api NISSAN SENTRA 1997 B14 / 4.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1997, Model line: SENTRA, Model: NISSAN SENTRA 1997 B14 / 4.GPages: 194, PDF Size: 1.62 MB

Page 16 of 194

Key reminder chime

A chime sounds if the driver side door is

opened while the key is left in the ignition

switch. Remove the key and take it with you

when leaving the vehicle.

Light reminder chime

A chime sounds when the driver side door is

opened if the headlights or parking lights

are on (ignition switch is turned off).

Turn the headlight control switch off before

you leave the vehicle.

Brake pad wear warning

The disc brake pads have audible wear

warnings. When a brake pad requires re-

placement, it makes a high pitched scraping

sound when the vehicle is in motion,

whether or not the brake pedal is de-

pressed. Have the brakes checked as soon

as possible if the warning sound is heard.

orMalfunction indi-

cator light (MIL)

If the malfunction indicator light comes on

steady or blinks while the engine is running,it may indicate a potential emission control

problem.

The malfunction indicator light will come on

in one of two ways:

1. Malfunction indicator light on steady - An

emission control system malfunction has

been detected. Have the vehicle in-

spected by an authorized NISSAN

dealer. You do not need to have your

vehicle towed to the dealer.

2. Malfunction indicator light blinking - An

engine misfire has been detected which

may damage the emission control sys-

tem. To reduce or avoid emission control

system damage:

cdo not drive at speeds above 45 MPH

(72 km/h).

c

avoid hard acceleration or deceleration.

cavoid steep uphill grades.

cif possible, reduce the amount of cargo

being hauled or towed.

The malfunction indicator light may stop

blinking and come on steady. Have the

vehicle inspected by an authorized NISSAN

dealer. You do not need to have your vehicle

towed to the dealer.

CAUTION

Continued vehicle operation without

having the emission control system

checked and repaired as necessary

could lead to poor driveability, reduced

fuel economy, and possible damage to

the emission control system, which

may affect your warranty coverage.

Some conditions may cause the malfunc-

tion indicator light to come on steady or

blink. Examples are as follows:

cvehicle ran out of fuel, which caused the

engine to misfire.

cfuel filler cap was left off or improperly

installed, allowing fuel to evaporate into

the atmosphere.

If you suspect that you experienced one or

both of the above conditions, drive the ve-

hicle to an authorized NISSAN dealer and

have the vehicle inspected. Avoid any un-

necessary diagnosis during the service by

informing the dealer of the conditions listed

above that may have occurred.

