NISSAN SERENA 1993 Service Repair Manual

Manufacturer: NISSAN, Model Year: 1993, Model line: SERENA, Model: NISSAN SERENA 1993Pages: 1254, PDF Size: 89.68 MB

Page 781 of 1254

ADJUSTMENT

Model

R200

Differenlial Case

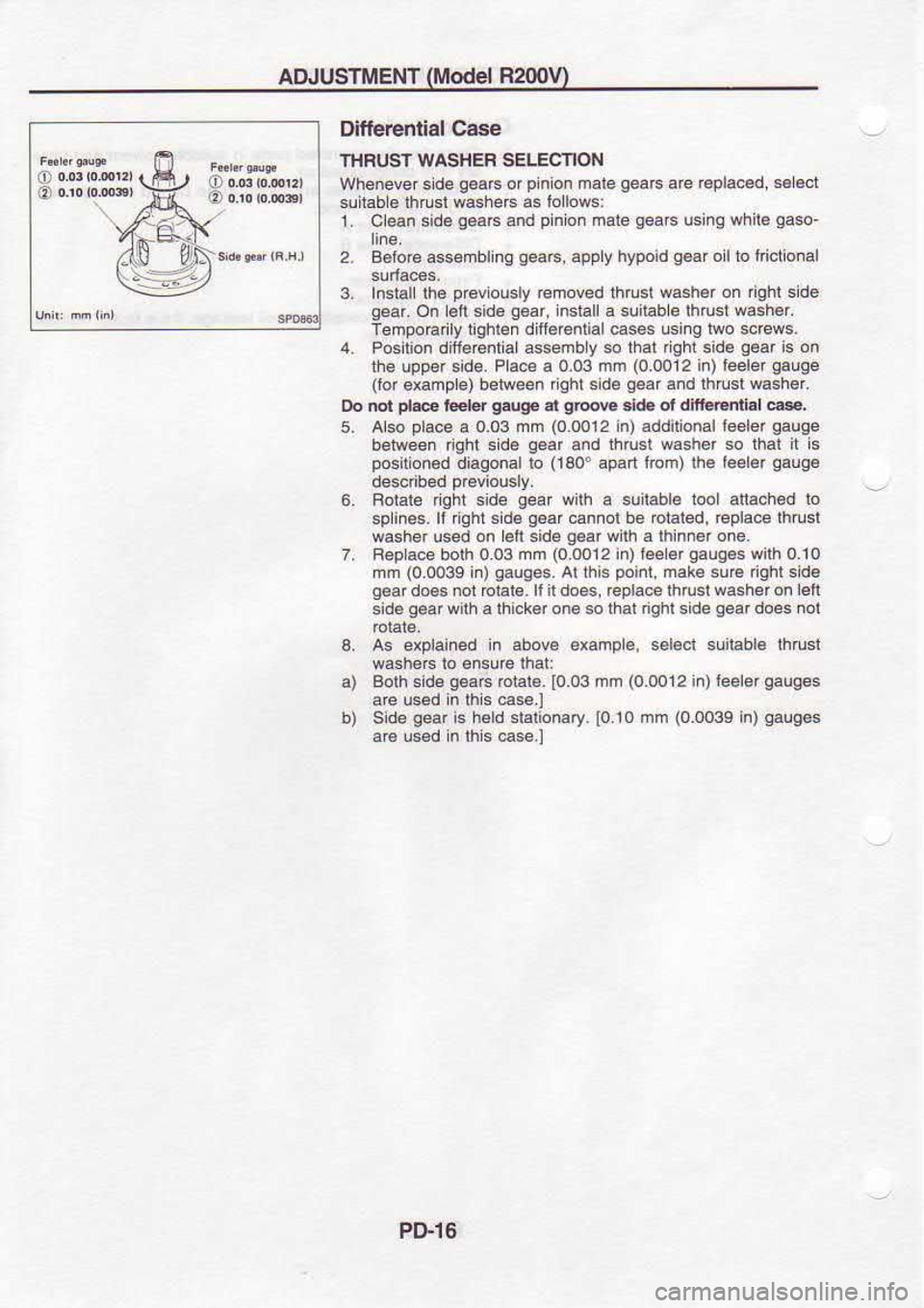

IHFUST WASHER SELECTION

whenever side qearc

of pinio.

male gea6

are replaced, 56

€ct

suitab e lhrusl w4hers as lo

lows:

1 Clean side g€aB

and p

non male gea6

using while

0a3o-

2. Belore assembllng gea6.

apply hypoid qoaf

o I lo lriolio.al

3. Insral lh6 pGviously

rcmoved thrusl wash€r

on nghl sde

gea' On efi

cido

aear nsblld:Litabe

th'Js sash€r

TempoErily Iighl€n difi€€nlial€ses using

tuo scres.

4 Posilion difie€nlial assedb y

so thal rqhl side

aear rs

on

the upper side Plac6

a 0.03 mm (0.0012

i.) leeler gauge

(for erample) betueen riqhtside ge.rand

lhrusl washer.

Do not pl.e

tccla gaqgp

at glo@

ltd€ ol difi.dtlisl de.

5. Also p

ace a 0 03 mm (o.o012

n) addilional leeler qauge

berween dght side gear

and thtu6l

washer so lhal it s

posilion€d diaqonallo (1a0'apalt

lom) ihe leelq gaug€

descibed DEviouslv.

6. Bolale iqht side geai

wlih a suilable tool allachod lo

sp ines

ll rqht sid6 g€ar

€nnol be rolaled, replace lhrusl

washer used on lei

side g6ar

wllh a lhlnnorone.

7. Rep ace bolh 0.03 mm (0

0012 in)

lee 6r gauges

wilh 0.10

mm (0.0039

in)qauges At

lhis point,

make su€ ghl

sd€

g€ar do€s nor olale.ll il does. repla@fttustwasheron lefi

side g€afwith

alhickd one so thal nghl side gear

does nol

3. As exolained in above examDe, s6l€cl

suilabl6 lhrusl

a) Borh

sid€ g6a6

btal6.

