battery NISSAN TEANA 2003 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: TEANA, Model: NISSAN TEANA 2003Pages: 3502, PDF Size: 74.56 MB

Page 3298 of 3502

SE-42

AUTOMATIC DRIVE POSITIONER

Check Sliding Sensor Circuit BIS0012X

1. CHECK FUNCTION

With CONSULT-II

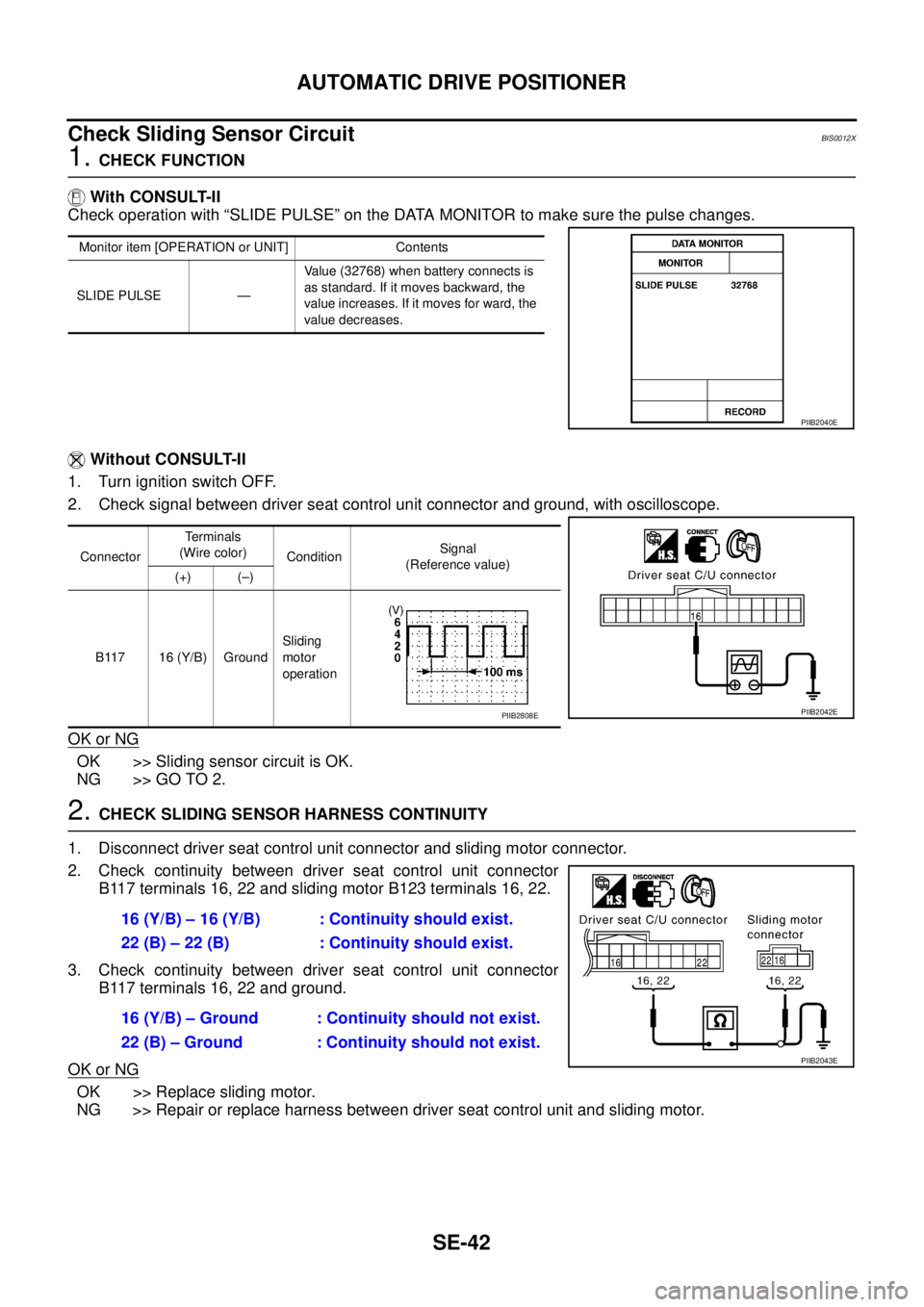

Check operation with “SLIDE PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and ground, with oscilloscope.

OK or NG

OK >> Sliding sensor circuit is OK.

NG >> GO TO 2.

2. CHECK SLIDING SENSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and sliding motor connector.

2. Check continuity between driver seat control unit connector

B117 terminals 16, 22 and sliding motor B123 terminals 16, 22.

3. Check continuity between driver seat control unit connector

B117 terminals 16, 22 and ground.

OK or NG

OK >> Replace sliding motor.

NG >> Repair or replace harness between driver seat control unit and sliding motor.

Monitor item [OPERATION or UNIT] Contents

SLIDE PULSE —Value (32768) when battery connects is

as standard. If it moves backward, the

value increases. If it moves for ward, the

value decreases.

PIIB2040E

ConnectorTerminals

(Wire color)

ConditionSignal

(Reference value)

(+) (–)

B117 16 (Y/B) GroundSliding

motor

operation

PIIB2042EPIIB2808E

16 (Y/B) – 16 (Y/B) : Continuity should exist.

22 (B) – 22 (B) : Continuity should exist.

16 (Y/B) – Ground : Continuity should not exist.

22 (B) – Ground : Continuity should not exist.

