Spark NISSAN SENTRA 1996 B14 / 4.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1996, Model line: SENTRA, Model: NISSAN SENTRA 1996 B14 / 4.GPages: 191, PDF Size: 1.43 MB

Page 36 of 191

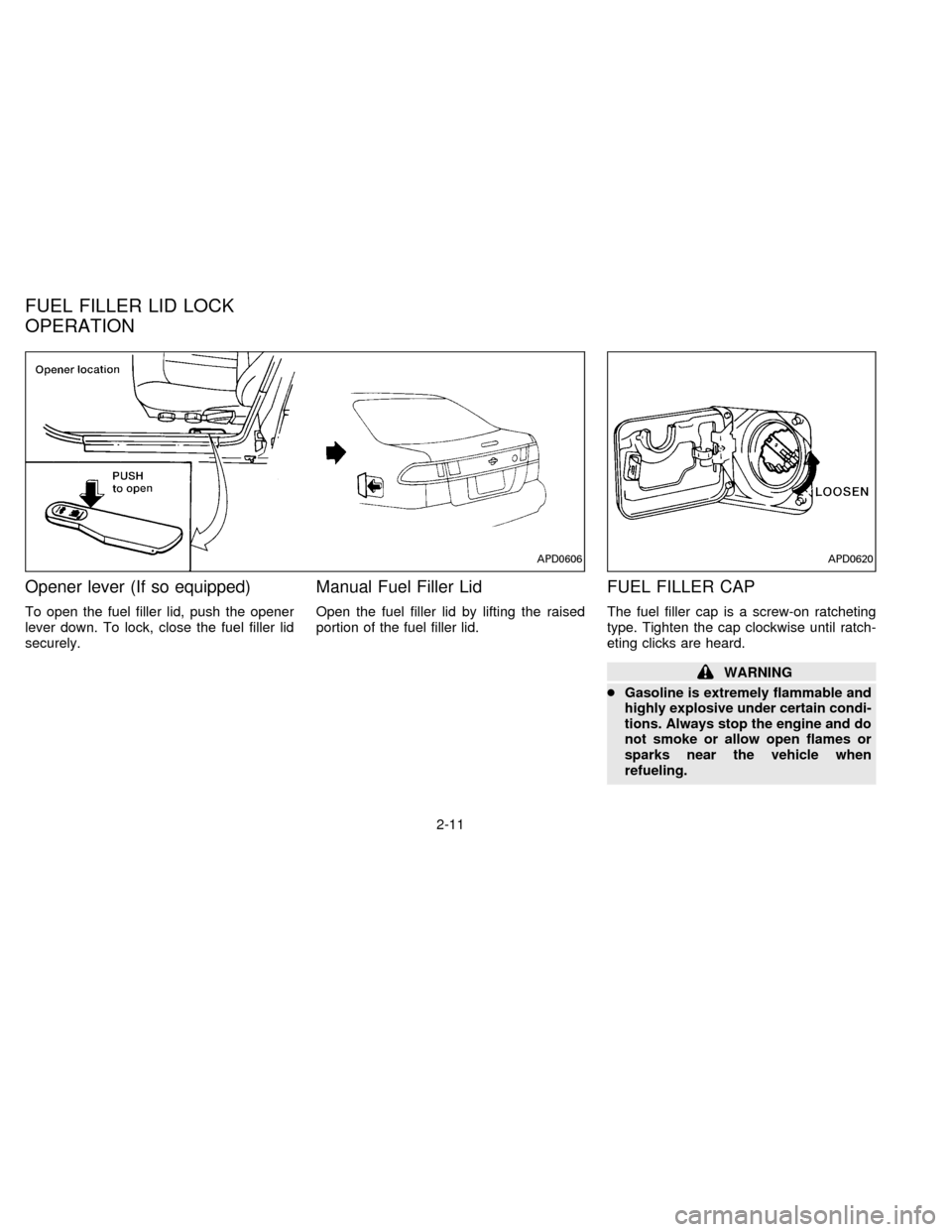

Opener lever (If so equipped)

To open the fuel filler lid, push the opener

lever down. To lock, close the fuel filler lid

securely.

Manual Fuel Filler Lid

Open the fuel filler lid by lifting the raised

portion of the fuel filler lid.

FUEL FILLER CAP

The fuel filler cap is a screw-on ratcheting

type. Tighten the cap clockwise until ratch-

eting clicks are heard.