[0.03 mm

(00012

in)lelergauges

are used n

lhis.as€.]

b) Side gear

is held slalionary.

10.10 mm

(0.003s

in)

aaus€s

a€ us6d in lhs €se.l

Pt>16

Page 782 of 1254

ADJUSTMEIIT

(Model

R20oV)

To avoid contusion whil€ €lculaling b€a ng shims, il is ab.o-

lulely ne€ssary to slay wilh tlre m€l c ayslem. lf you

measu€

anylhing in inches, lh€ 6ulr! nEl b€ ffirted

lo lhe rEtdc

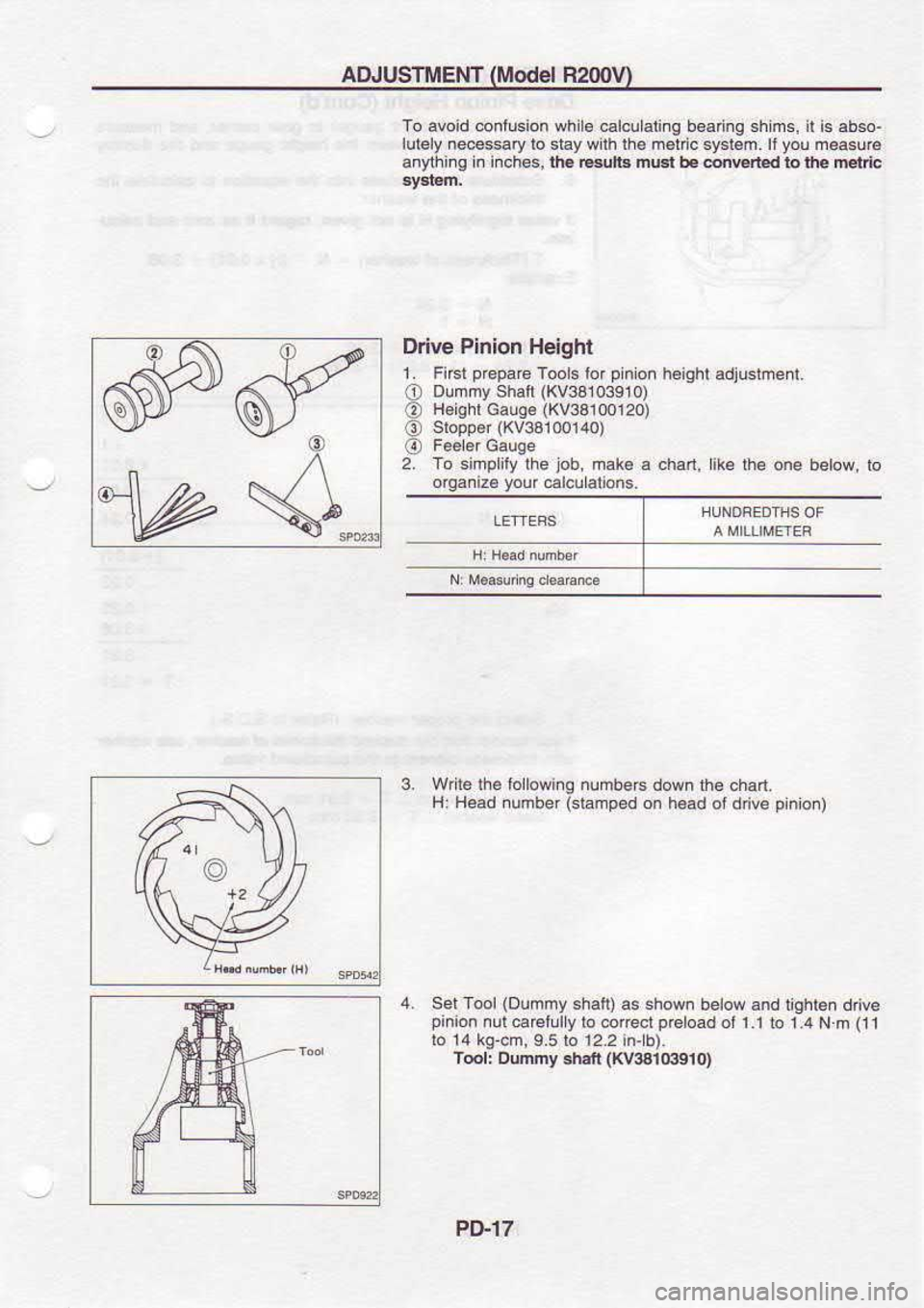

V<,""" Drive

Pinion

Height

1. o

@

o

o

2. Fi6l

prcpaE

Too s lor pinio.

height adiustment.

Dummy Shafi (KV33103910)

Hgiqhl Gauq6 (KV331@120)

To simprit the job,

mak€ a chart, ika

the one berow, lo

orAaniz€ youf

.alculalions.

3. Wit6 the lollowing

numbe6 down lh6 chan.

H: Head.udber

lslamo6d on

h€.d

oi dive Dinionl

4. Sel Tool (Dummy

shan) as show. below andlighl€n

d ve

pinion.ulca€fulylo.orc.tpreloadotl.l lo1.4Nm{11

lo 14 kg-cm,9.51o 12.2 in-b).

