ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3169 of 5121

![NISSAN TEANA 2008 Service Manual LAN-102

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

TCM BRANCH LINE CIRCUIT

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841818

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Di NISSAN TEANA 2008 Service Manual LAN-102

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

TCM BRANCH LINE CIRCUIT

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841818

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Di](/img/5/57391/w960_57391-3168.png)

LAN-102

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

TCM BRANCH LINE CIRCUIT

TCM BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841818

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con-

nector side).

-TCM

- Harness connector F123

- Harness connector E6

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of TCM.

2. Check the resistance between the TCM harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the TCM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the TCM. Refer to the following.

VQ25DE: TM-249, "

Diagnosis Procedure"

VQ35DE: TM-85, "Diagnosis Procedure"

Is the inspection result normal?

YES (Present error)>>Replace the TCM. Refer to the following.

VQ25DE: TM-315, "

Exploded View"

VQ35DE: TM-153, "Exploded View"

YES (Past error)>>Error was detected in the TCM branch line.

NO >> Repair the power supply and the ground circuit.

TCM harness connector

Resistance (Ω)

Connector No. Terminal No.

F23 32 31 Approx. 54 – 66

Page 3170 of 5121

![NISSAN TEANA 2008 Service Manual LAN

IPDM-E BRANCH LINE CIRCUIT

LAN-103

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM-E BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841819

1.CHECK CONNECTO NISSAN TEANA 2008 Service Manual LAN

IPDM-E BRANCH LINE CIRCUIT

LAN-103

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM-E BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841819

1.CHECK CONNECTO](/img/5/57391/w960_57391-3169.png)

LAN

IPDM-E BRANCH LINE CIRCUIT

LAN-103

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

IPDM-E BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000003841819

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the IPDM E/R for damage, bend and loose connection (unit side

and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of IPDM E/R.

2. Check the resistance between the IPDM E/R harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the IPDM E/R branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the IPDM E/R. Refer to PCS-19, "

Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the IPDM E/R. Refer to PCS-34, "Exploded View".

YES (Past error)>>Error was detected in the IPDM E/R branch line.

NO >> Repair the power supply and the ground circuit.

IPDM E/R harness connector

Resistance (Ω)

Connector No. Terminal No.

E11 40 39 Approx. 108 – 132

Page 3171 of 5121

![NISSAN TEANA 2008 Service Manual LAN-104

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis ProcedureINFOID:0000000003841820

1.CONNECTOR INSPECTION

1. Turn the ignition switch O NISSAN TEANA 2008 Service Manual LAN-104

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis ProcedureINFOID:0000000003841820

1.CONNECTOR INSPECTION

1. Turn the ignition switch O](/img/5/57391/w960_57391-3170.png)

LAN-104

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

CAN COMMUNICATION CIRCUIT

CAN COMMUNICATION CIRCUIT

Diagnosis ProcedureINFOID:0000000003841820

1.CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect all the unit connectors on CAN communication system.

4. Check terminals and connectors for damage, bend and loose connection.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector terminals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check the harness and repair the root cause.

3.CHECK HARNESS CONTINUITY (SHORT CIRCUIT)

Check the continuity between the data link connector and the ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Check the harness and repair the root cause.

4.CHECK ECM AND IPDM E/R TERMINATION CIRCUIT

1. Remove the ECM and the IPDM E/R.

2. Check the resistance between the ECM terminals.

3. Check the resistance between the IPDM E/R terminals.

Is the measurement value within the specification?

YES >> GO TO 5.

NO >> Replace the ECM and/or the IPDM E/R.

5.CHECK SYMPTOM

Connect all the connectors. Check if the symptoms described in the “Symptom (Results from interview with

customer)” are reproduced.

Data link connector

Continuity

Connector No. Terminal No.

M4 6 14 Not existed

Data link connector

GroundContinuity

Connector No. Terminal No.

M46 Not existed

14 Not existed

ECM

Resistance (Ω)

Te r m i n a l N o .

98 97 Approx. 108 – 132

IPDM E/R

Resistance (Ω)

Te r m i n a l N o .