PIIB2043E

Page 3299 of 3502

AUTOMATIC DRIVE POSITIONER

SE-43

C

D

E

F

G

H

J

K

L

MA

B

SE

Check Reclining Sensor Circuit BIS0012Y

1. CHECK FUNCTION

With CONSULT-II

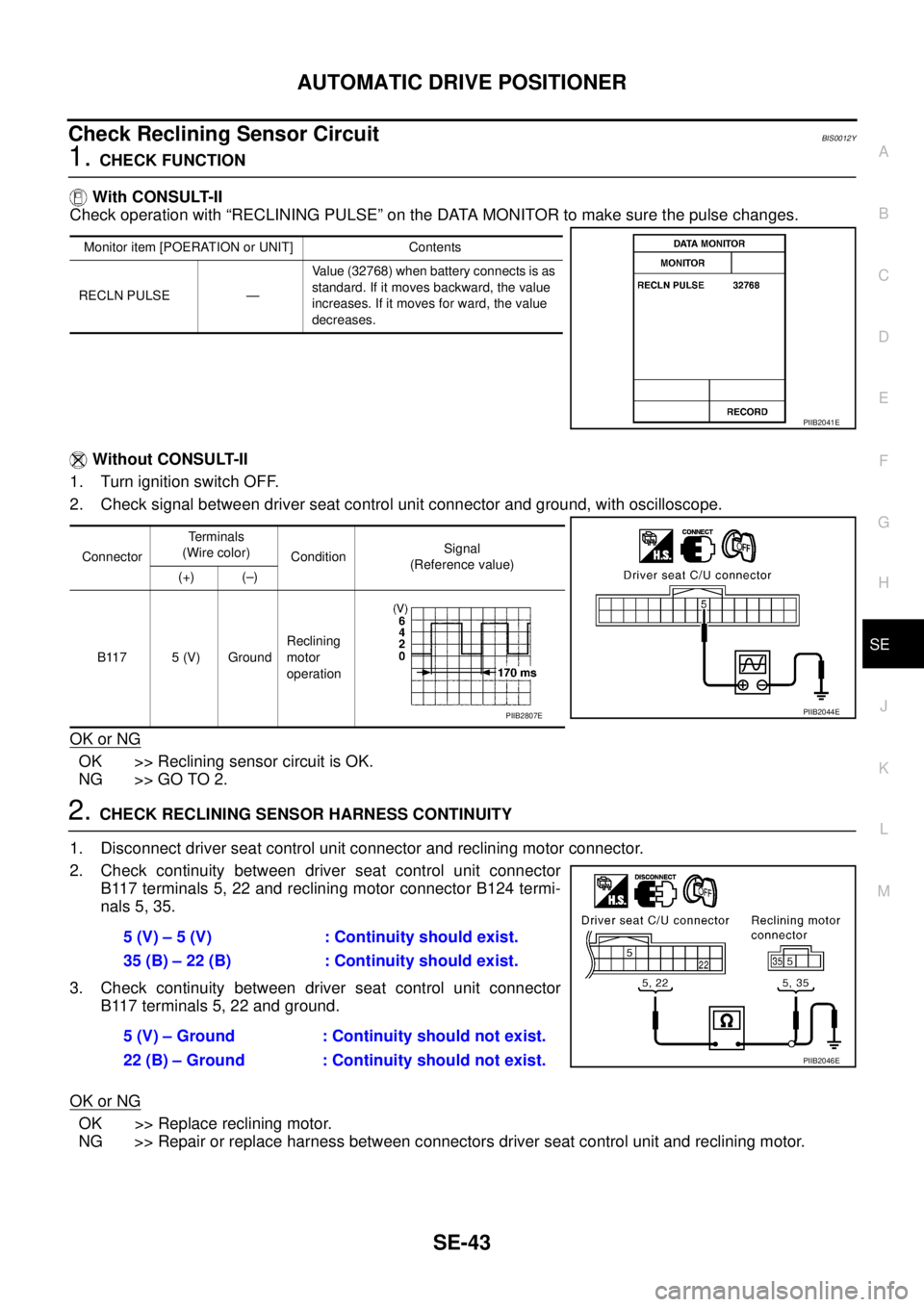

Check operation with “RECLINING PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and ground, with oscilloscope.

OK or NG

OK >> Reclining sensor circuit is OK.

NG >> GO TO 2.

2. CHECK RECLINING SENSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and reclining motor connector.

2. Check continuity between driver seat control unit connector

B117 terminals 5, 22 and reclining motor connector B124 termi-

nals 5, 35.

3. Check continuity between driver seat control unit connector

B117 terminals 5, 22 and ground.

OK or NG

OK >> Replace reclining motor.

NG >> Repair or replace harness between connectors driver seat control unit and reclining motor.

Monitor item [POERATION or UNIT] Contents

RECLN PULSE —Value (32768) when battery connects is as

standard. If it moves backward, the value

increases. If it moves for ward, the value

decreases.

PIIB2041E

ConnectorTerminals

(Wire color)

ConditionSignal

(Reference value)

(+) (–)

B117 5 (V) GroundReclining

motor

operation

PIIB2044EPIIB2807E

5 (V) – 5 (V) : Continuity should exist.

35 (B) – 22 (B) : Continuity should exist.

5 (V) – Ground : Continuity should not exist.

22 (B) – Ground : Continuity should not exist.