T@l: Dlnny

.hrlt (KV3alG910)

PT}'l7

Page 783 of 1254

ADJUSTMENT

(Mod6I

R2MV}

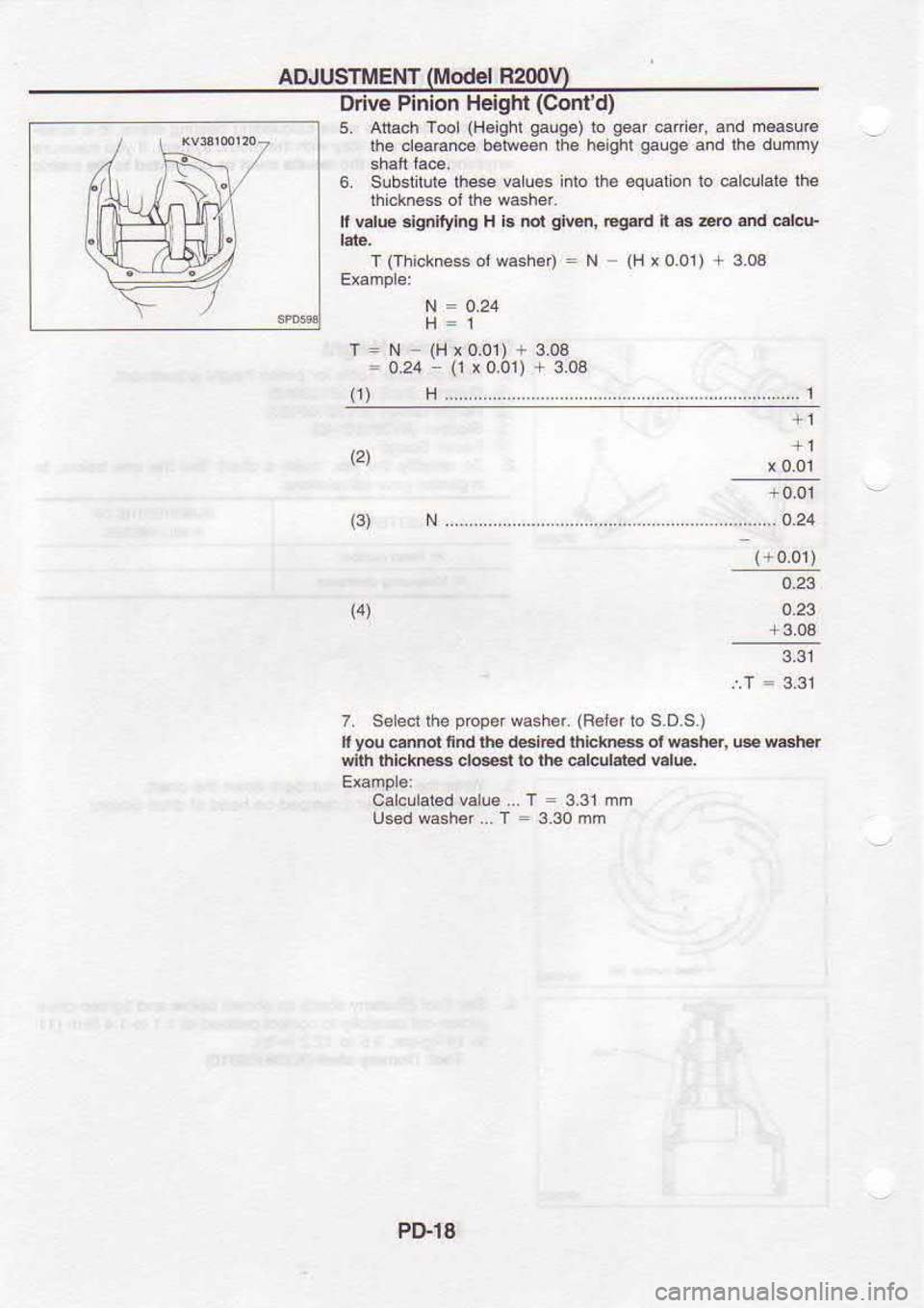

Drive Pinion Heigh (Cont

d)

5 Altach

Too (H€ighl

gauge)

to gear

€iier, and

m€asuro

lhe .ieaEn6 bolween

the heighl gauge

and lhe

dummy

6. Subslilute these values

into rh€ .quat on to calcu ale the

ihicknoss ol the washer.

It vd@

3igniti.g H

i5 nor gi6,

€gard n as 4b od €lcF

I (Thickness

or washer) =

N (N

x 0.01) +

3.03

N =

0.24

t:

0) N-(Hx0.01)

-3.03

0.24 (1

x 0.01) +

3.03

\2)

(3)

7. Seecl the proper

wash€r. (R€ld

ro s.D.s.)

It y@

cannot nnd

lhe desiEd rhickn* ol m8hs,

{nh thickns clo*st lo the elcllated value.

cal.ulaled vaLle ... T =

3.31 mm

used washer

T=330nm +l

4.24

(+0.01)

4.23

+3.03

3.31

.,T :