WARNING

cGasoline is extremely flammable and

highly explosive under certain condi-

tions. Always stop the engine and do

not smoke or allow open flames or

sparks near the vehicle when

refueling.

APD0606APD0620

FUEL FILLER LID LOCK

OPERATION

2-11

ZX

Page 106 of 191

tire placard affixed to the driver side

center pillar.

cRetighten the wheel nuts when the

vehicle has been run for 600 miles

(1,000 km).

5. Securely store the spare tire and jacking

equipment in the vehicle.

WARNING

cAlways make sure that the spare tire

and jacking equipment are properly

secured after use. The jack rod may

be used to securely tighten the hold-

down bolts. Such items can become

dangerous projectiles in an accident

or sudden stop.

cThe T-type spare tire and small size

spare tire are designed for emer-

gency use. See specific instructions

under the heading ``Wheels and

tires'' in the ``Do-it-yourself opera-

tions'' section.To start your engine with a booster battery,

the instructions and precautions below must

be followed.

CAUTION

cIf done incorrectly, jump starting can

be hazardous.

cExplosive hydrogen gas is always

present in the vicinity of the battery.

Keep all sparks and flames away

from the battery.

c

Do not allow battery fluid to come into

contact with eyes, skin, cloth or painted

surfaces. Battery fluid is a corrosive

sulfuric acid solution which can cause

severe burns. If the fluid should come

into contact with anything, immediately

flush the contacted area with water.

cA battery rated at above 12 volts

should not be used for a booster.

cWhenever working on or near a bat-

tery, always wear suitable eye protec-

tors (e.g., goggles or industrial safety

spectacles) and remove rings, metal

bands, or any other metal jewelry.

c

Keep battery out of the reach of chil-

dren.

Always follow the instructions below.

Failure to do so could result in damage

to the charging system and cause per-

sonal injury.

1.

If the booster battery is in another vehicle,

position the two vehicles to bring their

batteries into close proximity to each other.

Do not allow the two vehicles to touch.

2. Apply the parking brake. Move the shift

lever to Neutral (On automatic transmis-

sion models, move the lever to P). Switch

off all unnecessary electrical systems

(lights, heater, air conditioner, etc.).

3. Remove vent caps on the battery (if so

equipped). Cover the battery with an old

cloth to reduce explosion hazard.

4. Connect jumper cables in the sequence

as illustrated.

CAUTION

cAlways connect positive (+) to posi-

tive (+) and negative (þ) to body

ground (e.g., strut mounting bolt, etc.

Ðnot to the battery).

JUMP STARTING

5-7

ZX

Page 118 of 191

7 Do-it-yourself operations

Maintenance precautions ..................................... 7-2

Engine compartment check locations .................. 7-3

Engine cooling system ......................................... 7-5

Engine oil ............................................................ 7-8

Automatic transmission fluid .............................. 7-11

Power steering fluid............................................ 7-13

Brake fluid .......................................................... 7-13

Window washer fluid .......................................... 7-14

Battery ................................................................ 7-15

Drive belts .......................................................... 7-17

Spark plug replacement ..................................... 7-18

Air cleaner housing filter .................................... 7-19Wiper blades ...................................................... 7-20

Parking brake check........................................... 7-21

Brake pedal ........................................................ 7-21

Brake booster ..................................................... 7-22

Clutch pedal ....................................................... 7-23

Fuses .................................................................. 7-23

Light bulbs .......................................................... 7-25

Headlight aiming adjustment .............................. 7-26

Bulb replacement ............................................... 7-26

Wheels and tires ................................................ 7-32

ZX

Page 119 of 191

When performing any inspection or mainte-

nance work on your vehicle, always take

care to prevent serious accidental injury to

yourself or damage to the vehicle. The

following are general precautions which

should be closely observed.

cPark the vehicle on a level surface,

apply the parking brake securely and

block the wheels to prevent the ve-

hicle from moving. Move the gearshift

control lever to Neutral (N).

cBe sure the ignition key is OFF when

performing any parts replacement or

repairs.

cDo not work under the hood while the

engine is hot. Turn the engine off and

wait until it cools down.

cBe sure to turn the ignition key to the

OFF or LOCK position.

