ignition NISSAN ROGUE 2021 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2021, Model line: ROGUE, Model: NISSAN ROGUE 2021Pages: 556, PDF Size: 2.7 MB

Page 456 of 556

8-2Do-it-yourself

When performing any inspection or main-

tenance work on your vehicle, always

take care to prevent serious accidental

injury to yourself or damage to the

vehicle. The following are general precau-

tions which should be closely observed.

WARNING

.Park the vehicle on a level sur-

face, apply the parking brake

securely and block the wheels to

prevent the vehicle from moving.

Push the park button to shift to

the P (Park) position.

. Be sure the ignition switch is in

the OFF position when perform-

ing any parts replacement or

repairs.

. If you must work with the engine

running, keep your hands, cloth-

ing, hair and tools away from

moving fans, belts and any other

moving parts.

. It is advisable to secure or re-

move any loose clothing and

remove any jewelry, such as

rings, watches, etc. before work-

ing on your vehicle. .

Always wear eye protection

whenever you work on your ve-

hicle.

. If you must run the engine in an

enclosed space such as a garage,

be sure there is proper ventilation

for exhaust gases to escape.

. Never get under the vehicle while

it is supported only by a jack. If it

is necessary to work under the

vehicle, support it with safety

stands.

. Because the fuel lines are under

high pressure even when the

engine is off, it is recommended

you visit a NISSAN dealer for

service of the fuel filter or fuel

lines.

. Keep smoking materials, flame

and sparks away from fuel and

the battery.

. On gasoline engine models with

the Multiport Fuel Injection (MFI)

system, the fuel filter and fuel

lines should be serviced because

the fuel lines are under high

pressure even when the engine

is turned off. It is recommended

that you visit a NISSAN dealer for

this service. .

Your vehicle is equipped with an

automatic engine cooling fan. It

may come on at any time without

warning, even if the ignition

switch is in the OFF position and

the engine is not running. To

avoid injury, always disconnect

the negative battery cable before

working near the fan.

CAUTION

.Do not work under the hood while

the engine is hot. Turn the engine

off and wait until it cools down.

. Avoid direct contact with used

engine oil and coolant. Impro-

perly disposed engine oil, and

engine coolant and/or other ve-

hicle fluids can damage the en-

vironment. Always conform to

local regulations for disposal of

vehicle fluid.

. Never leave the engine or the CVT

related component harnesses

disconnected while the ignition

switch is in the ON position.

. Never connect or disconnect the

battery or any transistorized

component while the ignition

MAINTENANCE PRECAUTIONS

Page 467 of 556

WAI0223X

CAUTION

.Do not ground accessories di-

rectly to the battery terminal.

Doing so will bypass the variable

voltage control system and the

vehicle battery may not charge

completely.

. Use electrical accessories with

the engine running to avoid dis-

charging the vehicle battery.

The variable voltage control system mea-

sures the amount of electrical discharge

from the battery and controls voltage generated by the generator.

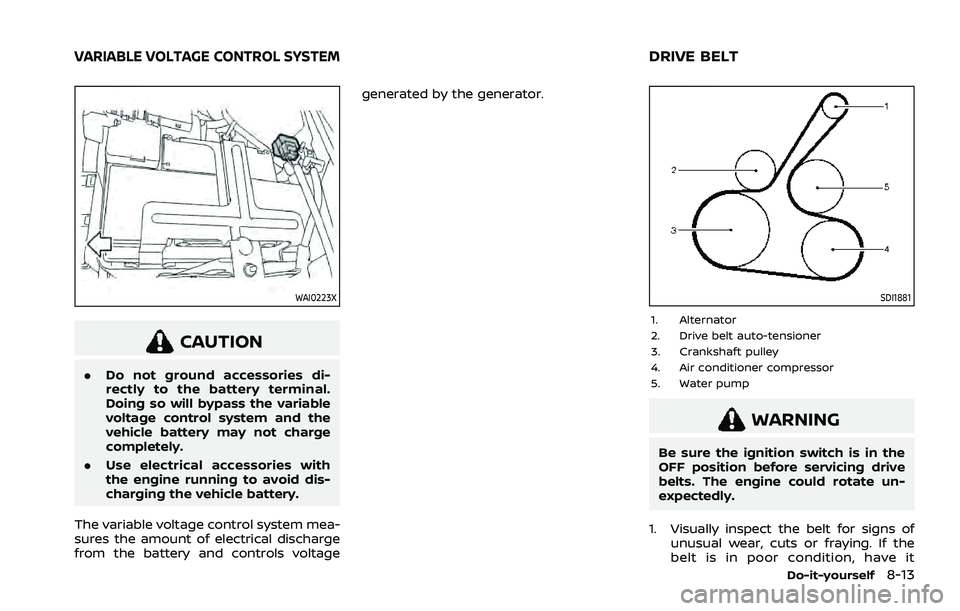

SDI1881

1. Alternator

2. Drive belt auto-tensioner

3. Crankshaft pulley

4. Air conditioner compressor

5. Water pump

WARNING

Be sure the ignition switch is in the

OFF position before servicing drive

belts. The engine could rotate un-

expectedly.