3.31

pI>l8

Page 784 of 1254

ADJUSTMENT

Model R2m

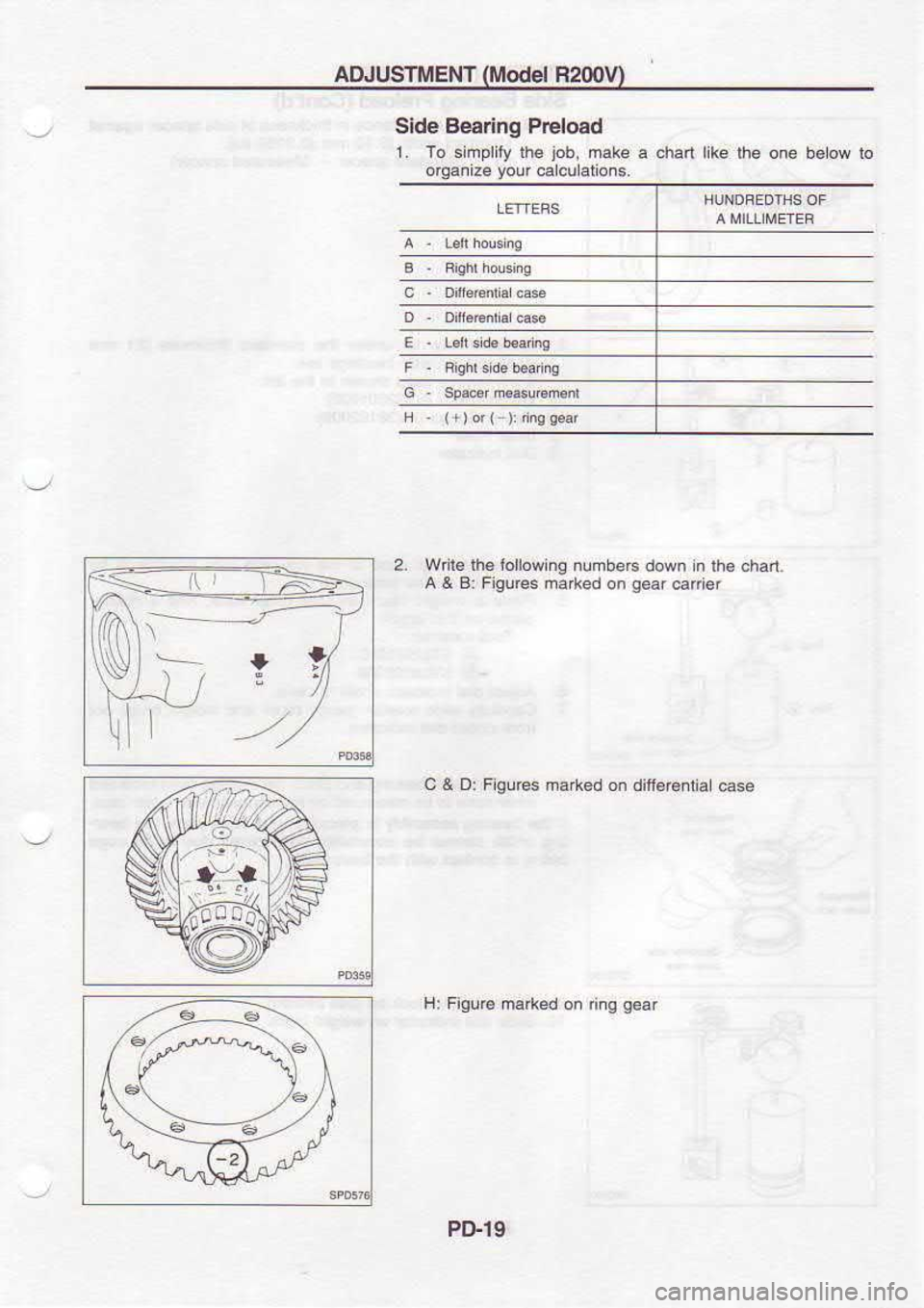

Side Besring

Preload

1. To simpliry

lhe

iob, make

a chad like fie one below lo

oBanize youi

ca lculation s.

2. Wnl€ lh€lollowing numbers

down nlh6chan.

A & a: Figures narked

on gear

cari6r

C A D

Fig!'es mar[ed on difl€@.riar

cse

.--a-'.

\\,.''ii

H: FiguE m.rted

o. 'ing

gear

PD.19

Page 785 of 1254

![NISSAN SERENA 1993 Service Repair Manual ADJUSTMEUT

(

odel Bznv)

Side Bearing

Preload (Contd)

G: This is lhe difi€€n€ in lh ckness

ol s de spacefagainsl

slandad widih

I3.1o mm

(0

3139 in)].

(c =

Sland.d spa@r

Meas NISSAN SERENA 1993 Service Repair Manual ADJUSTMEUT

(

odel Bznv)

Side Bearing

Preload (Contd)

G: This is lhe difi€€n€ in lh ckness

ol s de spacefagainsl

slandad widih

I3.1o mm

(0

3139 in)].

(c =

Sland.d spa@r

Meas](/img/5/57387/w960_57387-784.png)

ADJUSTMEUT

(

odel Bznv)

Side Bearing

Preload (Cont'd)

G: This is lhe difi€€n€ in lh ckness

ol s de spacefagainsl

slandad widih

I3.1o mm

(0

3139 in)].

(c =

Sland.d spa@r

Measurcd soa@r)

u>-\ U 3.

Medsu'6 how 'd'

u-de fe srdno".d ricrn€s<

121 trn

(0,33 in)l lhe s de beafnss a€.

It willrcqu rc lools shown ro

the reft.

O weishl

Brock (sT32501o00)

O Maerff

G6uq€ (Kv33102000)

4. Place

ihe oulef rac6 ol rh€ opposite

side bsa nq ro

be

me4ured on lhe bas€ plale

5. Pla@ a weqhl blo.k on

lhar ourer 6c€, .nd

a nasler

gauge on lhai block

@ sl325o1mo

(Bl KWAtOz0@

6 Adjusi dial ndicarorscae

to ze@.

7. Car6l! ly

slide masb. gaug€

btock and weighr btock oul

a. Lubicatesidebeadnoandda@thebea

ng ouler ra@

and

Inne.cono lo b€ measured

on th. opposile

side outer €c6.

ll rhe b.adng rsmbly

ls placrd

on th. be plate,

th6 b.EF

Ing widrh 6nor be a@urat€ly

d.i.mined due

[o its c5gE

boing in @m.d wnh

lhe b€s pld€.

S. Place weighi

block on sid6 bea/nO.

10. Side dialindicaloron welghi

btock.