1-8

ZX

Page 56 of 194

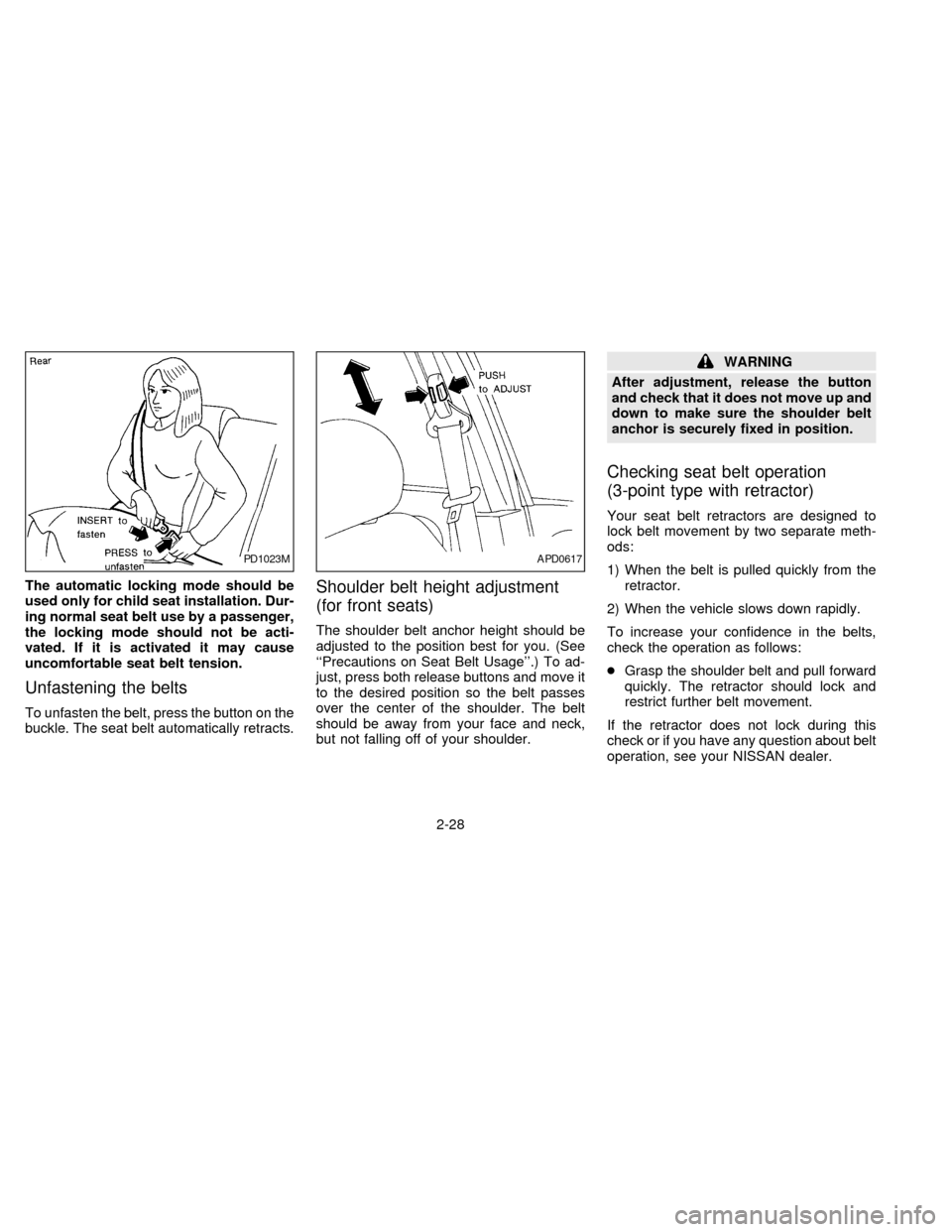

The automatic locking mode should be

used only for child seat installation. Dur-

ing normal seat belt use by a passenger,

the locking mode should not be acti-

vated. If it is activated it may cause

uncomfortable seat belt tension.

Unfastening the belts

To unfasten the belt, press the button on the

buckle. The seat belt automatically retracts.

Shoulder belt height adjustment

(for front seats)

The shoulder belt anchor height should be

adjusted to the position best for you. (See

``Precautions on Seat Belt Usage''.) To ad-

just, press both release buttons and move it

to the desired position so the belt passes

over the center of the shoulder. The belt

should be away from your face and neck,

but not falling off of your shoulder.

WARNING

After adjustment, release the button

and check that it does not move up and

down to make sure the shoulder belt

anchor is securely fixed in position.

Checking seat belt operation

(3-point type with retractor)

Your seat belt retractors are designed to

lock belt movement by two separate meth-

ods:

1) When the belt is pulled quickly from the

retractor.

2) When the vehicle slows down rapidly.

To increase your confidence in the belts,

check the operation as follows:

cGrasp the shoulder belt and pull forward

quickly. The retractor should lock and

restrict further belt movement.

If the retractor does not lock during this

check or if you have any question about belt

operation, see your NISSAN dealer.

PD1023MAPD0617

2-28

ZX

Page 92 of 194

2 (Second gear):

Use for hill climbing or engine braking on

downhill grades.

Do not shift into the 2 position at speeds

over 68 MPH (110 km/h). Do not exceed 68

MPH (110 km/h) in the 2 position.

1 (Low gear):

Use this position when climbing steep hills

slowly or driving slowly through deep snow,

sand or mud, or for maximum engine brak-

ing on steep downhill grades.

Do not shift into the 1 position at speeds

over 34 MPH (55 km/h).

Do not exceed 34 MPH (55 km/h) in the 1

position.

Accelerator downshift

Ð In D position Ð

For rapid passing or hill climbing, fully de-

press the accelerator pedal to the floor. This

shifts the transmission down into third gear,

second gear or first gear, depending on the

vehicle speed.

