light NISSAN SENTRA 2000 B15 / 5.G Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: SENTRA, Model: NISSAN SENTRA 2000 B15 / 5.GPages: 240, PDF Size: 1.94 MB

Page 186 of 240

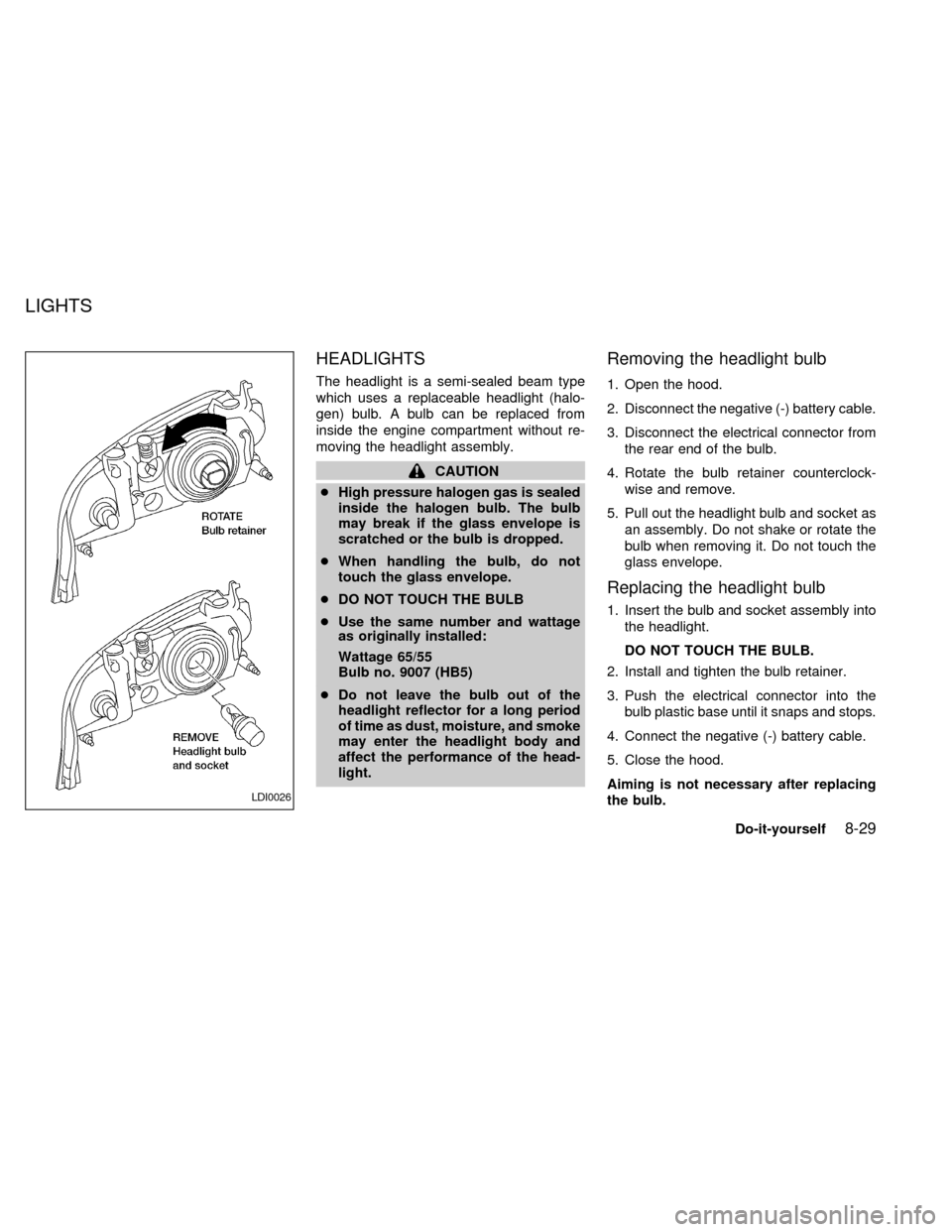

HEADLIGHTS

The headlight is a semi-sealed beam type

which uses a replaceable headlight (halo-

gen) bulb. A bulb can be replaced from

inside the engine compartment without re-

moving the headlight assembly.

CAUTION

cHigh pressure halogen gas is sealed

inside the halogen bulb. The bulb

may break if the glass envelope is

scratched or the bulb is dropped.

cWhen handling the bulb, do not

touch the glass envelope.

cDO NOT TOUCH THE BULB

cUse the same number and wattage

as originally installed:

Wattage 65/55

Bulb no. 9007 (HB5)

cDo not leave the bulb out of the

headlight reflector for a long period

of time as dust, moisture, and smoke

may enter the headlight body and

affect the performance of the head-

light.

