyre (where fitted) is

designed for emergency use. See “Spare tyre”

earlier in this section.

•Never use wheel bolts other than those pro-

vided with your vehicle. Incorrect wheel bolts

or improperly tightened wheel bolts may

cause the wheel to become loose or come

off. This could cause an accident.

•Never use oil or grease on the wheel bolts.

This may cause the wheel bolts to become

loose.

jATighten

jBLoosen

1. Clean any mud or dirt from the surface between

the wheel and the hub.

2. Carefully fit the wheel and tighten the wheel bolts

with your fingers. Check that all the wheel bolts

contact the wheel surface horizontally and on the

bevelled side.

Models with wheel lock bolt (where fitted):

Insert the wheel lock key into the wheel lock bolt

and tighten into the wheel finger tight.

NCE143Z

NCE309

NCE198Z

In case of emergency6-5

Page 250 of 338

3. With the wheel wrench, tighten the wheel bolts

alternately and evenly in the sequence as illus-

trated (

j1-j5 ) until they are tight.

4. Lower the vehicle slowly until the tyre touches

the ground.

5. Tighten the wheel bolts securely using the wheel

wrench in the sequence as illustrated.

6. Lower the vehicle completely.

7. Install the wheel cover (where fitted).

NOTE

Before installation, align NISSAN logo (centre

cap) with the wheel bolts/or perpendicular to

valve hole (where fitted), to correctly align to

the centre.

Wheel bolt tightening torque:

113 N•m (12 kg-m, 83 ft-lb)

As soon as possible, tighten the wheel bolts to

the specified torque with a torque wrench.

WARNING

Retighten the wheel bolts after the vehicle has

been driven for 1,000 km (600 miles) (also in

cases of a flat tyre, etc.).

The wheel bolts must be kept tightened to specifi-

cation at all times. It is recommended that the wheel

bolts be tightened to specification at each mainte-

nance interval.

Adjust the tyre pressure to the COLD pressure.COLD pressure is the tyre pressure as measured

after the vehicle has been parked for three hours or

more or driven for less than 1.6 km (1 mile).

COLD tyre pressures are shown on the tyre placard

affixed to the driver’s side centre pillar.

Stowing the wheel and tools

Securely store the wheel with the flat tyre, the jack

and the tools in the specified storage areas.

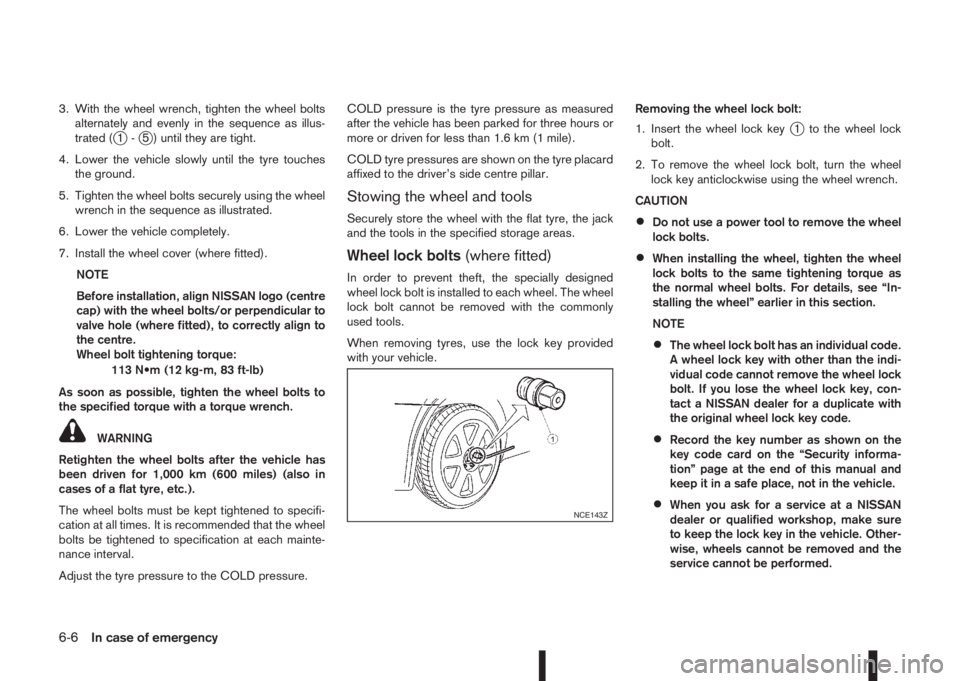

Wheel lock bolts(where fitted)

In order to prevent theft, the specially designed

wheel lock bolt is installed to each wheel. The wheel

lock bolt cannot be removed with the commonly

used tools.