PIIB2046E

Page 3300 of 3502

SE-44

AUTOMATIC DRIVE POSITIONER

Check Front Lifting Sensor Circuit BIS0012Z

1. CHECK FUNCTION

With CONSULT-II

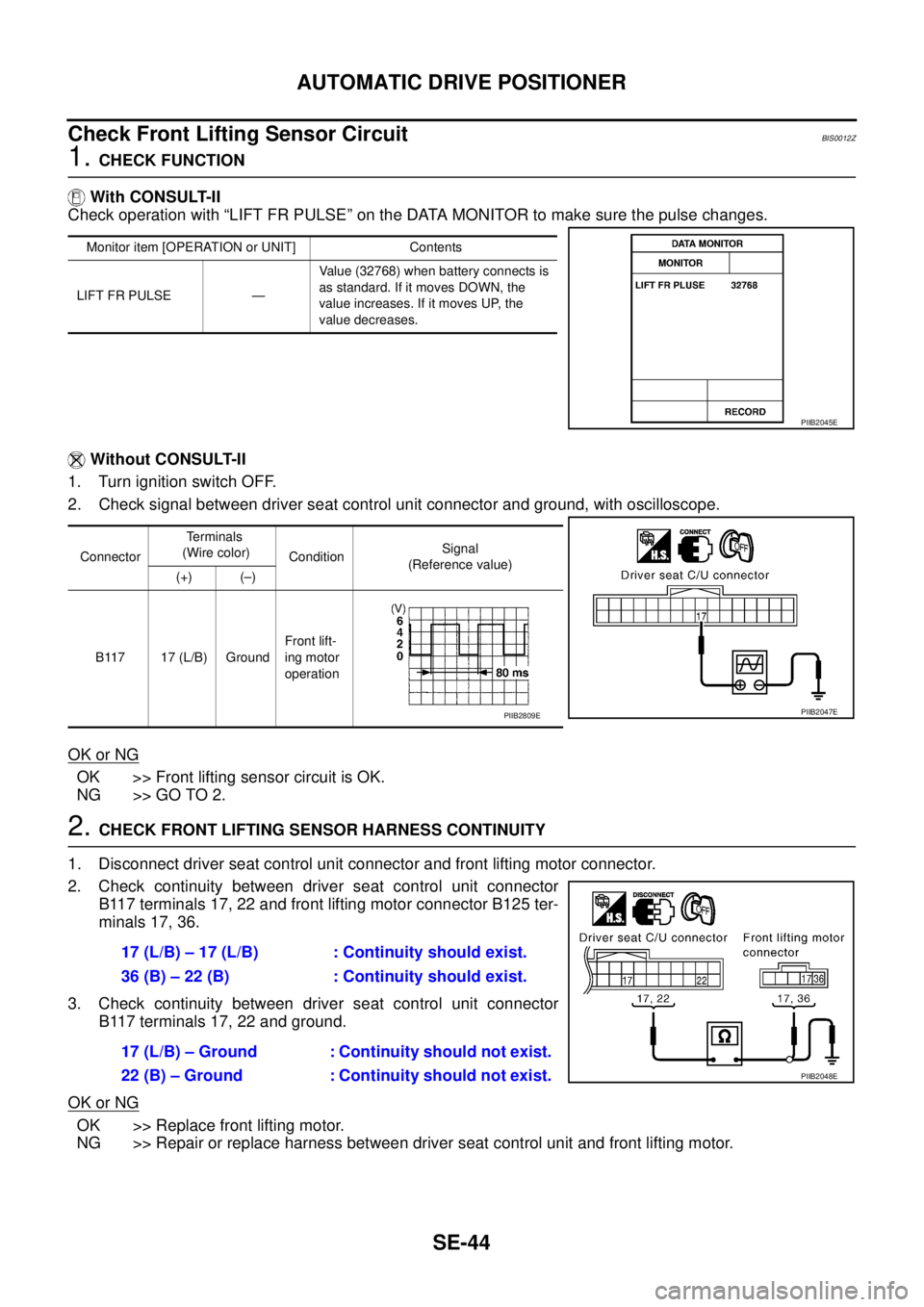

Check operation with “LIFT FR PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and ground, with oscilloscope.

OK or NG

OK >> Front lifting sensor circuit is OK.

NG >> GO TO 2.

2. CHECK FRONT LIFTING SENSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and front lifting motor connector.

2. Check continuity between driver seat control unit connector

B117 terminals 17, 22 and front lifting motor connector B125 ter-

minals 17, 36.

3. Check continuity between driver seat control unit connector

B117 terminals 17, 22 and ground.

OK or NG

OK >> Replace front lifting motor.

NG >> Repair or replace harness between driver seat control unit and front lifting motor.

Monitor item [OPERATION or UNIT] Contents

LIFT FR PULSE —Value (32768) when battery connects is

as standard. If it moves DOWN, the

value increases. If it moves UP, the

value decreases.

PIIB2045E

ConnectorTe r m i n a l s

(Wire color)

ConditionSignal

(Reference value)

(+) (–)

B117 17 (L/B) GroundFront lift-

ing motor

operation

PIIB2047EPIIB2809E

17 (L/B) – 17 (L/B) : Continuity should exist.

36 (B) – 22 (B) : Continuity should exist.

17 (L/B) – Ground : Continuity should not exist.

22 (B) – Ground : Continuity should not exist.

