NISSAN SENTRA 1998 B14 / 4.G Owners Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: SENTRA, Model: NISSAN SENTRA 1998 B14 / 4.GPages: 216, PDF Size: 1.82 MB

Page 161 of 216

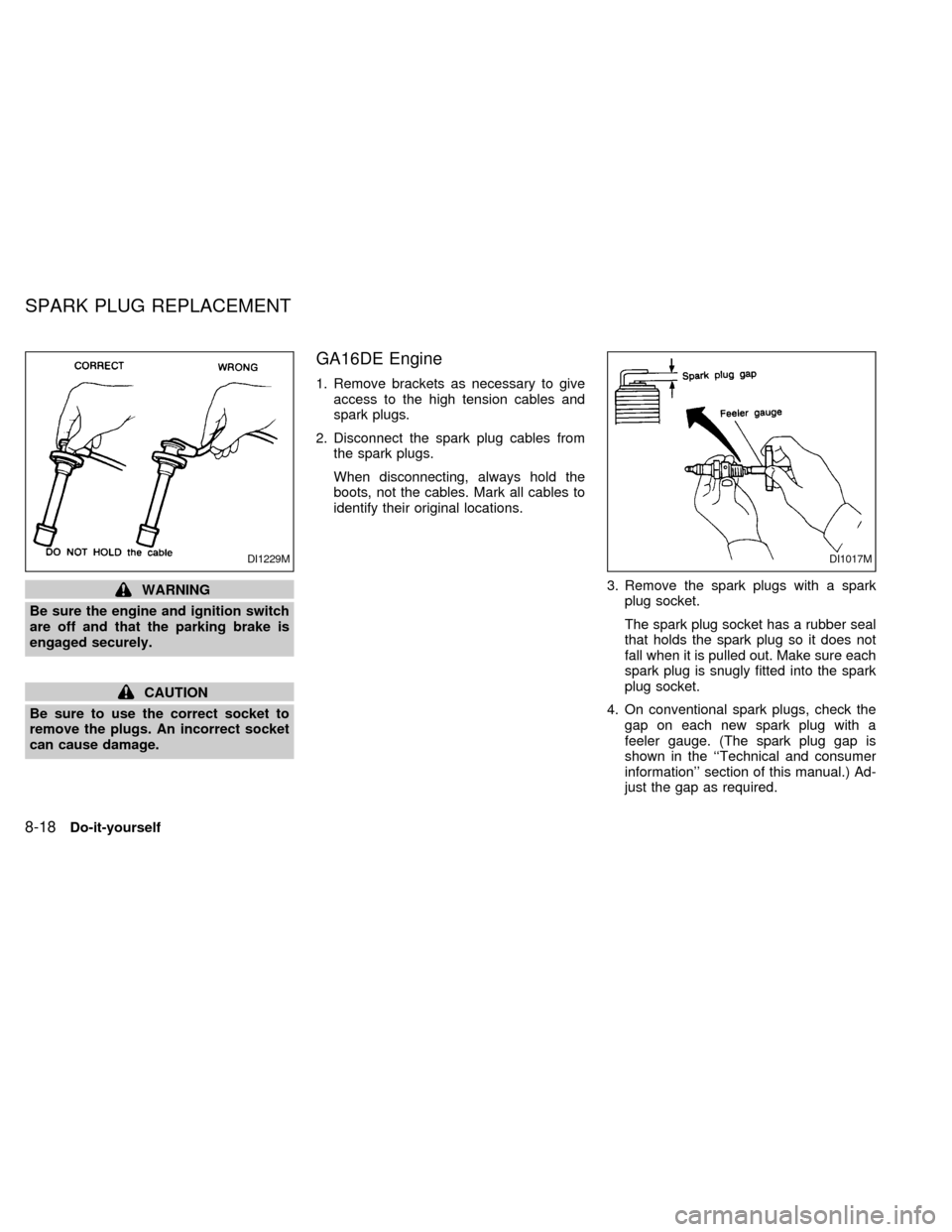

WARNING

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

CAUTION

Be sure to use the correct socket to

remove the plugs. An incorrect socket

can cause damage.

GA16DE Engine

1. Remove brackets as necessary to give

access to the high tension cables and

spark plugs.

2. Disconnect the spark plug cables from

the spark plugs.

When disconnecting, always hold the

boots, not the cables. Mark all cables to

identify their original locations.

3. Remove the spark plugs with a spark

plug socket.

The spark plug socket has a rubber seal

that holds the spark plug so it does not

fall when it is pulled out. Make sure each

spark plug is snugly fitted into the spark

plug socket.

4. On conventional spark plugs, check the

gap on each new spark plug with a

feeler gauge. (The spark plug gap is

shown in the ``Technical and consumer

information'' section of this manual.) Ad-

just the gap as required.