When removing tyres, use the lock key provided

with your vehicle.Removing the wheel lock bolt:

1. Insert the wheel lock key

j1 to the wheel lock

bolt.

2. To remove the wheel lock bolt, turn the wheel

lock key anticlockwise using the wheel wrench.

CAUTION

•Do not use a power tool to remove the wheel

lock bolts.

•When installing the wheel, tighten the wheel

lock bolts to the same tightening torque as

the normal wheel bolts. For details, see “In-

stalling the wheel” earlier in this section.

NOTE

•The wheel lock bolt has an individual code.

A wheel lock key with other than the indi-

vidual code cannot remove the wheel lock

bolt. If you lose the wheel lock key, con-

tact a NISSAN dealer for a duplicate with

the original wheel lock key code.

•Record the key number as shown on the

key code card on the “Security informa-

tion” page at the end of this manual and

keep it in a safe place, not in the vehicle.

•When you ask for a service at a NISSAN

dealer or qualified workshop, make sure

to keep the lock key in the vehicle. Other-

wise, wheels cannot be removed and the

service cannot be performed.NCE143Z

6-6In case of emergency

Page 251 of 338

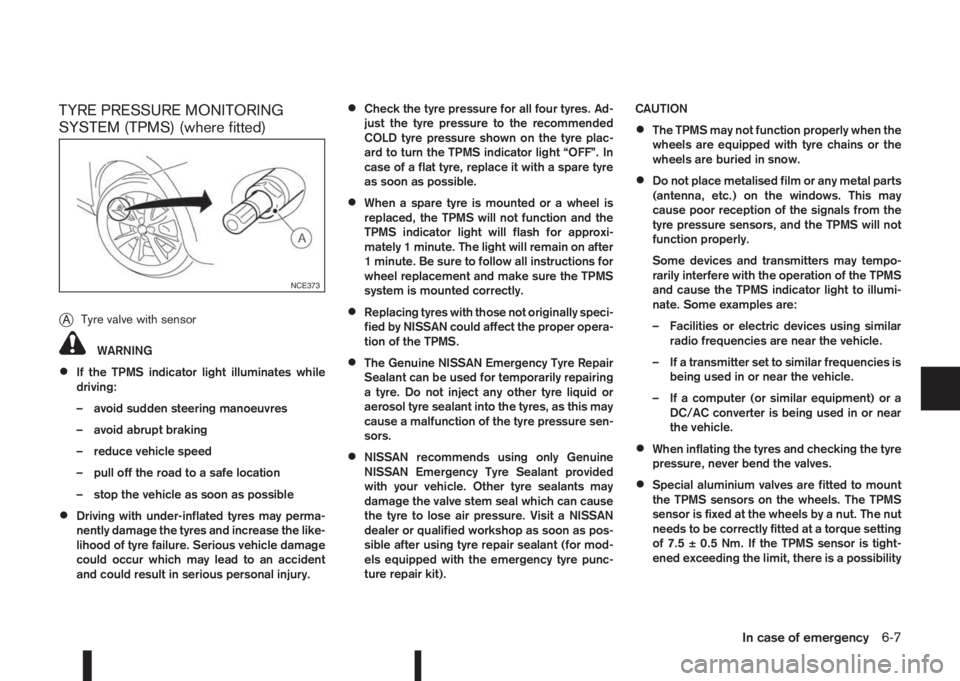

TYRE PRESSURE MONITORING

SYSTEM (TPMS) (where fitted)

j

ATyre valve with sensor

WARNING

•If the TPMS indicator light illuminates while

driving:

– avoid sudden steering manoeuvres

– avoid abrupt braking

– reduce vehicle speed

– pull off the road to a safe location

– stop the vehicle as soon as possible

•Driving with under-inflated tyres may perma-

nently damage the tyres and increase the like-

lihood of tyre failure. Serious vehicle damage

could occur which may lead to an accident

and could result in serious personal injury.

