NISSAN SERENA 1993 Service Repair Manual

SERENA 1993

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57387/w960_57387-0.png

NISSAN SERENA 1993 Service Repair Manual

Trending: wiring, roof, washer fluid, wheel, jump start terminals, lock, diagram

Page 801 of 1254

LIMITED

SLIP

DIFFERET{TIAL (FOT

H1SOA

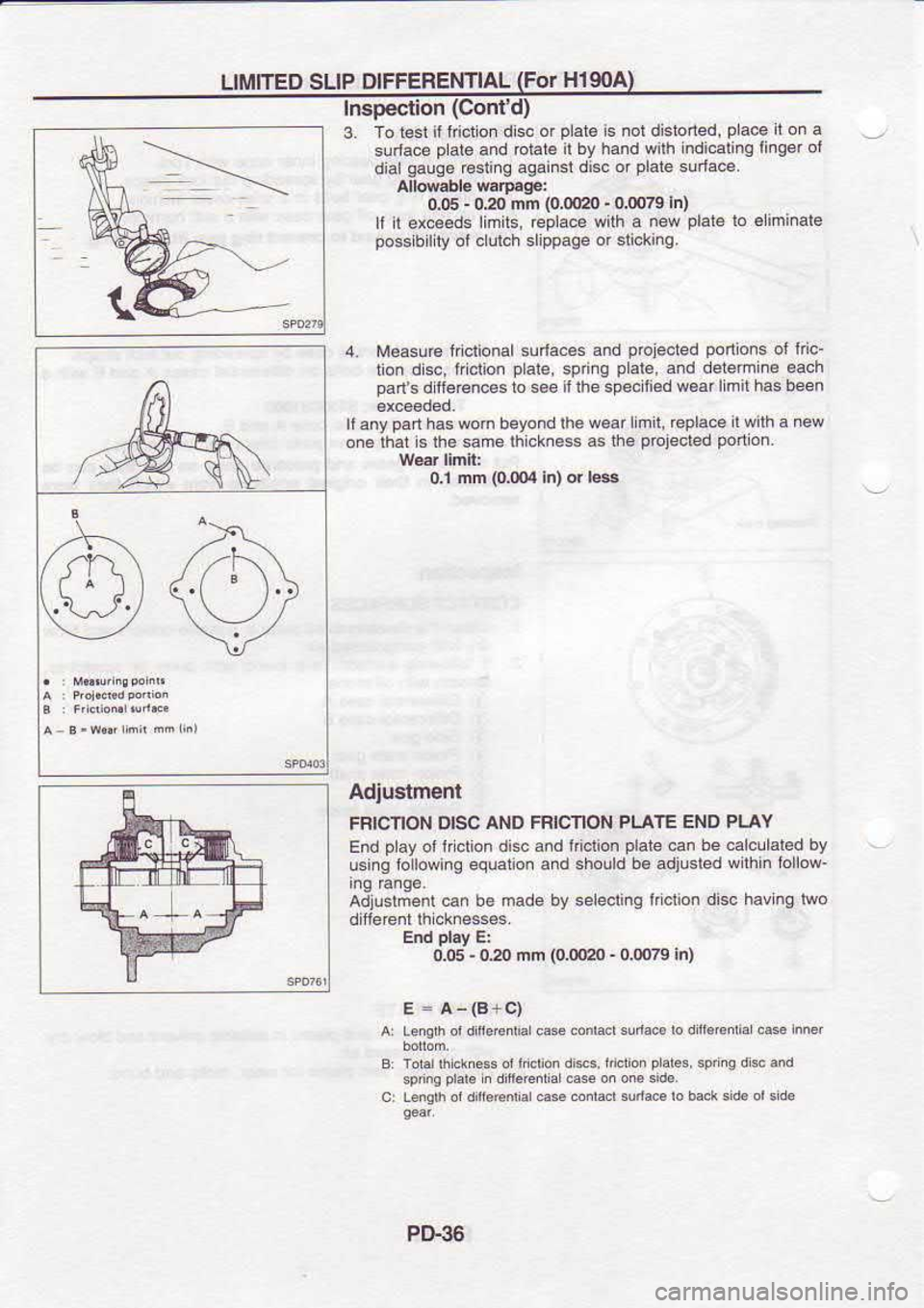

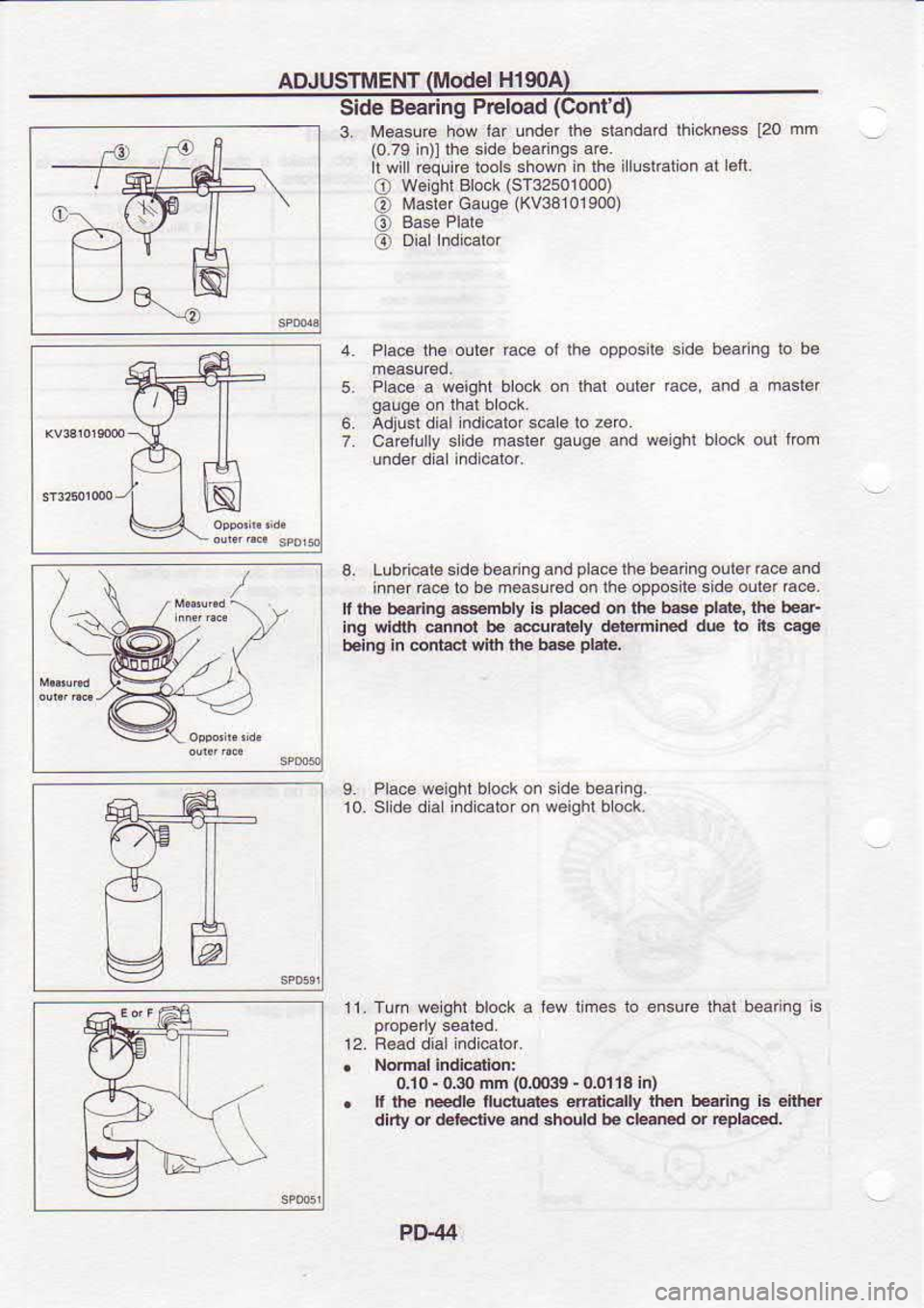

Inspec-tion (Cont'd)

3. To le.t il

l ouo. dl6c or plsi€

is nol distoded, place

I on a

su ace Dlar€ and

roiaie il

bv hand wilh lndicalinq li.ger

ot

dial saude €slins

againsr disc or pbre

surtace

Alldable Ep6gE:

0.05 -

0l0 mn (o,meo -

0.0079 |n)

lt il exce€ds limits,

reolace lith a

new plate

lo eliminate

possibllliy ol cLulch

slippage ot slicking.

4. Measu€

iiidional sud.ces and projecled ponions

of lrio_

ton dlsc, liclion plale,