Removing the headlight bulb

1. Open the hood.

2. Disconnect the negative (-) battery cable.

3. Disconnect the electrical connector from

the rear end of the bulb.

4. Rotate the bulb retainer counterclock-

wise and remove.

5. Pull out the headlight bulb and socket as

an assembly. Do not shake or rotate the

bulb when removing it. Do not touch the

glass envelope.

Replacing the headlight bulb

1. Insert the bulb and socket assembly into

the headlight.

DO NOT TOUCH THE BULB.

2. Install and tighten the bulb retainer.

3. Push the electrical connector into the

bulb plastic base until it snaps and stops.

4. Connect the negative (-) battery cable.

5. Close the hood.

Aiming is not necessary after replacing

the bulb.

LDI0026

LIGHTS

Do-it-yourself8-29

ZX

Page 187 of 240

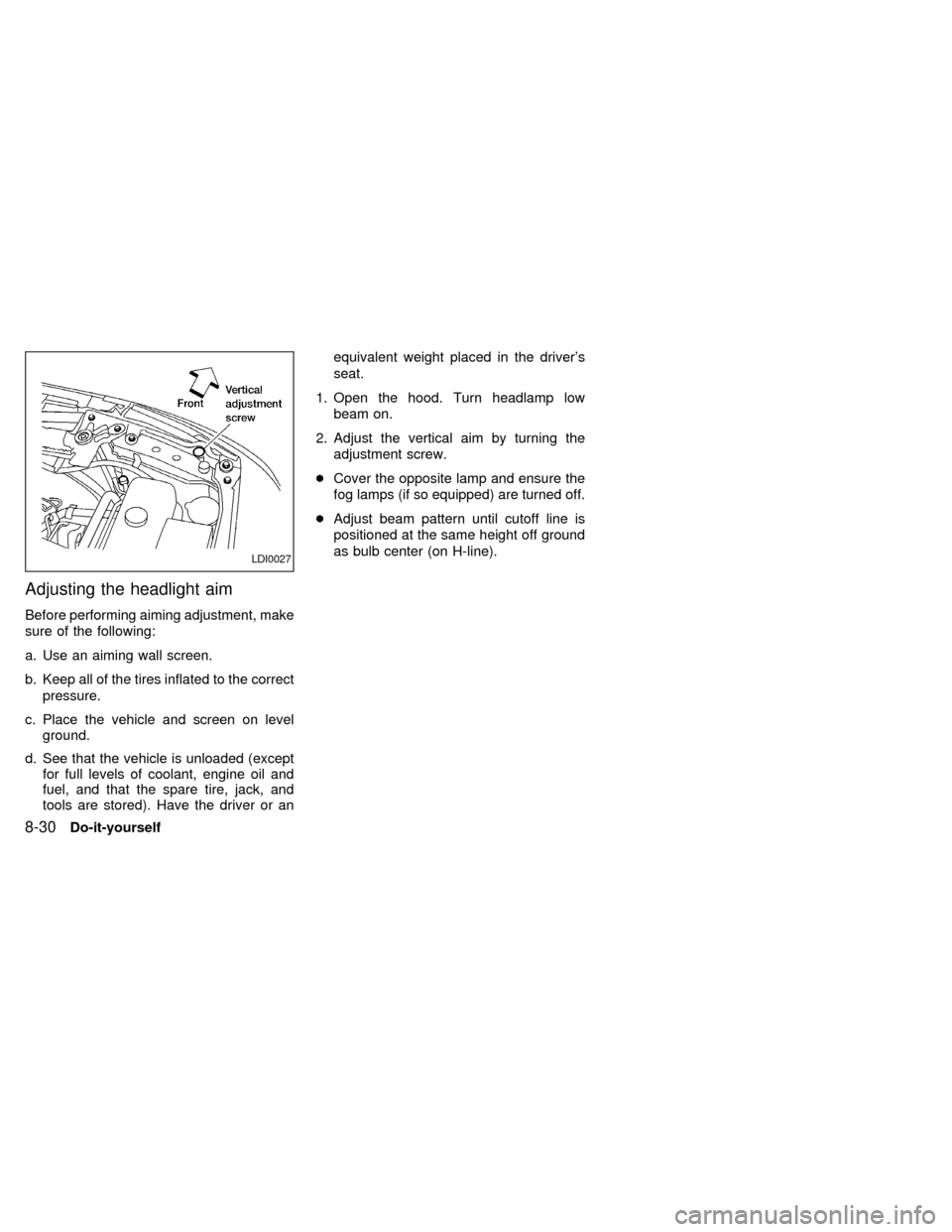

Adjusting the headlight aim

Before performing aiming adjustment, make

sure of the following:

a. Use an aiming wall screen.