PT}20

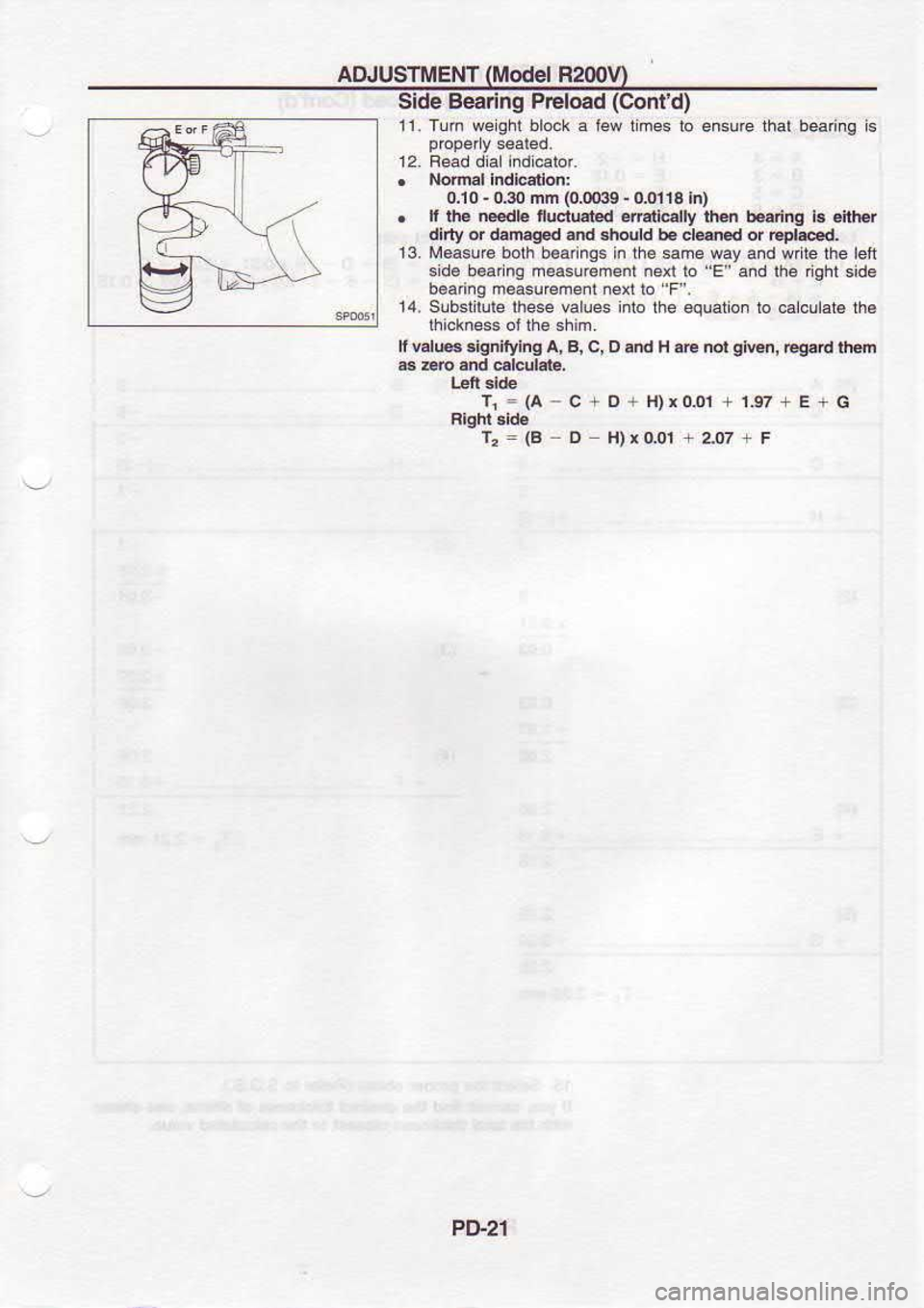

Page 786 of 1254

ADJUSTMENT

(Mode|

R2tO9

Slde Beadng

PEload (Conl'd)

11. Tln

weghl block a tew lmes to ensu@ that bea ng is

0.10 -

03) nn (0l)0:19

-

00116 In)

. I

rhe needle

nuduated err.rb y

riEn b.adng b.nlEr

dlrly or damad€d 6nd .hould b€ dEn€d or

FDl.c!d.

13. M.asur6 both beannOs in

the same way and wiie the tett

3id€ b.adna mea.ureme

nen b 'E'

and lhe dght side

b6a ng maa6uEne.t.exl

to F'.

14. Slbstilule lhese values into the equation ro calcular6 rh6

lhickness ol the shim.

