check engine NISSAN TEANA 2003 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: TEANA, Model: NISSAN TEANA 2003Pages: 3502, PDF Size: 74.56 MB

Page 1238 of 3502

![NISSAN TEANA 2003 Service Manual DI-32

UNIFIED METER AND A/C AMP

DTC [U1000] CAN Communication CircuitBKS002B1

1. CHECK CAN COMMUNICATION

1. Select “CAN DIAG SUPPORT MNTR” mode for “METER A/C AMP” with CONSULT-II.

2. Pri NISSAN TEANA 2003 Service Manual DI-32

UNIFIED METER AND A/C AMP

DTC [U1000] CAN Communication CircuitBKS002B1

1. CHECK CAN COMMUNICATION

1. Select “CAN DIAG SUPPORT MNTR” mode for “METER A/C AMP” with CONSULT-II.

2. Pri](/img/5/57392/w960_57392-1237.png)

DI-32

UNIFIED METER AND A/C AMP

DTC [U1000] CAN Communication CircuitBKS002B1

1. CHECK CAN COMMUNICATION

1. Select “CAN DIAG SUPPORT MNTR” mode for “METER A/C AMP” with CONSULT-II.

2. Print out CONSULT-II screen.

>> Go to “LAN SYSTEM”. Refer to LAN-49, "

CAN System Specification Chart" .

DTC [B2202] Meter Communication CircuitBKS002B2

1. CHECK CONNECTOR

Check combination meter, unified meter and A/C amp. and terminals (combination meter side, unified meter

and A/C amp. side and harness side) for looseness or bent terminals.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal or connector.

2. CHECK METER/GAUGES VISUALLY

Does the pointer on the meter/gauge fluctuate at the engine start?

Is the fluctuation acceptable?

YES >> GO TO 3.

NO >> GO TO 6.

3. CHECK CONTINUITY COMMUNICATION CIRCUIT (TX: COMBINATION METER)

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and unified meter and A/C amp. connector.

3. Check continuity between combination meter harness connector

M70 terminal 18 and unified meter and A/C amp. harness con-

nector M41 terminal 19.

4. Check continuity between combination meter harness connector

M70 terminal 18 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4. CHECK VOLTAGE OF UNIFIED METER AND A/C AMP.

1. Connect unified meter and A/C amp. connector.

2. Turn ignition switch ON.

3. Check voltage between combination meter harness connector

M70 terminal 18 and ground.

OK or NG

OK >> GO TO 5.

NG >> Replace unified meter and A/C amp. Refer to DI-34,

"Removal and Installation of Unified Meter and A/C

Amp." . 18 – 19 : Continuity should exist.

18 – Ground : Continuity should not exist.

SKIA8726E

18 – Ground : Approx. 5 V

SKIB1049E

Page 1251 of 3502

WARNING LAMPS

DI-45

C

D

E

F

G

H

I

J

L

MA

B

DI

Oil Pressure Warning Lamp Stays Off (Ignition Switch ON)BKS001SS

1. CHECK IPDM E/R OUTPUT SIGNAL

Activate IPDM E/R auto active test. Refer to PG-21, "

Auto Active Test" .

Is oil pressure warning lamp blinking?

No malfunction detected>> GO TO 5.

Malfunction detected>> Go to 2.

2. CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select “IPDM E/R” on CONSULT-II, and perform self diagnosis of IPDM E/R. Refer to PG-19, "

CONSULT-II

Function (IPDM E/R)"

Self-diagnosis result content?

YES >> GO TO 3.

NO >> GO TO PG-19, "

SELF-DIAG RESULTS" in “IPDM E/R”.