sp ng plal6,

and detemine each

pan s difie@nces to

se6 if lhe spe.ilied w€ar

limil has been

ll any p6d

has @n beyond lhe

wear I mit, repla€

il wilh a new

one rhat

s lhe same ihlckness .s

dr. pojecled

port

on.

0.1 mm (0.m4

h) or res

Adiuatm€r FR|CNON DISC

AND FFICION PIATE END

PLAY

End p

av ol Jf ction disc and

l clion plate

en be @lcllal€d by

usinq lollowing equalion and should

bs adjlsled wilhin

lollow-

Adjuslmenl can

b€ made by selecling liclion

disc havlng lwo

0.05 -

0,m nn (0,0@O -

o.dts in)

E =

A-(B+c)

LenglholdiisGdja|6a.onlelsun

PD36

Page 802 of 1254

LIMITED

SLIP DIFFERENTIAL (For

H19OA)

Adiuslmenl (Cont'd)

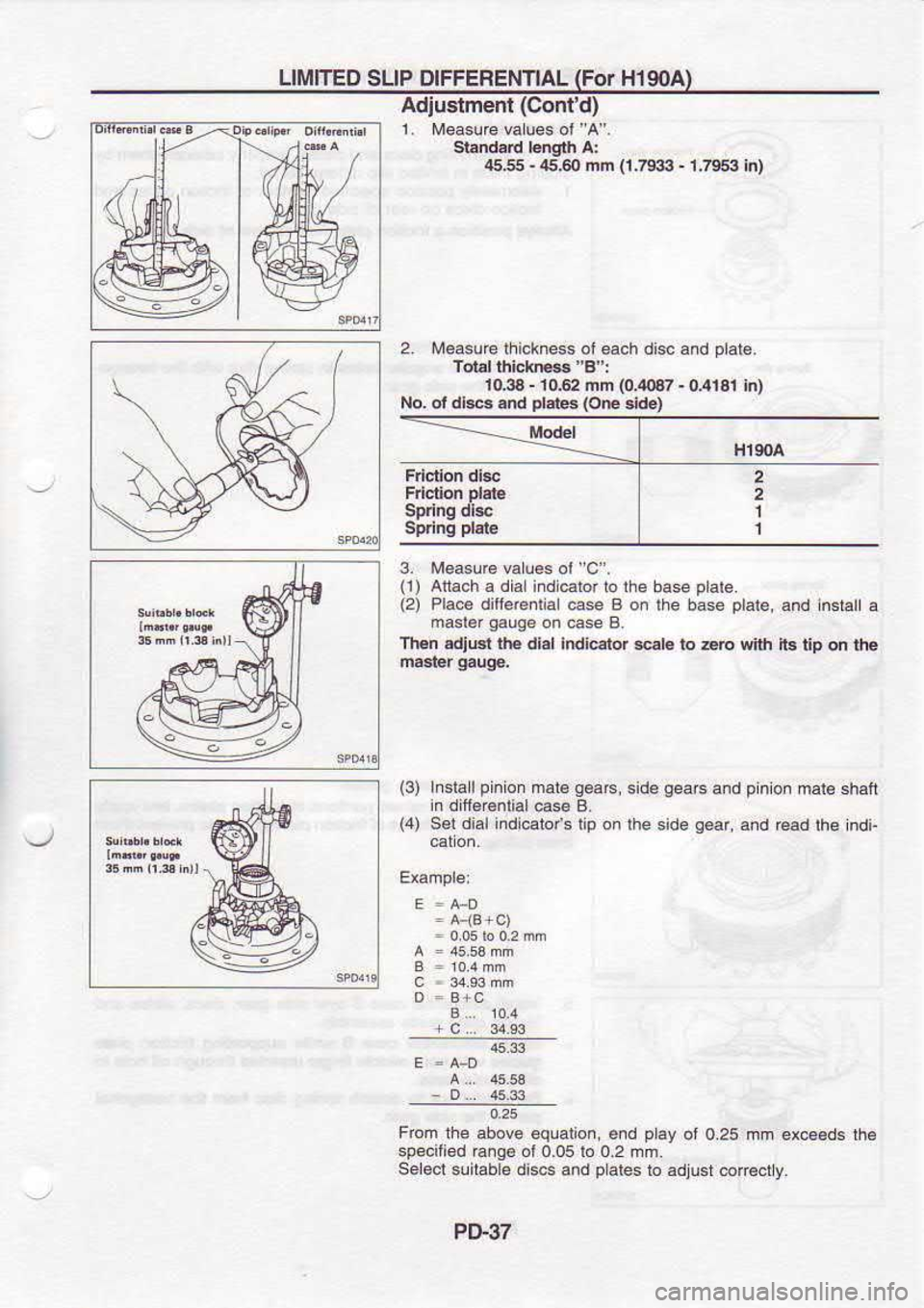

1 . Measurc va ues ot A .

sbndard l€ngih a:

t1555 -

'|5,60

nn

{1.79i|3 -

1.7953 in)

2 Measure

thickness ol each dis and plat€.