b. Keep all of the tires inflated to the correct

pressure.

c. Place the vehicle and screen on level

ground.

d. See that the vehicle is unloaded (except

for full levels of coolant, engine oil and

fuel, and that the spare tire, jack, and

tools are stored). Have the driver or anequivalent weight placed in the driver's

seat.

1. Open the hood. Turn headlamp low

beam on.

2. Adjust the vertical aim by turning the

adjustment screw.

cCover the opposite lamp and ensure the

fog lamps (if so equipped) are turned off.

cAdjust beam pattern until cutoff line is

positioned at the same height off ground

as bulb center (on H-line).

LDI0027

8-30Do-it-yourself

ZX

Page 189 of 240

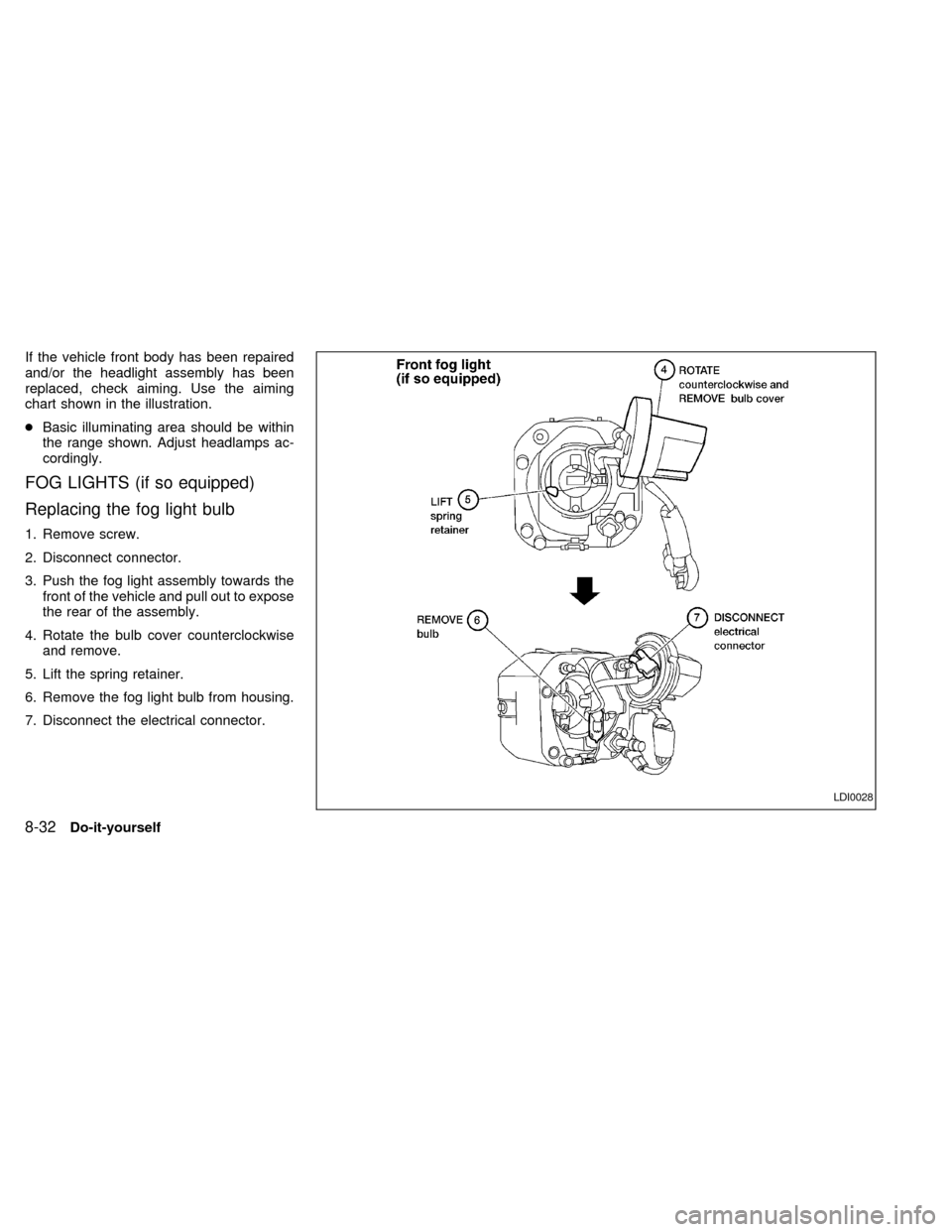

If the vehicle front body has been repaired

and/or the headlight assembly has been

replaced, check aiming. Use the aiming

chart shown in the illustration.

cBasic illuminating area should be within

the range shown. Adjust headlamps ac-

cordingly.