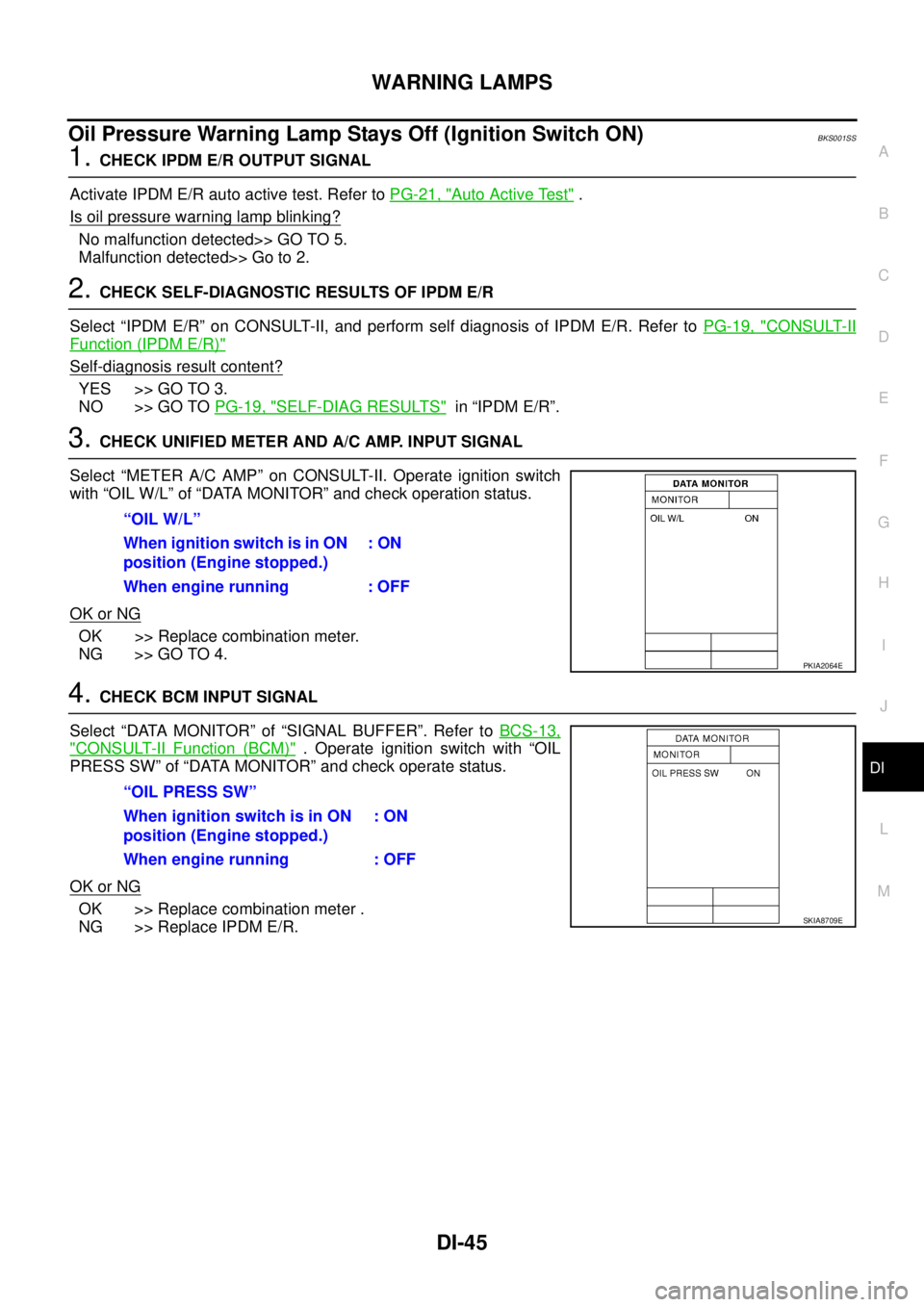

3. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

Select “METER A/C AMP” on CONSULT-II. Operate ignition switch

with “OIL W/L” of “DATA MONITOR” and check operation status.

OK or NG

OK >> Replace combination meter.

NG >> GO TO 4.

4. CHECK BCM INPUT SIGNAL

Select “DATA MONITOR” of “SIGNAL BUFFER”. Refer to BCS-13,

"CONSULT-II Function (BCM)" . Operate ignition switch with “OIL

PRESS SW” of “DATA MONITOR” and check operate status.

OK or NG

OK >> Replace combination meter .

NG >> Replace IPDM E/R.“OIL W/L”

When ignition switch is in ON

position (Engine stopped.): ON

When engine running : OFF

PKIA2064E

“OIL PRESS SW”

When ignition switch is in ON

position (Engine stopped.): ON

When engine running : OFF

SKIA8709E

Page 1252 of 3502

DI-46

WARNING LAMPS

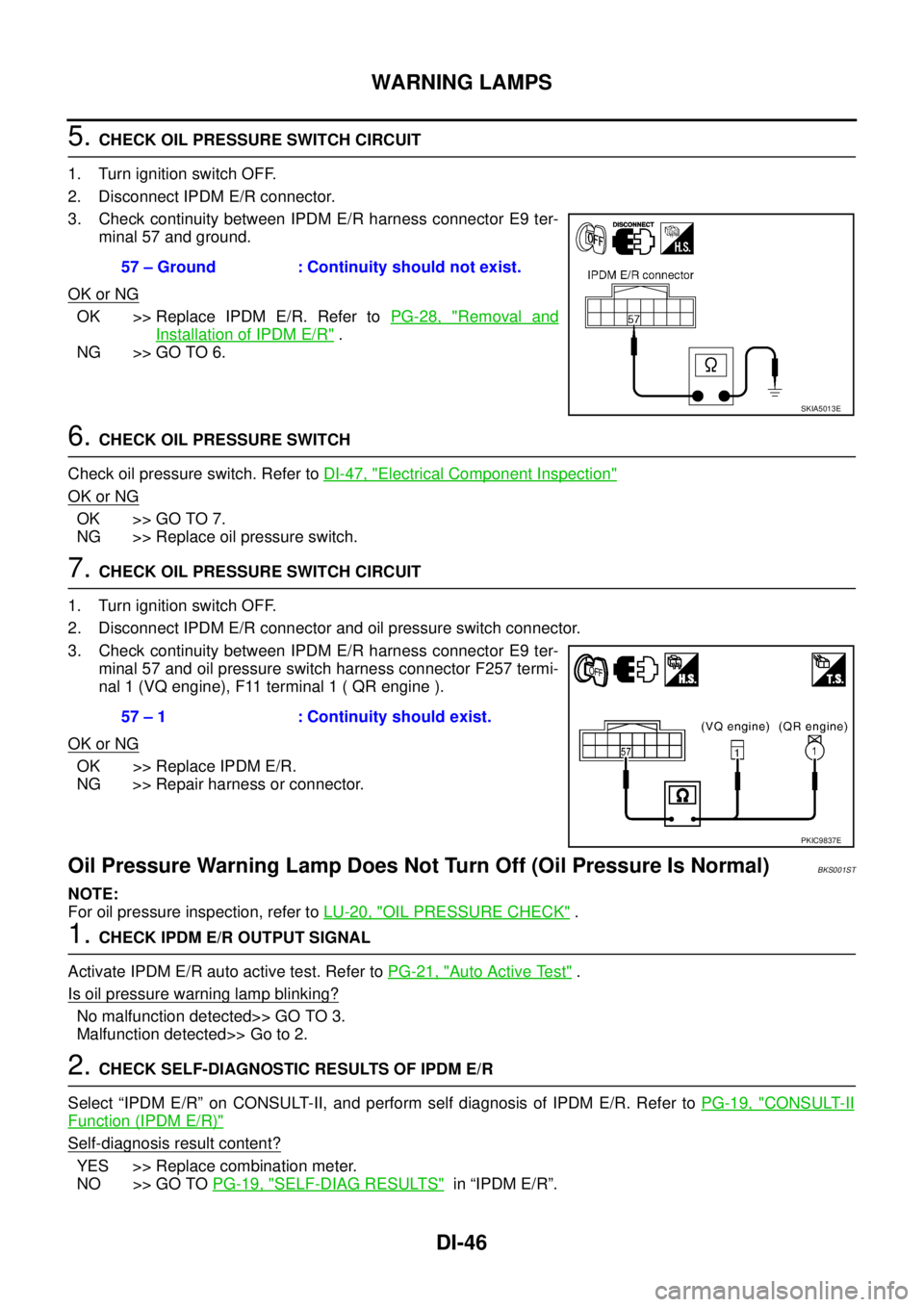

5. CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector E9 ter-

minal 57 and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> GO TO 6.

6. CHECK OIL PRESSURE SWITCH

Check oil pressure switch. Refer to DI-47, "

Electrical Component Inspection"

OK or NG

OK >> GO TO 7.

NG >> Replace oil pressure switch.

7. CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector and oil pressure switch connector.

3. Check continuity between IPDM E/R harness connector E9 ter-

minal 57 and oil pressure switch harness connector F257 termi-

nal 1 (VQ engine), F11 terminal 1 ( QR engine ).

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair harness or connector.

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)BKS001ST

NOTE:

For oil pressure inspection, refer to LU-20, "

OIL PRESSURE CHECK" .