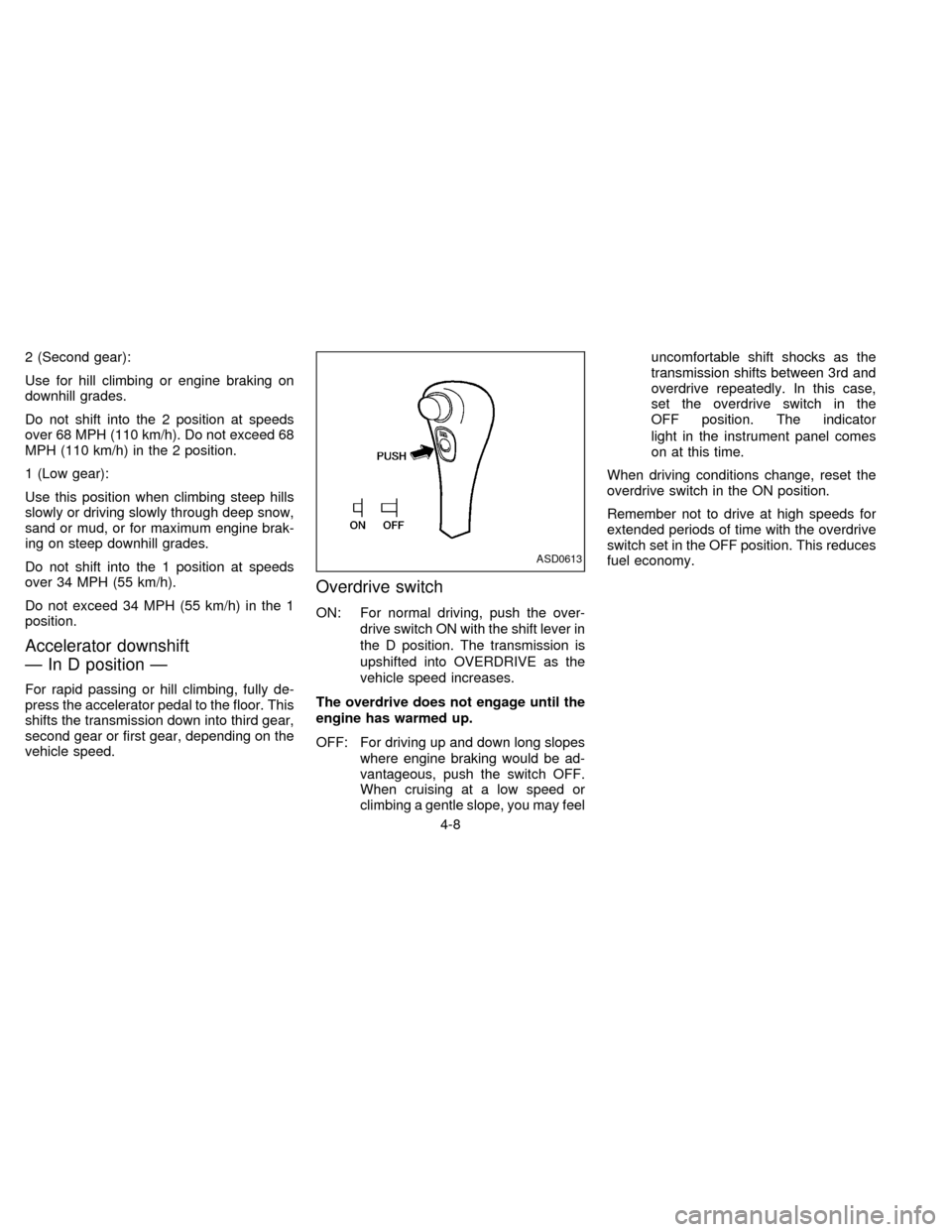

Overdrive switch

ON: For normal driving, push the over-

drive switch ON with the shift lever in

the D position. The transmission is

upshifted into OVERDRIVE as the

vehicle speed increases.

The overdrive does not engage until the

engine has warmed up.

OFF: For driving up and down long slopes

where engine braking would be ad-

vantageous, push the switch OFF.

When cruising at a low speed or

climbing a gentle slope, you may feeluncomfortable shift shocks as the

transmission shifts between 3rd and

overdrive repeatedly. In this case,

set the overdrive switch in the

OFF position. The indicator

light in the instrument panel comes

on at this time.

When driving conditions change, reset the

overdrive switch in the ON position.

Remember not to drive at high speeds for

extended periods of time with the overdrive

switch set in the OFF position. This reduces

fuel economy.

ASD0613

4-8

ZX

Page 101 of 194

The brake system has two separate hy-

draulic circuits. If one circuit develops a

problem, you will still have braking at

two wheels.

Vacuum assisted brakes

The brake booster aids braking by using

engine vacuum. If the engine stops, you can

stop the vehicle by depressing the brake

pedal. However, greater foot pressure on

the brake pedal will be required to stop the

vehicle and the stopping distance will be

longer.

Wet brakes

When the vehicle is washed or driven

through water, the brakes may get wet. As a

result, your braking distance will be longer

and the vehicle may pull to one side during

braking.

To dry brakes, drive the vehicle at a safe

speed while lightly pressing the brake pedal

to heat-up the brakes. Do this until the

brakes return to normal. Avoid driving the

vehicle at high speeds until the brakes

function correctly.