1. Visually inspect the belt for signs of unusual wear, cuts or fraying. If the

belt is in poor condition, have it

Do-it-yourself8-13

VARIABLE VOLTAGE CONTROL SYSTEMDRIVE BELT

Page 468 of 556

8-14Do-it-yourself

replaced. It is recommended that you

visit a NISSAN dealer for this service.

2. Have the belt condition checked reg- ularly.

WARNING

Be sure the engine and ignition

switch are off and that the parking

brake is applied.

CAUTION

Be sure to use the correct socket to

remove the spark plugs. An incorrect

socket can damage the spark plugs.

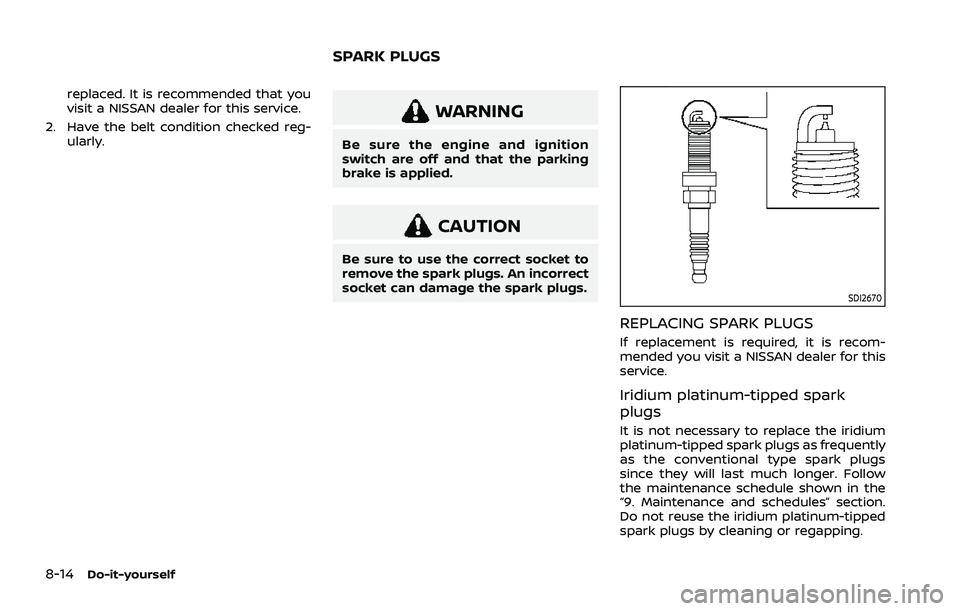

SDI2670

REPLACING SPARK PLUGS

If replacement is required, it is recom-

mended you visit a NISSAN dealer for this

service.

Iridium platinum-tipped spark

plugs

It is not necessary to replace the iridium

platinum-tipped spark plugs as frequently

as the conventional type spark plugs

since they will last much longer. Follow

the maintenance schedule shown in the

“9. Maintenance and schedules” section.

Do not reuse the iridium platinum-tipped

spark plugs by cleaning or regapping.

SPARK PLUGS

Page 472 of 556

8-18Do-it-yourself

WAI0124X

ENGINE COMPARTMENT

WARNING

Never use a fuse of a higher or lower

amperage rating than that specified

on the fuse box cover. This could

damage the electrical system or

electronic control units or cause a

fire.

If any electrical equipment does not

operate, check for an open fuse.

1. Be sure the ignition switch is turned off and the headlights are off. 2. Open the engine hood.

3. Remove the fuse/fusible link box cov-

er by using a suitable tool and pushing

the tab.

4. Locate the fuse that needs to be replaced.

5. Remove the fuse using the fuse puller located in the passenger compart-

ment fuse box.

SDI1753

6. If the fuse is open, replace it with a

new fuse.

7. If a new fuse also opens, have the electrical system checked and re-

paired. It is recommended you visit a

NISSAN dealer for this service.

Fusible links

If any electrical equipment does not

operate and the fuses are in good condi-

tion, check the fusible links. If any of these

fusible links are melted, replace only with

genuine NISSAN parts.