DI1229MDI1017M

SPARK PLUG REPLACEMENT

8-18Do-it-yourself

ZX

Page 162 of 216

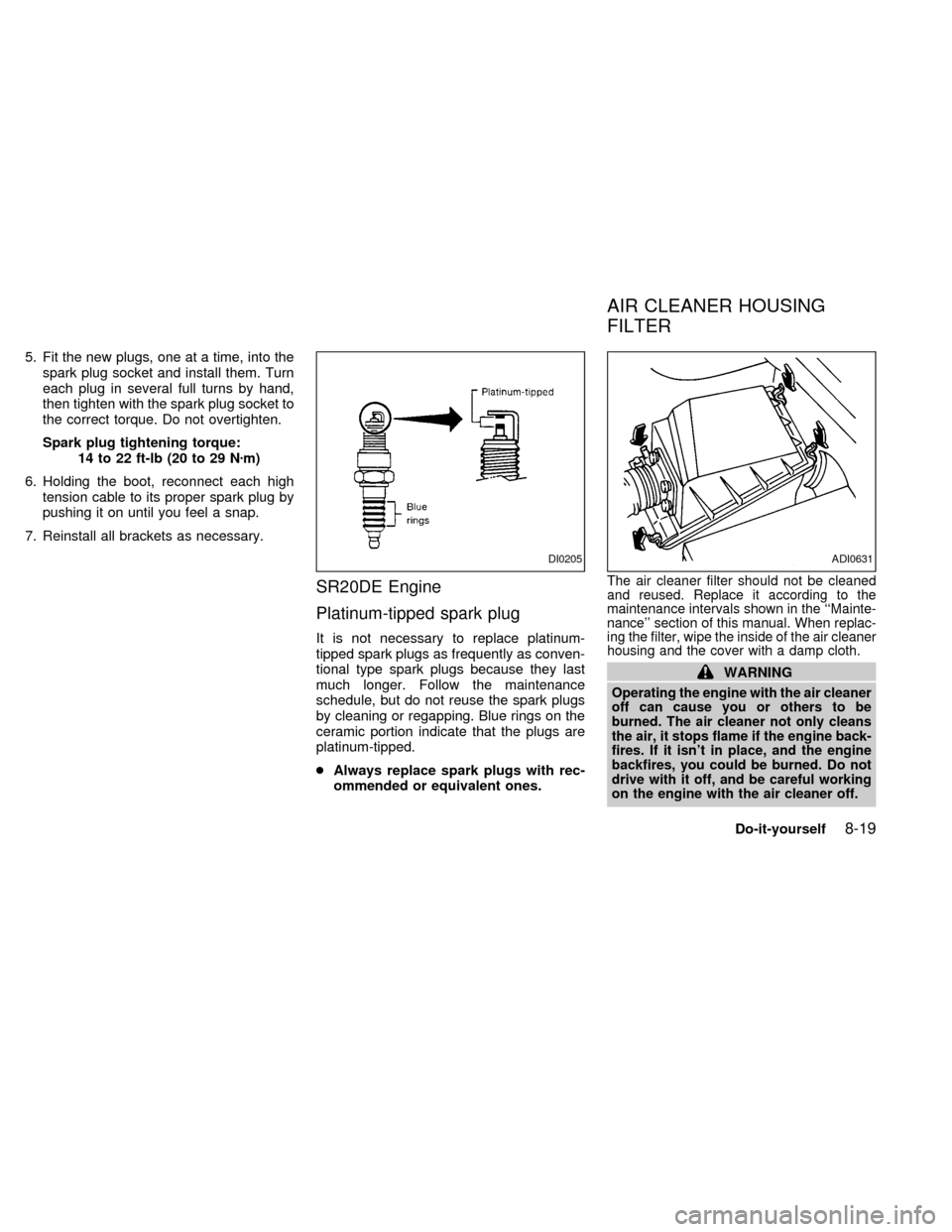

5. Fit the new plugs, one at a time, into the

spark plug socket and install them. Turn

each plug in several full turns by hand,

then tighten with the spark plug socket to

the correct torque. Do not overtighten.

Spark plug tightening torque:

14 to 22 ft-lb (20 to 29 Nzm)

6. Holding the boot, reconnect each high

tension cable to its proper spark plug by

pushing it on until you feel a snap.

7. Reinstall all brackets as necessary.

SR20DE Engine

Platinum-tipped spark plug

It is not necessary to replace platinum-

tipped spark plugs as frequently as conven-

tional type spark plugs because they last

much longer. Follow the maintenance

schedule, but do not reuse the spark plugs

by cleaning or regapping. Blue rings on the

ceramic portion indicate that the plugs are

platinum-tipped.

cAlways replace spark plugs with rec-

ommended or equivalent ones.

The air cleaner filter should not be cleaned

and reused. Replace it according to the

maintenance intervals shown in the ``Mainte-

nance'' section of this manual. When replac-

ing the filter, wipe the inside of the air cleaner

housing and the cover with a damp cloth.

WARNING

Operating the engine with the air cleaner

off can cause you or others to be

burned. The air cleaner not only cleans

the air, it stops flame if the engine back-

fires. If it isn't in place, and the engine

backfires, you could be burned. Do not

drive with it off, and be careful working

on the engine with the air cleaner off.