40 39 Approx. 108 – 132

LKIA0037E

Page 3172 of 5121

![NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-105

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follo NISSAN TEANA 2008 Service Manual LAN

CAN COMMUNICATION CIRCUIT

LAN-105

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follo](/img/5/57391/w960_57391-3171.png)

LAN

CAN COMMUNICATION CIRCUIT

LAN-105

< COMPONENT DIAGNOSIS >[CAN SYSTEM (TYPE 9)]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Inspection result

Reproduced>>GO TO 6.

Non-reproduced>>Start the diagnosis again. Follow the trouble diagnosis procedure when past error is

detected.

6.CHECK UNIT REPRODUCTION

Perform the reproduction test as per the following procedure for each unit.

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect one of the unit connectors of CAN communication system.

NOTE:

ECM and IPDM E/R have a termination circuit. Check other units first.

4. Connect the battery cable to the negative terminal. Check if the symptoms described in the “Symptom

(Results from interview with customer)” are reproduced.

NOTE:

Although unit-related error symptoms occur, do not confuse them with other symptoms.

Inspection result

Reproduced>>Connect the connector. Check other units as per the above procedure.

Non-reproduced>>Replace the unit whose connector was disconnected.

Page 3208 of 5121

MA-20

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

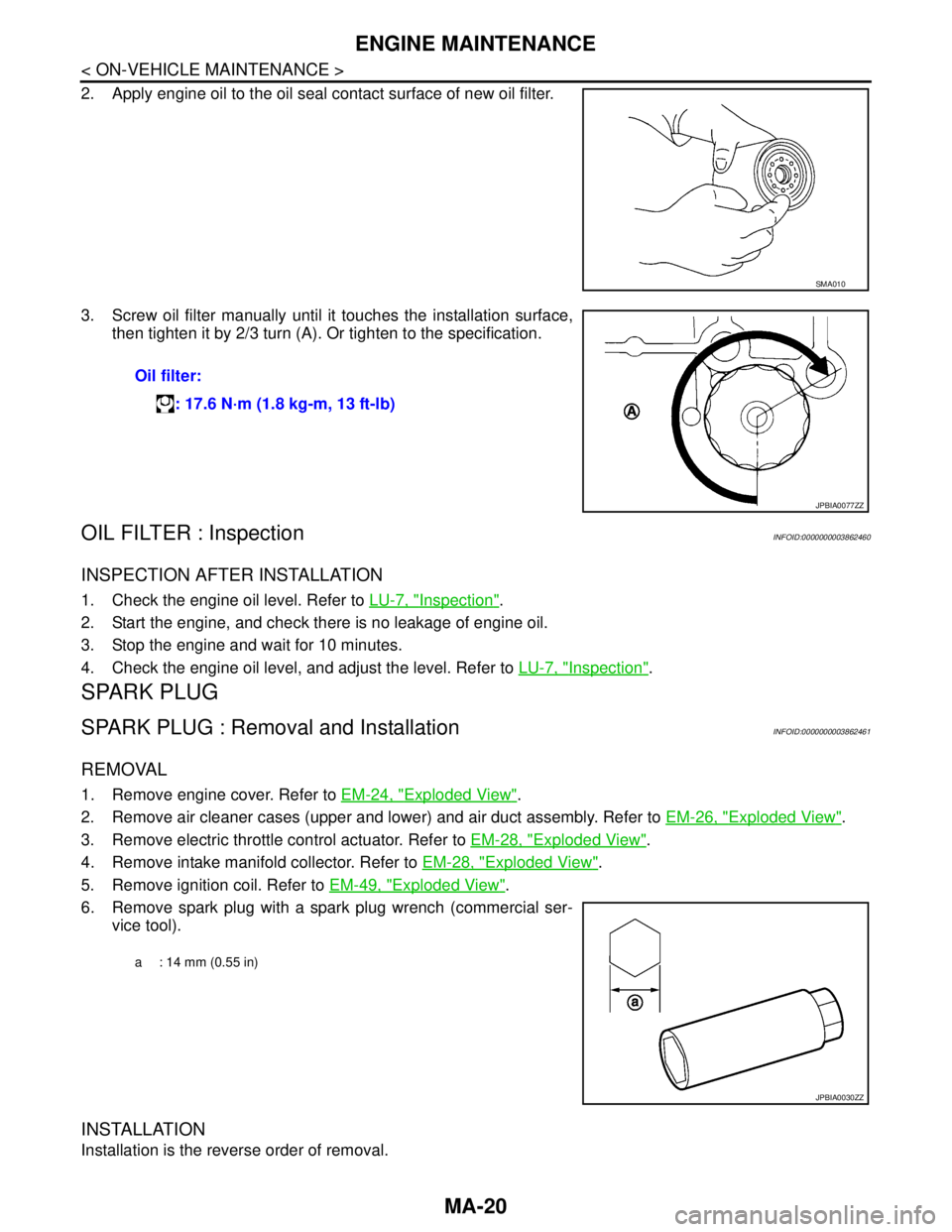

2. Apply engine oil to the oil seal contact surface of new oil filter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A). Or tighten to the specification.

OIL FILTER : InspectionINFOID:0000000003862460

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-7, "Inspection".

2. Start the engine, and check there is no leakage of engine oil.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to LU-7, "

Inspection".

SPARK PLUG

SPARK PLUG : Removal and InstallationINFOID:0000000003862461

REMOVAL

1. Remove engine cover. Refer to EM-24, "Exploded View".

2. Remove air cleaner cases (upper and lower) and air duct assembly. Refer to EM-26, "

Exploded View".

3. Remove electric throttle control actuator. Refer to EM-28, "

Exploded View".

4. Remove intake manifold collector. Refer to EM-28, "

Exploded View".

5. Remove ignition coil. Refer to EM-49, "

Exploded View".

6. Remove spark plug with a spark plug wrench (commercial ser-

vice tool).

INSTALLATION

Installation is the reverse order of removal.

SMA010

Oil filter:

: 17.6 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ

a : 14 mm (0.55 in)