PIIB2048E

Page 3301 of 3502

AUTOMATIC DRIVE POSITIONER

SE-45

C

D

E

F

G

H

J

K

L

MA

B

SE

Check Rear Lifting Sensor Circuit BIS00130

1. CHECK REAR END LIFTING SENSOR INPUT/OUTPUT SIGNAL

With CONSULT-II

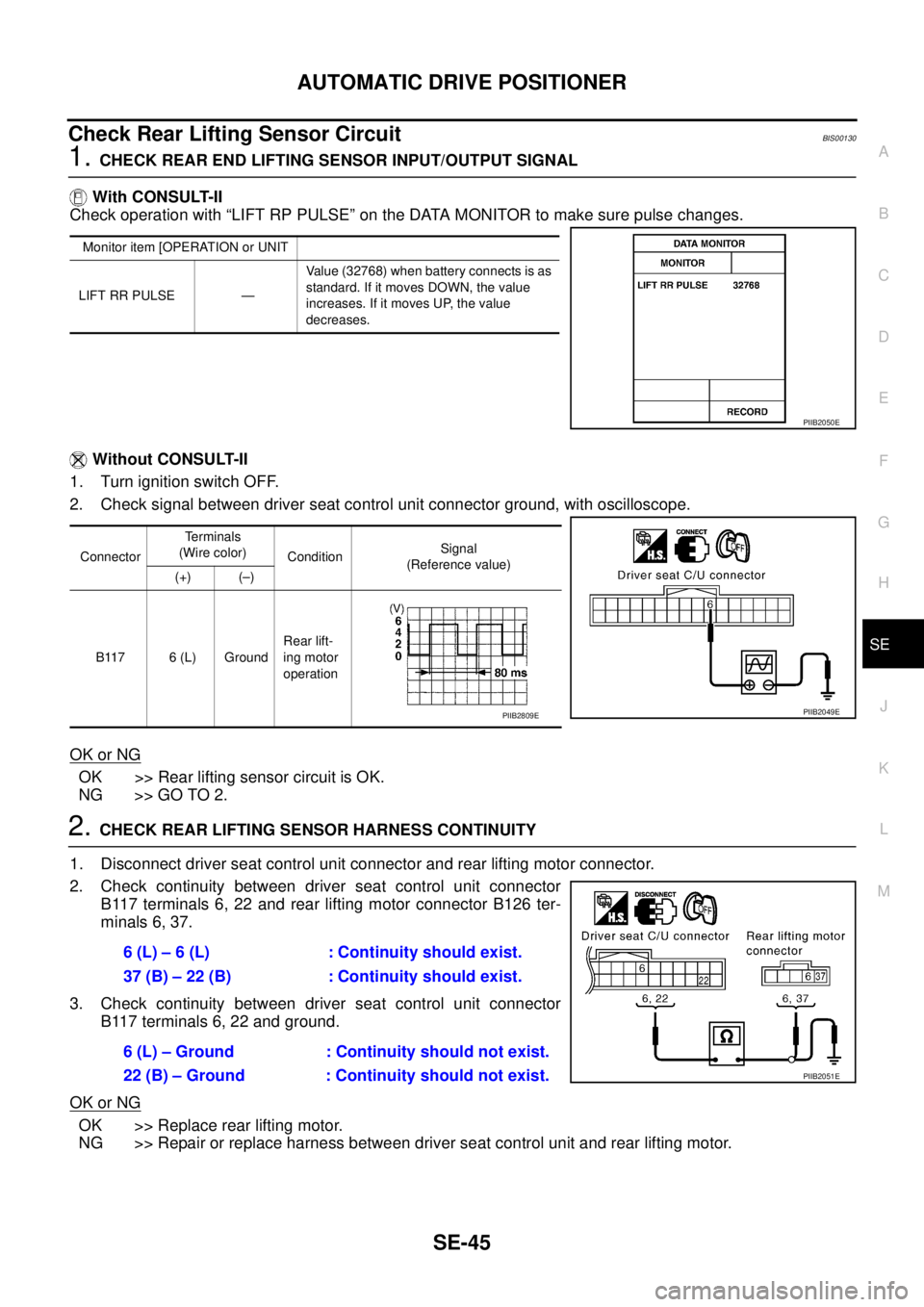

Check operation with “LIFT RP PULSE” on the DATA MONITOR to make sure pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector ground, with oscilloscope.

OK or NG

OK >> Rear lifting sensor circuit is OK.

NG >> GO TO 2.

2. CHECK REAR LIFTING SENSOR HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and rear lifting motor connector.

2. Check continuity between driver seat control unit connector

B117 terminals 6, 22 and rear lifting motor connector B126 ter-

minals 6, 37.

3. Check continuity between driver seat control unit connector

B117 terminals 6, 22 and ground.

OK or NG

OK >> Replace rear lifting motor.

NG >> Repair or replace harness between driver seat control unit and rear lifting motor.

Monitor item [OPERATION or UNIT

LIFT RR PULSE —Value (32768) when battery connects is as

standard. If it moves DOWN, the value

increases. If it moves UP, the value

decreases.

PIIB2050E

ConnectorTe r m i n a l s

(Wire color)

ConditionSignal

(Reference value)

(+) (–)

B117 6 (L) GroundRear lift-

ing motor

operation

PIIB2049EPIIB2809E

6 (L) – 6 (L) : Continuity should exist.

37 (B) – 22 (B) : Continuity should exist.

6 (L) – Ground : Continuity should not exist.

22 (B) – Ground : Continuity should not exist.

PIIB2051E

Page 3303 of 3502

AUTOMATIC DRIVE POSITIONER

SE-47

C

D

E

F

G

H

J

K

L

MA

B

SE

Check Sliding Switch Circuit BIS00132

1. CHECK FUNCTION

With CONSULT-II

With “SLIDE SW-FR, SLIDE SW-RR” on the DATA MONITOR, operate the sliding switch to check ON/OFF

operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Sliding switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Sliding switch circuit is OK.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and power seat switch (driver side) connector.

2. Check continuity between driver seat control unit connector

B117 terminals 7, 18 and driver power seat switch connector

B119 terminals 7, 18.

3. Check continuity between driver seat control unit connector

B117 terminals 7, 18 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control unit and power seat switch.

Monitor item

[OPERATION or UNIT]Contents

SLIDE SW – FR“ON/

OFF”ON/OFF status judged from the sliding switch

(FR) signal is displayed.

SLIDE SW – RR“ON/

OFF”ON/OFF status judged from the sliding switch

(RR) signal is displayed.

PIIB2055E

ConnectorTe r m i n a l s

(Wire color)

Sliding switch conditionVoltage (V)

(Approx.)

(+) (-)

B11718 (LG/B)

GroundFORWARD 0

Other than above Battery voltage

7 (G/R)BACKWARD 0

Other than above Battery voltage

PIIB2057E

7 (GR) – 7 (GR) : Continuity should exist.

18 (LG/B) – 18 (LG/B) : Continuity should exist.

7 (GR) – Ground : Continuity should not exist.

18 (LG/B) – Ground : Continuity should not exist.