DI0205ADI0631

AIR CLEANER HOUSING

FILTER

Do-it-yourself8-19

ZX

Page 163 of 216

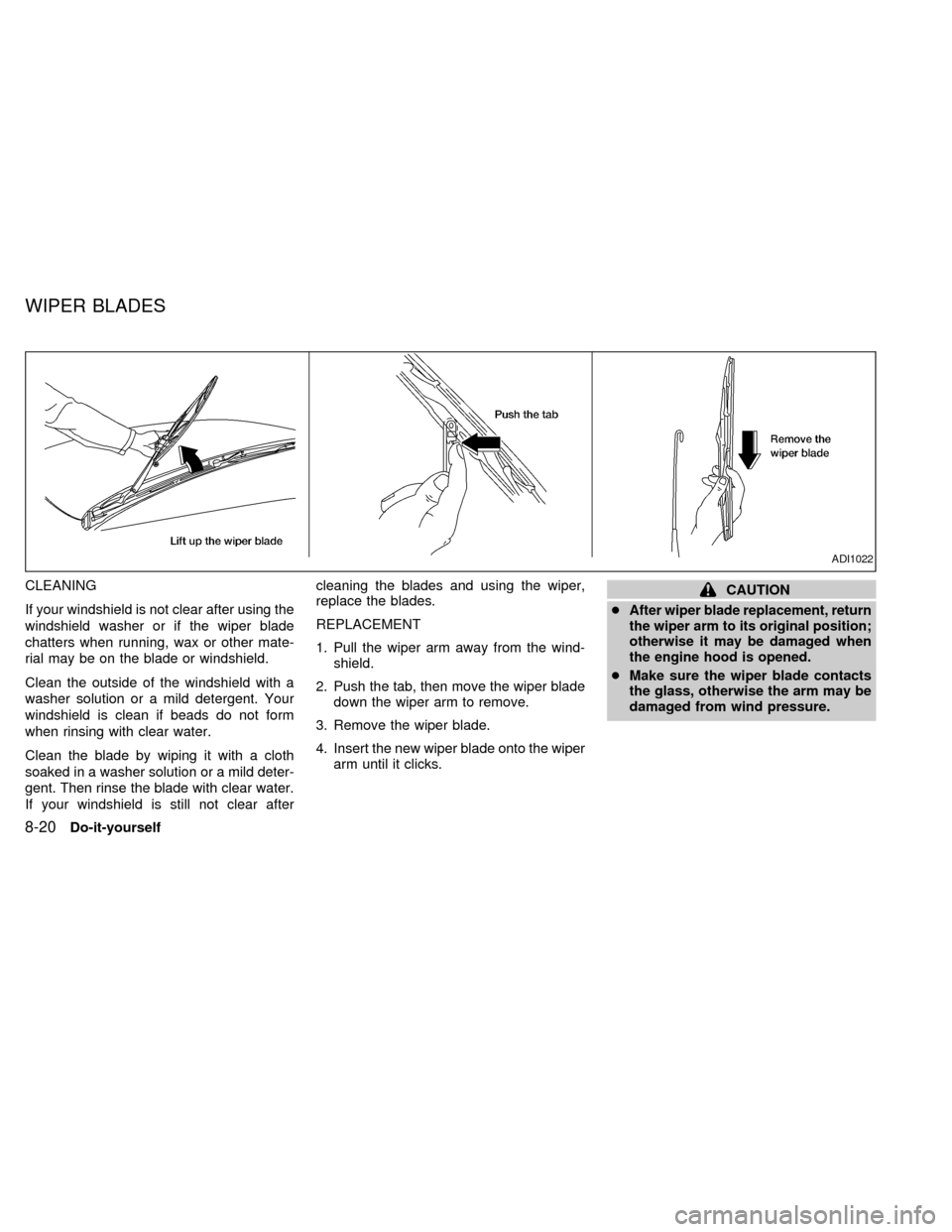

CLEANING

If your windshield is not clear after using the

windshield washer or if the wiper blade

chatters when running, wax or other mate-

rial may be on the blade or windshield.

Clean the outside of the windshield with a

washer solution or a mild detergent. Your

windshield is clean if beads do not form

when rinsing with clear water.

Clean the blade by wiping it with a cloth

soaked in a washer solution or a mild deter-

gent. Then rinse the blade with clear water.

If your windshield is still not clear aftercleaning the blades and using the wiper,

replace the blades.

REPLACEMENT

1. Pull the wiper arm away from the wind-

shield.

2. Push the tab, then move the wiper blade

down the wiper arm to remove.

3. Remove the wiper blade.

4. Insert the new wiper blade onto the wiper

arm until it clicks.CAUTION

c

After wiper blade replacement, return

the wiper arm to its original position;

otherwise it may be damaged when

the engine hood is opened.

cMake sure the wiper blade contacts

the glass, otherwise the arm may be

damaged from wind pressure.