When the ignition key is in the ON or

ACC position, the cooling fan may

start to operate suddenly even when

the engine is not running.

cIf you must work with the engine run-

ning, keep your hands, clothing, hair

and tools away from moving fans,

belts and any other moving parts.cIt is advisable to remove ties and any

jewelry, such as rings, watches, etc.,

before working on your vehicle.

cIf you must run the engine in an en-

closed space such as a garage, be

sure there is proper ventilation for

exhaust gases.

cNever get under the vehicle while it is

supported only by a jack. If it is nec-

essary to work under the vehicle, sup-

port it with safety stands.

cKeep smoking materials, flame and

sparks away from fuel and battery.

cNever connect or disconnect either

the battery or any transistorized com-

ponent connector while the ignition is

on.

cOn gasoline engine models with the

Multiport Fuel Injection (MFI) system,

the fuel filter or fuel lines should be

serviced by a NISSAN dealer because

the fuel lines are under high pressure

even when the engine is off.

cFailure to follow these or other com-

mon sense guidelines may lead to

serious injury or vehicle damage.cImproperly disposed motor oil and/or

other vehicle fluids can hurt the envi-

ronment. Always conform to local

regulations for disposal of vehicle

fluid. Avoid contact with used motor

oil.

This ``Do-it-yourself operations'' section

gives instructions regarding only those

items which are relatively easy for an owner

to perform.

You should be aware that incomplete or

improper servicing may result in operating

difficulties or excessive emissions, and

could affect your warranty coverage.If in

doubt about any servicing, have it done

by your NISSAN dealer.