PIIB2058E

Page 3304 of 3502

SE-48

AUTOMATIC DRIVE POSITIONER

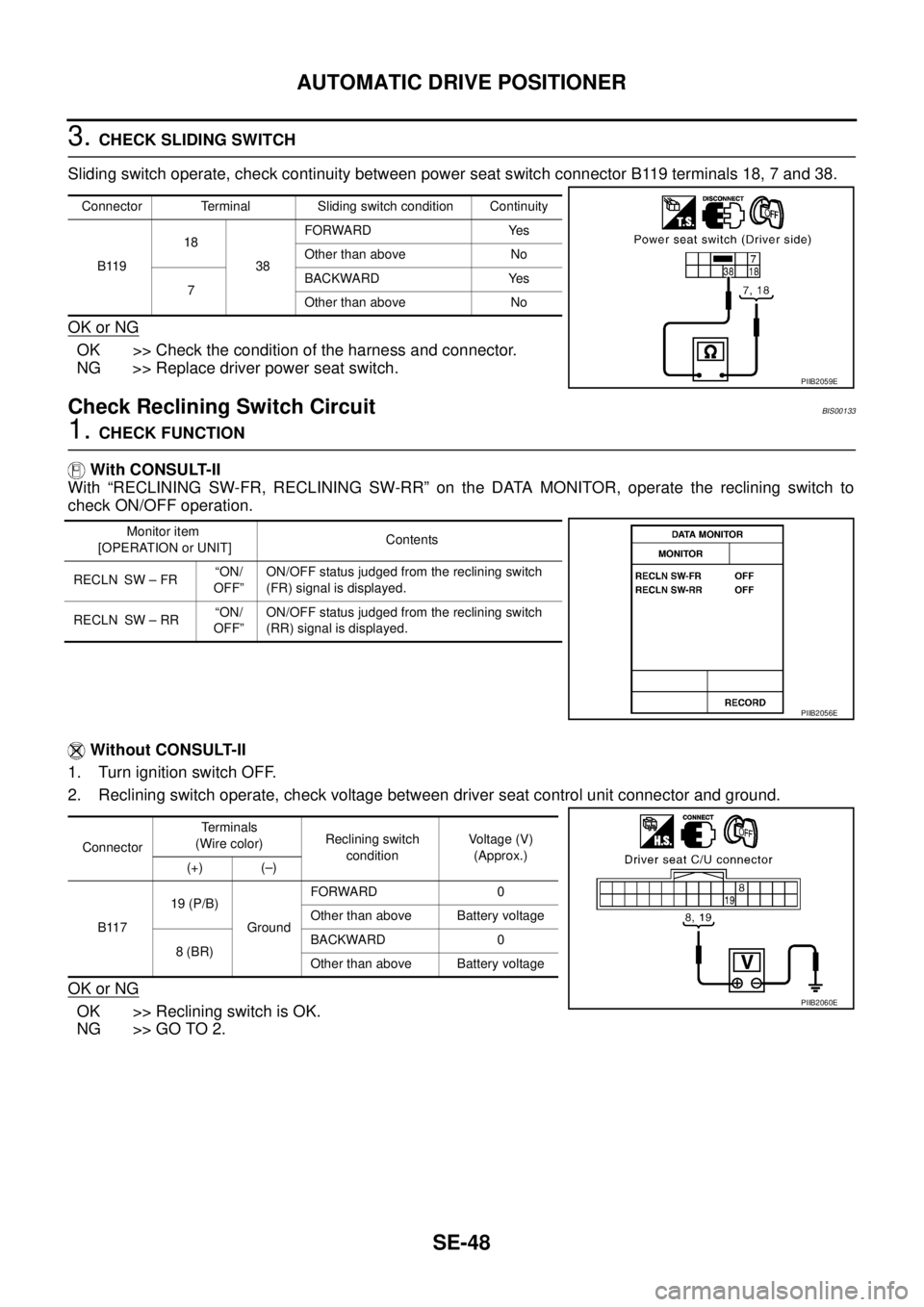

3. CHECK SLIDING SWITCH

Sliding switch operate, check continuity between power seat switch connector B119 terminals 18, 7 and 38.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace driver power seat switch.

Check Reclining Switch CircuitBIS00133

1. CHECK FUNCTION

With CONSULT-II

With “RECLINING SW-FR, RECLINING SW-RR” on the DATA MONITOR, operate the reclining switch to

check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Reclining switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Reclining switch is OK.

NG >> GO TO 2.

Connector Terminal Sliding switch condition Continuity

B11918

38FORWARD Yes

Other than above No

7BACKWARD Yes

Other than above No

PIIB2059E

Monitor item

[OPERATION or UNIT]Contents

RECLN SW – FR“ON/

OFF”ON/OFF status judged from the reclining switch

(FR) signal is displayed.

RECLN SW – RR“ON/

OFF”ON/OFF status judged from the reclining switch

(RR) signal is displayed.

PIIB2056E

ConnectorTe r m i n a l s

(Wire color)Reclining switch

conditionVoltage (V)

(Approx.)

(+) (–)

B11719 (P/B)