1. CHECK IPDM E/R OUTPUT SIGNAL

Activate IPDM E/R auto active test. Refer to PG-21, "

Auto Active Test" .

Is oil pressure warning lamp blinking?

No malfunction detected>> GO TO 3.

Malfunction detected>> Go to 2.

2. CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select “IPDM E/R” on CONSULT-II, and perform self diagnosis of IPDM E/R. Refer to PG-19, "

CONSULT-II

Function (IPDM E/R)"

Self-diagnosis result content?

YES >> Replace combination meter.

NO >> GO TO PG-19, "

SELF-DIAG RESULTS" in “IPDM E/R”. 57 – Ground : Continuity should not exist.

SKIA5013E

57 – 1 : Continuity should exist.

PKIC9837E

Page 1253 of 3502

WARNING LAMPS

DI-47

C

D

E

F

G

H

I

J

L

MA

B

DI

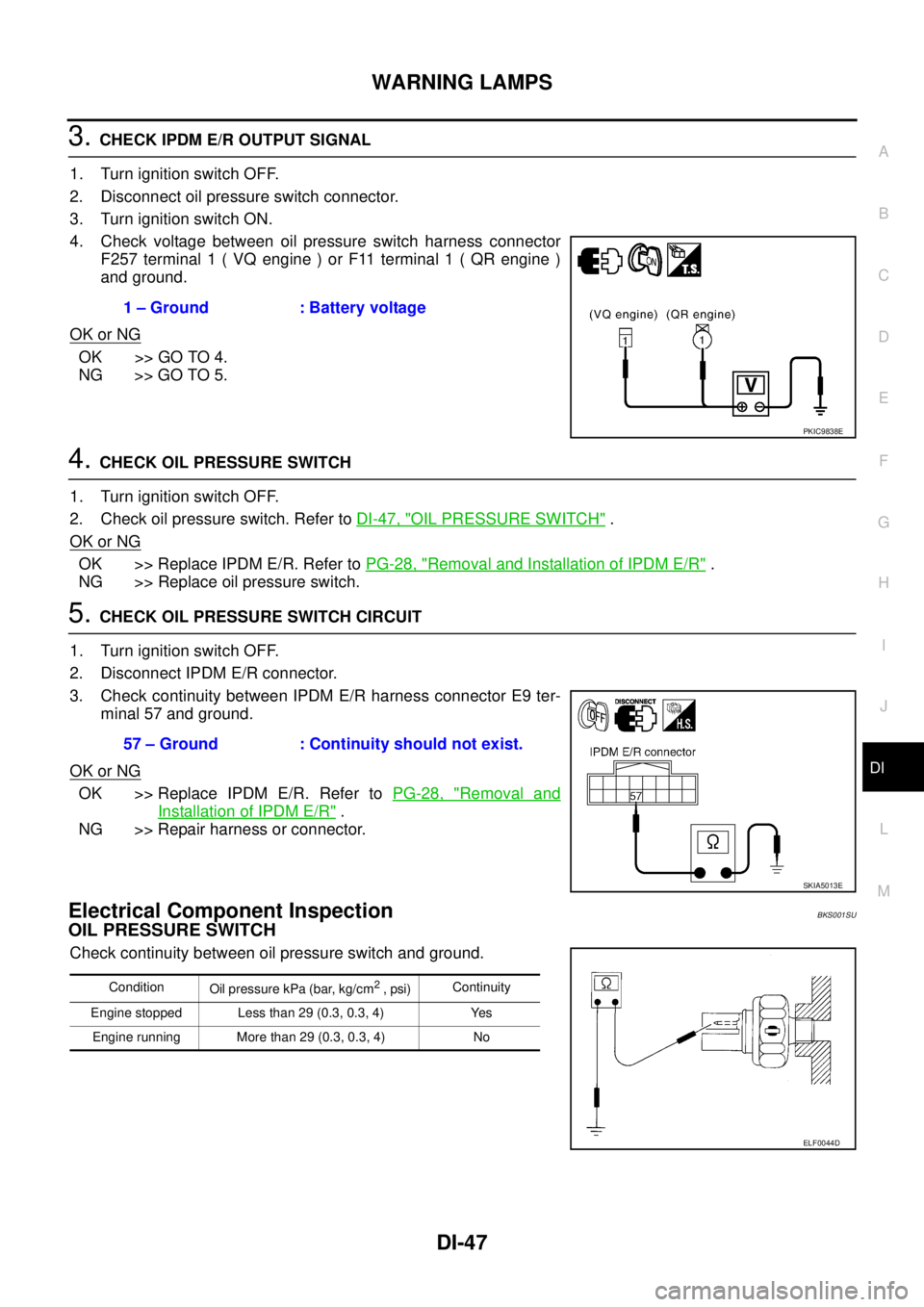

3. CHECK IPDM E/R OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect oil pressure switch connector.

3. Turn ignition switch ON.

4. Check voltage between oil pressure switch harness connector

F257 terminal 1 ( VQ engine ) or F11 terminal 1 ( QR engine )

and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 5.

4. CHECK OIL PRESSURE SWITCH

1. Turn ignition switch OFF.

2. Check oil pressure switch. Refer to DI-47, "

OIL PRESSURE SWITCH" .

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> Replace oil pressure switch.

5. CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector E9 ter-

minal 57 and ground.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Repair harness or connector.

Electrical Component InspectionBKS001SU

OIL PRESSURE SWITCH

Check continuity between oil pressure switch and ground.1 – Ground : Battery voltage

PKIC9838E

57 – Ground : Continuity should not exist.