MAINTENANCE

PRECAUTIONS

7-2

ZX

Page 132 of 191

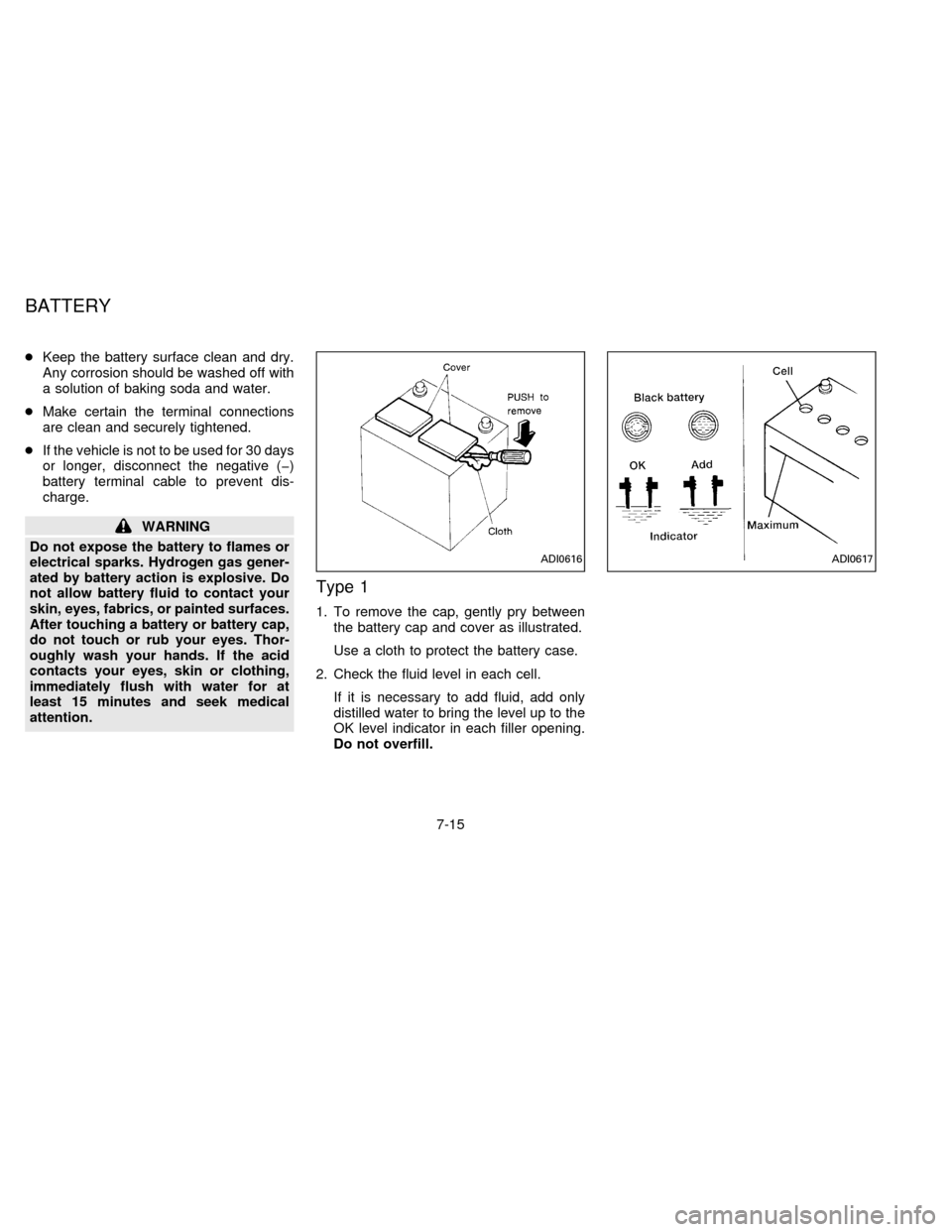

cKeep the battery surface clean and dry.

Any corrosion should be washed off with

a solution of baking soda and water.

cMake certain the terminal connections

are clean and securely tightened.

cIf the vehicle is not to be used for 30 days

or longer, disconnect the negative (þ)

battery terminal cable to prevent dis-

charge.

WARNING

Do not expose the battery to flames or

electrical sparks. Hydrogen gas gener-

ated by battery action is explosive. Do

not allow battery fluid to contact your

skin, eyes, fabrics, or painted surfaces.

After touching a battery or battery cap,

do not touch or rub your eyes. Thor-

oughly wash your hands. If the acid

contacts your eyes, skin or clothing,

immediately flush with water for at

least 15 minutes and seek medical

attention.

Type 1

1. To remove the cap, gently pry between

the battery cap and cover as illustrated.

Use a cloth to protect the battery case.

2. Check the fluid level in each cell.

If it is necessary to add fluid, add only

distilled water to bring the level up to the

OK level indicator in each filler opening.

Do not overfill.