ADI1022

WIPER BLADES

8-20Do-it-yourself

ZX

Page 164 of 216

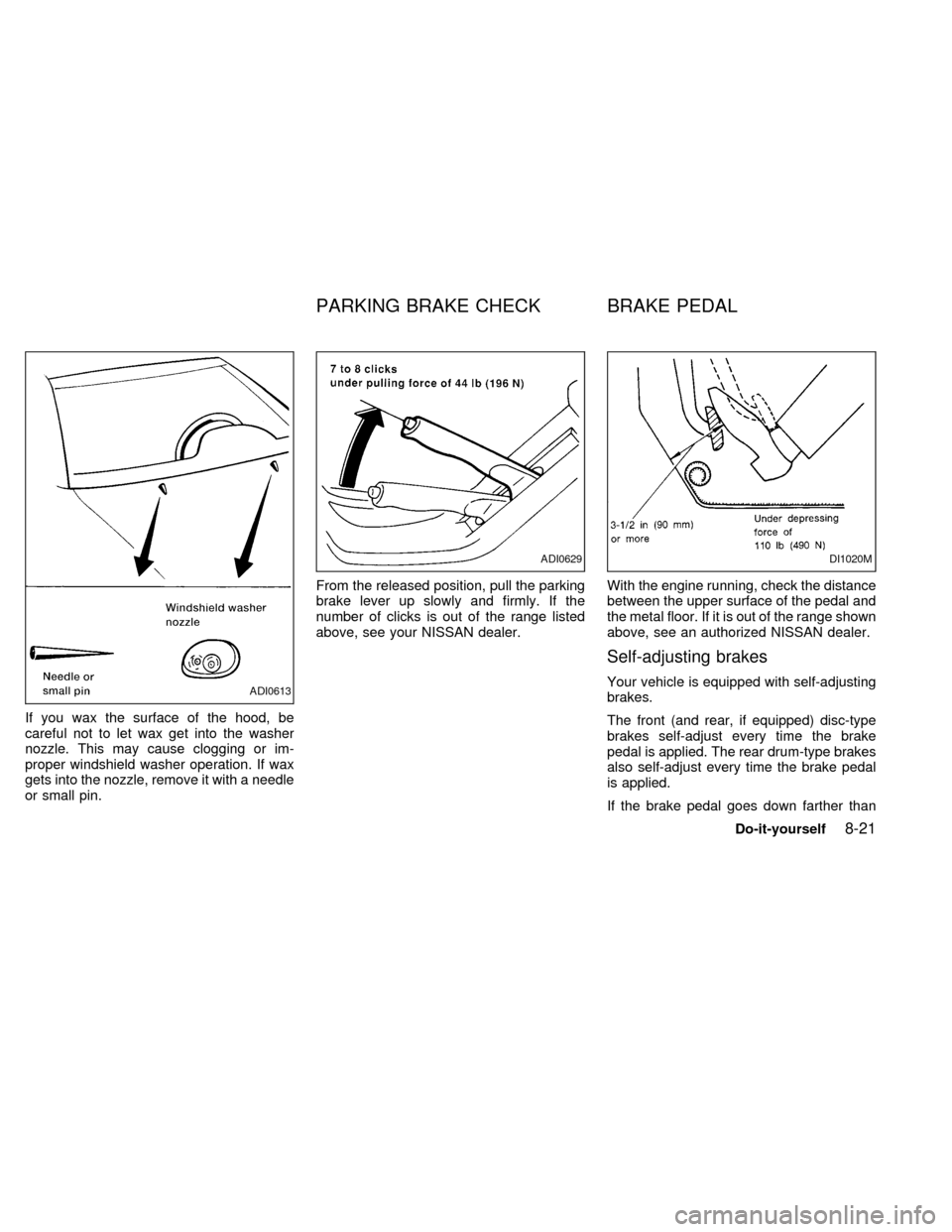

If you wax the surface of the hood, be

careful not to let wax get into the washer

nozzle. This may cause clogging or im-

proper windshield washer operation. If wax

gets into the nozzle, remove it with a needle

or small pin.From the released position, pull the parking

brake lever up slowly and firmly. If the

number of clicks is out of the range listed

above, see your NISSAN dealer.With the engine running, check the distance

between the upper surface of the pedal and

the metal floor. If it is out of the range shown

above, see an authorized NISSAN dealer.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front (and rear, if equipped) disc-type

brakes self-adjust every time the brake

pedal is applied. The rear drum-type brakes

also self-adjust every time the brake pedal

is applied.

If the brake pedal goes down farther thanADI0613

ADI0629DI1020M

PARKING BRAKE CHECK BRAKE PEDAL

Do-it-yourself8-21

ZX

Page 165 of 216

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. To adjust

apply the parking brake several times.

WARNING

See an authorized NISSAN dealer and

have it checked if the brake pedal

height does not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it makes a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise fromthe rear drum brakes, have them inspected

as soon as possible by an authorized NIS-

SAN dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance'' section of this manual.Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to the

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keeping the pedal depressed for

about 30 seconds, the pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see an

authorized NISSAN dealer.