SKIA5013E

Condition

Oil pressure kPa (bar, kg/cm2 , psi) Continuity

Engine stopped Less than 29 (0.3, 0.3, 4) Yes

Engine running More than 29 (0.3, 0.3, 4) No

ELF0044D

Page 1256 of 3502

DI-50

A/T INDICATOR

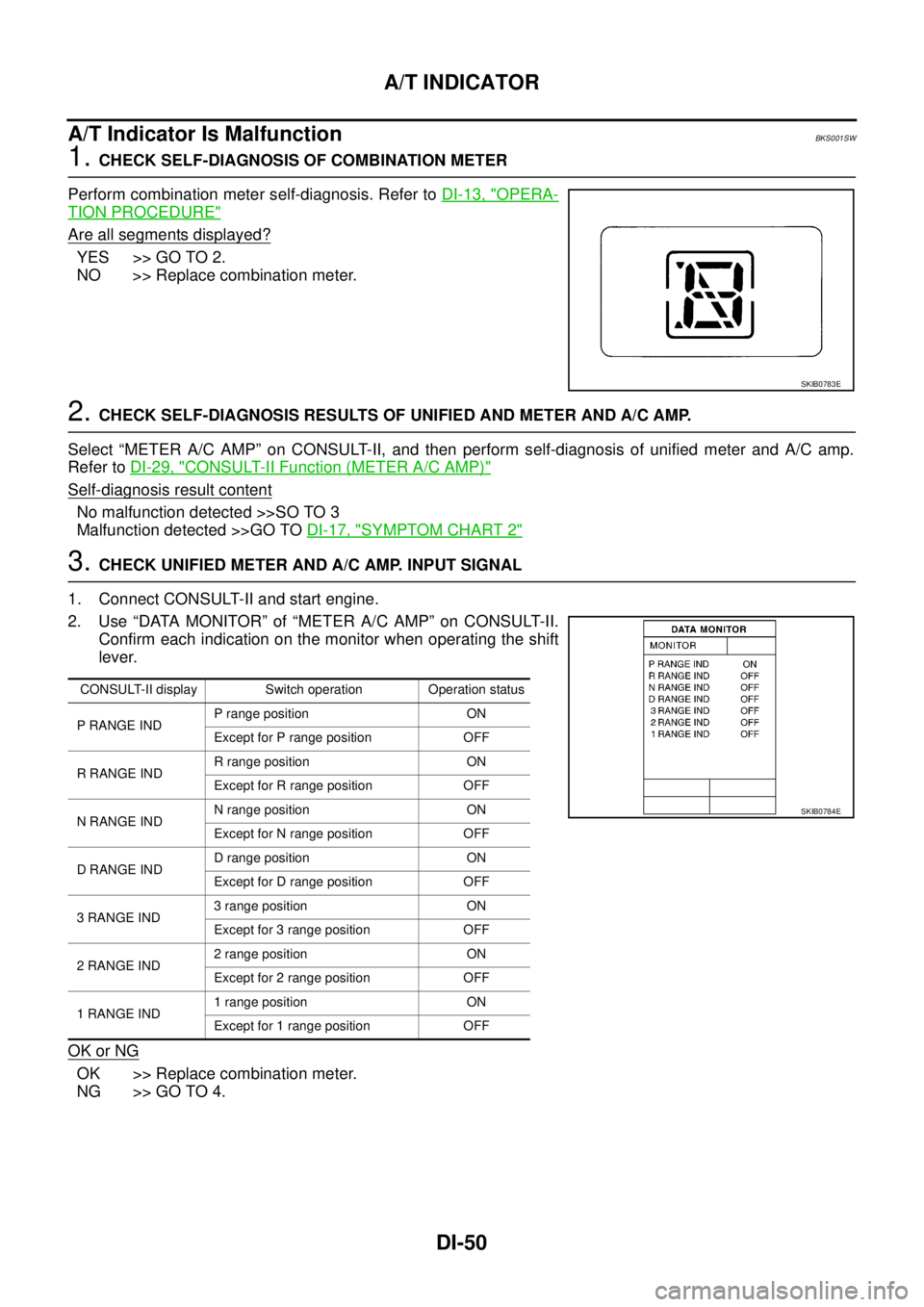

A/T Indicator Is MalfunctionBKS001SW

1. CHECK SELF-DIAGNOSIS OF COMBINATION METER

Perform combination meter self-diagnosis. Refer to DI-13, "

OPERA-

TION PROCEDURE"

Are all segments displayed?

YES >> GO TO 2.

NO >> Replace combination meter.

2. CHECK SELF-DIAGNOSIS RESULTS OF UNIFIED AND METER AND A/C AMP.

Select “METER A/C AMP” on CONSULT-II, and then perform self-diagnosis of unified meter and A/C amp.

Refer to DI-29, "

CONSULT-II Function (METER A/C AMP)"

Self-diagnosis result content

No malfunction detected >>SO TO 3

Malfunction detected >>GO TO DI-17, "

SYMPTOM CHART 2"

3. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Connect CONSULT-II and start engine.

2. Use “DATA MONITOR” of “METER A/C AMP” on CONSULT-II.

Confirm each indication on the monitor when operating the shift

lever.

OK or NG

OK >> Replace combination meter.

NG >> GO TO 4.