GroundFORWARD 0

Other than above Battery voltage

8 (BR)BACKWARD 0

Other than above Battery voltage

PIIB2060E

Page 3306 of 3502

SE-50

AUTOMATIC DRIVE POSITIONER

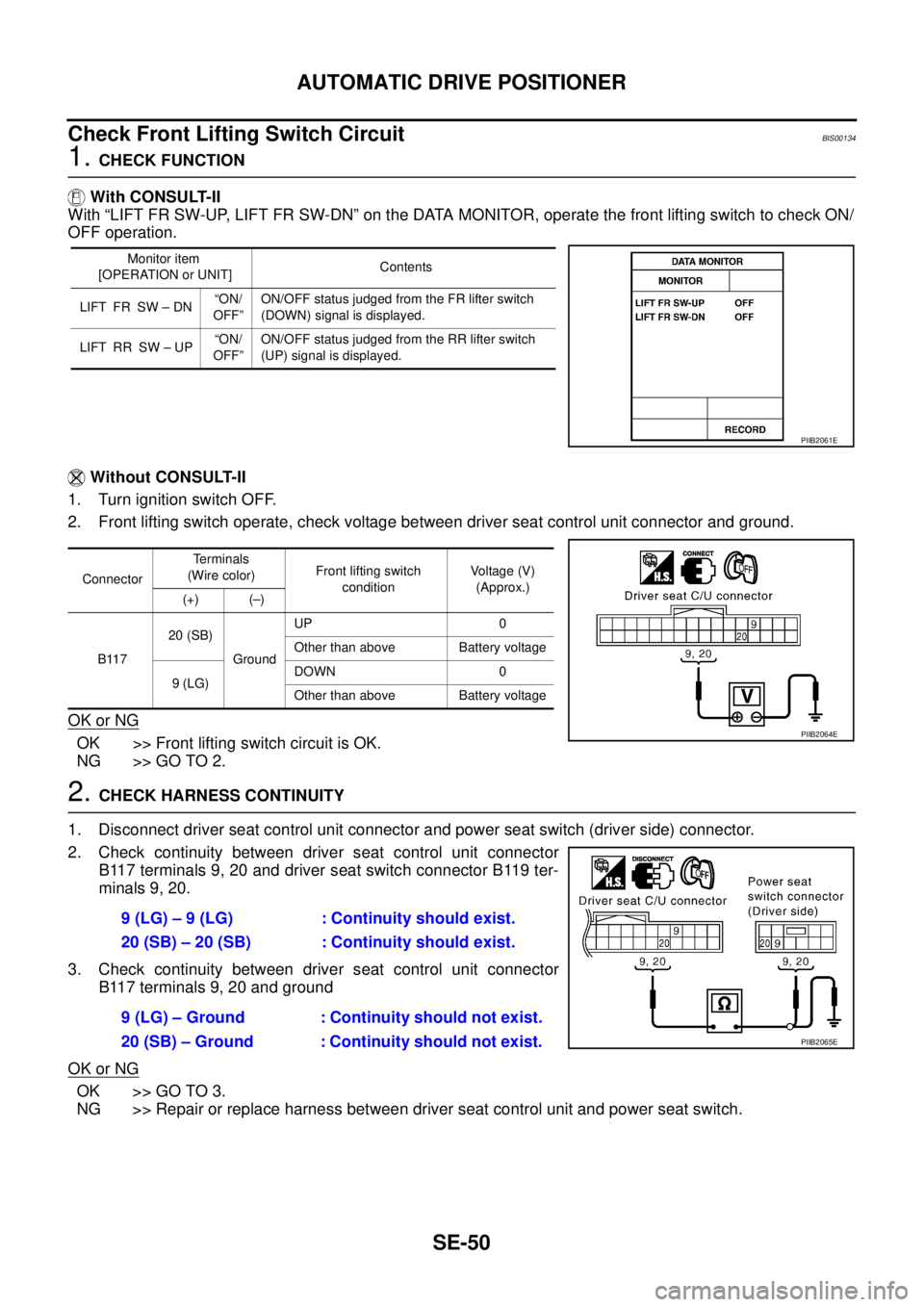

Check Front Lifting Switch Circuit BIS00134

1. CHECK FUNCTION

With CONSULT-II

With “LIFT FR SW-UP, LIFT FR SW-DN” on the DATA MONITOR, operate the front lifting switch to check ON/

OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Front lifting switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Front lifting switch circuit is OK.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and power seat switch (driver side) connector.

2. Check continuity between driver seat control unit connector

B117 terminals 9, 20 and driver seat switch connector B119 ter-

minals 9, 20.

3. Check continuity between driver seat control unit connector

B117 terminals 9, 20 and ground

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control unit and power seat switch.

Monitor item

[OPERATION or UNIT]Contents

LIFT FR SW – DN“ON/

OFF”ON/OFF status judged from the FR lifter switch

(DOWN) signal is displayed.

LIFT RR SW – UP“ON/

OFF”ON/OFF status judged from the RR lifter switch

(UP) signal is displayed.

PIIB2061E

ConnectorTerminals

(Wire color)Front lifting switch

conditionVoltage (V)

(Approx.)

(+) (–)

B11720 (SB)

GroundUP 0

Other than above Battery voltage

9 (LG)DOWN 0

Other than above Battery voltage

PIIB2064E

9 (LG) – 9 (LG) : Continuity should exist.

20 (SB) – 20 (SB) : Continuity should exist.

9 (LG) – Ground : Continuity should not exist.

20 (SB) – Ground : Continuity should not exist.

PIIB2065E

Page 3307 of 3502

AUTOMATIC DRIVE POSITIONER

SE-51

C

D

E

F

G

H

J

K

L

MA

B

SE

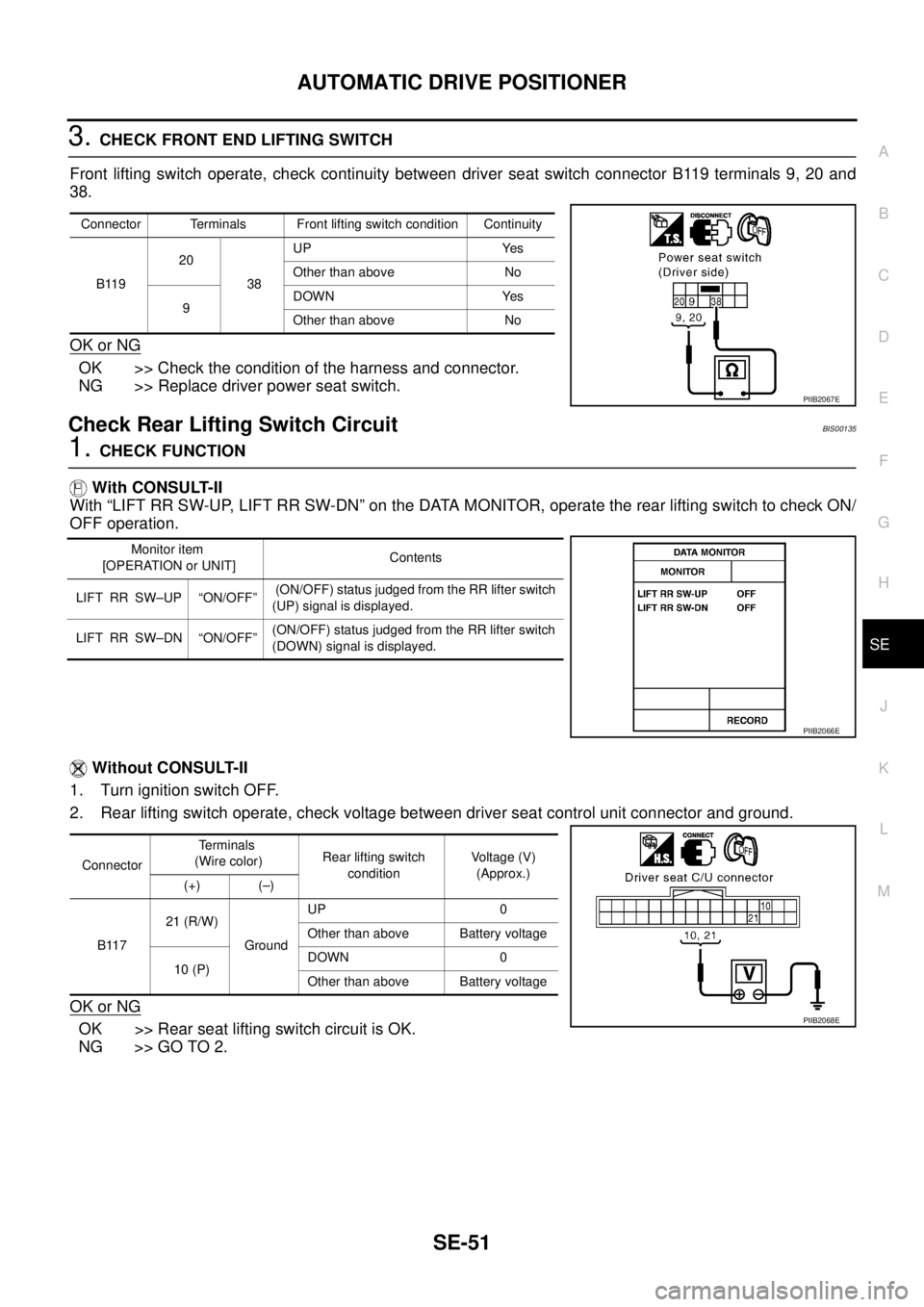

3. CHECK FRONT END LIFTING SWITCH

Front lifting switch operate, check continuity between driver seat switch connector B119 terminals 9, 20 and

38.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace driver power seat switch.