Using the brakes

Avoid resting your foot on the brake pedalwhile driving. This overheats the brakes,

increases wear on the brake linings and

pads, and reduces gas mileage.

To help save the brakes and to prevent the

brakes from overheating, reduce speed and

downshift to a lower gear before going down

a slope or long grade. Overheated brakes

may reduce braking performance and could

result in loss of vehicle control.

WARNING

While driving on a slippery surface, be

careful when braking, accelerating or

downshifting. Abrupt braking or accel-

erating could cause the wheels to skid

and result in an accident.The anti-lock brake system controls the

brakes at each wheel so the wheels do not

lock when braking abruptly or when braking

on slippery surfaces. The system detects

the rotation speed at each wheel and varies

the brake fluid pressure to prevent each

wheel from locking and sliding. By prevent-

ing wheel lockup, the system helps the

driver maintain steering control and helps to

minimize swerving and spinning on slippery

surfaces.

Using the System

Depress the brake pedal and hold it down.

WARNING

Do not pump the brake pedal. Doing so

may result in increased stopping dis-

tances.

Normal operation

The anti-lock brake system does not oper-

ate at speeds below 3 to 6 MPH (5 to 10

km/h) to completely stop the vehicle. (The

speeds vary according to road conditions.)

When the anti-lock system senses that one

or more wheels are close to locking up, the

actuator (under the hood) rapidly applies

BRAKE SYSTEM ANTI-LOCK BRAKE SYSTEM

(ABS) (if so equipped)

4-17

ZX

Page 114 of 194

If your vehicle is overheating (indicated by

an extremely high temperature gauge read-

ing), or if you feel a lack of engine power,

detect abnormal noise, etc., take the follow-

ing steps:

WARNING

cDo not continue to drive if your ve-

hicle overheats. Doing so could

cause a vehicle fire.

cTo avoid the danger of being

scalded, never remove the radiator

cap while the engine is still hot.

When the radiator cap is removed,

pressurized hot water will spurt out,

possibly causing serious injury.

cDo not open the hood if steam is

coming out.

1. Move the vehicle safely off the road,

apply the parking brake and move the

gearshift lever to Neutral (automatic

transmission to P).

Do not stop the engine.

2. Turn off the air conditioner. Open all the

windows, move the heater or air condi-

tioner temperature control to maximum

hot and fan control to high speed.3. If engine overheating is caused by climb-

ing a long hill on a hot day, run the engine

at a fast idle (approximately 1,500 rpm)

until the temperature gauge indication

returns to normal.

4. Get out of the vehicle. Look and listen for

steam or coolant escaping from the ra-

diator before opening the hood. Wait until

no steam or coolant can be seen before

proceeding.

5. Open the engine hood.

WARNING

If steam or water is coming from the

engine, stand clear to prevent getting

burned.

6. Visually check drive belts for damage or

looseness. Also check if the cooling fan

is running. The radiator hoses and radia-

tor should not leak water. If coolant is

leaking, the water pump belt is missing or

loose, or the cooling fan does not run,

stop the engine.

WARNING

Be careful not to allow your hands, hair,

jewelry or clothing to come into contact

with, or to get caught in, the running

fan, belts, or fan motor. The fan motor

can start at any time when the coolant

temperature is high.

7. After the engine cools down, check the

coolant level in the reservoir tank with the

engine running. Add coolant to the res-

ervoir tank if necessary. Have your ve-

hicle repaired at the nearest NISSAN

dealer.

IF YOUR VEHICLE

OVERHEATS

5-10

ZX

Page 127 of 194

The engine cooling system is filled at the

factory with a high-quality, year-round, anti-

freeze coolant solution. The anti-freeze so-

lution contains rust and corrosion inhibitors,

therefore additional cooling system addi-

tives are not necessary.

CAUTION

When adding or replacing coolant, be

sure to use only an ethylene glycol

anti-freeze with the proper mixture ratio

of 50% anti-freeze and 50% distilled

water. The use of other types of coolant

solutions may damage your cooling

system.

Outside tempera-

ture down toAnti-

freezeDistilled

water

ÉC ÉF

þ35 þ30 50% 50%

WARNING

cNever remove the radiator cap when

the engine is hot. Wait until the en-

gine and radiator cool down. Seriousburns could be caused by high pres-

sure fluid escaping from the

radiator.

cSee precautions in ``If your vehicle

overheats'' found in the ``In case of

emergency'' section.

cThe radiator is equipped with a pres-

sure cap. Use a genuine NISSAN cap

or its equivalent when replacement

is required.