Total thickE "B":

10-39 -

10.52 nn (0,4037 -

0,4131 in)

No. ol dle8

and plal6

(Ore

slde)

3. Measurc valu$ ol "C".

(l) anach a di. ind

@tor to lhe base plale.

(2) Pla.6 difi66nlial

case B oi the base plal6,

masler gauge

on case B.

TlEn .djBr rhe

dlal lndletor sb ro are witr

(3) hsla I pin

on mal6

96a6, side gea6

and p

n of malB shatt

in ditl€Gnlial

case B.

(4) 36l dial ind

calo/s tip on lhe side q€ar,

and €ad

the ndi-

2

2

1

1

Fom the above eqlaron, end pay

ol0.25 mm ex.6eds

specitied 6nqe ol0.05lo 0.2

mm.

Selecl sliiab

e disci and p

ales b adjust.or6cty.

Pt>37

Page 803 of 1254

LIMITED

SLIP DIFFERENTIAL (FoT

Hl 9OA)

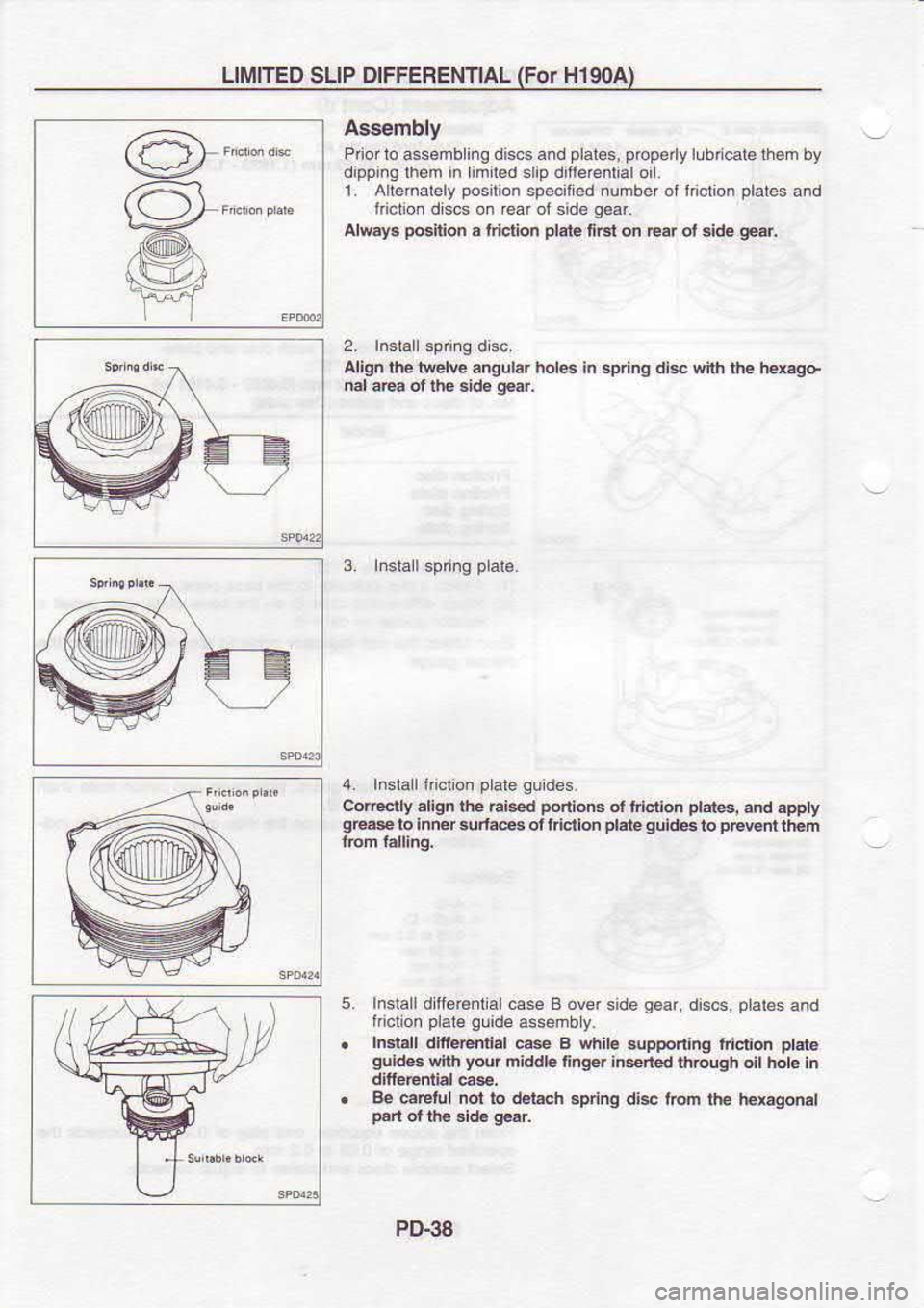

rA!.""-." \4/ A$€mbly

Priorto assemb ifg dis6 and plai6s,

pfop6 ylub

c.l€ th.m by

dppi.g lh6m in limlled slip difierenlialoil.

1 Altenalely posilion

specitied.umber of l.iclion plales

a.d

niclo. d scs on .ea. ol side g€ar.

Always po€irion

a tricrion plst€

6Bt o E.r oi 3lde gsi

Allg. lhe twdw angular hd6 in spring di$ whh E henge

ml a@ of lh€ sid. qeu.

4. InslaLllriction pale

guides.