•Check the tyre pressure for all four tyres. Ad-

just the tyre pressure to the recommended

COLD tyre pressure shown on the tyre plac-

ard to turn the TPMS indicator light “OFF”. In

case of a flat tyre, replace it with a spare tyre

as soon as possible.

•When a spare tyre is mounted or a wheel is

replaced, the TPMS will not function and the

TPMS indicator light will flash for approxi-

mately 1 minute. The light will remain on after

1 minute. Be sure to follow all instructions for

wheel replacement and make sure the TPMS

system is mounted correctly.

•Replacing tyres with those not originally speci-

fied by NISSAN could affect the proper opera-

tion of the TPMS.

•The Genuine NISSAN Emergency Tyre Repair

Sealant can be used for temporarily repairing

a tyre. Do not inject any other tyre liquid or

aerosol tyre sealant into the tyres, as this may

cause a malfunction of the tyre pressure sen-

sors.

•NISSAN recommends using only Genuine

NISSAN Emergency Tyre Sealant provided

with your vehicle. Other tyre sealants may

damage the valve stem seal which can cause

the tyre to lose air pressure. Visit a NISSAN

dealer or qualified workshop as soon as pos-

sible after using tyre repair sealant (for mod-

els equipped with the emergency tyre punc-

ture repair kit).CAUTION

•The TPMS may not function properly when the

wheels are equipped with tyre chains or the

wheels are buried in snow.

•Do not place metalised film or any metal parts

(antenna, etc.) on the windows. This may

cause poor reception of the signals from the

tyre pressure sensors, and the TPMS will not

function properly.

Some devices and transmitters may tempo-

rarily interfere with the operation of the TPMS

and cause the TPMS indicator light to illumi-

nate. Some examples are:

– Facilities or electric devices using similar

radio frequencies are near the vehicle.

– If a transmitter set to similar frequencies is

being used in or near the vehicle.

– If a computer (or similar equipment) or a

DC/AC converter is being used in or near

the vehicle.

•When inflating the tyres and checking the tyre

pressure, never bend the valves.