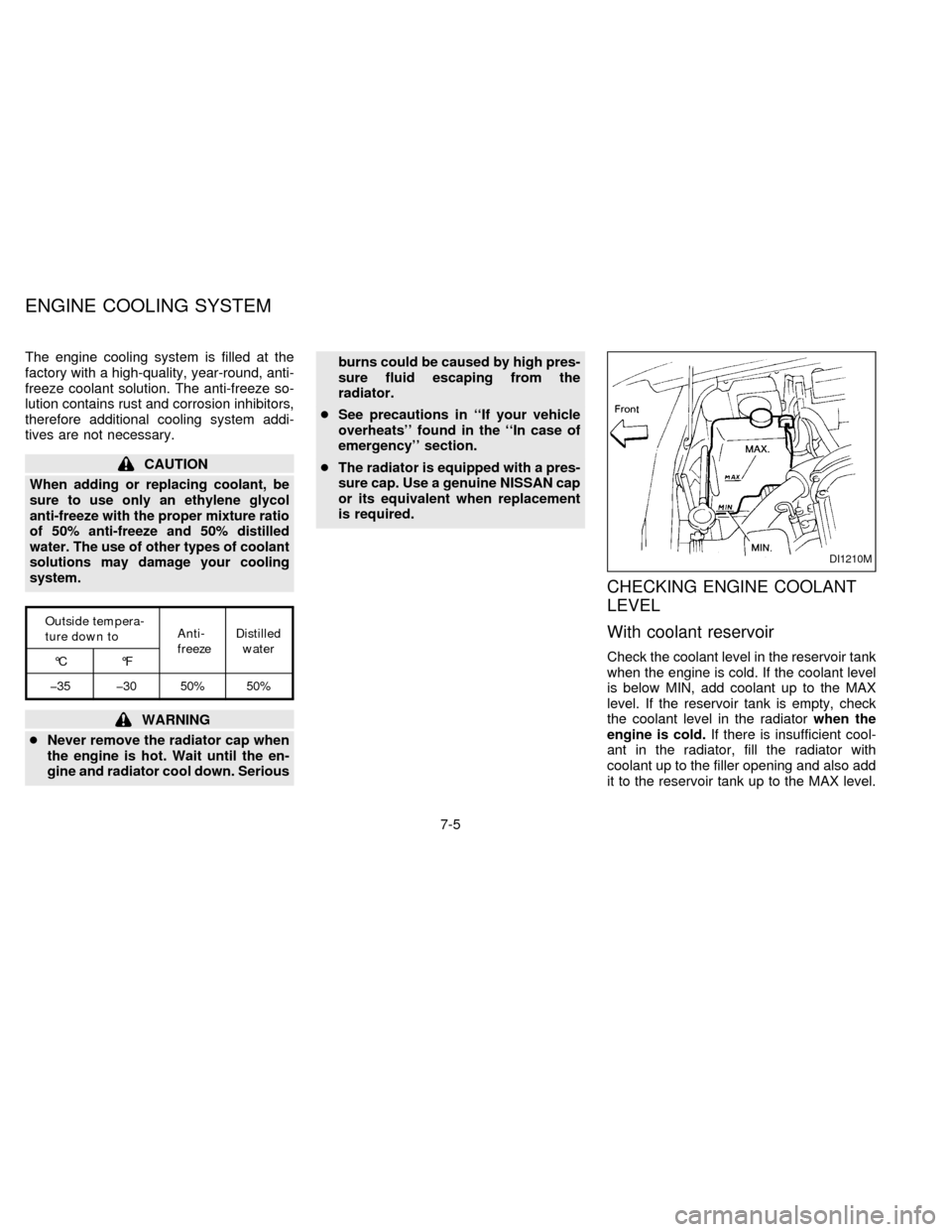

CHECKING ENGINE COOLANT

LEVEL

With coolant reservoir

Check the coolant level in the reservoir tank

when the engine is cold. If the coolant level

is below MIN, add coolant up to the MAX

level. If the reservoir tank is empty, check

the coolant level in the radiatorwhen the

engine is cold.If there is insufficient cool-

ant in the radiator, fill the radiator with

coolant up to the filler opening and also add

it to the reservoir tank up to the MAX level.