r v.l6 .ignilying A, B, c, D .nd H

a€ not glH,

Eg6rd th6

rr =

(A- c + D+ H)r0.0i + 1.97 + E+G

T2={B D

H)!O01 +2:07+F

Pt>2'l

Page 787 of 1254

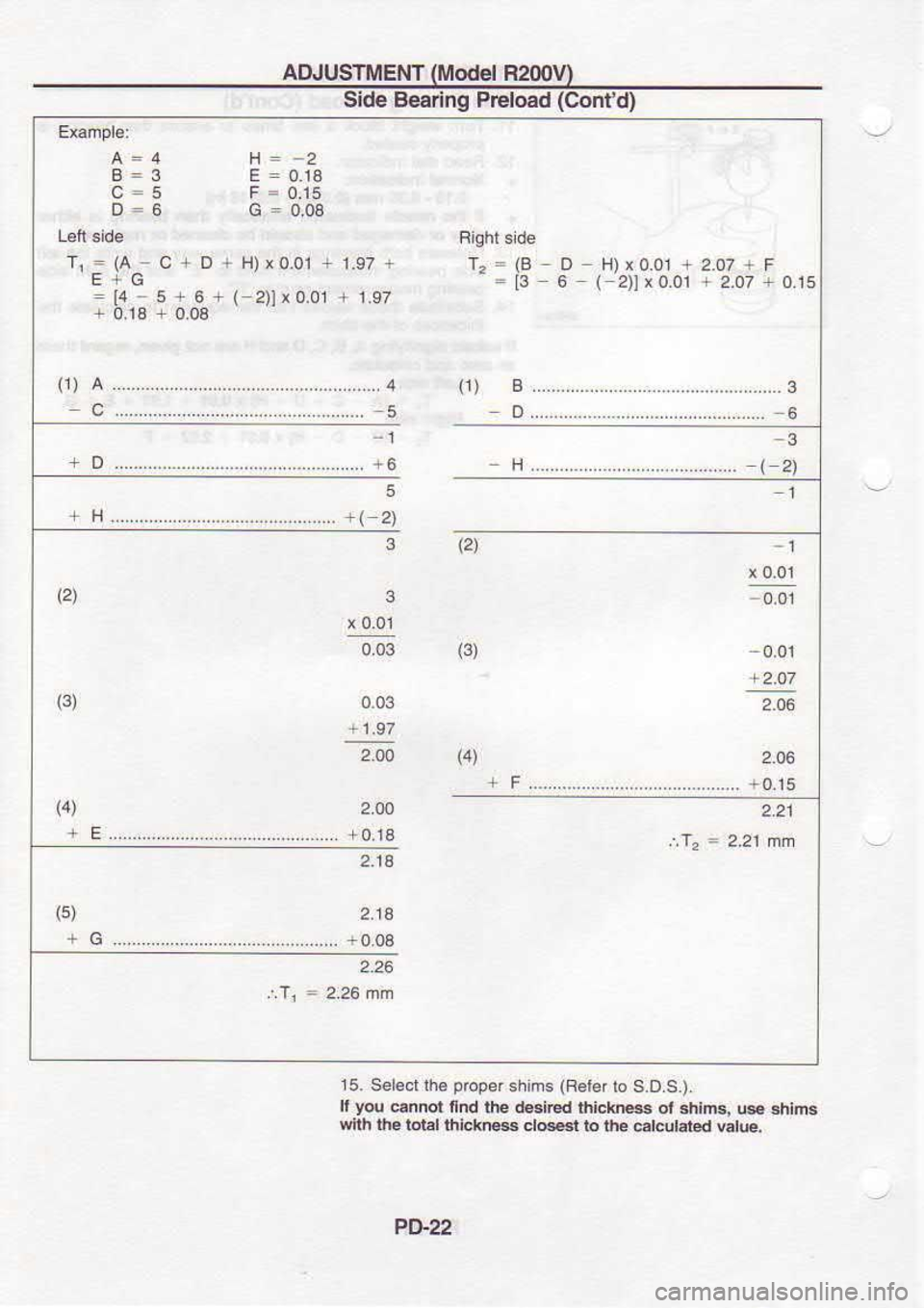

ADJUSTIi,IENT

(Model

R200V)

Side B€aring Preload (Conl'd)

O-6 G=

018

:0.15

- 0.08

T,E=1A-C+D =[4 5+6+

(

2)lr 0.01 +

L97 12=(B

D H)r0.01 +2.07+

F

= t3 6 (

2)lx 0.01 + 2.07 +

0.15

j

+D (1)

B

o

I

H 1

+( 2)

3

3 t2)

-1

t2) 0.03(3)

(3) 2.06

2.06

+ 0.15

2.00

2.00

r9.ll 2.14

2.14 (4)

(4) +E 2.21

(5)

15. Sel€cl lh€ p@per

shims (Retef

lo S.D.S

).