SKIB0783E

CONSULT-II display Switch operation Operation status

P RANGE INDP range position ON

Except for P range position OFF

R RANGE INDR range position ON

Except for R range position OFF

N RANGE INDN range position ON

Except for N range position OFF

D RANGE INDD range position ON

Except for D range position OFF

3 RANGE IND3 range position ON

Except for 3 range position OFF

2 RANGE IND2 range position ON

Except for 2 range position OFF

1 RANGE IND1 range position ON

Except for 1 range position OFF

SKIB0784E

Page 1260 of 3502

DI-54

CVT INDICATOR

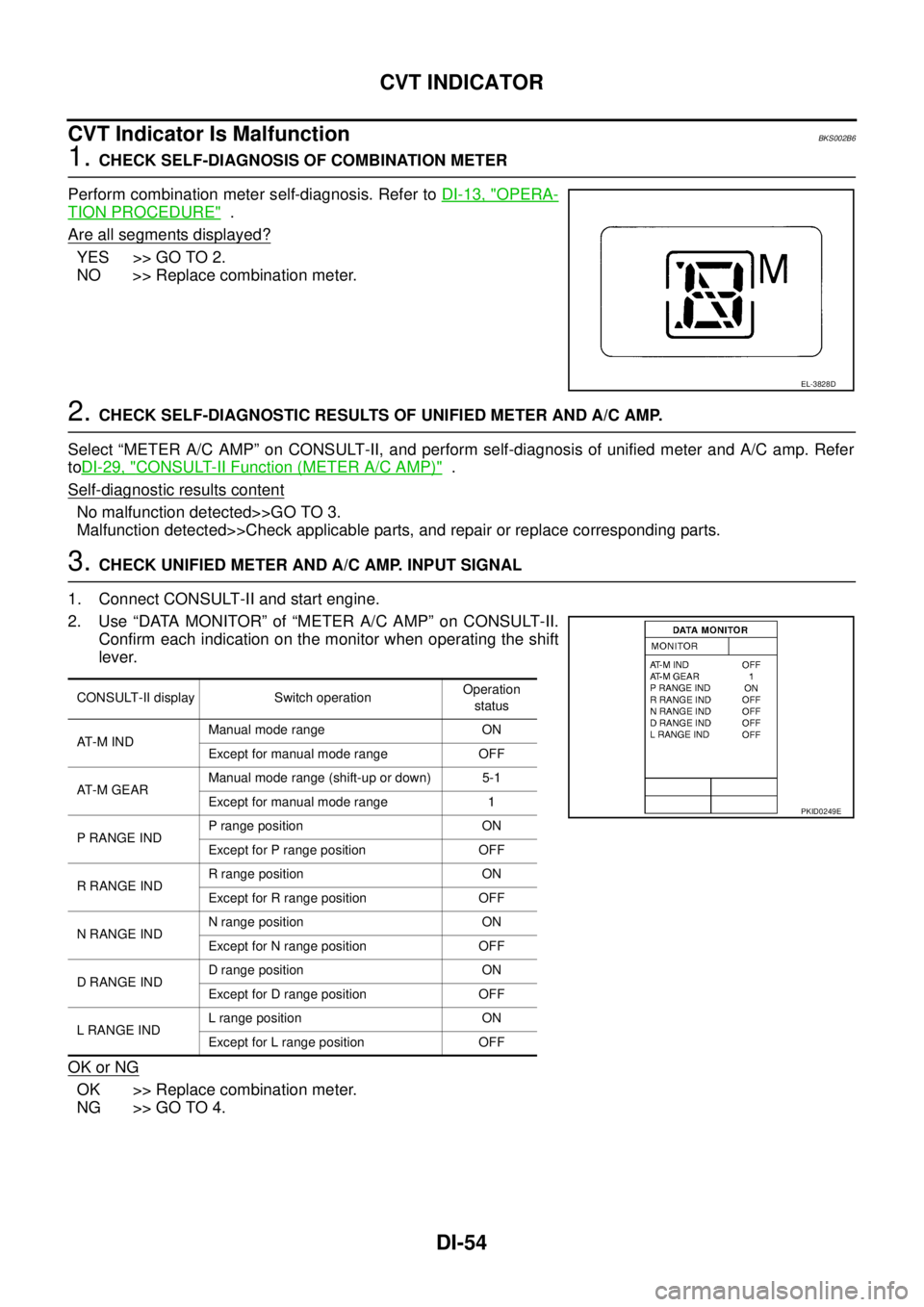

CVT Indicator Is MalfunctionBKS002B6

1. CHECK SELF-DIAGNOSIS OF COMBINATION METER

Perform combination meter self-diagnosis. Refer to DI-13, "

OPERA-

TION PROCEDURE" .

Are all segments displayed?

YES >> GO TO 2.

NO >> Replace combination meter.

2. CHECK SELF-DIAGNOSTIC RESULTS OF UNIFIED METER AND A/C AMP.

Select “METER A/C AMP” on CONSULT-II, and perform self-diagnosis of unified meter and A/C amp. Refer

toDI-29, "

CONSULT-II Function (METER A/C AMP)" .

Self

-diagnostic results content

No malfunction detected>>GO TO 3.

Malfunction detected>>Check applicable parts, and repair or replace corresponding parts.

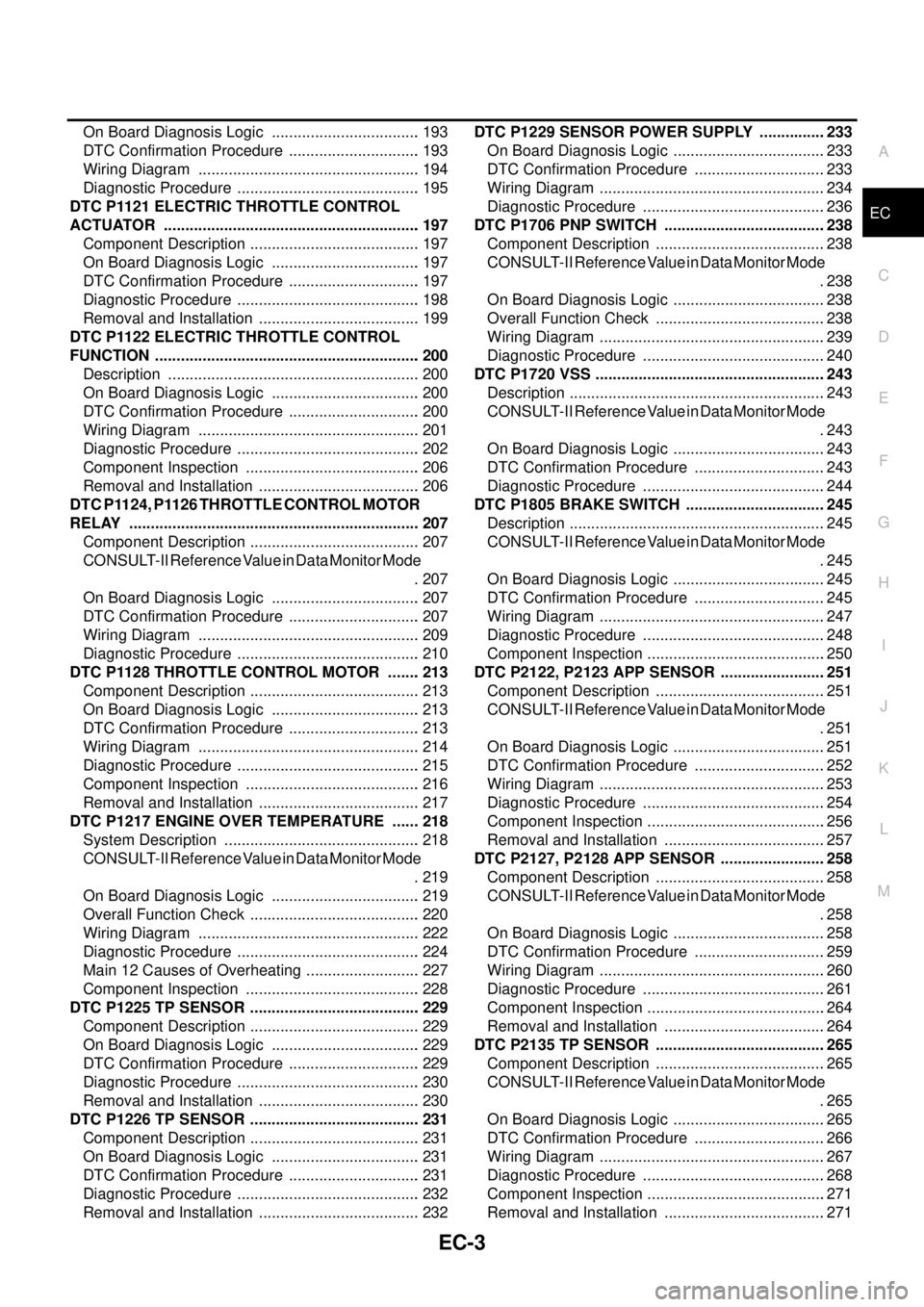

3. CHECK UNIFIED METER AND A/C AMP. INPUT SIGNAL

1. Connect CONSULT-II and start engine.

2. Use “DATA MONITOR” of “METER A/C AMP” on CONSULT-II.

Confirm each indication on the monitor when operating the shift

lever.