Coreclly .llgn the €E€d porriona

ol lrlcdon plal6,

and .ppty

g€* io hner &rG@ ol ldcrld pl.le

gul.le€

to p|wit

tlEm

5. Inslall d fiercnr a €se B

over side gear,

discs, ptates

and

t cfon plate

Auide assefrby.

h3r.ll dfiGcndd ca* B whib supporting

trtcdon pt6r.

guk es qflh

yolr middb tings inened

threugh oit hote in

A€ €etul nol [o d.reh Epdng dl$

lbn the tEragd.l

PI)34

Page 804 of 1254

LIMITED

SLIP DIFFERENTIAL (FoT

H19OA}

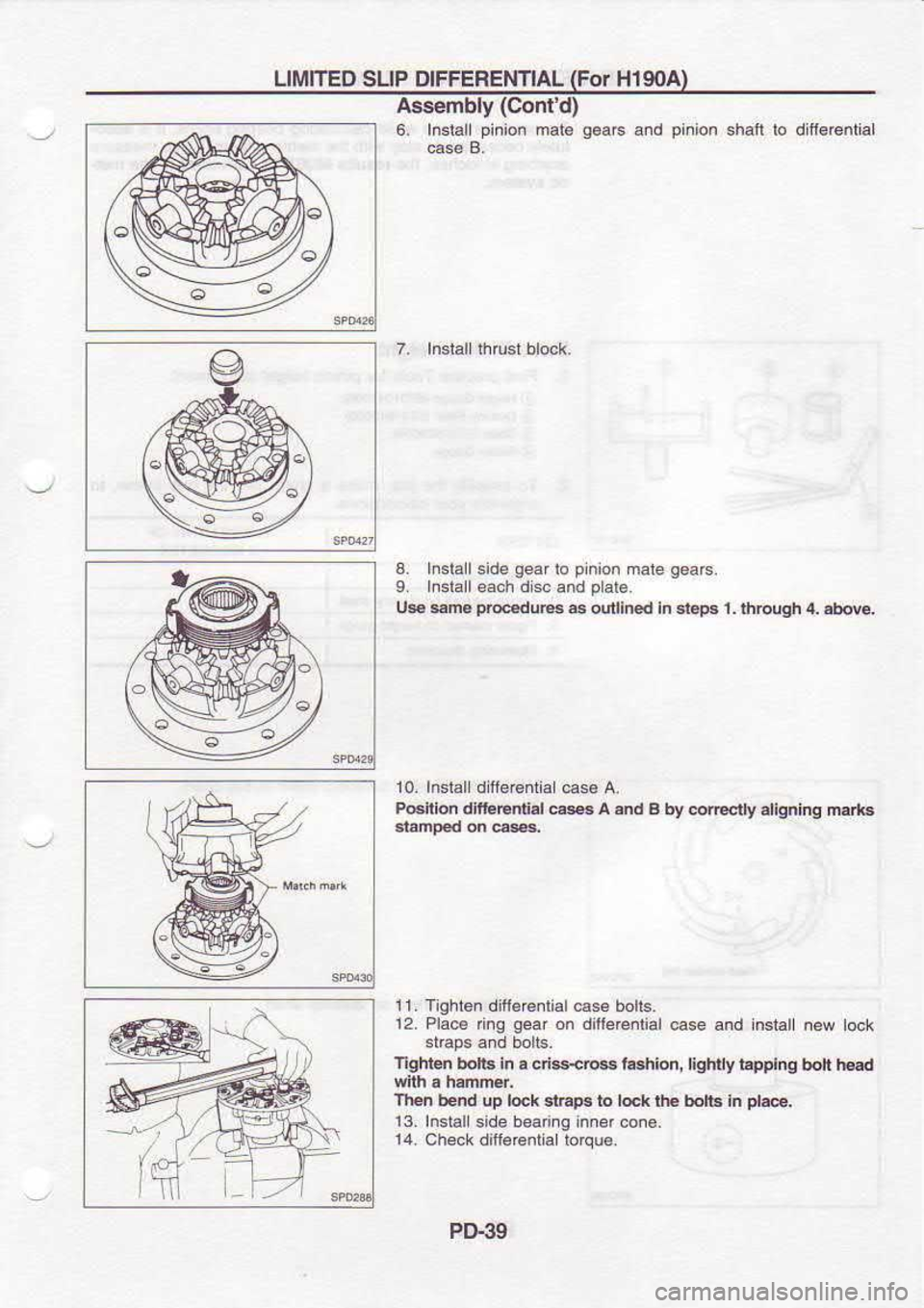

Assembly (Cont'O

6. Inslall pinion

mal6 gea6

a.d pinion

shan b dift€.onlral

a. Inslalside gearto

pinion

ma€ gearc.

9. Inslalreach

disc and pale.

Us *n. pro.€dlE

6 outlned in st€p€ l. though 4

.b*.

10. lnslall dllereda es€ A.

PG&ion difi.Enrid es a .nd B

by @retly atlgning rod€

1 1 . Tighlon dili€€nlial c.s€ bolls

12. Pla6 ng gear

on difierential

€se and insiall new lock

Tlghten bolb in a cds*|@ l*hion, liglnly

t pplng

bo[ h€'d

Then bend up lo.k ddps to lek rlE boh6 In pl.e.

13. Insiar

side beaing inner @ne.

14. Check ditleGnlial torqu6.

PD€9

Page 805 of 1254

AINUSTMENT

(Model

H19OA)