FOG LIGHTS (if so equipped)

Replacing the fog light bulb

1. Remove screw.

2. Disconnect connector.

3. Push the fog light assembly towards the

front of the vehicle and pull out to expose

the rear of the assembly.

4. Rotate the bulb cover counterclockwise

and remove.

5. Lift the spring retainer.

6. Remove the fog light bulb from housing.

7. Disconnect the electrical connector.

LDI0028

8-32Do-it-yourself

ZX

Page 190 of 240

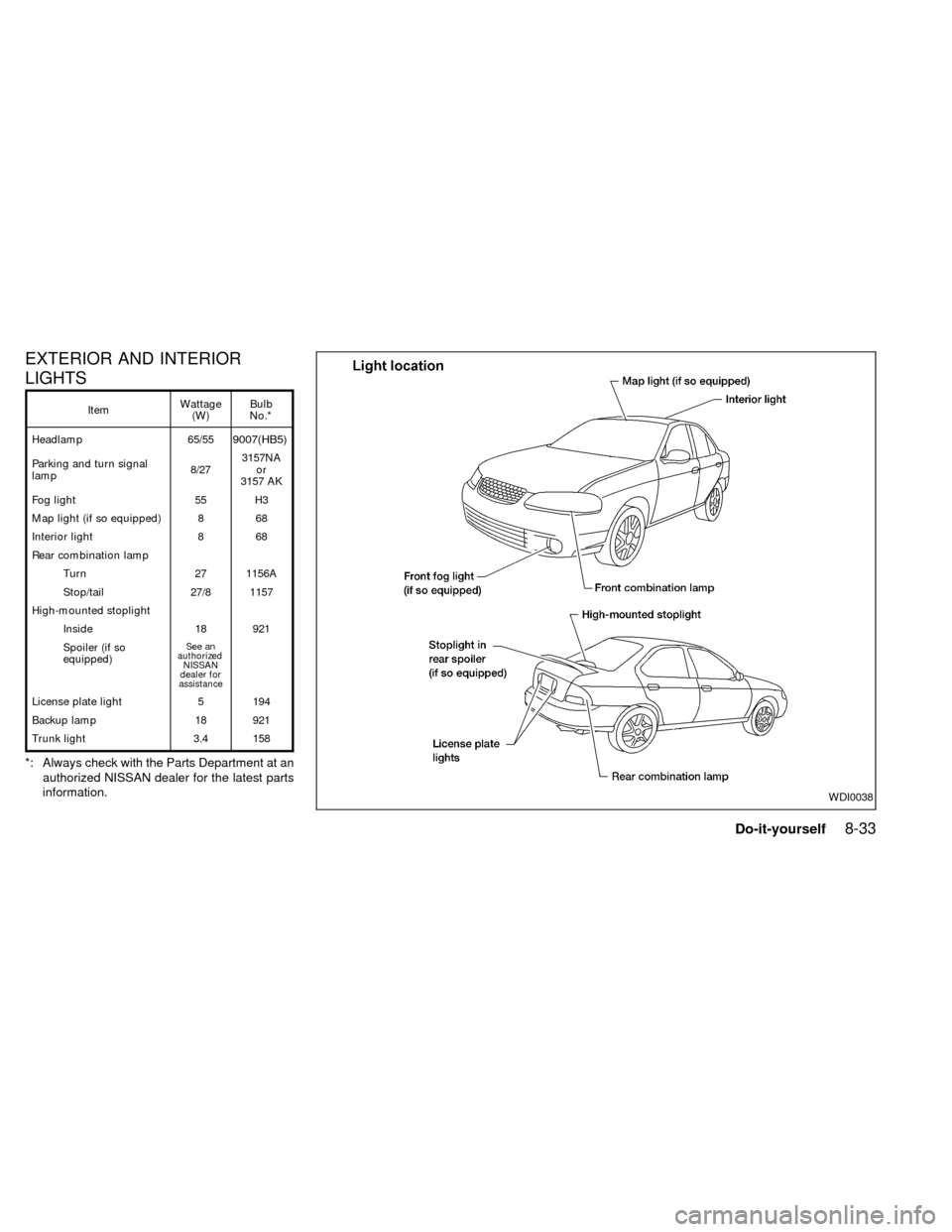

EXTERIOR AND INTERIOR

LIGHTS

ItemWattage

(W)Bulb

No.*

Headlamp 65/55

9007(HB5)