DI1210M

ENGINE COOLING SYSTEM

7-5

ZX

Page 128 of 194

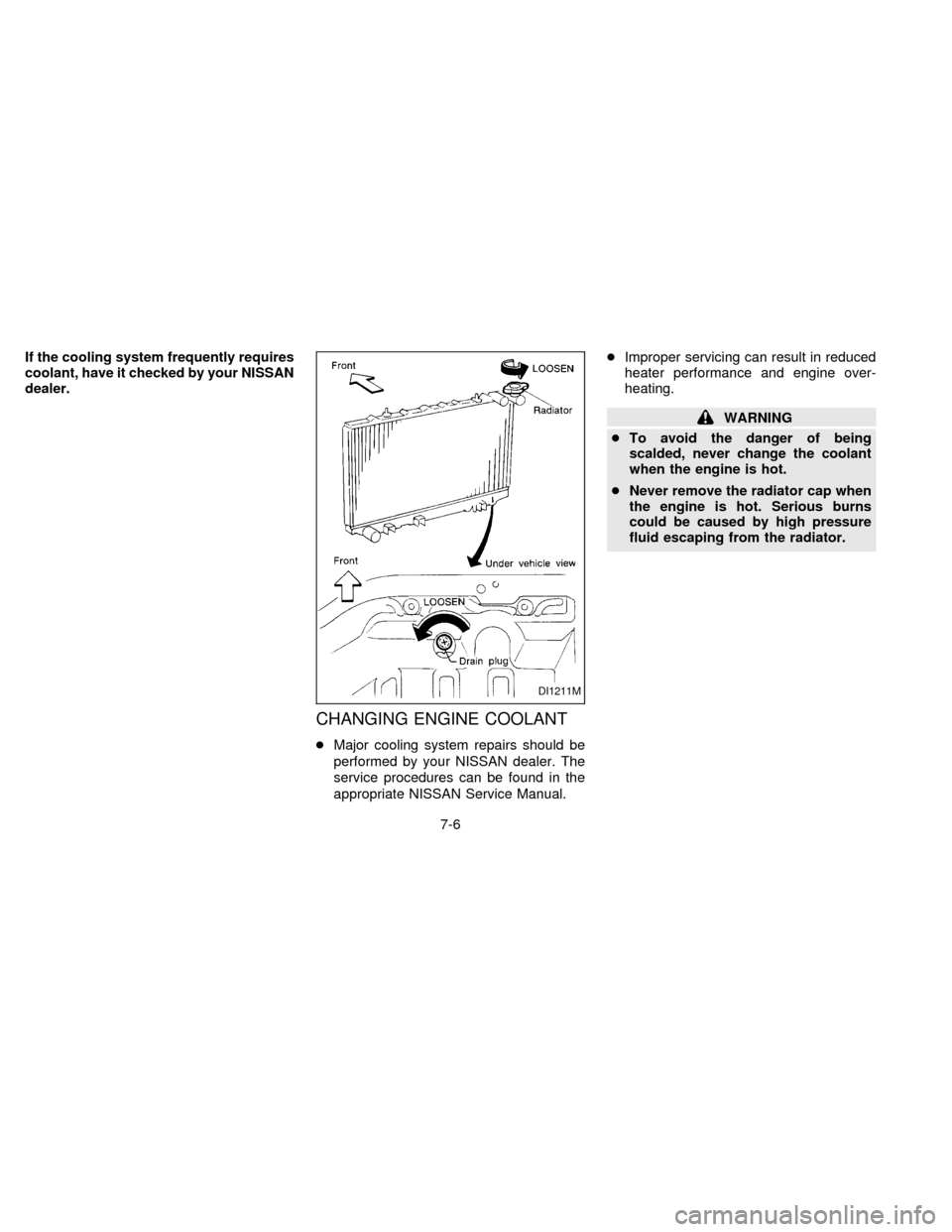

If the cooling system frequently requires

coolant, have it checked by your NISSAN

dealer.

CHANGING ENGINE COOLANT

cMajor cooling system repairs should be

performed by your NISSAN dealer. The

service procedures can be found in the

appropriate NISSAN Service Manual.cImproper servicing can result in reduced

heater performance and engine over-

heating.

WARNING

cTo avoid the danger of being

scalded, never change the coolant

when the engine is hot.

cNever remove the radiator cap when

the engine is hot. Serious burns

could be caused by high pressure

fluid escaping from the radiator.

DI1211M

7-6

ZX

Page 144 of 194

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. Apply the

parking brake several times.

WARNING

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it makes a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise fromthe rear drum brakes, have them inspected

as soon as possible by your NISSAN

dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance Schedule'' section of this

manual.Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to the

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keeping the pedal depressed for

about 30 seconds, the pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see

your NISSAN dealer.

BRAKE BOOSTER

7-22

ZX

Page 168 of 194

Additional information on the following

items with ``*'' is found in the ``Do-it-

yourself operations'' section.

Emission control system

maintenance

Drive belts* ÐCheck drive belts for wear,

fraying or cracking and also for proper tension.