To avoid co.tusioh rtile calcllating beadng shlm.,

il is abso-

lutely n46ssary to stay wilh ihe melic srslem. ll you

m€surc

anylhing in

inch€s, tlE Buft3 MUST be @vqled io

dE nEr-

Drive Pinlon Heigh

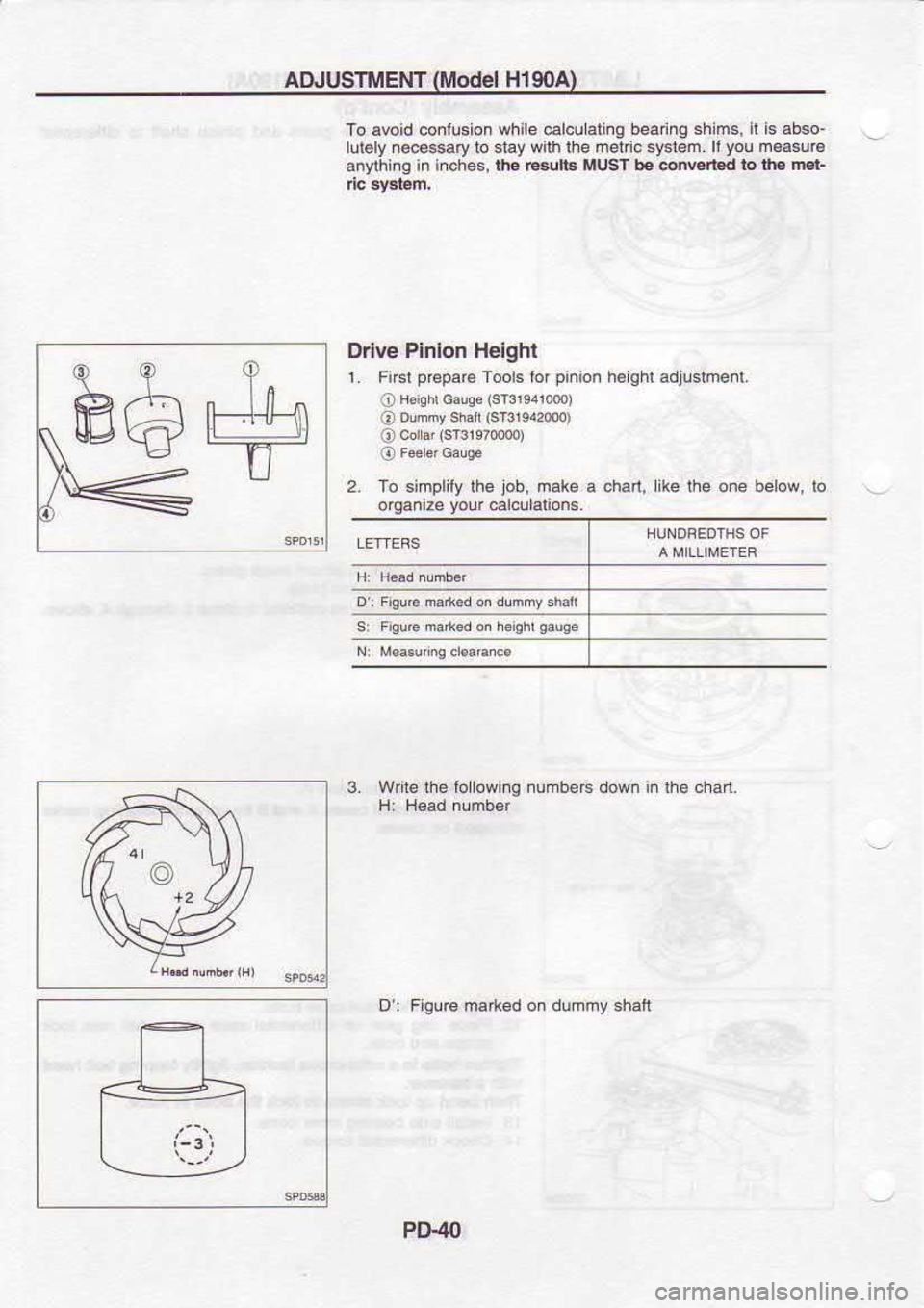

1 Fi6l p€par€

Tool.lor pinion

h€qhtadjushenl

o N€ishr

sau@ (sB'04i0o)

o ounny

shdh (sB1o4m)

2. To simplily lhe job,

make a chan, like lhe one below, lo

organize your

€lculalions.

Wite the lollowing numbeE dow. in lhe chan.

O': Frglre ma*ed on dummY shan

3.

h,&

$r' (gl

PD4O

Page 806 of 1254

ADJUSTT

ENT (lilodel

H190A)

Drive Pinion Heighl (Cont'd)

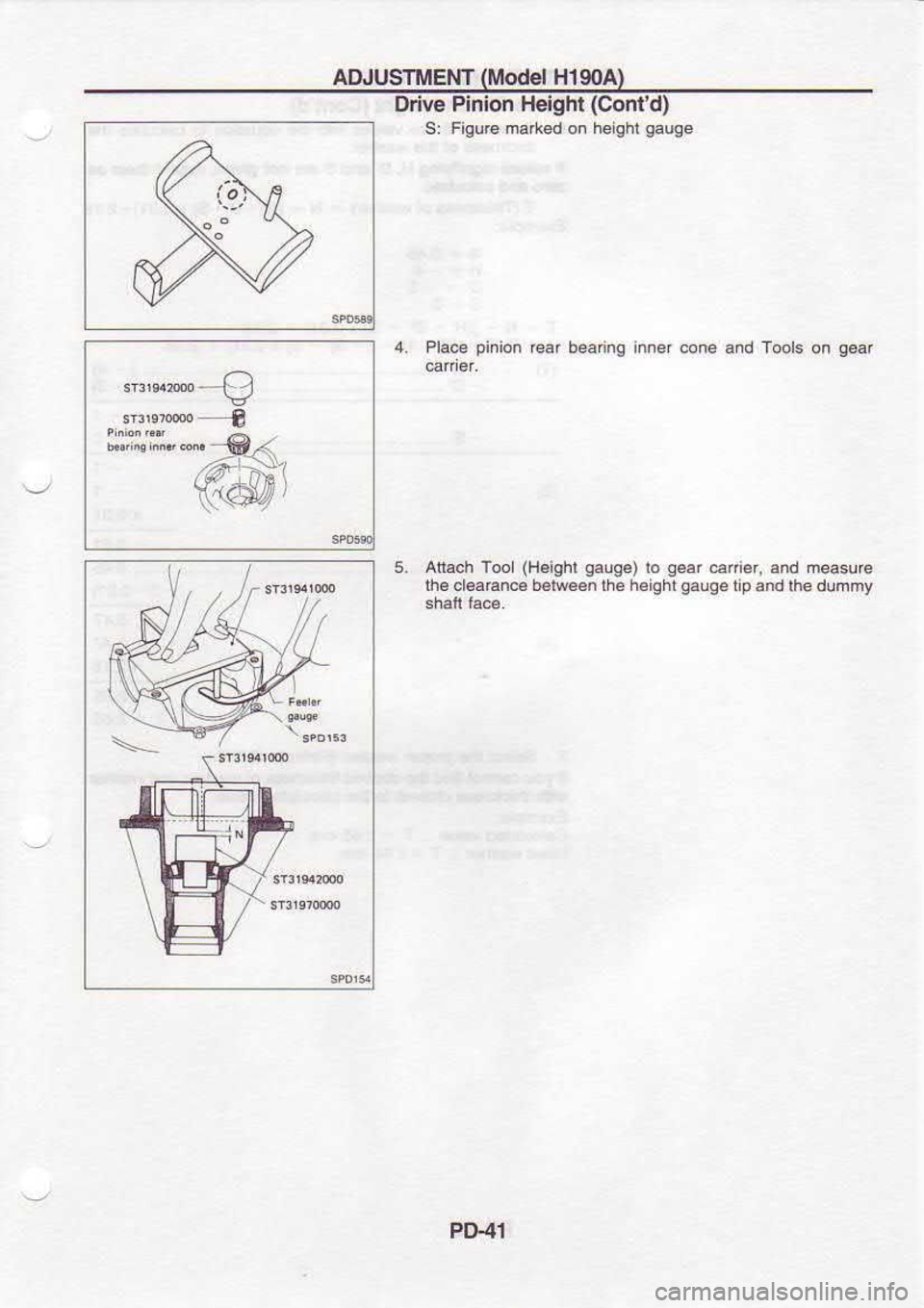

S: Figurc ma*ed on heigftgauge

4. Pla@ pifion

rear beaing i.ner cone and Tools on gear

.'.'"-,-€

h,.sii!@N pr<

aalr;1

\{4/ r

5. Af6ch Tool (Heighl

gauge)

lo gear

carrer, and measure

lh€ clearance boftleen tho heightgalge

lip and fie dlmmy

Pt!41

Page 807 of 1254

AAJUSTMENT

(ilodel

HISOA)