For checking and replacing the fusible

links, it is recommended you visit a

NISSAN dealer.

FUSES

Page 473 of 556

WAI0205X

PASSENGER COMPARTMENT

WARNING

Never use a fuse of a higher or lower

amperage rating than that specified

on the fuse box cover. This could

damage the electrical system or

electronic control units or cause a

fire.

If any electrical equipment does not

operate, check for an open fuse.

1. Be sure the ignition switch is turned off and the headlights are off. 2. Remove the fuse box cover.

3. Remove the fuse with the fuse puller

.

SDI1753

4. If the fuse is open, replace it with a

new fuse.

5. If a new fuse also opens, have the electrical system checked and re-

paired. It is recommended you visit a

NISSAN dealer for this service.

Do-it-yourself8-19

Page 474 of 556

8-20Do-it-yourself

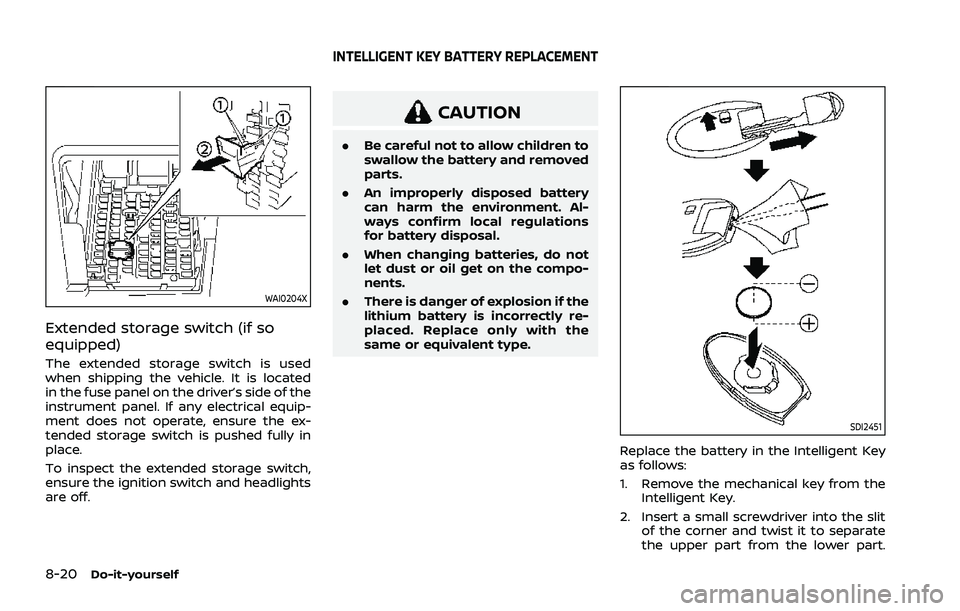

WAI0204X

Extended storage switch (if so

equipped)

The extended storage switch is used

when shipping the vehicle. It is located

in the fuse panel on the driver’s side of the

instrument panel. If any electrical equip-

ment does not operate, ensure the ex-

tended storage switch is pushed fully in

place.

To inspect the extended storage switch,

ensure the ignition switch and headlights

are off.

CAUTION

.Be careful not to allow children to

swallow the battery and removed

parts.

. An improperly disposed battery

can harm the environment. Al-

ways confirm local regulations

for battery disposal.

. When changing batteries, do not

let dust or oil get on the compo-

nents.

. There is danger of explosion if the

lithium battery is incorrectly re-

placed. Replace only with the

same or equivalent type.

SDI2451

Replace the battery in the Intelligent Key

as follows:

1. Remove the mechanical key from the

Intelligent Key.

2. Insert a small screwdriver into the slit of the corner and twist it to separate

the upper part from the lower part.

INTELLIGENT KEY BATTERY REPLACEMENT

Page 517 of 556

.If a methanol blend is used, it should

contain no more than 5% methanol

(methyl alcohol, wood alcohol). It

should also contain a suitable

amount of appropriate cosolvents

and corrosion inhibitors. If not prop-

erly formulated with appropriate

cosolvents and corrosion inhibitors,

such methanol blends may cause

fuel system damage and/or vehicle

performance problems. At this time,

sufficient data is not available to

ensure that all methanol blends are

suitable for use in NISSAN vehicles.

If any driveability problems such as en-

gine stalling and difficult hot-starting are

experienced after using oxygenate-blend

fuels, immediately change to a non-oxy-

genate fuel or a fuel with a low blend of

MTBE.