OK or NG

OK >> Replace combination meter.

NG >> GO TO 4.

EL-3828D

CONSULT-II display Switch operationOperation

status

AT - M I N DManual mode range ON

Except for manual mode range OFF

AT - M G E A RManual mode range (shift-up or down) 5-1

Except for manual mode range 1

P RANGE INDP range position ON

Except for P range position OFF

R RANGE INDR range position ON

Except for R range position OFF

N RANGE INDN range position ON

Except for N range position OFF

D RANGE INDD range position ON

Except for D range position OFF

L RANGE INDL range position ON

Except for L range position OFF

PKID0249E

Page 1283 of 3502

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

ENGINE CONTROL SYSTEM

QR

INDEX FOR DTC ...................................................... 10

DTC No. Index ....................................................... 10

Alphabetical Index .................................................. 12

PRECAUTIONS ........................................................ 14

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 14

On Board Diagnostic (OBD) System of Engine ...... 14

Precaution .............................................................. 14

PREPARATION ......................................................... 18

Special Service Tools ............................................. 18

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 20

System Diagram ..................................................... 20

Multiport Fuel Injection (MFI) System .................... 21

Electronic Ignition (EI) System ............................... 23

Fuel Cut Control (At No Load and High Engine

Speed) .................................................................... 24

AIR CONDITIONING CUT CONTROL ..................... 25

Input/Output Signal Chart ....................................... 25

CAN COMMUNICATION .......................................... 26

System Description ................................................ 26

EVAPORATIVE EMISSION SYSTEM ....................... 27

Description ............................................................. 27

Component Inspection ........................................... 29

POSITIVE CRANKCASE VENTILATION ................. 30

Description ............................................................. 30

Component Inspection ........................................... 30

NATS (NISSAN ANTI-THEFT SYSTEM) .................. 32

Description ............................................................. 32

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 33

Introduction ............................................................ 33

Two Trip Detection Logic ........................................ 33

Emission-related Diagnostic Information ................ 33

Malfunction Indicator (MI) ....................................... 36

BASIC SERVICE PROCEDURE .............................. 40

Basic Inspection ..................................................... 40

Idle Speed and Ignition Timing Check .................... 45

Procedure After Replacing ECM ............................ 47Accelerator Pedal Released Position Learning ...... 47

Throttle Valve Closed Position Learning ................. 47

Idle Air Volume Learning ........................................ 47

Fuel Pressure Check .............................................. 49

TROUBLE DIAGNOSIS ............................................ 52

Trouble Diagnosis Introduction ............................... 52

DTC Inspection Priority Chart ................................. 58

Fail-Safe Chart ....................................................... 59

Symptom Matrix Chart ............................................ 60

Engine Control Component Parts Location ............ 64

Vacuum Hose Drawing ........................................... 69

Circuit Diagram ....................................................... 70

ECM Harness Connector Terminal Layout ............. 72

ECM Terminals and Reference Value ..................... 72

CONSULT-II Function (ENGINE) ............................ 80

CONSULT-II Reference Value in Data Monitor Mode

... 90

Major Sensor Reference Graph in Data Monitor

Mode ....................................................................... 93

TROUBLE DIAGNOSIS - SPECIFICATION VALUE ... 95

Description .............................................................. 95

Testing Condition .................................................... 95

Inspection Procedure .............................................. 95

Diagnostic Procedure ............................................. 96

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................105

Description ............................................................105

Diagnostic Procedure ...........................................105

POWER SUPPLY AND GROUND CIRCUIT ...........106

Wiring Diagram .....................................................106

Diagnostic Procedure ...........................................107

Ground Inspection .................................................111

DTC U1000, U1001 CAN COMMUNICATION LINE .113

Description ............................................................113

On Board Diagnosis Logic ....................................113

DTC Confirmation Procedure ...............................113

Wiring Diagram .....................................................114

Diagnostic Procedure ...........................................115

DTC P0011 IVT CONTROL .....................................116

Description ............................................................116

Page 1285 of 3502

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA

On Board Diagnosis Logic ................................... 193

DTC Confirmation Procedure ............................... 193

Wiring Diagram .................................................... 194

Diagnostic Procedure ........................................... 195

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR ............................................................ 197

Component Description ........................................ 197

On Board Diagnosis Logic ................................... 197

DTC Confirmation Procedure ............................... 197

Diagnostic Procedure ........................................... 198

Removal and Installation ...................................... 199

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION .............................................................. 200

Description ........................................................... 200

On Board Diagnosis Logic ................................... 200

DTC Confirmation Procedure ............................... 200

Wiring Diagram .................................................... 201

Diagnostic Procedure ........................................... 202

Component Inspection ......................................... 206

Removal and Installation ...................................... 206

DTC P1124, P1126 THROTTLE CONTROL MOTOR

RELAY .................................................................... 207

Component Description ........................................ 207

CONSULT-II Reference Value in Data Monitor Mode

. 207

On Board Diagnosis Logic ................................... 207

DTC Confirmation Procedure ............................... 207

Wiring Diagram .................................................... 209

Diagnostic Procedure ........................................... 210

DTC P1128 THROTTLE CONTROL MOTOR ........ 213

Component Description ........................................ 213

On Board Diagnosis Logic ................................... 213

DTC Confirmation Procedure ............................... 213

Wiring Diagram .................................................... 214

Diagnostic Procedure ........................................... 215

Component Inspection ......................................... 216

Removal and Installation ...................................... 217

DTC P1217 ENGINE OVER TEMPERATURE ....... 218

System Description .............................................. 218

CONSULT-II Reference Value in Data Monitor Mode

. 219

On Board Diagnosis Logic ................................... 219

Overall Function Check ........................................ 220

Wiring Diagram .................................................... 222

Diagnostic Procedure ........................................... 224

Main 12 Causes of Overheating ........................... 227

Component Inspection ......................................... 228

DTC P1225 TP SENSOR ........................................ 229

Component Description ........................................ 229

On Board Diagnosis Logic ................................... 229

DTC Confirmation Procedure ............................... 229

Diagnostic Procedure ........................................... 230

Removal and Installation ...................................... 230

DTC P1226 TP SENSOR ........................................ 231

Component Description ........................................ 231

On Board Diagnosis Logic ................................... 231

DTC Confirmation Procedure ............................... 231

Diagnostic Procedure ........................................... 232

Removal and Installation ...................................... 232DTC P1229 SENSOR POWER SUPPLY ................233