BRAKE BOOSTER

8-22Do-it-yourself

ZX

Page 166 of 216

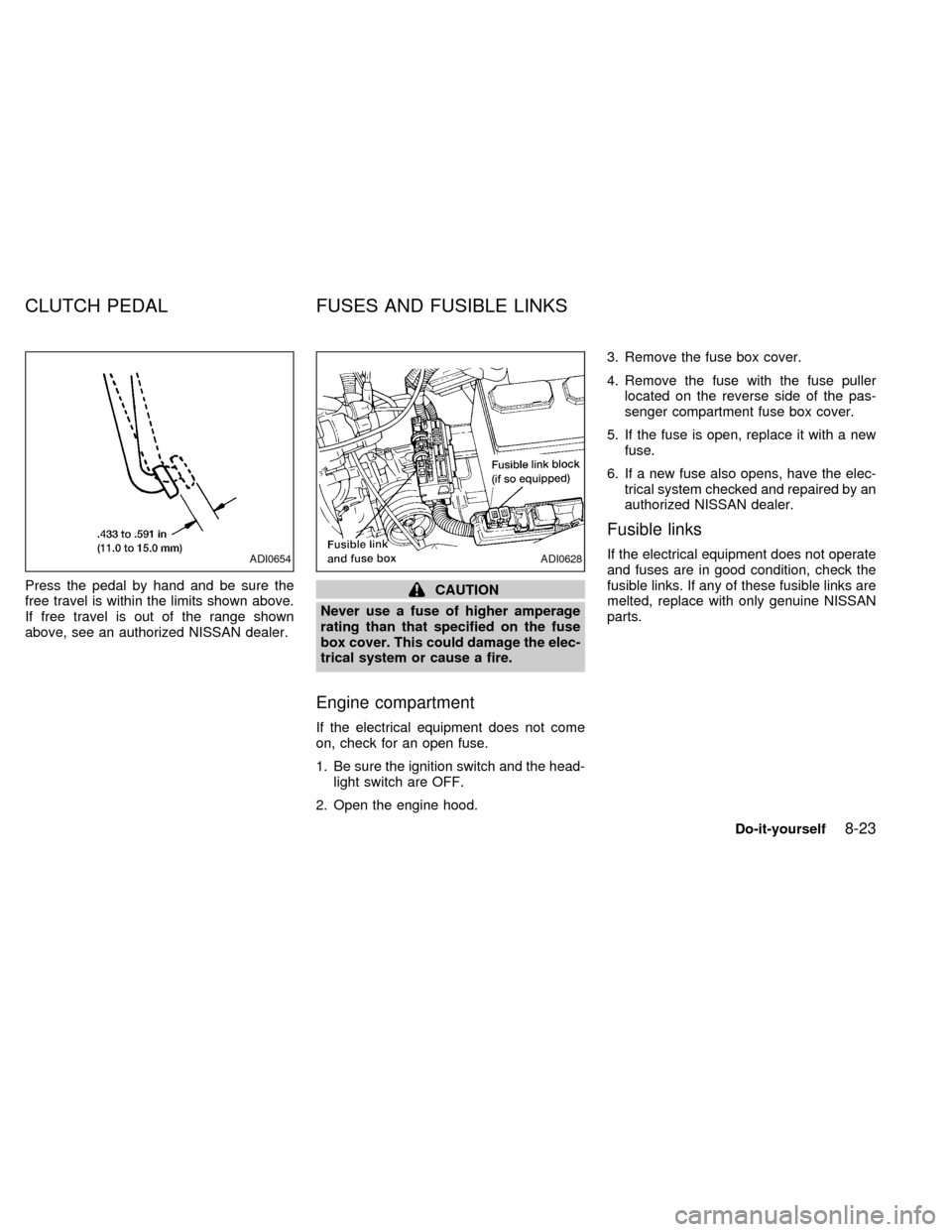

Press the pedal by hand and be sure the

free travel is within the limits shown above.

If free travel is out of the range shown

above, see an authorized NISSAN dealer.CAUTION

Never use a fuse of higher amperage

rating than that specified on the fuse

box cover. This could damage the elec-

trical system or cause a fire.

Engine compartment

If the electrical equipment does not come

on, check for an open fuse.

1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the engine hood.3. Remove the fuse box cover.

4. Remove the fuse with the fuse puller

located on the reverse side of the pas-

senger compartment fuse box cover.

5. If the fuse is open, replace it with a new

fuse.

6. If a new fuse also opens, have the elec-

trical system checked and repaired by an

authorized NISSAN dealer.