ADI0616ADI0617

BATTERY

7-15

ZX

Page 135 of 191

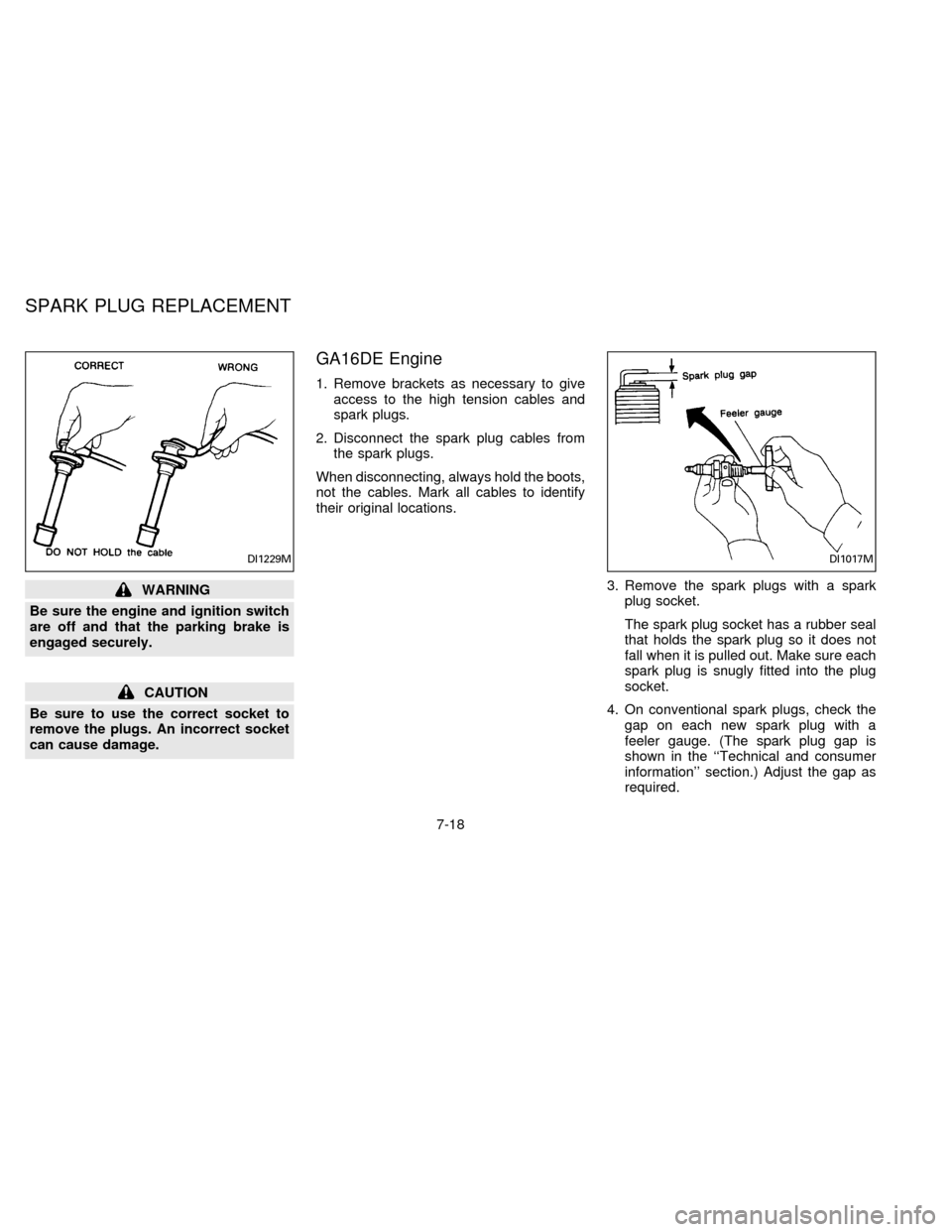

WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to

remove the plugs. An incorrect socket

can cause damage.

GA16DE Engine

1. Remove brackets as necessary to give

access to the high tension cables and

spark plugs.

2. Disconnect the spark plug cables from

the spark plugs.

When disconnecting, always hold the boots,

not the cables. Mark all cables to identify

their original locations.

3. Remove the spark plugs with a spark

plug socket.

The spark plug socket has a rubber seal

that holds the spark plug so it does not

fall when it is pulled out. Make sure each

spark plug is snugly fitted into the plug

socket.