On Board Diagnosis Logic ....................................233

DTC Confirmation Procedure ...............................233

Wiring Diagram .....................................................234

Diagnostic Procedure ...........................................236

DTC P1706 PNP SWITCH ......................................238

Component Description ........................................238

CONSULT-II Reference Value in Data Monitor Mode

.238

On Board Diagnosis Logic ....................................238

Overall Function Check ........................................238

Wiring Diagram .....................................................239

Diagnostic Procedure ...........................................240

DTC P1720 VSS ......................................................243

Description ............................................................243

CONSULT-II Reference Value in Data Monitor Mode

.243

On Board Diagnosis Logic ....................................243

DTC Confirmation Procedure ...............................243

Diagnostic Procedure ...........................................244

DTC P1805 BRAKE SWITCH .................................245

Description ............................................................245

CONSULT-II Reference Value in Data Monitor Mode

.245

On Board Diagnosis Logic ....................................245

DTC Confirmation Procedure ...............................245

Wiring Diagram .....................................................247

Diagnostic Procedure ...........................................248

Component Inspection ..........................................250

DTC P2122, P2123 APP SENSOR .........................251

Component Description ........................................251

CONSULT-II Reference Value in Data Monitor Mode

.251

On Board Diagnosis Logic ....................................251

DTC Confirmation Procedure ...............................252

Wiring Diagram .....................................................253

Diagnostic Procedure ...........................................254

Component Inspection ..........................................256

Removal and Installation ......................................257

DTC P2127, P2128 APP SENSOR .........................258

Component Description ........................................258

CONSULT-II Reference Value in Data Monitor Mode

.258

On Board Diagnosis Logic ....................................258

DTC Confirmation Procedure ...............................259

Wiring Diagram .....................................................260

Diagnostic Procedure ...........................................261

Component Inspection ..........................................264

Removal and Installation ......................................264

DTC P2135 TP SENSOR ........................................265

Component Description ........................................265

CONSULT-II Reference Value in Data Monitor Mode

.265

On Board Diagnosis Logic ....................................265

DTC Confirmation Procedure ...............................266

Wiring Diagram .....................................................267

Diagnostic Procedure ...........................................268

Component Inspection ..........................................271

Removal and Installation ......................................271

Page 1287 of 3502

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA

PREPARATION ....................................................... 355

Special Service Tools ........................................... 355

Commercial Service Tools .................................... 356

ENGINE CONTROL SYSTEM ................................ 357

System Diagram ................................................... 357

Multiport Fuel Injection (MFI) System .................. 358

Electronic Ignition (EI) System ............................. 360

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................. 361

AIR CONDITIONING CUT CONTROL ................... 362

Input/Output Signal Chart ..................................... 362

System Description .............................................. 362

AUTOMATIC SPEED CONTROL DEVICE (ASCD) . 363

System Description .............................................. 363

Component Description ........................................ 364

CAN COMMUNICATION ........................................ 365

System Description .............................................. 365

EVAPORATIVE EMISSION SYSTEM ..................... 366

Description ........................................................... 366

Component Inspection ......................................... 369

POSITIVE CRANKCASE VENTILATION ............... 370

Description ........................................................... 370

Component Inspection ......................................... 370

NATS (NISSAN ANTI-THEFT SYSTEM) ................ 372

Description ........................................................... 372

ON BOARD DIAGNOSTIC (OBD) SYSTEM .......... 373

Introduction .......................................................... 373

Two Trip Detection Logic ...................................... 373

Emission-related Diagnostic Information .............. 373

Malfunction Indicator (MI) ..................................... 377

BASIC SERVICE PROCEDURE ............................ 381

Basic Inspection ................................................... 381

Idle Speed and Ignition Timing Check .................. 387

Procedure After Replacing ECM .......................... 389

Accelerator Pedal Released Position Learning .... 389

Throttle Valve Closed Position Learning .............. 389

Idle Air Volume Learning ...................................... 389

Fuel Pressure Check ............................................ 392

TROUBLE DIAGNOSIS .......................................... 394

Trouble Diagnosis Introduction ............................. 394

DTC Inspection Priority Chart .............................. 400

Fail-Safe Chart ..................................................... 401

Symptom Matrix Chart ......................................... 402

Engine Control Component Parts Location .......... 406

Vacuum Hose Drawing ......................................... 412

Circuit Diagram .................................................... 413

ECM Harness Connector Terminal Layout ........... 415

ECM Terminals and Reference Value .................. 415

CONSULT-II Function (ENGINE) ......................... 425

CONSULT-II Reference Value in Data Monitor Mode

. 434

Major Sensor Reference Graph in Data Monitor

Mode .................................................................... 438

TROUBLE DIAGNOSIS - SPECIFICATION VALUE . 440

Description ........................................................... 440

Testing Condition .................................................. 440

Inspection Procedure ........................................... 440

Diagnostic Procedure ........................................... 441

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-DENT .......................................................................450