•Special aluminium valves are fitted to mount

the TPMS sensors on the wheels. The TPMS

sensor is fixed at the wheels by a nut. The nut

needs to be correctly fitted at a torque setting

of 7.5 ± 0.5 Nm. If the TPMS sensor is tight-

ened exceeding the limit, there is a possibility

NCE373

In case of emergency6-7

Page 255 of 338

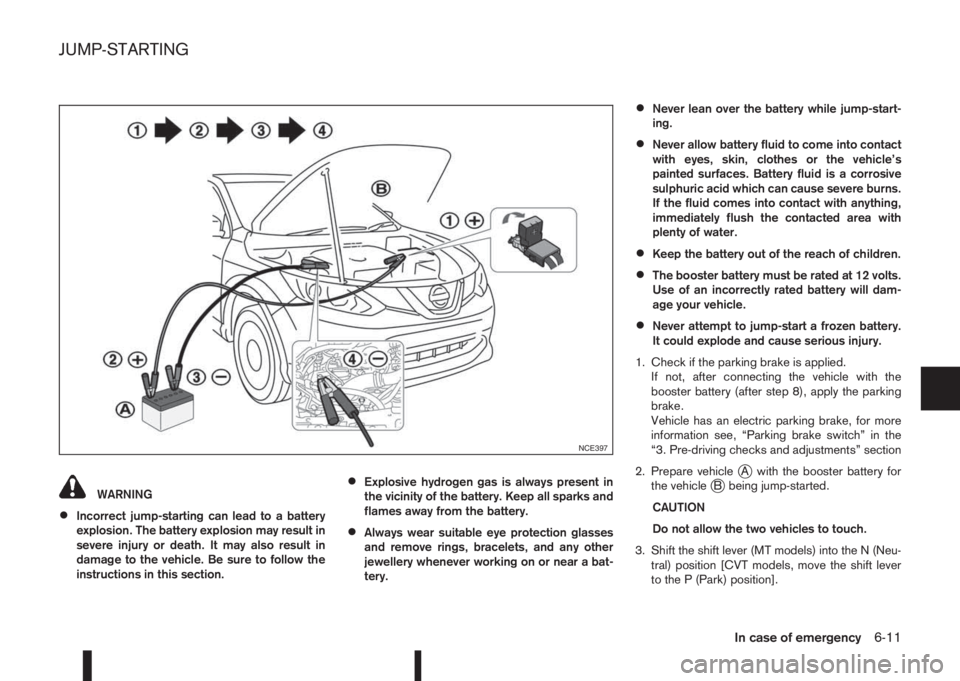

WARNING

•Incorrect jump-starting can lead to a battery

explosion. The battery explosion may result in

severe injury or death. It may also result in

damage to the vehicle. Be sure to follow the

instructions in this section.

•Explosive hydrogen gas is always present in

the vicinity of the battery. Keep all sparks and

flames away from the battery.

•Always wear suitable eye protection glasses

and remove rings, bracelets, and any other

jewellery whenever working on or near a bat-

tery.

•Never lean over the battery while jump-start-

ing.

•Never allow battery fluid to come into contact

with eyes, skin, clothes or the vehicle’s

painted surfaces. Battery fluid is a corrosive

sulphuric acid which can cause severe burns.

If the fluid comes into contact with anything,

immediately flush the contacted area with

plenty of water.

•Keep the battery out of the reach of children.

•The booster battery must be rated at 12 volts.

Use of an incorrectly rated battery will dam-

age your vehicle.

•Never attempt to jump-start a frozen battery.

It could explode and cause serious injury.

1. Check if the parking brake is applied.

If not, after connecting the vehicle with the

booster battery (after step 8), apply the parking

brake.

Vehicle has an electric parking brake, for more

information see, “Parking brake switch” in the

“3. Pre-driving checks and adjustments” section

2. Prepare vehicle

jA with the booster battery for

the vehiclejB being jump-started.

CAUTION

Do not allow the two vehicles to touch.

3. Shift the shift lever (MT models) into the N (Neu-

tral) position [CVT models, move the shift lever

to the P (Park) position].

NCE397

JUMP-STARTING

In case of emergency6-11

Page 257 of 338

CAUTION

•Three-way catalyst equipped models (where

fitted) should not be started by pushing the

vehicle as the three-way catalyst may be dam-

aged.

•XTRONIC transmission (CVT) models cannot

be started by pushing the vehicle. This may

cause transmission damage.

•Never try to start the vehicle by towing it; when

the engine starts, the forward surge could

cause the vehicle to collide with the tow ve-

hicle.

WARNING

•Never continue driving if the engine of your

vehicle overheats. Doing so could cause a ve-

hicle fire.

•Never open the bonnet if steam is coming

out.

•Never remove engine coolant reservoir cap

when the engine is hot. If the engine coolant

reservoir cap is removed while the engine is

hot, pressurised hot water will spurt out and

possibly cause burning, scalding or serious

injury.

•If steam or coolant is coming out of the en-

gine, stand clear of the vehicle to prevent get-

ting injured.

•The engine cooling fan will start whenever the

coolant temperature exceeds preset degrees.

•Be careful not to allow your hands, hair, jewel-

lery or clothing to come into contact with, or

get caught in, the cooling fan or drive belts.

If the engine of your vehicle is overheating (indi-

cated by the engine coolant temperature gauge) or

if you feel a lack of engine power, detect unusual

noise, etc., proceed as follows:

1. Move and park the vehicle safely off the road and

away from traffic.

2. Turn on the hazard warning flasher lights.

3. Apply the parking brake.4. Shift the shift lever (MT models) into the N (Neu-

tral) position, XTRONIC transmission (CVT)

models: move the shift lever to the P (Park) posi-

tion.

DO NOT STOP THE ENGINE.

5. Open all windows.

6. Switch off the air conditioner system (where fit-

ted).

7. Set the heater or air conditioner temperature

control to maximum “HOT” and fan speed con-

trol to maximum speed.

8. Exit the vehicle.

9. Visually inspect and listen for steam or coolant

escaping from the radiator before opening the

bonnet. Wait until no steam or coolant can be

seen before proceeding.