Parking and turn signal

lamp8/273157NA

or

3157 AK

Fog light 55 H3

Map light (if so equipped) 8 68

Interior light 8 68

Rear combination lamp

Turn 27 1156A

Stop/tail 27/8 1157

High-mounted stoplight

Inside 18 921

Spoiler (if so

equipped)See an

authorized

NISSAN

dealer for

assistance

License plate light 5 194

Backup lamp 18 921

Trunk light 3.4 158

*: Always check with the Parts Department at an

authorized NISSAN dealer for the latest parts

information.

WDI0038

Do-it-yourself8-33

ZX

Page 191 of 240

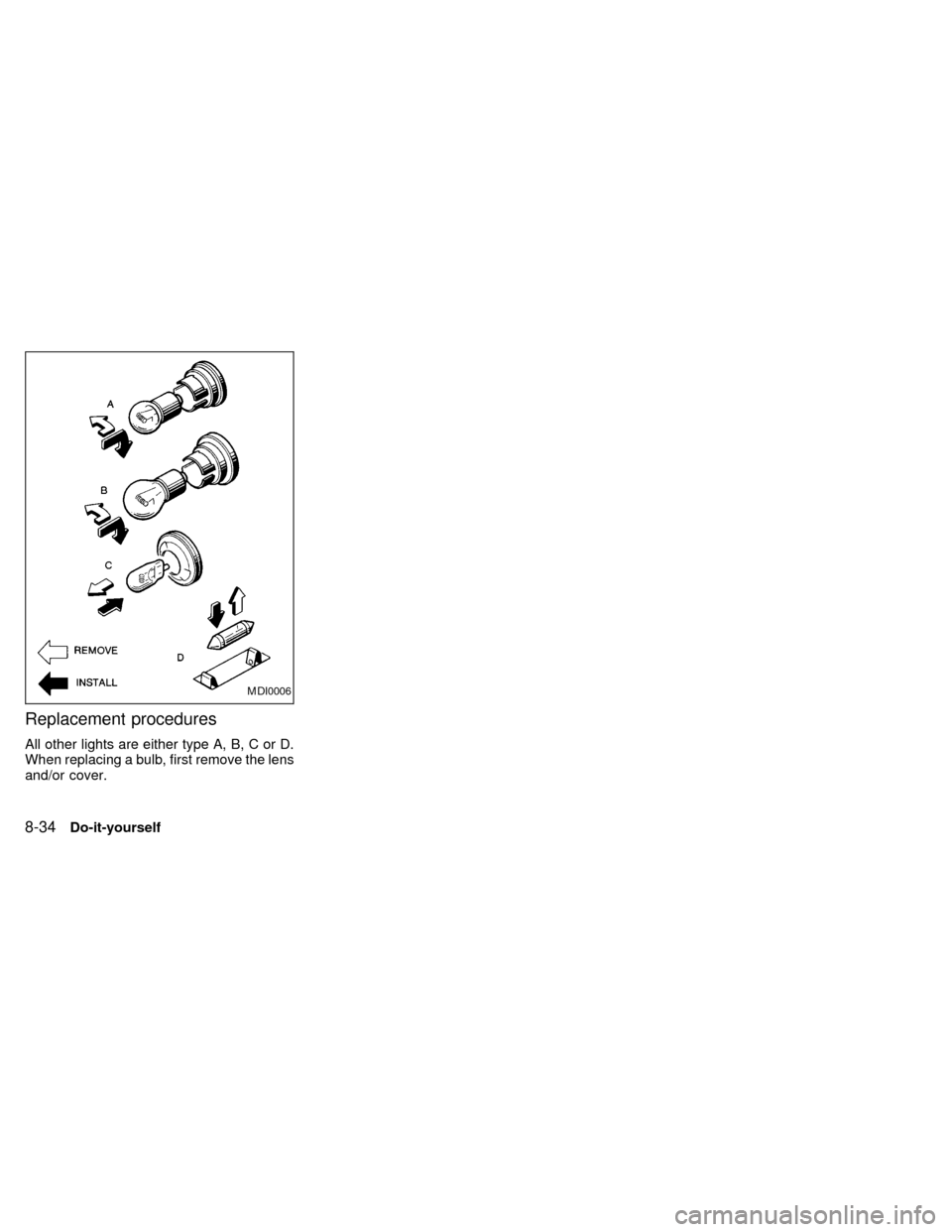

Replacement procedures

All other lights are either type A, B, C or D.