Description ............................................................450

Diagnostic Procedure ...........................................450

POWER SUPPLY AND GROUND CIRCUIT ...........451

Wiring Diagram .....................................................451

Diagnostic Procedure ...........................................452

Ground Inspection ................................................457

DTC U1000, U1001 CAN COMMUNICATION LINE .458

Description ............................................................458

On Board Diagnosis Logic ....................................458

DTC Confirmation Procedure ...............................458

Wiring Diagram .....................................................459

Diagnostic Procedure ...........................................460

DTC P0011, P0021 IVT CONTROL ........................461

Description ............................................................461

CONSULT-II Reference Value in Data Monitor Mode

.461

On Board Diagnosis Logic ....................................462

DTC Confirmation Procedure ...............................462

Overall Function Check ........................................463

Diagnostic Procedure ...........................................464

Component Inspection ..........................................465

Removal and Installation ......................................465

DTC P0102, P0103 MAF SENSOR ........................466

Component Description ........................................466

CONSULT-II Reference Value in Data Monitor Mode

.466

On Board Diagnosis Logic ....................................466

DTC Confirmation Procedure ...............................467

Wiring Diagram .....................................................468

Diagnostic Procedure ...........................................469

Component Inspection ..........................................472

Removal and Installation ......................................473

DTC P0117, P0118 ECT SENSOR .........................474

Component Description ........................................474

On Board Diagnosis Logic ....................................474

DTC Confirmation Procedure ...............................475

Wiring Diagram .....................................................476

Diagnostic Procedure ...........................................477

Component Inspection ..........................................478

Removal and Installation ......................................478

DTC P0122, P0123 TP SENSOR ............................479

Component Description ........................................479

CONSULT-II Reference Value in Data Monitor Mode

.479

On Board Diagnosis Logic ....................................479

DTC Confirmation Procedure ...............................480

Wiring Diagram .....................................................481

Diagnostic Procedure ...........................................482

Component Inspection ..........................................485

Removal and Installation ......................................485

DTC P0132, P0152 HO2S1 .....................................486

Component Description ........................................486

CONSULT-II Reference Value in Data Monitor Mode

.486

On Board Diagnosis Logic ....................................486

DTC Confirmation Procedure ...............................487

Wiring Diagram .....................................................488

Diagnostic Procedure ...........................................491

Page 1289 of 3502

EC-7

C

D

E

F

G

H

I

J

K

L

M

ECA

DTC P1212 TCS COMMUNICATION LINE ............ 574

Description ........................................................... 574

On Board Diagnosis Logic ................................... 574

DTC Confirmation Procedure ............................... 574

Diagnostic Procedure ........................................... 574

DTC P1217 ENGINE OVER TEMPERATURE ....... 575

System Description .............................................. 575

CONSULT-II Reference Value in Data Monitor Mode

. 576

On Board Diagnosis Logic ................................... 577

Overall Function Check ........................................ 577

Wiring Diagram .................................................... 579

Diagnostic Procedure ........................................... 581

Main 12 Causes of Overheating ........................... 584

Component Inspection ......................................... 585

DTC P1225 TP SENSOR ........................................ 586

Component Description ........................................ 586

On Board Diagnosis Logic ................................... 586

DTC Confirmation Procedure ............................... 586

Diagnostic Procedure ........................................... 587

Removal and Installation ...................................... 587

DTC P1226 TP SENSOR ........................................ 588

Component Description ........................................ 588

On Board Diagnosis Logic ................................... 588

DTC Confirmation Procedure ............................... 588

Diagnostic Procedure ........................................... 589

Removal and Installation ...................................... 589

DTC P1229 SENSOR POWER SUPPLY ................ 590

On Board Diagnosis Logic ................................... 590

DTC Confirmation Procedure ............................... 590

Wiring Diagram .................................................... 591

Diagnostic Procedure ........................................... 592

DTC P1564 ASCD STEERING SWITCH ................ 595

Component Description ........................................ 595

CONSULT-II Reference Value in Data Monitor Mode

. 595

On Board Diagnosis Logic ................................... 595

DTC Confirmation Procedure ............................... 596

Wiring Diagram .................................................... 597

Diagnostic Procedure ........................................... 598

Component Inspection ......................................... 601

DTC P1572 ASCD BRAKE SWITCH ..................... 602

Component Description ........................................ 602

CONSULT-II Reference Value in Data Monitor Mode

. 602

On Board Diagnosis Logic ................................... 602

DTC Confirmation Procedure ............................... 603

Overall Function Check ........................................ 604

Wiring Diagram .................................................... 605

Diagnostic Procedure ........................................... 606

Component Inspection ......................................... 610

DTC P1574 ASCD VEHICLE SPEED SENSOR .....611

Component Description ......................................... 611

On Board Diagnosis Logic .................................... 611

DTC Confirmation Procedure ................................ 611

Diagnostic Procedure ........................................... 612

DTC P1700 CVT CONTROL SYSTEM ................... 613

Description ........................................................... 613DTC P1706 PNP SWITCH ......................................614

Component Description ........................................614

CONSULT-II Reference Value in Data Monitor Mode

.614

On Board Diagnosis Logic ....................................614

Overall Function Check ........................................614

Wiring Diagram .....................................................615

Diagnostic Procedure ...........................................618

DTC P1715 INPUT SPEED SENSOR (PRIMARY

SPEED SENSOR) ...................................................622

Description ............................................................622

CONSULT-II Reference Value in Data Monitor Mode

.622

On Board Diagnosis Logic ....................................622

DTC Confirmation Procedure ...............................622

Diagnostic Procedure ...........................................623

DTC P1720 VSS ......................................................624

Description ............................................................624

CONSULT-II Reference Value in Data Monitor Mode

.624

On Board Diagnosis Logic ....................................624

DTC Confirmation Procedure ...............................624

Diagnostic Procedure ...........................................625

DTC P1805 BRAKE SWITCH .................................626

Description ............................................................626

CONSULT-II Reference Value in Data Monitor Mode

.626

On Board Diagnosis Logic ....................................626

DTC Confirmation Procedure ...............................626

Wiring Diagram .....................................................627

Diagnostic Procedure ...........................................628

Component Inspection ..........................................630

DTC P2122, P2123 APP SENSOR .........................631

Component Description ........................................631

CONSULT-II Reference Value in Data Monitor Mode

.631

On Board Diagnosis Logic ....................................631

DTC Confirmation Procedure ...............................632

Wiring Diagram .....................................................633

Diagnostic Procedure ...........................................634

Component Inspection ..........................................637

Removal and Installation ......................................637

DTC P2127, P2128 APP SENSOR .........................638

Component Description ........................................638

CONSULT-II Reference Value in Data Monitor Mode

.638

On Board Diagnosis Logic ....................................638

DTC Confirmation Procedure ...............................639

Wiring Diagram .....................................................640

Diagnostic Procedure ...........................................641

Component Inspection ..........................................644

Removal and Installation ......................................644

DTC P2135 TP SENSOR ........................................645

Component Description ........................................645

CONSULT-II Reference Value in Data Monitor Mode

.645

On Board Diagnosis Logic ....................................645

DTC Confirmation Procedure ...............................646

Wiring Diagram .....................................................647