N =

0.46

H= 4

D'= -3

s=0

T =

N -

[(H -

D'- S)x0.011 +

2.13

= 0,46 I{( 4) (

3) 0} x0.011 +

2.13

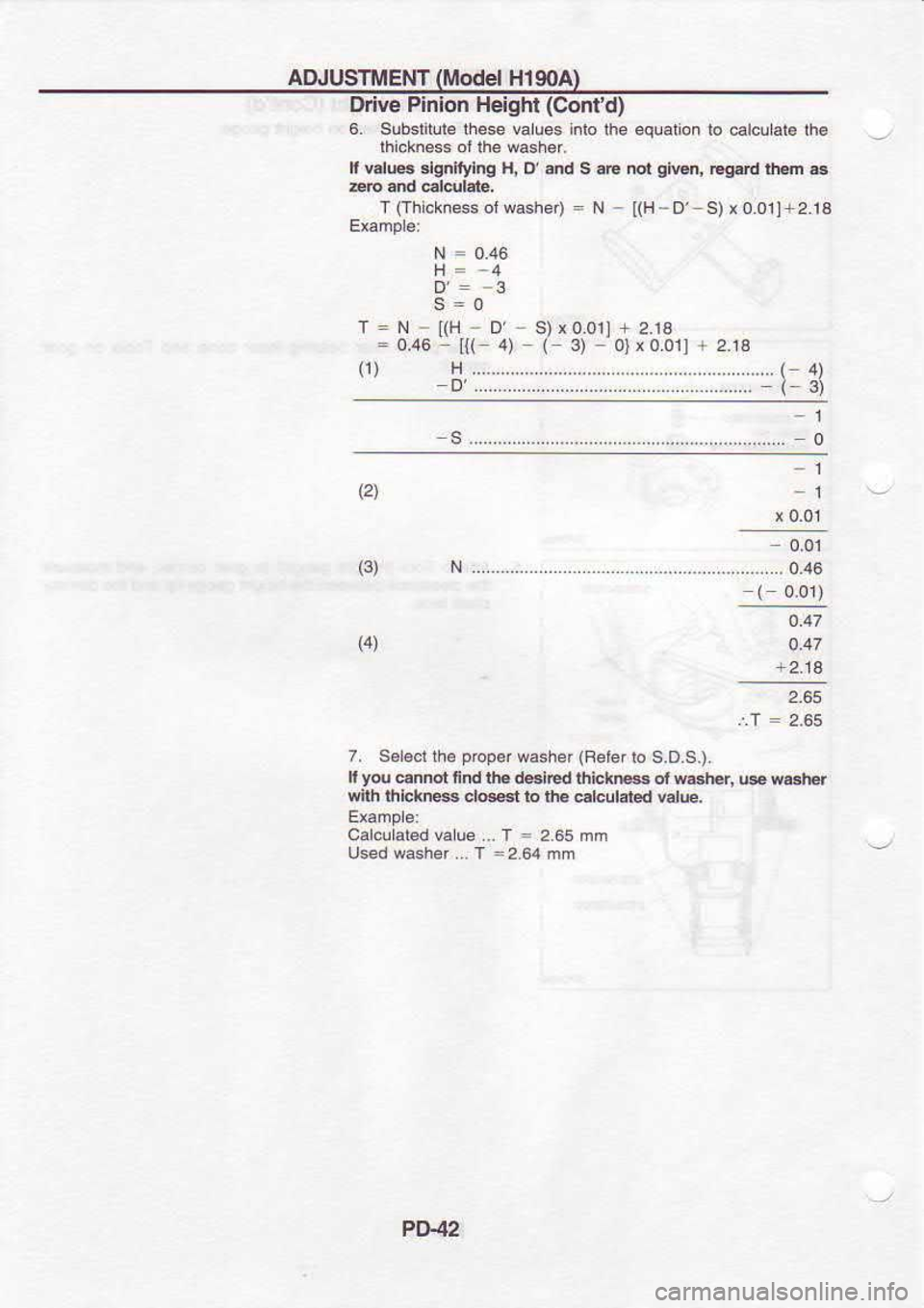

Ddve

Pinion Height (Conl'd)

6. SubsliM.lhese values inlo lhe equation lo €lculat€ rh€

lhlckness ot lhe lasher.

t vd€ slgnrylng H, D. and S aE not gt€n,

Egsd nEn e

T(lhrck.essolwashe0 -

N -

(H-D' s)x0,011+2.13

(1) H

D'

s -1

0.01

............-...... 0.40

( 0.01)

+2.14 2.65

:.T -

2.65

7. S€l€cl the poper

w4her (Fete.

to S.D.S.).

t yd

ennot fnd

ttF d6lre

@ m3rEr

wfth rhbk s d@*t to rh6 erculated

val@,

calcllated vatue... T =

2.55 mm

used washer... T =2.64

mm (4)

(3)

(2)

(3)

{4)