Check Rear Lifting Switch Circuit BIS00135

1. CHECK FUNCTION

With CONSULT-II

With “LIFT RR SW-UP, LIFT RR SW-DN” on the DATA MONITOR, operate the rear lifting switch to check ON/

OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Rear lifting switch operate, check voltage between driver seat control unit connector and ground.

OK or NG

OK >> Rear seat lifting switch circuit is OK.

NG >> GO TO 2.

Connector Terminals Front lifting switch condition Continuity

B11920

38UP Yes

Other than above No

9DOWN Yes

Other than above No

PIIB2067E

Monitor item

[OPERATION or UNIT]Contents

LIFT RR SW–UP “ON/OFF” (ON/OFF) status judged from the RR lifter switch

(UP) signal is displayed.

LIFT RR SW–DN “ON/OFF”(ON/OFF) status judged from the RR lifter switch

(DOWN) signal is displayed.

PIIB2066E

ConnectorTerminals

(Wire color)Rear lifting switch

conditionVoltage (V)

(Approx.)

(+) (–)

B11721 (R/W)

GroundUP 0

Other than above Battery voltage

10 (P)DOWN 0

Other than above Battery voltage

PIIB2068E

Page 3309 of 3502

AUTOMATIC DRIVE POSITIONER

SE-53

C

D

E

F

G

H

J

K

L

MA

B

SE

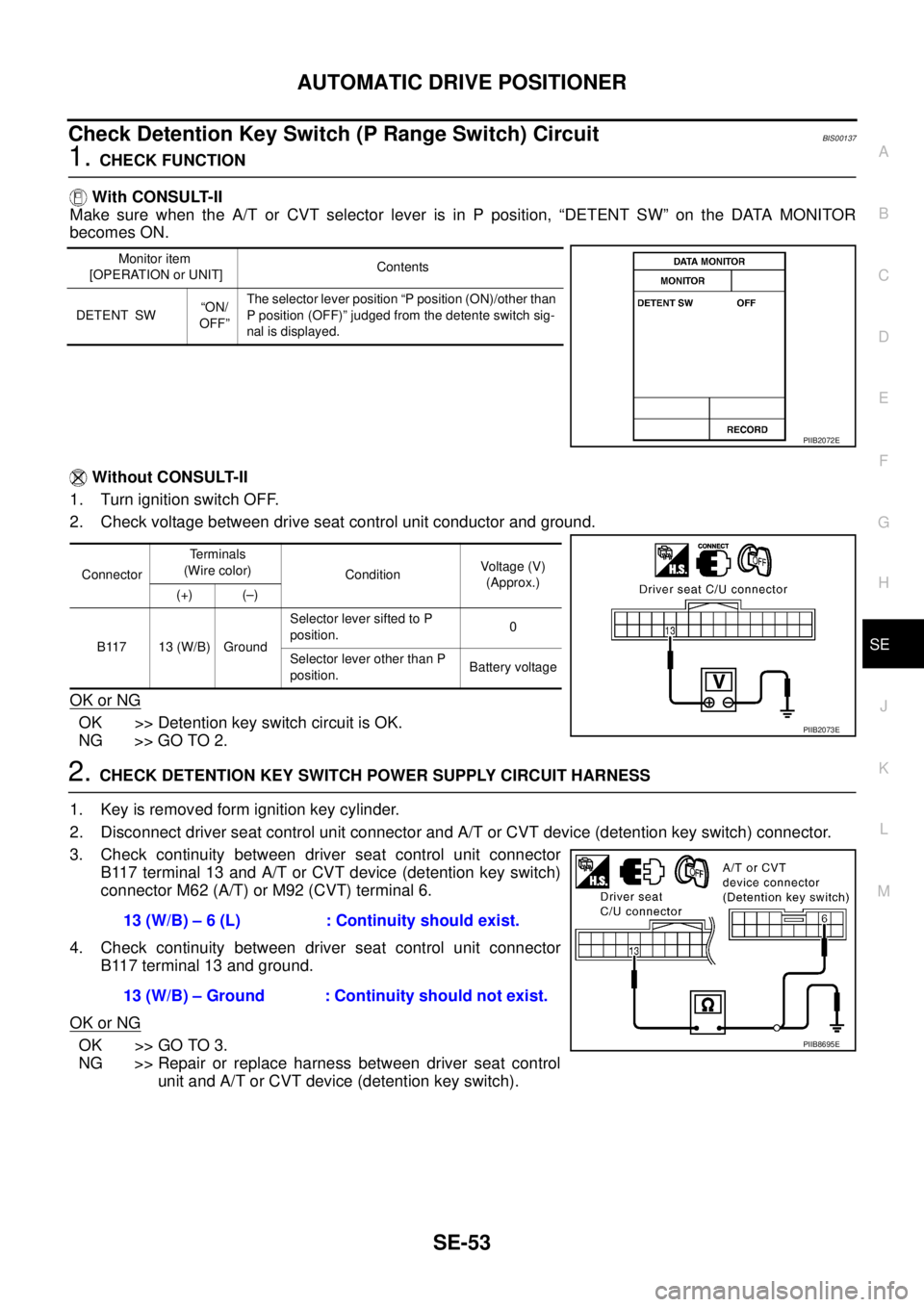

Check Detention Key Switch (P Range Switch) Circuit BIS00137

1. CHECK FUNCTION

With CONSULT-II

Make sure when the A/T or CVT selector lever is in P position, “DETENT SW” on the DATA MONITOR

becomes ON.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between drive seat control unit conductor and ground.

OK or NG

OK >> Detention key switch circuit is OK.

NG >> GO TO 2.