I yd

ennot fnd the .t siEd ihickn*

ot .hhs, u* shtms

whh ihe

total lhickr@ dc*r ro

the €tcutated vstue

PD.22

Page 788 of 1254

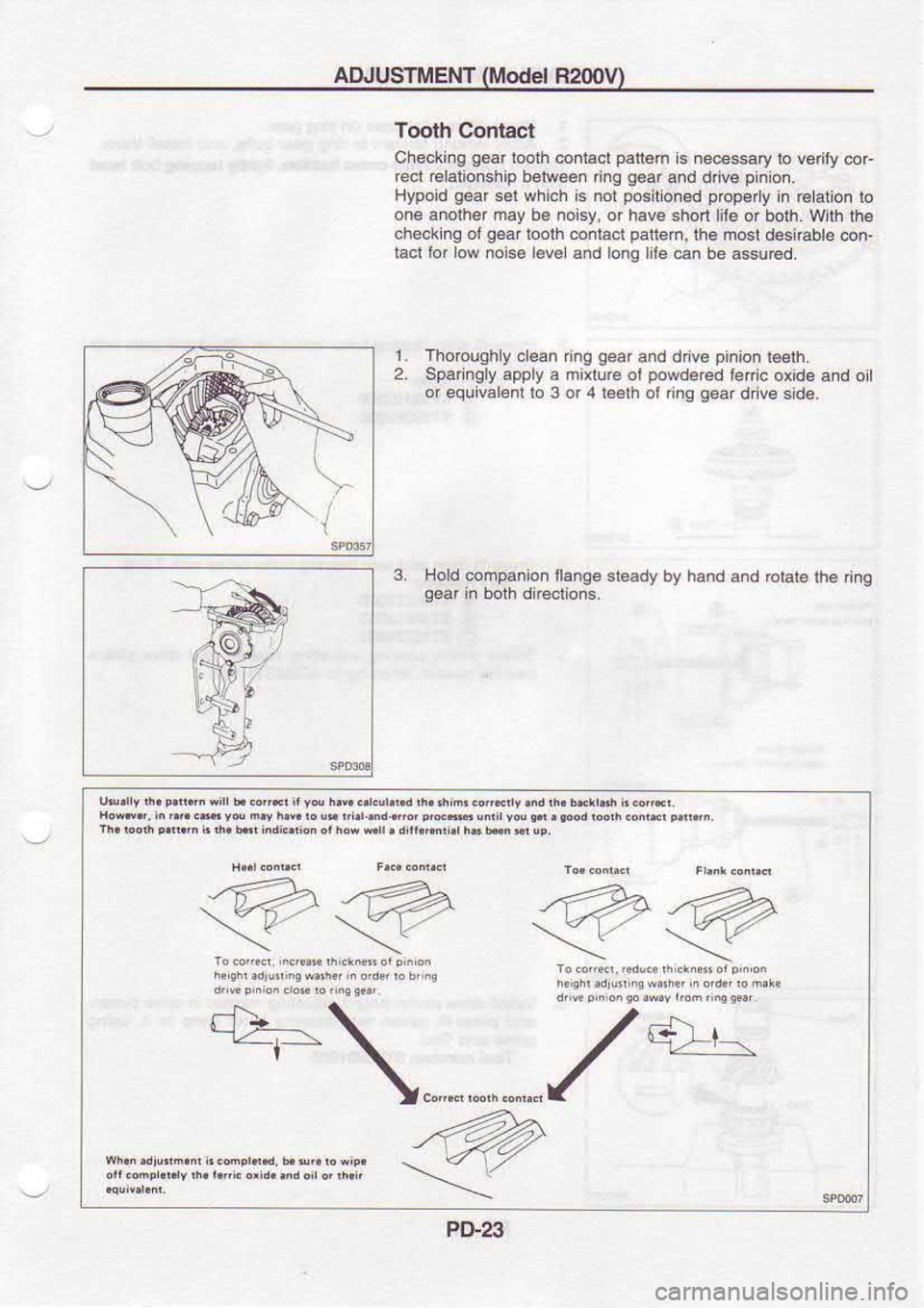

ADJUSTiIENT

(Model

R2mV)

Tooth Contact

Cheoking gear

l@lh 6.1acl patem

ls ne@ssary to v6

ry coF

red Elationship b6tw6.n ng g.ar

and ddve plnio..

Hypoid g6af

ser which i6 not positoned

propeny

in Gtstion

lo

on6 anolh€r may be

noisy, or have short lile of bolh. wirh

th€

checkinS of

9€.r toorh

@ntact pattem,

th€ mosl d6si6bte

@n-

tacl tor low nois€ l€v€

and lonq lile €n be assuGd.

1. Thooughy.l€an

ing qear

and dfve pinion

re6lh

2. Spadngly apply a mbaruro ol powdered

fedc oxide and o I

orequivalentlo 3 or 4l.€rh ol ring gearddve

sid€.

3. Bold.ompanion

llange steady by hand

and @tate lhe nng

oear in

both directons.

I'

1

€7q @@

.).^.^.-,"..:"""" \

;::"*,:;;:,*"*::, t;'"

l:"i;:Ti i;:"l

i'T:l:i 1 1..

|+>. ..

!2F ./ \-)_

\"."""""_.-,1

Pt!23

Page 789 of 1254

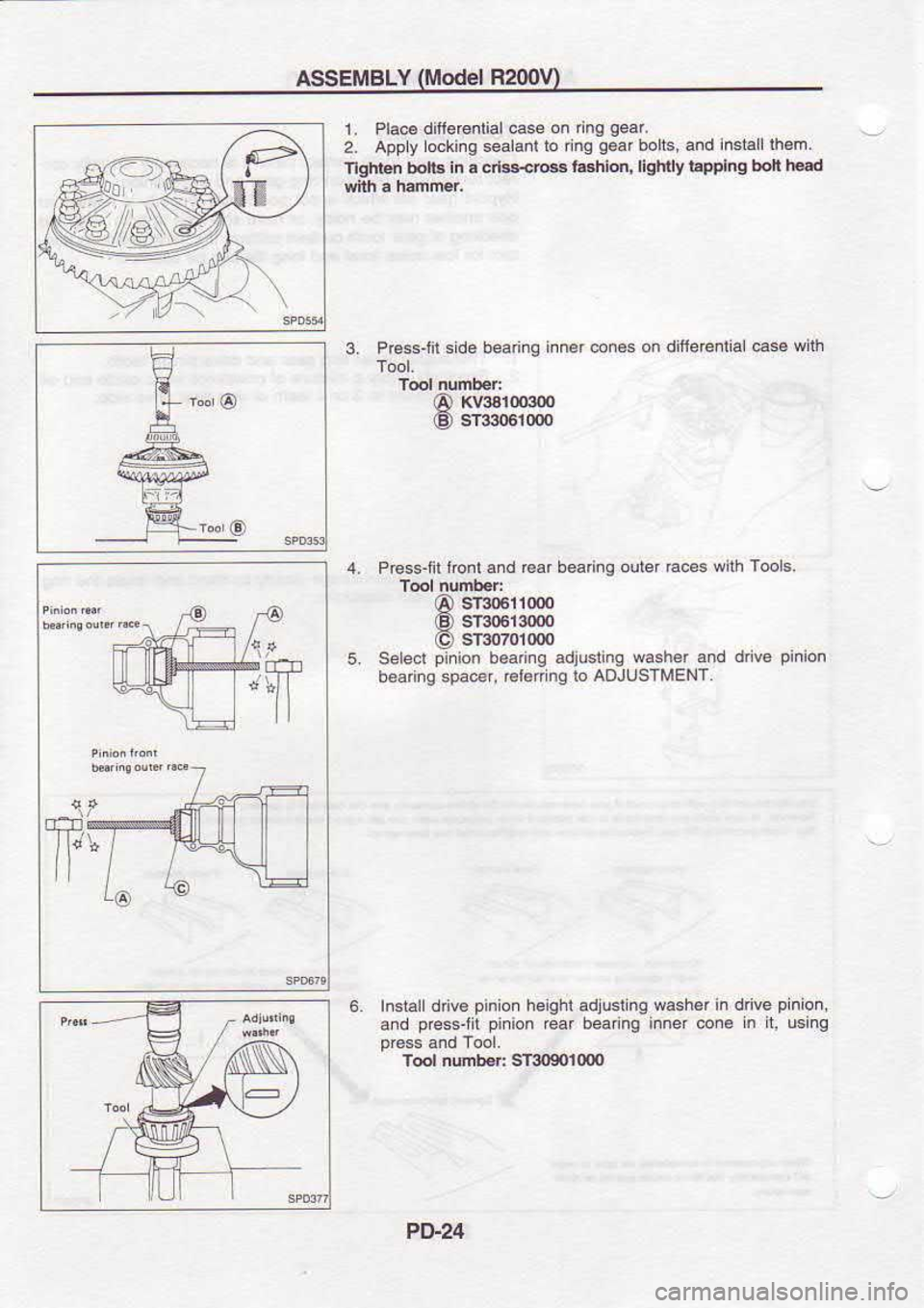

6/A>

ASSEMBLY

Mod€l

R200

1. Pla@ difie€ntalc6e

on rng gear.