10. Open the bonnet. For details, see “Bonnet

release” in the “3. Pre-driving checks and

adjustments” section.

11. Visually check if the cooling fan is running.

12. Visually check the radiator and radiator hoses

for leakage.

WARNING

If coolant is leaking, the cooling fan belt is

missing or loose or the cooling fan is not run-

ning, stop the engine.

PUSH-STARTING ENGINE OVERHEAT

In case of emergency6-13

Page 258 of 338

13. After the engine cools down, check the coolant

level in the engine coolant reservoir with the

engine running.

14. If the level is low, remove the engine coolant

reservoir cap and add coolant slowly into the

reservoir. After refilling the reservoir to the MAX

level, install the reservoir cap.

WARNING

Before removing the engine coolant reservoir

cap and to avoid the danger of being scalded,

cover the reservoir cap with a rag and loosen

the reservoir cap to the first notch to allow the

steam to escape.

15. Close the bonnet.

Have your vehicle inspected or repaired by a

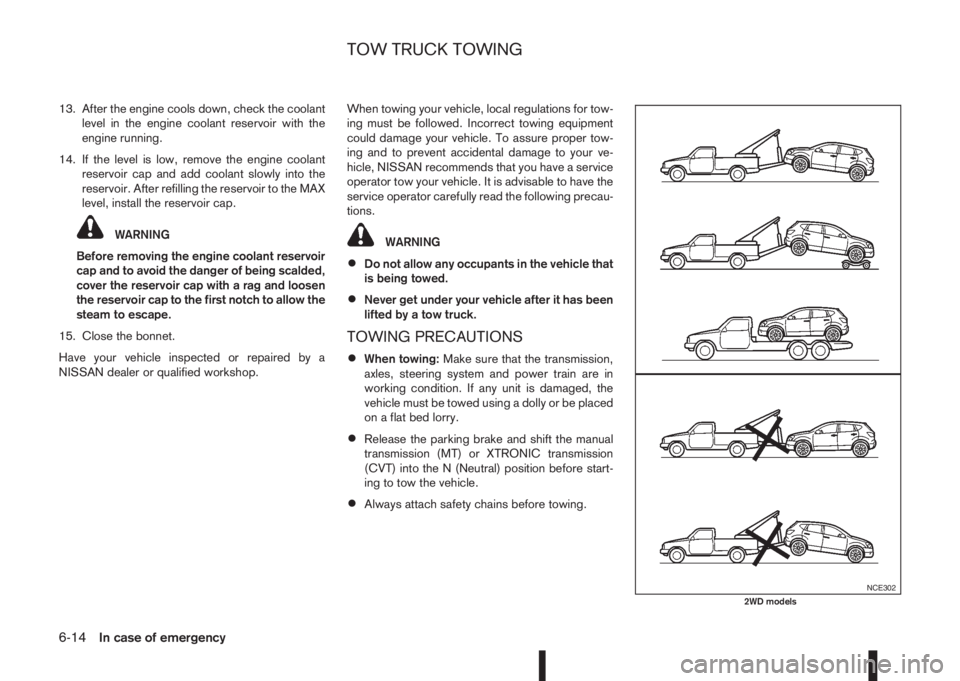

NISSAN dealer or qualified workshop.When towing your vehicle, local regulations for tow-

ing must be followed. Incorrect towing equipment

could damage your vehicle. To assure proper tow-

ing and to prevent accidental damage to your ve-

hicle, NISSAN recommends that you have a service

operator tow your vehicle. It is advisable to have the

service operator carefully read the following precau-

tions.WARNING

•Do not allow any occupants in the vehicle that

is being towed.

•Never get under your vehicle after it has been

lifted by a tow truck.

TOWING PRECAUTIONS

•When towing:Make sure that the transmission,

axles, steering system and power train are in

working condition. If any unit is damaged, the

vehicle must be towed using a dolly or be placed

on a flat bed lorry.

•Release the parking brake and shift the manual

transmission (MT) or XTRONIC transmission

(CVT) into the N (Neutral) position before start-

ing to tow the vehicle.

•Always attach safety chains before towing.