Fusible links

If the electrical equipment does not operate

and fuses are in good condition, check the

fusible links. If any of these fusible links are

melted, replace with only genuine NISSAN

parts.ADI0654ADI0628

CLUTCH PEDAL FUSES AND FUSIBLE LINKS

Do-it-yourself8-23

ZX

Page 167 of 216

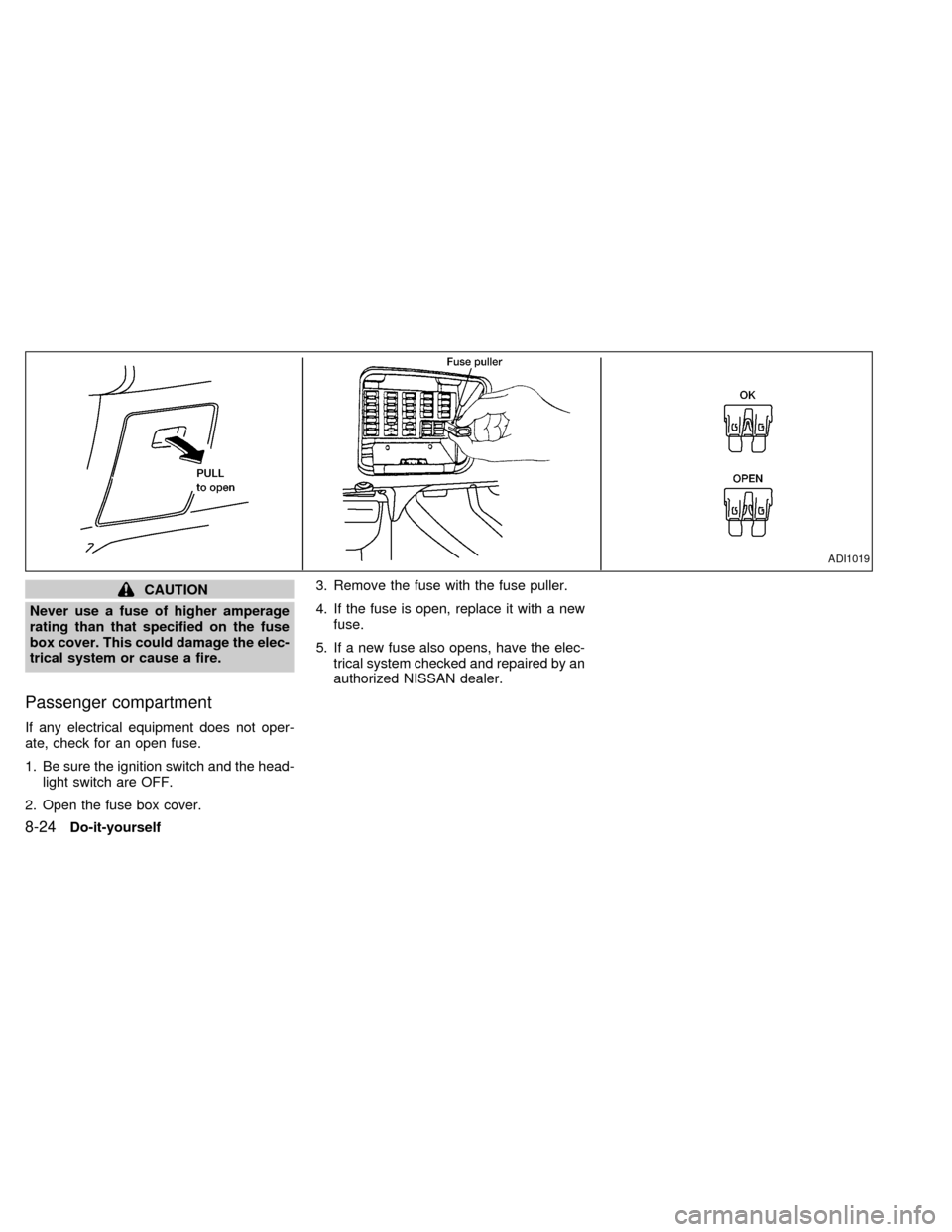

CAUTION

Never use a fuse of higher amperage

rating than that specified on the fuse

box cover. This could damage the elec-

trical system or cause a fire.

Passenger compartment

If any electrical equipment does not oper-

ate, check for an open fuse.

1. Be sure the ignition switch and the head-

light switch are OFF.

2. Open the fuse box cover.3. Remove the fuse with the fuse puller.

4. If the fuse is open, replace it with a new

fuse.

5. If a new fuse also opens, have the elec-

trical system checked and repaired by an

authorized NISSAN dealer.

ADI1019

8-24Do-it-yourself

ZX

Page 168 of 216

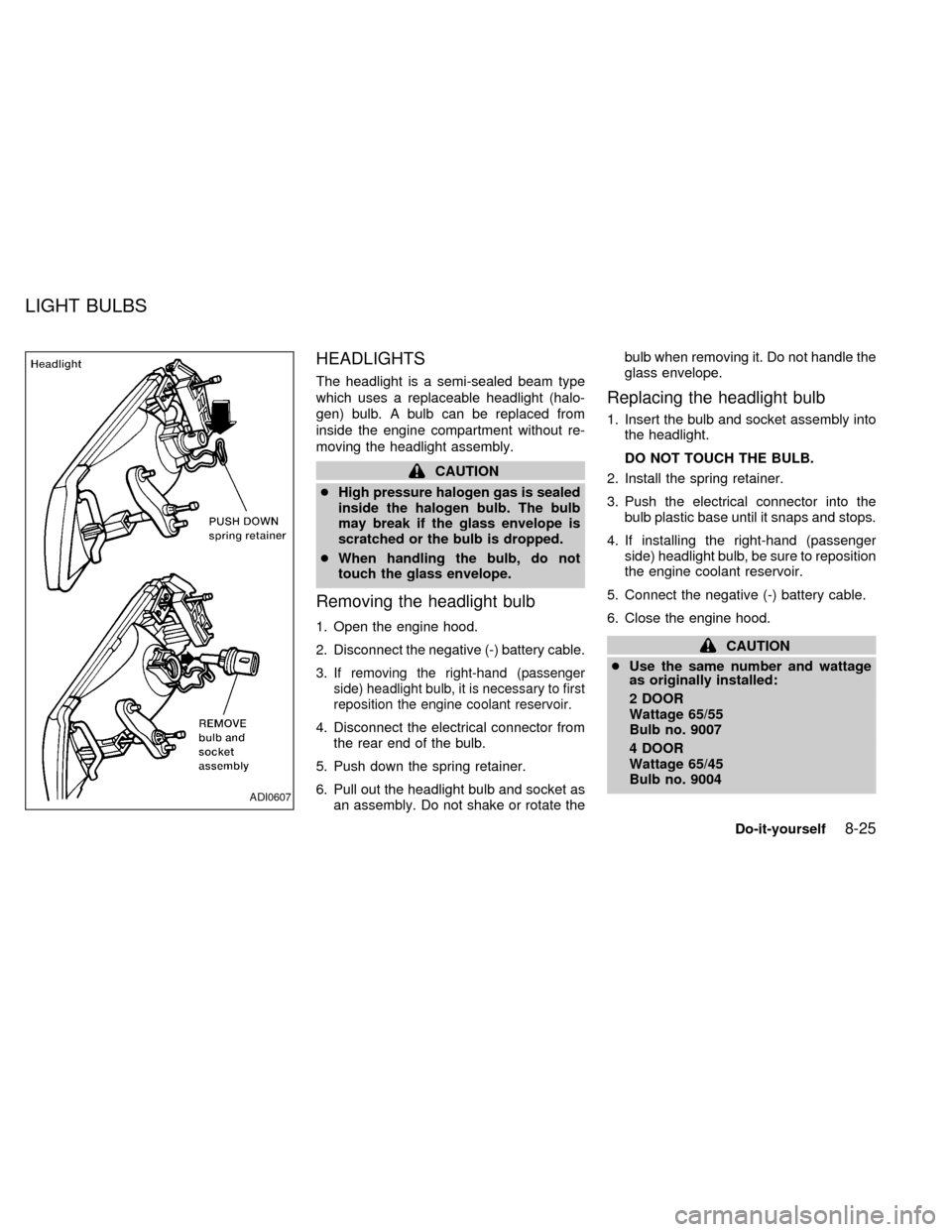

HEADLIGHTS

The headlight is a semi-sealed beam type

which uses a replaceable headlight (halo-

gen) bulb. A bulb can be replaced from

inside the engine compartment without re-

moving the headlight assembly.