Take care not to spill gasoline during

refueling. Gasoline containing oxyge-

nates can cause paint damage.

E-15 fuel

E-15 fuel is a mixture of approximately

15% fuel ethanol and 85% unleaded gaso-

line. E-15 can only be used in vehicles

designed to run on E- 15 fuel. U.S. govern-

ment regulations require fuel ethanol

dispensing pumps to be identified with

small, square, orange and black label with

the common abbreviation or the appro- priate percentage for that region.

E-85 fuel

E-85 fuel is a mixture of approximately

85% fuel ethanol and 15% unleaded gaso-

line. E-85 can only be used in a Flexible

Fuel Vehicle (FFV). Do not use E-85 fuel in

your vehicle. U.S. government regulations

require fuel ethanol dispensing pumps to

be identified by a small, square, orange

and black label with the common abbre-

viation or the appropriate percentage for

that region.

Fuel containing MMT

MMT, or methylcyclopentadienyl manga-

nese tricarbonyl, is an octane boosting

additive. NISSAN does not recommend

the use of fuel containing MMT. Such fuel

may adversely affect vehicle perfor-

mance, including the emissions control

system. Note that while some fuel pumps

label MMT content, not all do, so you may

have to consult your gasoline retailer for

more details.

Aftermarket fuel additives

NISSAN does not recommend the use of

any aftermarket fuel additives (for exam-

ple, fuel injector cleaner, octane booster,

intake valve deposit removers, etc.) which

are sold commercially. Many of these

additives intended for gum, varnish or

deposit removal may contain active sol-

vent or similar ingredients that can be

harmful to the fuel system and engine.

Octane rating tips

Using unleaded gasoline with an octane

rating lower than recommended can

cause persistent, heavy “spark knock”.

(Spark knock is a metallic rapping

noise.) If severe, this can lead to engine

damage. If you detect a persistent

heavy spark knock even when using

gasoline of the stated octane rating, or

if you hear steady spark knock while

holding a steady speed on level roads, it

is recommended you have a NISSAN

dealer correct the condition. Failure to

correct the condition is misuse of the

vehicle, for which NISSAN is not respon-

sible.

Incorrect ignition timing will result in

spark knock, after-run and/or overheat-

ing, which may cause excessive fuel

consumption or engine damage. If any

of the above symptoms are encountered,

have your vehicle checked. It is recom-

mended you visit a NISSAN dealer for

servicing.

However, now and then you may notice

light spark knock for a short time while

accelerating or driving up hills. This is

not a cause for concern, because you

Technical and consumer information10-5

Page 520 of 556

10-8Technical and consumer information

ENGINE

ModelPR25DD

Type Gasoline, 4-cycle, DOHC

Cylinder arrangement 4-cylinder, in-line

Bore × Stroke in (mm)3.504 × 3.937 (89.0 × 100.0)

Displacement cu in (cm

3)151.85 (2,488)

Firing order 1-3-4-2

Idle speed rpm

No adjustment is necessary.

Ignition timing (B.T.D.C.) degree/rpm

Spark plug StandardDXE22H11C

Spark plug gap (Normal) in (mm)0.043 (1.1)

Camshaft operation Timing chain

This spark ignition system complies with the Canadian standard ICES-002.

WHEELS AND TIRES

Road wheel

TypeSize Offset in

(mm)

Conven-

tional 17 × 7.5J 1.57 (40)

18 × 7.5J 1.57 (40)

19 × 7.5J 1.57 (40)

Spare 17 × 4T 1.18 (30)

Tire

Type

SizePressure PSI

(kPa) [Cold]

Con-

ven-

tional 235/65 R17Front: 36

(250)

Rear: 33 (230)

235/60 R18 Front: 33

(230)

Rear: 30 (210)

235/55 R19

Spare T155/80 D17

(2WD)

T165/90 D17

(AWD)

60 (420)

SPECIFICATIONS

Page 534 of 556

10-22Technical and consumer information

.The diameter of the threaded shank of

the hitch ball must be matched to the

ball mount hole diameter. The hitch

ball shank should be no more than

1/16″ smaller than the hole in the ball

mount.

. The threaded shank of the hitch ball

must be long enough to be properly

secured to the ball mount. There

should be at least 2 threads showing

beyond the lock washer and nut.

Ball mount

The hitch ball is attached to the ball

mount and the ball mount is inserted into

the hitch receiver. Choose a proper class

ball mount based on the trailer weight.

Additionally, the ball mount should be

chosen to keep the trailer tongue level

with the ground.

Weight carrying hitches

A weight carrying or “dead weight” ball

mount is one that is designed to carry the

whole amount of tongue weight and

gross weight directly on the ball mount

and on the receiver.