NCE3022WD models

TOW TRUCK TOWING

6-14In case of emergency

Page 260 of 338

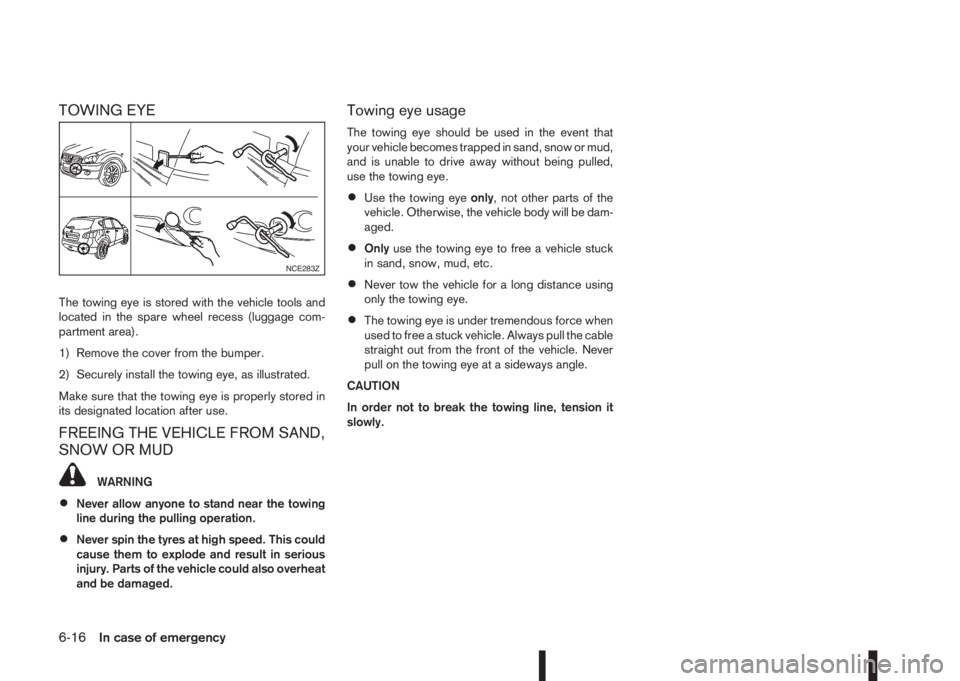

TOWING EYE

The towing eye is stored with the vehicle tools and

located in the spare wheel recess (luggage com-

partment area).

1) Remove the cover from the bumper.

2) Securely install the towing eye, as illustrated.

Make sure that the towing eye is properly stored in

its designated location after use.

FREEING THE VEHICLE FROM SAND,

SNOW OR MUD

WARNING

•Never allow anyone to stand near the towing

line during the pulling operation.

•Never spin the tyres at high speed. This could

cause them to explode and result in serious

injury. Parts of the vehicle could also overheat

and be damaged.

Towing eye usage

The towing eye should be used in the event that

your vehicle becomes trapped in sand, snow or mud,

and is unable to drive away without being pulled,

use the towing eye.

•Use the towing eyeonly, not other parts of the

vehicle. Otherwise, the vehicle body will be dam-

aged.

•Onlyuse the towing eye to free a vehicle stuck

in sand, snow, mud, etc.

•Never tow the vehicle for a long distance using

only the towing eye.

•The towing eye is under tremendous force when

used to free a stuck vehicle. Always pull the cable

straight out from the front of the vehicle. Never

pull on the towing eye at a sideways angle.

CAUTION

In order not to break the towing line, tension it

slowly.

NCE283Z

6-16In case of emergency

Page 265 of 338

CLEANING GLASS

Use glass cleaner to remove smoke and dust film

from the glass surfaces. It is normal for glass to

become coated with a film after the vehicle is parked

in the hot sun. Glass cleaner and a soft cloth will

easily remove this film.

CAUTION

When cleaning the inside of the windows, do not

use sharp-edged tools, abrasive cleaners or chlo-

rine-based disinfectant cleaners. They could

damage elements in the rear windows (such as

the window defogger).

Inside rear-view mirror (Automatic

anti-dazzling, where fitted)

Use a soft cloth dampened only with water to clean

the automatic anti-dazzling inside rear view mirror

(where fitted).