JPBIA0030ZZ

Page 3270 of 5121

MWI-16

< FUNCTION DIAGNOSIS >

METER SYSTEM

ENGINE COOLANT TEMPERATURE GAUGE : Component Description

INFOID:0000000003792522

FUEL GAUGE

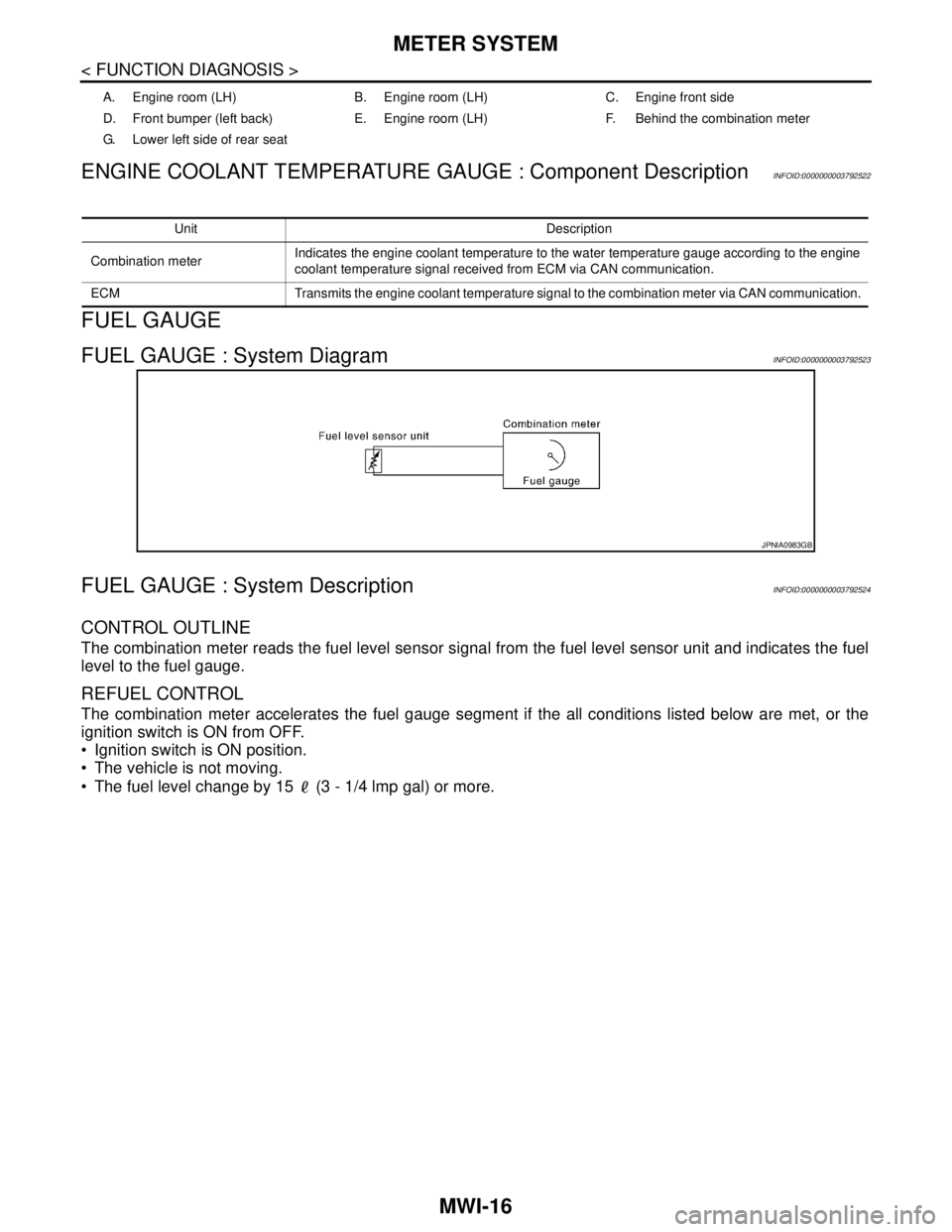

FUEL GAUGE : System DiagramINFOID:0000000003792523

FUEL GAUGE : System DescriptionINFOID:0000000003792524

CONTROL OUTLINE

The combination meter reads the fuel level sensor signal from the fuel level sensor unit and indicates the fuel

level to the fuel gauge.

REFUEL CONTROL

The combination meter accelerates the fuel gauge segment if the all conditions listed below are met, or the

ignition switch is ON from OFF.

Ignition switch is ON position.

The vehicle is not moving.

The fuel level change by 15 (3 - 1/4 lmp gal) or more.

A. Engine room (LH) B. Engine room (LH) C. Engine front side

D. Front bumper (left back) E. Engine room (LH) F. Behind the combination meter

G. Lower left side of rear seat

Unit Description

Combination meterIndicates the engine coolant temperature to the water temperature gauge according to the engine

coolant temperature signal received from ECM via CAN communication.

ECM Transmits the engine coolant temperature signal to the combination meter via CAN communication.

JPNIA0983GB

Page 3282 of 5121

MWI-28

< FUNCTION DIAGNOSIS >

METER SYSTEM

LOW FUEL WARNING

The combination meter indicates the low fuel warning judged by the fuel level sensor signal received from the

fuel level sensor unit.

Warning operation condition

Fuel level: Approx. 11 (2 - 2/5 Imp gal) or less

DOOR/TRUNK OPEN WARNING

The combination meter indicates the door open warning judged by each door switch signal received from the