Pt!4il

Page 808 of 1254

AD,IUSTMENT

ModelH19OA

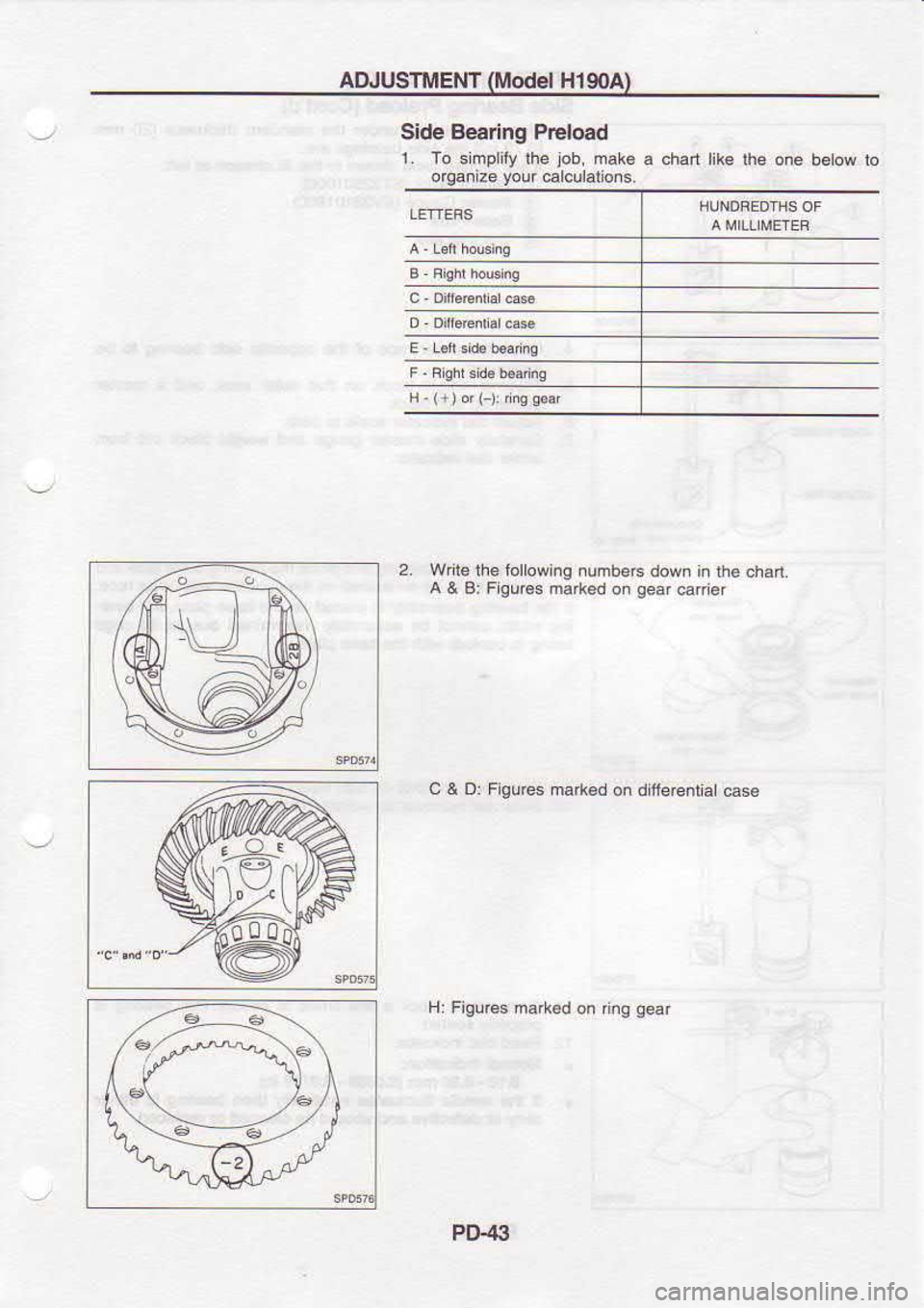

Side Be€ring Preload

1. To simplify the job,

mak6 a chart like

lhe one beiow lo

organize your

calculslions.

2. wfite

lhe tollowing nunbers

dow. in the chart.

A & B: Figur6s ma*ed

o. gear

€ref

C A D Figues

marked on

H Figlres

mar[€d on nng gear

PD4i'

Page 809 of 1254

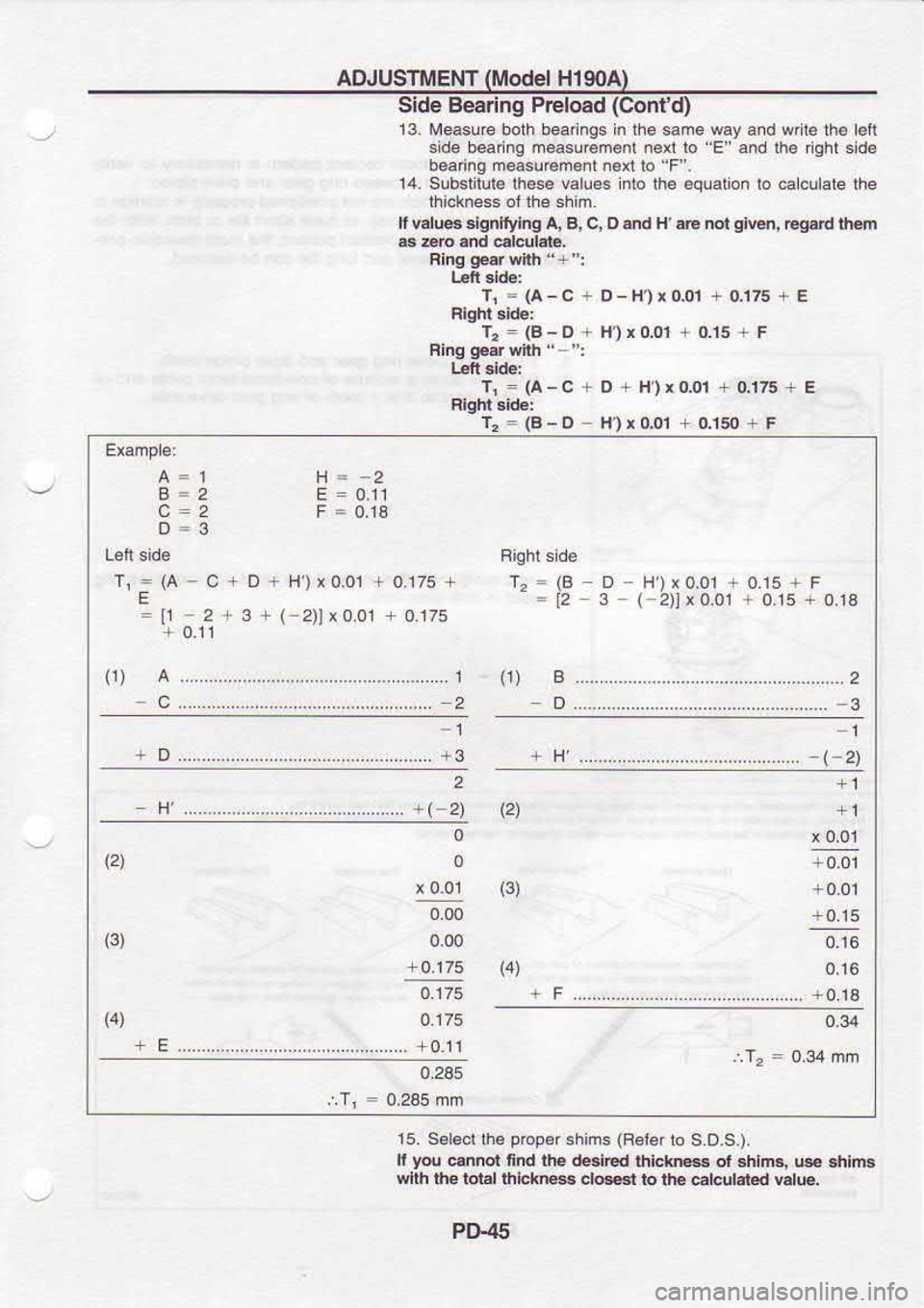

ADJUSTMENT

(Model

H190A

l- ,, Side

Be€ring Preload (Cont'd)

3. Measure how laf

under lhe slandad lhckness

[20 mm

(0.79 in)lfte side b€annss

are.

ll wiLlGquire tools shown

n lhe ilustration al

letl

O wolqhl

Block (ST32501000)

O Marl€r

Gause (xv331o19oo)

A. Lubicale 6

d€ beadng and

da@the bearn9oul.r

ra€and

inner6c6 rob6

m6asu rcd on lhe opposile side olld

a€.

ll the ba.dng.embly b plaed

d ltF bte pLL,lh6

beaF

ing wldth €nnot be

suErdy d.Lrnined dE b n5

ega

b.ing in contacl whh tie b4 pl.r..