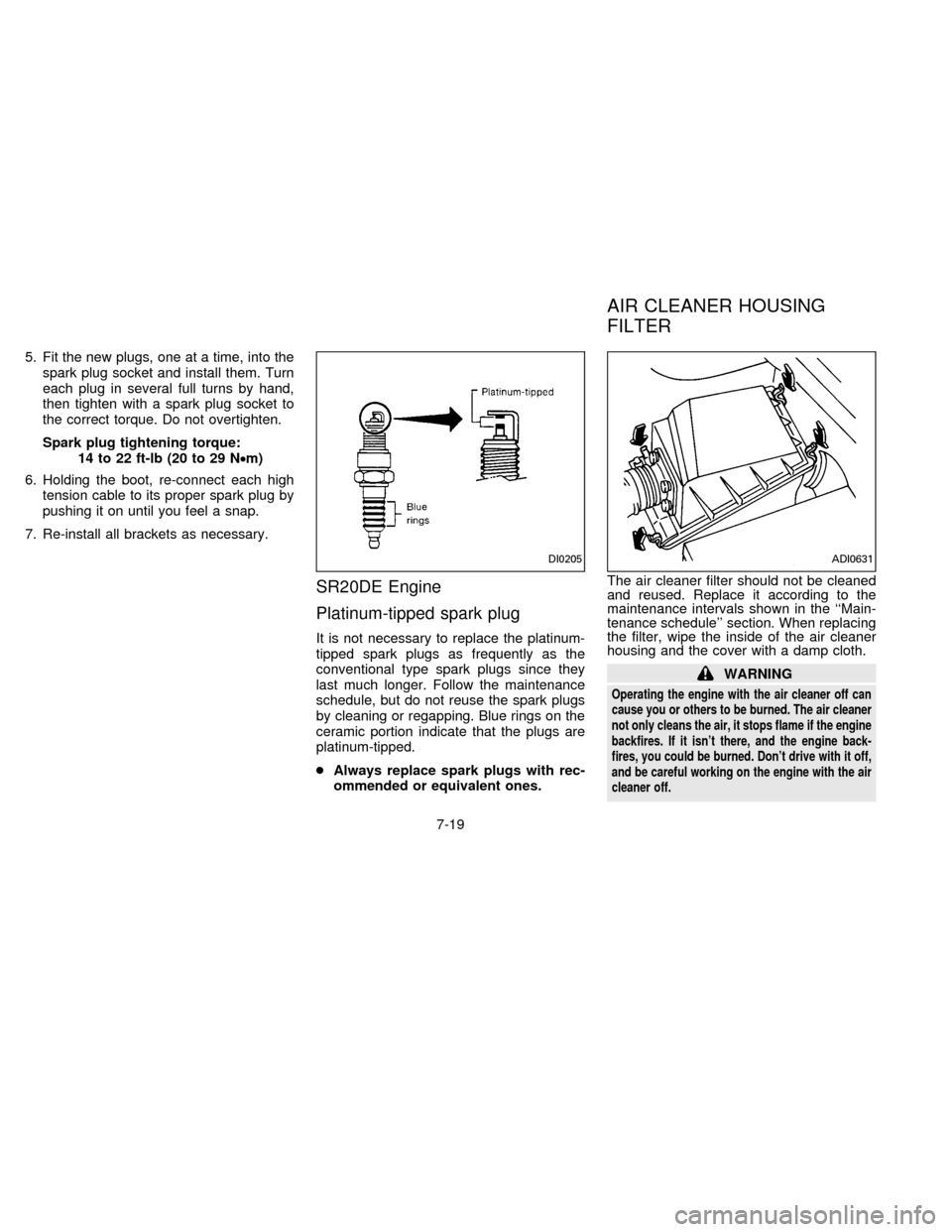

4. On conventional spark plugs, check the

gap on each new spark plug with a

feeler gauge. (The spark plug gap is

shown in the ``Technical and consumer

information'' section.) Adjust the gap as

required.

DI1229MDI1017M

SPARK PLUG REPLACEMENT

7-18

ZX

Page 136 of 191

5. Fit the new plugs, one at a time, into the

spark plug socket and install them. Turn

each plug in several full turns by hand,

then tighten with a spark plug socket to

the correct torque. Do not overtighten.

Spark plug tightening torque:

14 to 22 ft-lb (20 to 29 N²m)

6. Holding the boot, re-connect each high

tension cable to its proper spark plug by

pushing it on until you feel a snap.

7. Re-install all brackets as necessary.

SR20DE Engine

Platinum-tipped spark plug

It is not necessary to replace the platinum-

tipped spark plugs as frequently as the

conventional type spark plugs since they

last much longer. Follow the maintenance

schedule, but do not reuse the spark plugs

by cleaning or regapping. Blue rings on the

ceramic portion indicate that the plugs are

platinum-tipped.

cAlways replace spark plugs with rec-

ommended or equivalent ones.The air cleaner filter should not be cleaned

and reused. Replace it according to the

maintenance intervals shown in the ``Main-

tenance schedule'' section. When replacing

the filter, wipe the inside of the air cleaner

housing and the cover with a damp cloth.

WARNING

Operating the engine with the air cleaner off can

cause you or others to be burned. The air cleaner

not only cleans the air, it stops flame if the engine

backfires. If it isn't there, and the engine back-

fires, you could be burned. Don't drive with it off,

and be careful working on the engine with the air

cleaner off.

DI0205ADI0631

AIR CLEANER HOUSING

FILTER

7-19

ZX

Page 159 of 191

![NISSAN SENTRA 1996 B14 / 4.G Owners Manual SCHEDULE 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers NISSAN SENTRA 1996 B14 / 4.G Owners Manual SCHEDULE 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers](/img/5/599/w960_599-158.png)

SCHEDULE 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months,

whichever comes first.Miles ý 1,000 3.75 7.5 11.25 15 18.75 22.5 26.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25 60

(km ý 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48

Emission control system maintenance

Drive belts See NOTE (1).I*

Air cleaner filter See NOTE (2). [R] [R]

Idle rpm (GA16DE engine)I* I*

Vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (3)*.

Engine coolant See NOTE (4)*.R*

Engine oilRRRRRRRRRRRRRRRR

Engine oil filter (Use Nissan PREMIUM type or equivalent)RRRRRRRRRRRRRRRR

Spark plugs (GA16DE engine)[R] [R]

(SR20DE engine) (PLATINUM-TIPPED type) See NOTE (5)*.[R]

Intake & exhaust valve clearance (GA16DE engine) See NOTE (6)*.