CAUTION

Do not use glass cleaner. Doing so will reduce

the sensitivity of the sensor, resulting in improper

operation.

PLASTIC PARTS

Plastic parts can be cleaned with a mild soap solu-

tion. If the dirt cannot be easily removed, use a plas-

tic cleaner. Do not use any solvents.

SEAT BELTS

WARNING

•Do not allow wet seat belts to roll up in the

retractor.

•Never use bleach, dye or chemical solvents to

clean the seat belts, since these materials

may severely weaken the seat belt webbing.

The seat belts can be cleaned by wiping them with

a sponge dampened in a mild soap solution.

Allow the belts to dry completely in the shade before

using them.

MOST COMMON FACTORS

CONTRIBUTING TO VEHICLE

CORROSION

•The accumulation of moisture-retaining dirt and

debris in body panel sections, cavities, and other

areas.

•Damage to the paint surface and other protec-

tive coatings caused by gravel and stone chips

or minor traffic accidents.

ENVIRONMENTAL FACTORS

INFLUENCE THE RATE OF

CORROSION

Moisture

Accumulation of sand, dirt and water on the vehicle

body underside can accelerate corrosion. Wet floor

coverings will not dry completely inside the vehicle,

and should be removed for drying to avoid floor pan-

els corrosion.

Relative humidity

Corrosion will be accelerated in areas of high rela-

tive humidity, especially those areas where the tem-

peratures stay above freezing, where atmospheric

pollution exists and road salt is used.

Temperature

A temperature increase will accelerate the rate of

corrosion to those parts which are not well venti-

lated.

CORROSION PROTECTION

Appearance and care7-5

Page 272 of 338

longer to stop, contact a NISSAN dealer or qualified

workshop immediately. Keep the floor mat away

from the pedal.

Parking brake*:

Confirm that your vehicle is held securely on a fairly

steep hill with only the parking brake applied.

Seats:

Check seat position controls such as seat adjust-

ers, seatback recliner, etc. to ensure they operate

smoothly and all latches lock securely in every posi-

tion. Check that the head restraints move up and

down smoothly and the locks hold securely in all

latched positions.

Seat belts:

Check that all parts of the seat belt system (e.g.

buckles, anchors, adjusters and retractors) operate

properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or

damage. See “Seat belts” in the “1. Safety — Seats,

Seat belts and Supplemental Restraint System” sec-

tion for further details.

Steering wheel:

Check for any change in the steering conditions,

such as excessive free play, hard steering or strange

noises.

Warning lights and audible reminders:

Make sure that all warning/indicator lights and au-

dible reminders are operating properly.Windscreen defogger:

Check that the air comes out of the defogger outlets

properly when operating the heater or air condi-

tioner.

Windscreen wiper and washer*:

Check that the wipers and washer operate properly

and that the wipers do not streak.When performing any inspection or maintenance

work on your vehicle, always take care to prevent

serious accidental injury to yourself or damage to

the vehicle. The following are general precautions

which should be closely observed.

•Park the vehicle on a level surface, apply the

parking brake securely and block the wheels

to prevent the vehicle from moving. For

manual transmission models, move the shift

lever to N (Neutral) position.For continuously

variable transmission models: move the shift

lever to P (Park) position.

•Do not work under the engine bonnet while

the engine is hot. Turn off the engine and wait

until it cools down.

•Be sure to turn the ignition switch to the “OFF”

or LOCK position.

When the ignition switch is in the ON or Acc

position, the cooling fan may start to operate

suddenly even when the engine is not run-

ning. To avoid injury, always disconnect the

negative battery cable before working near

the engine.

•If you must work with the engine running,

keep your hands, clothing, hair and tools away

from moving fans, belts and any other moving

parts.

•It is advisable to remove ties and any jewel-

lery, such as rings, watches, etc. before work-

ing on your vehicle.

MAINTENANCE PRECAUTIONS

8-4Maintenance and do-it-yourself

Page 274 of 338

WARNING

•Never remove the engine coolant reservoir

cap when the engine is hot. Serious burns

could be caused by high pressure fluid es-

caping from the engine coolant reservoir. Wait

until the engine and radiator have cooled

down.

•Engine coolant is poisonous and should be

stored carefully in marked containers out of

the reach of children.