When replacing a bulb, first remove the lens

and/or cover.

MDI0006

8-34Do-it-yourself

ZX

Page 196 of 240

The wheel nuts must be kept tightened to

specifications at all times. It is recom-

mended that wheel nuts be tightened to

specification at each tire rotation interval.

WARNING

cAfter rotating the tires, check and

adjust the tire pressure.

cRetighten the wheel nuts when the

vehicle has been driven for 600 miles

(1,000 km) (also in cases of a flat tire,

etc.).

cDo not include the spare tire in the

tire rotation.

Tire wear and damage

WARNING

c

Tires should be periodically inspected

for wear, cracking, bulging, or objects

caught in the tread. If excessive wear,

cracks, bulging, or deep cuts are

found, the tire(s) should be replaced.

cThe original tires have a built-in

tread wear indicator. When the wear

indicator is visible, the tire(s) should

be replaced.cImproper service of the spare tire

may result in serious personal in-

jury. If it is necessary to repair the

spare tire, contact an authorized

NISSAN dealer.

Replacing tires and wheels

When replacing a tire, use the same size,

tread design, speed rating and load carrying

capacity as originally equipped. Recom-

mended types and sizes are shown in

``Wheel/Tire Size'' of the ``Technical and con-

sumer information'' section of this manual.

WARNING

c

The use of tires other than those

recommended, or the mixed use of

tires of different brands, construction

(bias, bias-belted, radial), or tread

patterns can adversely affect the ride,

braking, handling, ground clearance,

body-to-tire clearance, tire chain

clearance, speedometer calibration,

headlight aim and bumper height.

Some of these effects may lead to

accidents and could result in serious

personal injury.

DI1035M

Do-it-yourself8-39

ZX

Page 202 of 240

fied pressure if necessary. Check carefully

for damage, cuts or excessive wear.

Wheel nuts* ÐWhen checking the tires,

make sure no wheel nuts are missing, and

check for any loose wheel nuts. Tighten if

necessary.

Tire rotation* ÐTires should be rotated

every 7,500 miles (12,000 km).

Wheel alignment and balance ÐIf the

vehicle should pull to either side while driv-

ing on a straight and level road, or if you

detect uneven or abnormal tire wear, there

may be a need for a wheel alignment.

If the steering wheel or seat vibrates at

normal highway speeds, wheel balancing

may be needed.

Windshield wiper blades* ÐCheck for

cracks or wear if they do not wipe properly.

Doors and engine hood ÐCheck that all

doors and the hood operate properly. Also

ensure that all latches lock securely. Lubri-

cate hinges, latches, rollers and links if

necessary. Make sure the secondary latch

keeps the hood from opening when the

primary latch is released.

When driving in areas that use road salt orother corrosive materials, check lubrication

frequently.

Lights* ÐMake sure the headlamps, stop-

lights, tail lights, turn signal lights, and other

lights are all operating properly and installed

securely. Also check headlamp aim.

INTERIOR MAINTENANCE

The maintenance items listed here should

be checked on a regular basis, such as

when performing periodic maintenance,

cleaning the vehicle, etc.

Additional information on the following

items with an ``*'' is found in the ``Do-it-

yourself'' section of this manual.

Warning lights and chimes ÐMake sure

all warning lights and chimes are operating

properly.

Windshield wiper and washer* ÐCheck

that the wipers and washer operate properly

and that the wipers do not streak.

Windshield defroster ÐCheck that the air

comes out of the defroster outlets properly

and in sufficient quantity when operating the

heater or air conditioner.

Steering wheel ÐCheck for changes inthe steering conditions, such as excessive

freeplay, hard steering or strange noises.

Seats ÐCheck seat position controls such

as seat adjusters, seatback recliner, etc. to

ensure they operate smoothly and all

latches lock securely in every position.

Check that the head restraints move up and

down smoothly and the locks hold securely

in all latched positions.

Seat belts ÐCheck that all parts of the seat

belt system (For example buckles, anchors,

adjusters and retractors) operate properly

and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying,

wear or damage.

Accelerator pedal ÐCheck the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort.

Keep the floor mat away from the pedal.