Replace the drive belts if found damaged.

Air cleaner filter ÐUnder normal driving

conditions, the air cleaner filter should be

replaced in accordance with the maintenance

schedule. However, driving the vehicle in

dusty areas may cause more rapid clogging

of the element. Consequently, the element

may have to be replaced more frequently.

Vapor lines ÐCheck vapor lines and con-

nections for failure or looseness. If leaks are

found, replace them.

Fuel lines ÐCheck the fuel hoses, piping

and connections for leaks, looseness or

deterioration. Replace any parts if they are

damaged.

Fuel filter ÐIf the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are ei-

ther extremely low or extremely high, thefilter might become clogged. In such an

event, replace the filter immediately.

Engine coolant* ÐDrain and flush the

cooling system.

Engine oil & oil filter* ÐUnder normal

driving conditions, the engine oil and oil filter

should be replaced in accordance with the

maintenance schedule. However, under se-

vere driving conditions, they may have to be

replaced more frequently.

Spark plugs* ÐReplace with new plugs

having the correct heat range.

Intake & exhaust valve clearance Ð

Check and adjust the valve clearance.

Chassis and body maintenance

Brake lines & cables ÐCheck the brake

lines and hoses (including brake booster

vacuum hoses, connections & check valve)

and parking brake cables for proper attach-

ment, leaks, cracks, chafing, abrasion, de-

terioration, etc.

Brake pads, discs, drums & linings Ð

Check these and the other neighboring brake

components for wear, deterioration and

leaks. Under severe driving conditions, they

may have to be inspected more frequently.

Manual & automatic transmission fluid*

ÐCheck the fluid level and visually inspect

for signs of leakage.

Under severe driving conditions, the fluid

should be replaced at the specified interval.

Steering gear & linkage, axle & suspen-

sion parts, and drive shaft boots Ð

Check for damage, looseness and leakage

of oil or grease. Under severe driving con-

ditions, more frequent inspection should be

performed.

Steering linkage ball joints & front sus-

pension ball joints ÐCheck the ball joints

for damage, looseness and grease leakage.

Exhaust system ÐVisually check the ex-

haust pipes, muffler, and hangers for proper

attachment, leaks, cracks, chafing, abra-

sion, deterioration, etc. Under severe

driving conditions, inspection should be per-

formed more frequently.

Supplemental air bag system (if so

equipped) ÐCheck the supplemental air

bag system components for proper attach-

ment, damage, deformities, cracks, rust,

etc. Work around and on the supplemental

air bag system should be done by an autho-

rized NISSAN dealer.