9 Pla€

weight block or sde bea ng.

10. Slde dia indi€tor

on weighl b ock.

P

ace th€

ouler ra@ o1 fie opposile s

do

Placo a weighl block on

lhal outer ra@,

adjusl dial ndicalorscae to 2ero

Carelllly side

masler gauge

and weiqhl

Tum weghl block a

few limes to ensure thal beaing ls

0.1O -

0.lll nn (0.m39 -

Ofi 1a In)

t ttE needle iuctualqs en llelly llEn

b.5ri.g i5 .ilh€r

diny or dehtire and should be derEd d

€plac.d.

'12.

Pt!44

Page 810 of 1254

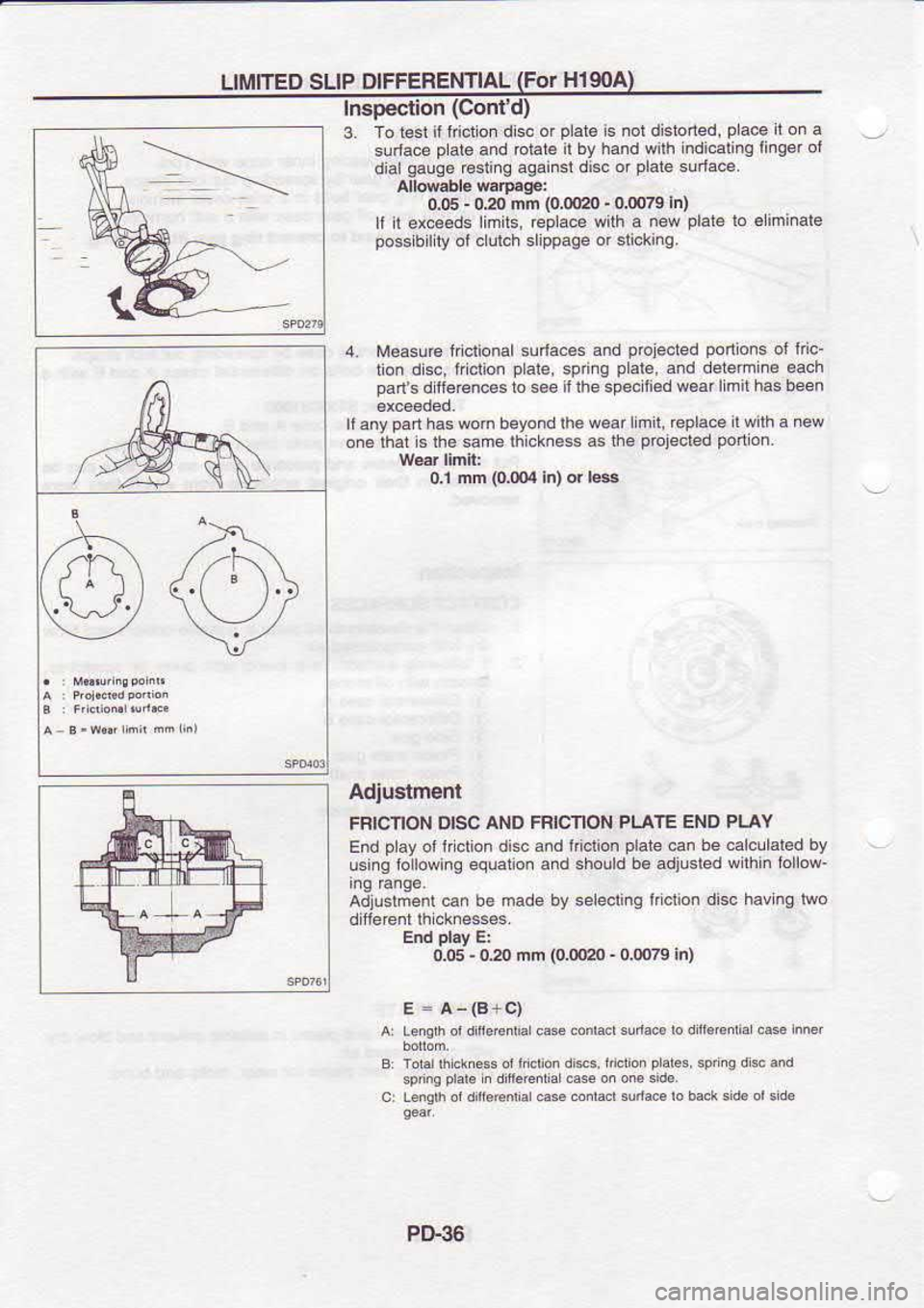

ADJUSTMENT

(Model

H190A)

Side Be€ring Preload (Conl'd)

13. t'reasuro both b@nngs in tho same way and w t6lh616fr

side beadns measur6m6 n€n b 'E"

and lh€ dght sid6

b€a ng m6asu€me.1.€n b 'F".

14. Substlur.lh€s valles into

th. equation to ca culate the

thickness oi the shim.

rv.lu63lgnlMnoA,B,qDandH.EnotsiH,Eg.rdrh€m

n =

(A-c + D-H)x 0.01 +

0.175 + E

T2 -

(B-D +

H')xO01 + O15 + F

Tl =

G-c +

D + H')xo.ol +

0.175 +

E

T2=(B-O H') r O.0l +O1aO+F

B

D

E =tr

c =1

=3 H

E =2

= 0.14

c+ D +

H) x0.01 +

0.175 +

o+( 2)lx0.0r +0.17s T":

(B

D

-12 3(

2)1x0.01 +

0.15 +

0,13

1 0)B

o

2

3

+D +H

H' 2

+t 2)

t2) +1

+1

(21 (3)

(3) 0.00

+0.175 0,16

(4)

0.175

+0.11

+E

0.285

15. S6l6cr lh€ pbp6f

shims (Beter

to S.D.S.).

I yd

ennol fnd lhe

de.lred thicbe ol bhin4 ue

3l m.

whn the tolal lhlclo* dosr ro

lhe eldlated value,

Pt!,15

Trending: lock, set clock, turn signal, differential, fuel pressure, warning light, weight