Clutch pedal* ÐMake sure the pedal

operates smoothly and check that it has the

proper free travel.

Brakes ÐCheck that the brakes do not pull

the vehicle to one side when applied.

Brake pedal and booster* ÐCheck the

pedal for smooth operation and make sure it

Maintenance

9-3

ZX

Page 213 of 240

![NISSAN SENTRA 2000 B15 / 5.G Repair Manual of at least 87 AKI (Anti-Knock Index). How-

ever, you may use unleaded gasoline with

an octane rating as low as 85 AKI (Anti-

Knock Index) in high altitude areas (over

4,000 ft [1,219 m]) such as: Col NISSAN SENTRA 2000 B15 / 5.G Repair Manual of at least 87 AKI (Anti-Knock Index). How-

ever, you may use unleaded gasoline with

an octane rating as low as 85 AKI (Anti-

Knock Index) in high altitude areas (over

4,000 ft [1,219 m]) such as: Col](/img/5/642/w960_642-212.png)

of at least 87 AKI (Anti-Knock Index). How-

ever, you may use unleaded gasoline with

an octane rating as low as 85 AKI (Anti-

Knock Index) in high altitude areas (over

4,000 ft [1,219 m]) such as: Colorado, Mon-

tana, New Mexico, Utah, Wyoming, north-

eastern Nevada, southern Idaho, western

South Dakota, western Nebraska, and the

part of Texas which is directly south of New

Mexico.

Using unleaded gasoline with an octane

rating lower than stated above can cause

persistent, heavy ``spark knock.'' (``Spark

knock'' is a metallic rapping noise.) If

severe, this can lead to engine damage. If

you detect a persistent heavy spark

knock even when using gasoline of the

stated octane rating, or if you hear steady

spark knock while holding a steady

speed on level roads, have an authorized

NISSAN dealer correct the condition.

Failure to correct the condition is misuse

of the vehicle, for which NISSAN is not

responsible.

Incorrect ignition timing may result in spark

knock, after-run and/or overheating, which

may cause excessive fuel consumption or

engine damage. If any of the above symp-toms are encountered, have your vehicle

checked at an authorized NISSAN dealer or

other competent service facility.

However, now and then you may notice

light spark knock for a short time while

accelerating or driving up hills. This is

not a cause for concern, because you

get the greatest fuel benefit when there

is light spark knock for a short time

under heavy engine load.