CAUTION

cHigh pressure halogen gas is sealed

inside the halogen bulb. The bulb

may break if the glass envelope is

scratched or the bulb is dropped.

cWhen handling the bulb, do not

touch the glass envelope.

Removing the headlight bulb

1. Open the engine hood.

2. Disconnect the negative (-) battery cable.

3.

If removing the right-hand (passenger

side) headlight bulb, it is necessary to first

reposition the engine coolant reservoir.

4. Disconnect the electrical connector from

the rear end of the bulb.

5. Push down the spring retainer.

6. Pull out the headlight bulb and socket as

an assembly. Do not shake or rotate thebulb when removing it. Do not handle the

glass envelope.

Replacing the headlight bulb

1. Insert the bulb and socket assembly into

the headlight.

DO NOT TOUCH THE BULB.

2. Install the spring retainer.

3. Push the electrical connector into the

bulb plastic base until it snaps and stops.

4. If installing the right-hand (passenger

side) headlight bulb, be sure to reposition

the engine coolant reservoir.

5. Connect the negative (-) battery cable.

6. Close the engine hood.

CAUTION

cUse the same number and wattage

as originally installed:

2 DOOR

Wattage 65/55

Bulb no. 9007

4 DOOR

Wattage 65/45

Bulb no. 9004

ADI0607

LIGHT BULBS

Do-it-yourself8-25

ZX

Page 169 of 216

cAiming is not necessary after replac-

ing the bulb.

cDo not leave the bulb out of the

headlight reflector for a long period

of time as dust, moisture, and smoke

may enter the headlight body and

affect the performance of the head-

light.

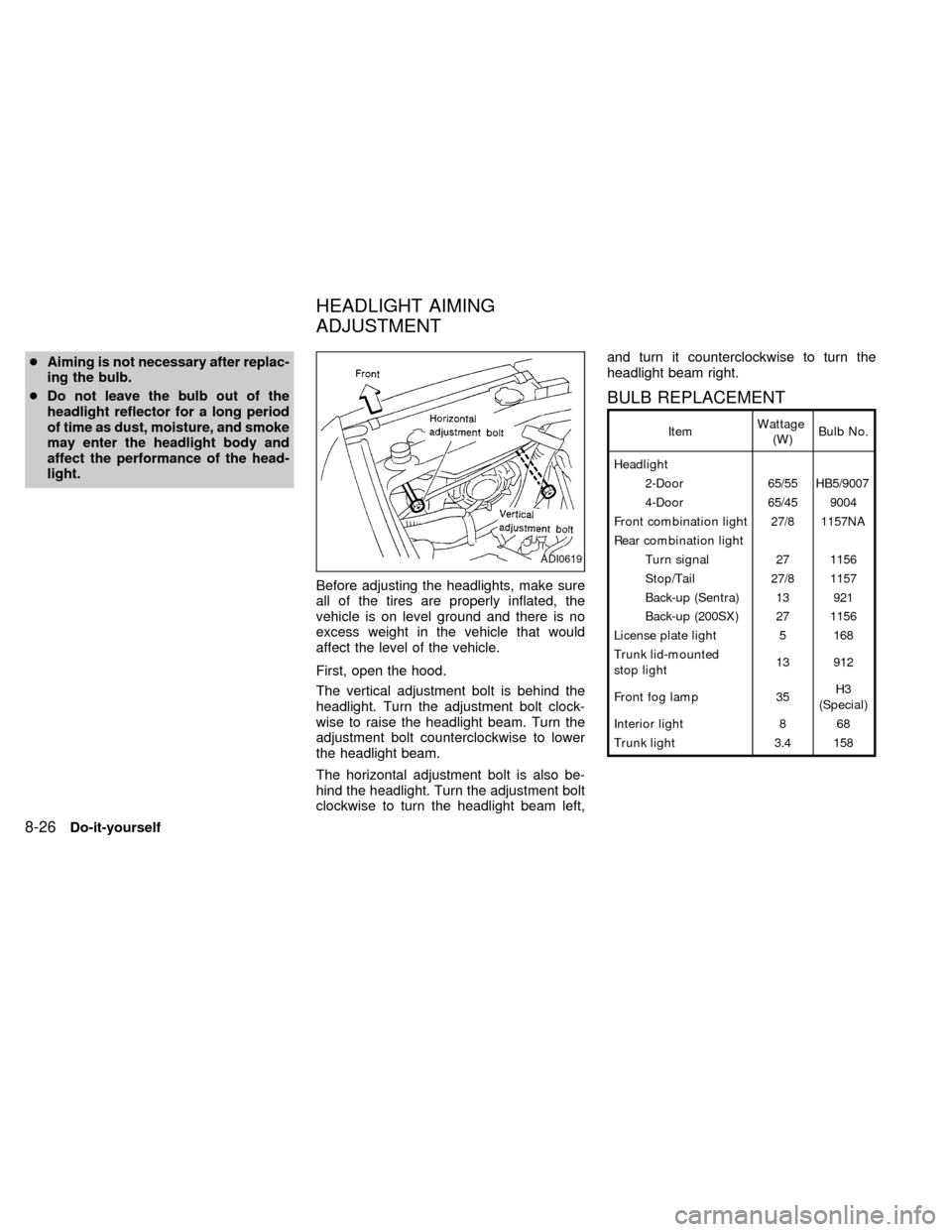

Before adjusting the headlights, make sure

all of the tires are properly inflated, the

vehicle is on level ground and there is no

excess weight in the vehicle that would

affect the level of the vehicle.