Weight distribution hitch

This type of hitch is also called a “load-

leveling” or “equalizing” hitch. A set of bars

attach to the ball mount and to the trailer

to distribute the tongue weight (hitch

weight) of your trailer. Many vehicles

cannot carry the full tongue weight of a

given trailer, and need some of the

tongue weight transferred through the

frame and pushing down on the front

wheels. This gives stability to the tow

vehicle.

A weight-distributing hitch system (Class

IV) is recommended if you plan to tow

trailers with a maximum weight over

5,000 lbs (2,267 kg). Check with the trailer

and towing equipment manufacturers to

determine if they recommend the use of a

weight-distributing hitch system.

NOTE:

A weight-distributing hitch system may

affect the operation of trailer surge

brakes. If you are considering use of a

weight-distributing hitch system with a

surge brake-equipped trailer, check

with the surge brake, hitch or trailer

manufacturer to determine if and how

this can be done.

Follow the instructions provided by the

manufacturer for installing and using the

weight-distributing hitch system. General set-up instructions are as follows:

1. Park unloaded vehicle on a level sur-

face. With the ignition switch in the ON

position and the doors closed, allow

the vehicle to stand for several min-

utes so that it can level.

2. Measure the height of a reference point on the front and rear bumpers

at the center of the vehicle.

3. Attach the trailer to the vehicle and adjust the hitch equalizers so that the

front bumper height is within 0 - .5

inches (0 - 13 mm) of the reference

height measured in step 2. The rear

bumper should be no higher than the

reference height measured in step 2.

WARNING

Properly adjust the weight distribut-

ing hitch so the rear of the bumper is

no higher than the measured refer-

ence height when the trailer is at-

tached. If the rear bumper is higher

than the measured reference height

when loaded, the vehicle may handle

unpredictably which could cause a

loss of vehicle control and cause

serious personal injury or property

damage.

Page 542 of 556

10-30Technical and consumer information

condition”. Before taking the I/M test,

check the vehicle’s inspection/mainte-

nance test readiness condition. Place the

ignition switch in the ON position without

starting the engine. If the Malfunction

Indicator Light (MIL) comes on steady for

20 seconds and then blinks for 10 sec-

onds, the I/M test condition is “not ready”.

If the MIL does not blink after 20 seconds,

the I/M test condition is “ready”.

It is recommended you visit a NISSAN

dealer to set “ready condition” or to

prepare the vehicle for testing.This vehicle is equipped with an Event

Data Recorder (EDR). The main purpose of

an EDR is to record, in certain crash or

near crash-like situations, such as an air

bag deployment or hitting a road obsta-

cle, data that will assist in understanding

how a vehicle’s systems performed. The

EDR is designed to record data related to

vehicle dynamics and safety systems for a

short period of time, typically 30 seconds

or less. The EDR in this vehicle is designed

to record such data as:

.How various systems in your vehicle

were operating;

. Whether or not the driver and passen-

ger safety belts were buckled/fas-

tened;

. How far (if at all) the driver was

depressing the accelerator and/or

brake pedal; and,

. How fast the vehicle was traveling.

. Sounds are not recorded.

These data can help provide a better

understanding of the circumstances in

which crashes and injuries occur.

NOTE: EDR data are recorded by your

vehicle only if a nontrivial crash situation

occurs; no data are recorded by the EDR

under normal driving conditions and no

personal data (e.g. name, gender, age and

crash location) are recorded. However,

other parties, such as law enforcement, could combine the EDR data with the type

of personally identifying data routinely

acquired during a crash investigation.

To read data recorded by an EDR, special

equipment is required and access to the

vehicle or the EDR is needed. In addition

to the vehicle manufacturer and NISSAN

dealer, other parties, such as law enforce-

ment, that have the special equipment,

can read the information if they have

access to the vehicle or the EDR. EDR data

will only be accessed with the consent of

the vehicle owner or lessee or as other-

wise required or permitted by law.

ADDITIONAL DATA RECORDING (on

vehicles equipped with optional

ProPILOT Assist)

If your vehicle is equipped with the

optional ProPILOT Assist, it will also be

equipped with supplemental data record-

ing function intended to assist in under-

standing how ProPILOT Assist performs in

certain nontrivial crash or near-crash

scenarios. Specifically, supplemental re-

cording is designed to capture the follow-

ing:

.

Driver operational status of the accel-

erator, brakes, steering, etc.

. Detection status of a vehicle ahead

and lane markers

EVENT DATA RECORDERS (EDR)