EXPLANATION OF

MAINTENANCE ITEMS

8-10

ZX

Page 170 of 194

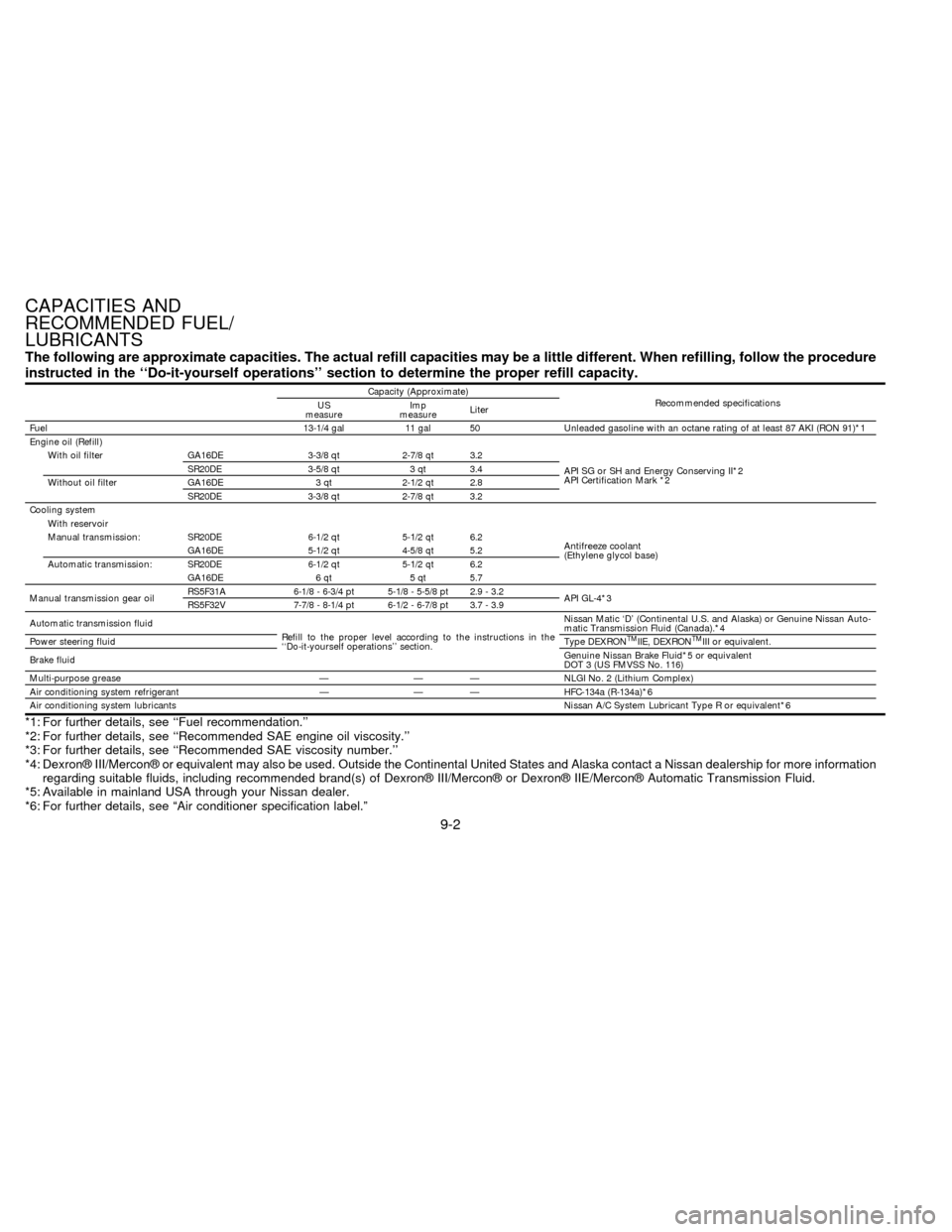

The following are approximate capacities. The actual refill capacities may be a little different. When refilling, follow the procedure

instructed in the ``Do-it-yourself operations'' section to determine the proper refill capacity.

Capacity (Approximate)

Recommended specifications

US

measureImp

measureLiter

Fuel 13-1/4 gal 11 gal 50 Unleaded gasoline with an octane rating of at least 87 AKI (RON 91)*1

Engine oil (Refill)

With oil filter GA16DE 3-3/8 qt 2-7/8 qt 3.2

API SG or SH and Energy Conserving II*2

API Certification Mark *2 SR20DE 3-5/8 qt 3 qt 3.4

Without oil filter GA16DE 3 qt 2-1/2 qt 2.8

SR20DE 3-3/8 qt 2-7/8 qt 3.2

Cooling system

With reservoir

Antifreeze coolant

(Ethylene glycol base) Manual transmission: SR20DE 6-1/2 qt 5-1/2 qt 6.2

GA16DE 5-1/2 qt 4-5/8 qt 5.2

Automatic transmission: SR20DE 6-1/2 qt 5-1/2 qt 6.2

GA16DE 6 qt 5 qt 5.7

Manual transmission gear oilRS5F31A 6-1/8 - 6-3/4 pt 5-1/8 - 5-5/8 pt 2.9 - 3.2

API GL-4*3

RS5F32V 7-7/8 - 8-1/4 pt 6-1/2 - 6-7/8 pt 3.7 - 3.9

Automatic transmission fluid

Refill to the proper level according to the instructions in the

``Do-it-yourself operations'' section.Nissan Matic `D' (Continental U.S. and Alaska) or Genuine Nissan Auto-

matic Transmission Fluid (Canada).*4

Power steering fluidType DEXRON

TMIIE, DEXRONTMIII or equivalent.

Brake fluidGenuine Nissan Brake Fluid*5 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium Complex)

Air conditioning system refrigerant Ð Ð Ð HFC-134a (R-134a)*6

Air conditioning system lubricantsNissan A/C System Lubricant Type R or equivalent*6

*1: For further details, see ``Fuel recommendation.''

*2: For further details, see ``Recommended SAE engine oil viscosity.''

*3: For further details, see ``Recommended SAE viscosity number.''

*4: Dexronž III/Merconž or equivalent may also be used. Outside the Continental United States and Alaska contact a Nissan dealership for more information

regarding suitable fluids, including recommended brand(s) of Dexronž III/Merconž or Dexronž IIE/Merconž Automatic Transmission Fluid.

*5: Available in mainland USA through your Nissan dealer.

*6: For further details, see ªAir conditioner specification label.º

CAPACITIES AND

RECOMMENDED FUEL/

LUBRICANTS

9-2

ZX