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) If vehicle is operated under extremely adverse weather conditions or in areas where ambient temperatures are either extremely low or extremely

high, the filters might become clogged. In such an event, replace them immediately.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) Original equipment platinum-tipped plugs should be replaced at 60,000 miles (96,000 km). Conventional spark plugs can be used but should be

replaced at 30,000 miles (48,000 km) intervals. (See ``Technical and consumer Information'' section for details.)

(6) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with ``*'' are recommended by NISSAN for reliable vehicle operation. The owner need not perform such

maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-6

ZX

Page 161 of 191

![NISSAN SENTRA 1996 B14 / 4.G Owners Manual SCHEDULE 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers NISSAN SENTRA 1996 B14 / 4.G Owners Manual SCHEDULE 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers](/img/5/599/w960_599-160.png)

SCHEDULE 2

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,

kilometers or months, whichever comes first.Miles ý 1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km ý 1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Emission control system maintenance

Drive belts See NOTE (1).I*

Air cleaner filter[R] [R]

Idle rpm (GA16DE engine)I* I*

Vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (2)*.

Engine coolant See NOTE (3)*.R*

Engine oilRRRRRRRR

Engine oil filter (Use Nissan PREMIUM type or equivalent)RRRRRRRR

Spark plugs (GA16DE engine)[R] [R]

(SR20DE engine) (PLATINUM-TIPPED type) See NOTE (4)*.[R]

Intake & exhaust valve clearance (GA16DE engine) See NOTE (5)*.

NOTE: (1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If vehicle is operated under extremely adverse weather conditions or in areas where outside temperatures are either extremely low or extremely high, the

filters might become clogged. In such an event, replace them immediately.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) Original equipment platinum-tipped plugs should be replaced at 60,000 miles (96,000 km). Conventional spark plugs can be used but should be replaced

at 30,000 miles (48,000 km) intervals. (See ``Technical and consumer information'' section for details.)

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with ``*'' are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in

order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

8-8

ZX

Page 163 of 191

EXPLANATION OF MAINTE-

NANCE ITEMS

Additional information on the following

items with ``*'' is found in the ``Do-it-

yourself operations'' section.

Emission control system

maintenance

Drive belts*Check drive belts for wear,

fraying or cracking and also for proper ten-

sion. Replace the drive belts if found dam-

aged.

Air cleaner filterUnder normal driving con-

ditions, the air cleaner filter should be re-

placed in accordance with the maintenance

schedule. However, driving the vehicle in

dusty areas may cause more rapid clogging

of the element. Consequently, the element

may have to be replaced more frequently.

Idle rpmInspection and adjustment should

be made with a tachometer to ensure

accuracy.

Vapor linesCheck vapor lines and connec-

tions for failure or looseness. If leaks are

found, replace them.

Fuel linesCheck the fuel hoses, pipingand connections for leaks, looseness or

deterioration. Replace any parts if they are

damaged.

Fuel filterIf the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are ei-

ther extremely low or extremely high, the

filter might become clogged. In such an

event, replace the filter immediately.

Engine coolant*Drain and flush the cool-

ing system.

Engine oil & oil filter*Under normal driving

conditions, the engine oil and oil filter should

be replaced in accordance with the mainte-

nance schedule. However, under severe

driving conditions, they may have to be

replaced more frequently.

Spark plugs*Replace with new plugs hav-

ing the correct heat range.

Intake & exhaust valve clearanceCheck

and adjust the valve clearance.

Chassis and body maintenance

Brake lines & cablesCheck the brake lines

and hoses (including brake booster vacuum

hoses, connections & check valve) and

parking brake cables for proper attachment,leaks, cracks, chafing, abrasion, deteriora-

tion, etc.

Brake pads, discs, drums & linings

Check these and the other neighboring

brake components for wear, deterioration

and leaks. Under severe driving conditions,

they may have to be inspected more fre-

quently.

Manual & automatic transmission gear

oil*Check the oil level and visually inspect

for signs of leakage.

Under severe driving conditions, the oil

should be replaced at the specified interval.

Steering gear & linkage, axle & suspen-

sion parts, and drive shaft bootsCheck

for damage, looseness and leakage of oil or

grease. Under severe driving conditions,

more frequent inspection should be per-

formed.

Steering linkage ball joints & front sus-

pension ball jointsCheck the ball joints for

damage, looseness and grease leakage.

Exhaust systemVisually check the ex-

haust pipes, muffler, and hangers for proper

attachment, leaks, cracks, chafing, abra-

sion, deterioration, etc. Under severe

8-10

ZX