The engine cooling system is filled at the factory

with a high-quality, year-round and extended life en-

gine coolant. The high quality engine coolant con-

tains the specific solutions effective for the anti-cor-

rosion and the anti-freeze function. Therefore, addi-

tional cooling system additives are not necessary.

CAUTION

•Never use any cooling system additives such

as radiator sealer. Additives may clog the

cooling system and cause damage to the en-

gine, transmission and/or cooling system.

•When adding or replacing engine coolant, be

sure to use Genuine NISSAN engine coolant

or equivalent.

•The use of other types of engine coolant may

damage the engine cooling system.

•The engine coolant reservoir tank is equipped

with a pressure cap, use a Genuine NISSAN

cap or its equivalent when replacement is re-

quired.

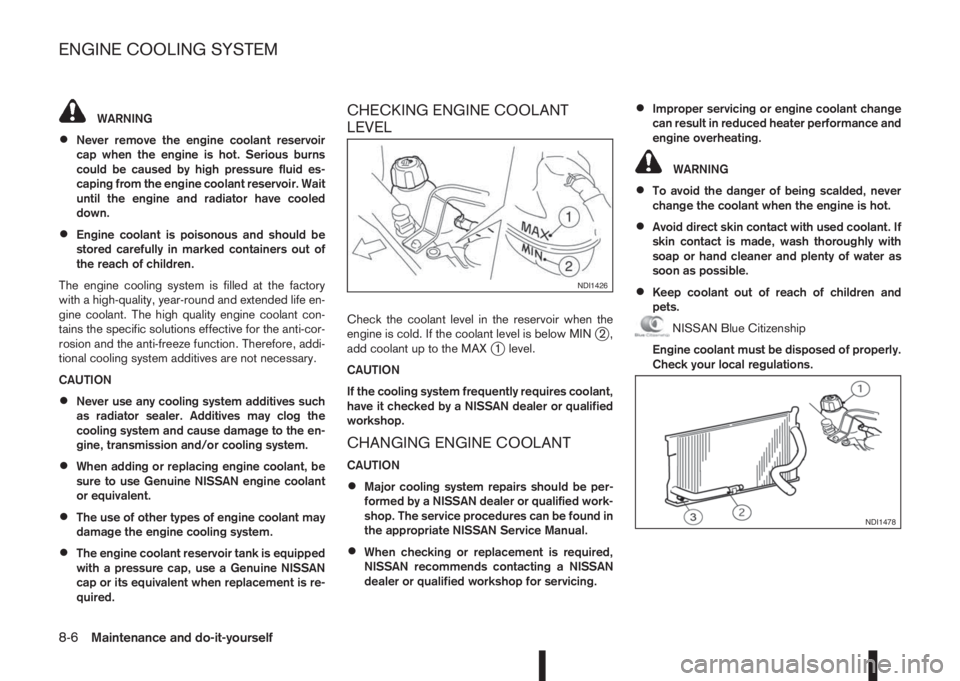

CHECKING ENGINE COOLANT

LEVEL

Check the coolant level in the reservoir when the

engine is cold. If the coolant level is below MINj2,

add coolant up to the MAXj1 level.

CAUTION

If the cooling system frequently requires coolant,

have it checked by a NISSAN dealer or qualified

workshop.

CHANGING ENGINE COOLANT

CAUTION

•Major cooling system repairs should be per-

formed by a NISSAN dealer or qualified work-

shop. The service procedures can be found in

the appropriate NISSAN Service Manual.

•When checking or replacement is required,

NISSAN recommends contacting a NISSAN

dealer or qualified workshop for servicing.

•Improper servicing or engine coolant change

can result in reduced heater performance and

engine overheating.

WARNING

•To avoid the danger of being scalded, never

change the coolant when the engine is hot.

•Avoid direct skin contact with used coolant. If

skin contact is made, wash thoroughly with

soap or hand cleaner and plenty of water as

soon as possible.

•Keep coolant out of reach of children and

pets.

NISSAN Blue Citizenship

Engine coolant must be disposed of properly.

Check your local regulations.

NDI1426

NDI1478

ENGINE COOLING SYSTEM

8-6Maintenance and do-it-yourself