2. CHECK DETENTION KEY SWITCH POWER SUPPLY CIRCUIT HARNESS

1. Key is removed form ignition key cylinder.

2. Disconnect driver seat control unit connector and A/T or CVT device (detention key switch) connector.

3. Check continuity between driver seat control unit connector

B117 terminal 13 and A/T or CVT device (detention key switch)

connector M62 (A/T) or M92 (CVT) terminal 6.

4. Check continuity between driver seat control unit connector

B117 terminal 13 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between driver seat control

unit and A/T or CVT device (detention key switch).

Monitor item

[OPERATION or UNIT]Contents

DETENT SW“ON/

OFF”The selector lever position “P position (ON)/other than

P position (OFF)” judged from the detente switch sig-

nal is displayed.

PIIB2072E

ConnectorTerminals

(Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

B117 13 (W/B) GroundSelector lever sifted to P

position.0

Selector lever other than P

position.Battery voltage

PIIB2073E

13 (W/B) – 6 (L) : Continuity should exist.

13 (W/B) – Ground : Continuity should not exist.

PIIB8695E

Page 3310 of 3502

SE-54

AUTOMATIC DRIVE POSITIONER

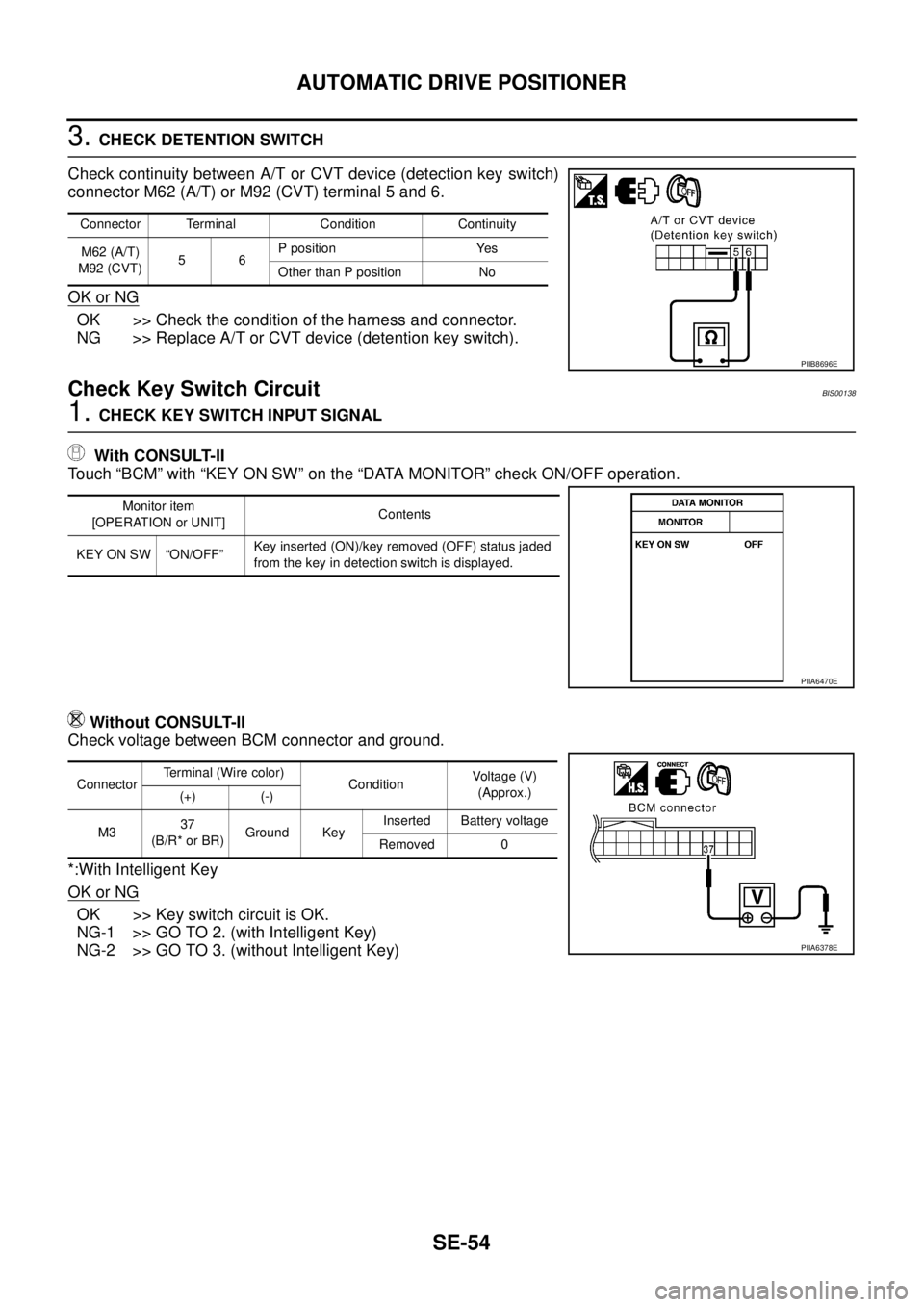

3. CHECK DETENTION SWITCH

Check continuity between A/T or CVT device (detection key switch)

connector M62 (A/T) or M92 (CVT) terminal 5 and 6.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace A/T or CVT device (detention key switch).

Check Key Switch CircuitBIS00138

1. CHECK KEY SWITCH INPUT SIGNAL

With CONSULT-II

Touch “BCM” with “KEY ON SW” on the “DATA MONITOR” check ON/OFF operation.

Without CONSULT-II

Check voltage between BCM connector and ground.

*:With Intelligent Key

OK or NG

OK >> Key switch circuit is OK.

NG-1 >> GO TO 2. (with Intelligent Key)

NG-2 >> GO TO 3. (without Intelligent Key)

Connector Terminal Condition Continuity

M62 (A/T)

M92 (CVT)56P position Yes

Other than P position No

PIIB8696E

Monitor item

[OPERATION or UNIT]Contents

KEY ON SW “ON/OFF”Key inserted (ON)/key removed (OFF) status jaded

from the key in detection switch is displayed.

PIIA6470E

ConnectorTerminal (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (-)

M337

(B/R* or BR)Ground KeyInserted Battery voltage

Removed 0

PIIA6378E