10-4Technical and consumer information

ZX

Page 222 of 240

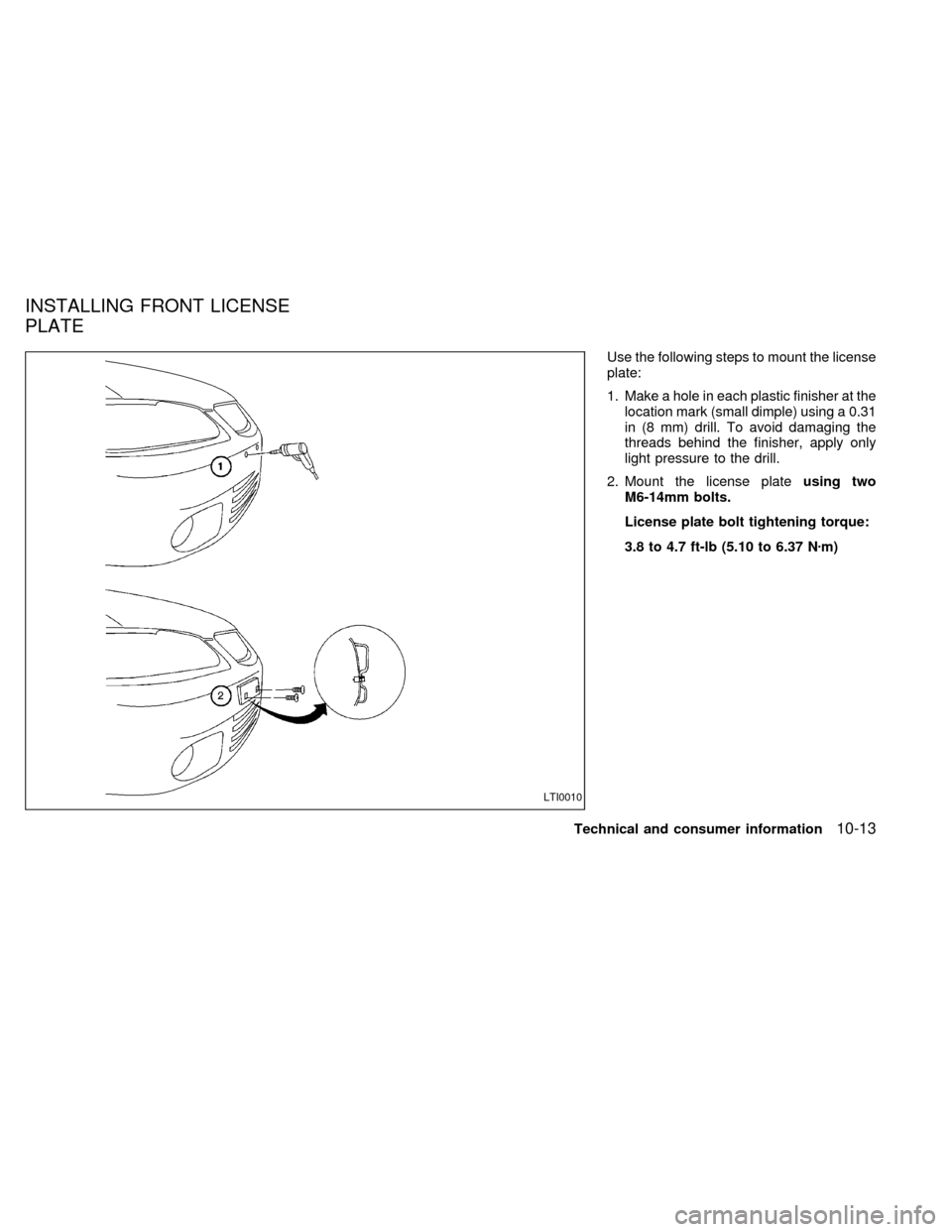

Use the following steps to mount the license

plate:

1. Make a hole in each plastic finisher at the

location mark (small dimple) using a 0.31

in (8 mm) drill. To avoid damaging the

threads behind the finisher, apply only

light pressure to the drill.

2. Mount the license plateusing two

M6-14mm bolts.

License plate bolt tightening torque:

3.8 to 4.7 ft-lb (5.10 to 6.37 Nzm)

LTI0010

INSTALLING FRONT LICENSE

PLATE

Technical and consumer information10-13

ZX

Page 226 of 240

cDo not modify the vehicle exhaust

system, brake system, etc. to install

a trailer hitch.

cTo reduce the possibility of addi-

tional damage if your vehicle is

struck from the rear, where practical,

remove the hitch and/or receiver

when not in use.

cAfter the hitch is removed, seal the

bolt holes to prevent exhaust fumes,

water or dust from entering the pas-

senger compartment.

cRegularly check that all hitch mount-

ing bolts are securely mounted.

Tire pressures

cWhen towing a trailer, inflate the vehicle

tires to the recommended cold tire pres-

sure indicated on the tire placard (lo-

cated on the driver's side rear door

pillar).

cTrailer tire condition, size, load rating

and proper inflation pressure should be

in accordance with the trailer and tire

manufacturers' specifications.

Safety chains

Always use suitable safety chains between

your vehicle and the trailer. Safety chains

should be crossed and should be attached

to the hitch, not to the vehicle bumper or

axle. Be sure to leave enough slack in the

chains to permit turning corners.

Trailer lights

Trailer lights should comply with federal

and/ or local regulations. When wiring the

vehicle for towing, connect the stop and tail

light pickup into the vehicle electrical circuit.

Trailer brakes

If your trailer is equipped with a braking

system, make sure it conforms to federal

and/or local regulations and that it is prop-

erly installed.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

cBe certain your vehicle maintains a level

position when a loaded and/or unloadedtrailer is hitched. Do not drive the vehicle if

it has an abnormal nose-up or nose- down

condition; check for improper tongue load,

overload, worn suspension or other pos-

sible causes of either condition.

cAlways secure items in the trailer to

prevent load shift while driving.

cBe certain your rear view mirrors con-

form to all federal, state or local regula-

tions. If not, install any mirrors required

for towing before driving the vehicle.

Trailer towing tips

In order to gain skill and an understanding

of the vehicle's behavior, you should prac-

tice turning, stopping and backing up in an

area which is free from traffic. Steering,

stability, and braking performance are

somewhat different than under normal driv-

ing conditions.

cAlways secure items in the trailer to

prevent load shift while driving.

c

Avoid abrupt starts, acceleration or stops.

cAvoid sharp turns or lane changes.

cAlways drive your vehicle at a moderate

speed.

c

Always block the wheels on both vehicle

and trailer when parking. Parking on a

Technical and consumer information10-17

ZX