2. Apply ocking

sealanl io dnq q4r

bolts, and inslalllh6m.

nghen borb in

a cd33'.|@ lshion,

liqhny t.pplng bot lFd

con.s on

drlierenial @s wlth

3.

5. P@ssjil

side bea nq innar

@ Kv33rGd

(9 STlltt061000

Prcss-fit ibnl and €ar

b€a rg

In$alld v. pinlon

heighl

a.d pres6jit

pinion

€ar

Tdl nunb€f Slll{m1040

st3o611@O

s'30613oOO

sTtto701000

Selecl pinion

b.a ng adjuslinq washer and

dnve pinion

bea ng spa@r, reletr ns

to ADJUSTMENT.

adjustng wa.her

in d ve pinio.,

b4dng innei cone h

[, using

Ftr

1l

PtI24

Page 790 of 1254

ASSEMBLY

(Modet

RAXIV)

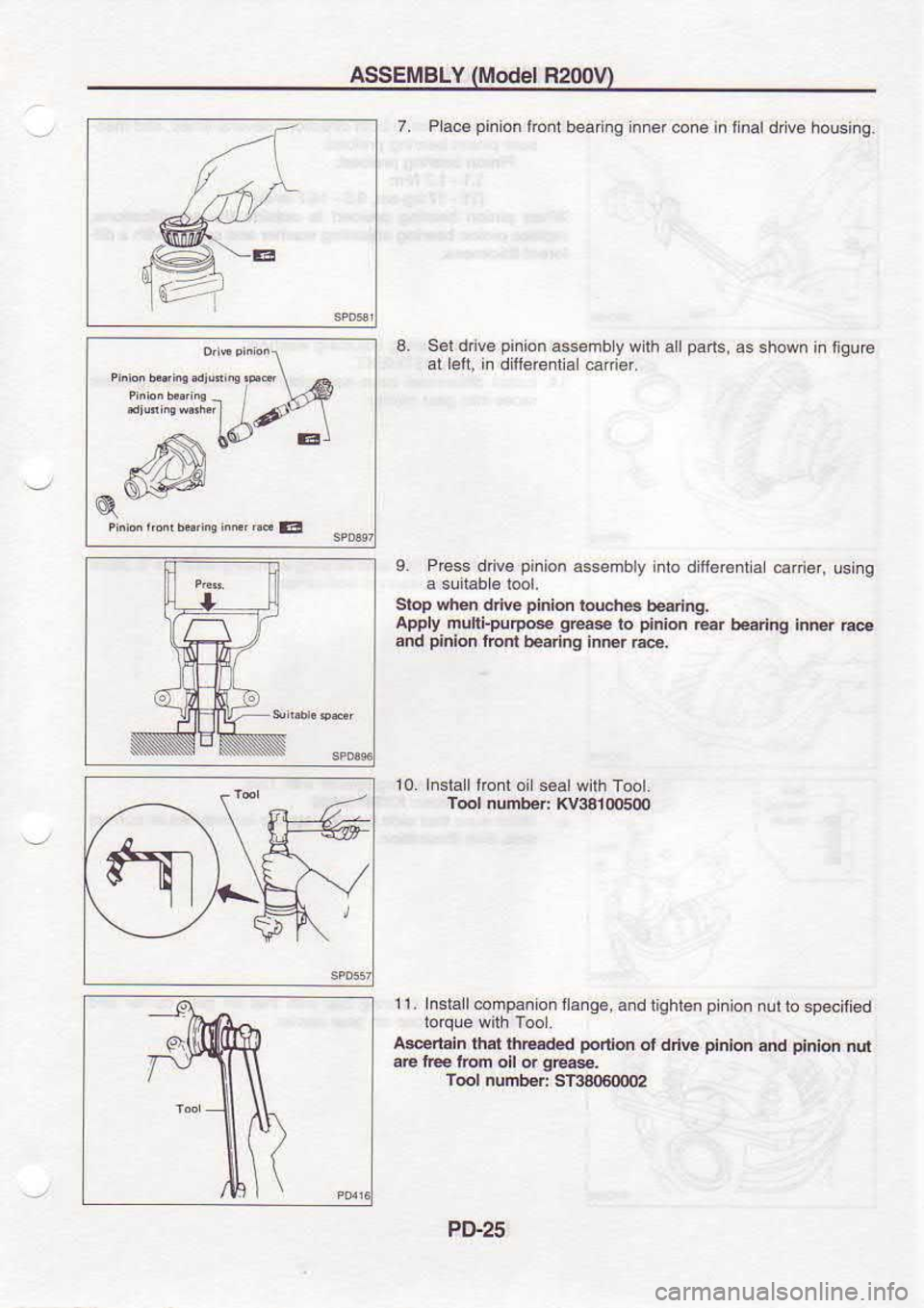

7. Plac€ pinion

lront beaing inner@r€ in tinalddve

housing.

a. Serdnv6pFion

arsembyw'lh dllp€rr6,

a6 shown ra hgure

at len.

i. dltterenlial €flier

9. P@$ dnv. pi.ion

assembly into diff6r6nt. cader,

using

S-top sir6 di!6 pinion

rouchB beadng,

Apply nu nputpoe g|€e

lo pinion

Er belrlng Inmr |8

and dnion rrcnr

be.dng inEr te..

10. hsla I lrcnt oil seal

with Toot.

Tol numbdi

Kv3a1m5m

11. l"sr.ll conp€nro. t

srq€ a.d rghten pirion.ullo

specitEd

Asdah th6t lhEded portd

of driE pt.ton

and pinid

tr(

a€ rb tlm

oll or

9@e.

t@l numb6r: 5T36060002

r.-,.q

- / \-#

-^'-*'l

1/* \

-e, 6@ Er

rnbirorbd4hry, {o

E

stue7

Pt!25