First, open the hood.

The vertical adjustment bolt is behind the

headlight. Turn the adjustment bolt clock-

wise to raise the headlight beam. Turn the

adjustment bolt counterclockwise to lower

the headlight beam.

The horizontal adjustment bolt is also be-

hind the headlight. Turn the adjustment bolt

clockwise to turn the headlight beam left,and turn it counterclockwise to turn the

headlight beam right.

BULB REPLACEMENT

ItemWattage

(W)Bulb No.

Headlight

2-Door 65/55 HB5/9007

4-Door 65/45 9004

Front combination light 27/8 1157NA

Rear combination light

Turn signal 27 1156

Stop/Tail 27/8 1157

Back-up (Sentra) 13 921

Back-up (200SX) 27 1156

License plate light 5 168

Trunk lid-mounted

stop light13 912

Front fog lamp 35H3

(Special)

Interior light 8 68

Trunk light 3.4 158

ADI0619

HEADLIGHT AIMING

ADJUSTMENT

8-26Do-it-yourself

ZX

Page 170 of 216

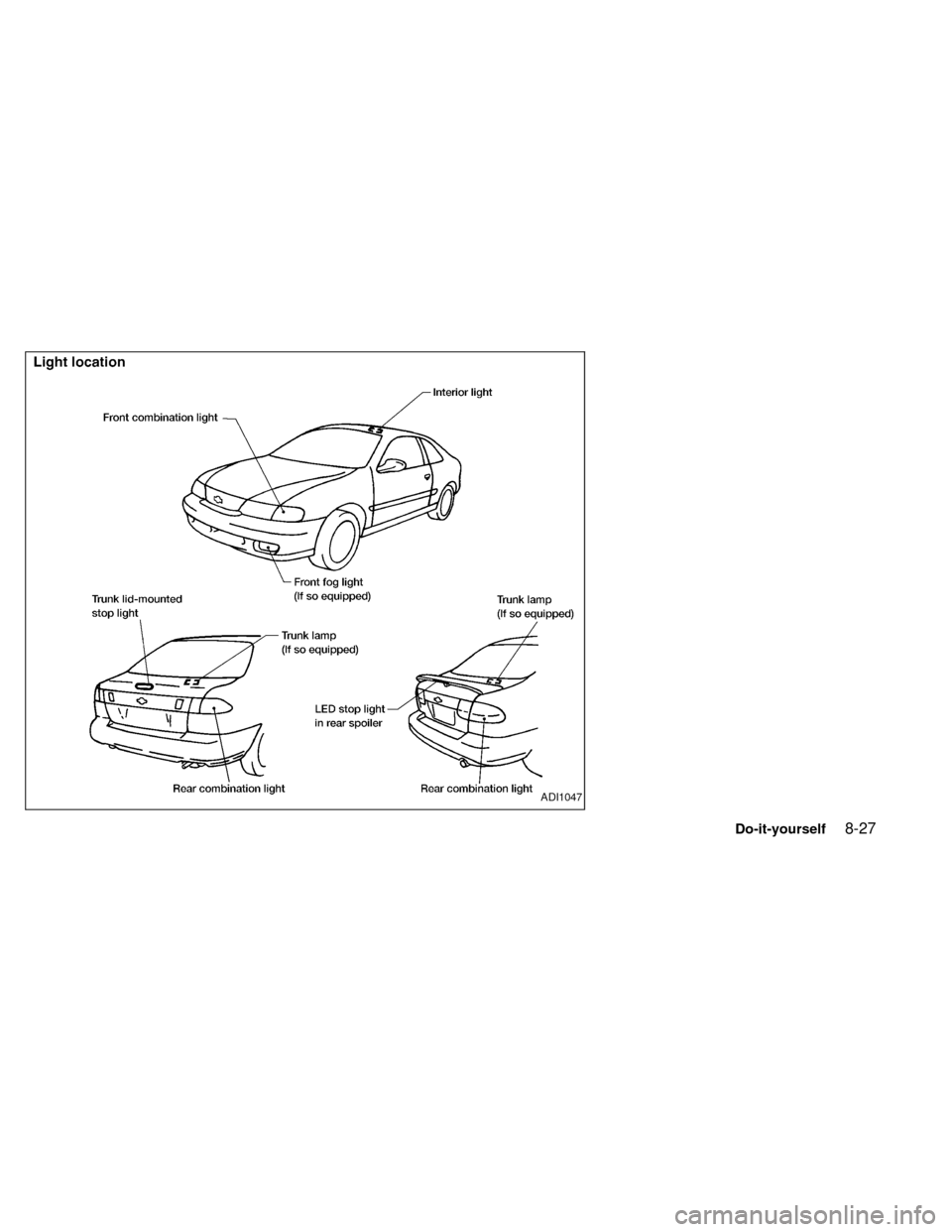

ADI1047

Do-it-yourself8-27

ZX