BCM via CAN communication line.

The combination meter indicates the trunk open warning judged by trunk switch signal received from the

BCM via CAN communication line.

INSTANTANEOUS FUEL CONSUMPTION

The combination meter receives the fuel consumption monitor signal from the ECM and the vehicle speed

signal from the ABS actuator and electric unit (control unit) via CAN communication.

The combination meter calculates instantaneous fuel consumption according to the fuel consumption moni-

tor signal and the vehicle speed signal received via CAN communication.

AVERAGE FUEL CONSUMPTION

The combination meter receives the fuel consumption monitor signal from the ECM and the vehicle speed

signal from the ABS actuator and electric unit (control unit) via CAN communication.

The combination meter calculates the average fuel consumption according to the fuel consumption monitor

signal and the vehicle speed signal received via CAN communication.

The average fuel consumption displayed on the information display is uploaded in approximately 30-second

intervals.

NOTE:

When turning ON the ignition switch after triggering a reset or removing/installing the battery, “−−−−” is indi-

cated until 30 seconds/500 m (0.31 miles) of driving.

AVERAGE VEHICLE SPEED

The combination meter receives the vehicle speed signal from the ABS actuator and electric unit (control

unit) via CAN communication.

Measures the time while the ignition switch is ON through the combination meter.

The combination meter the average vehicle speed according to the above signals.

The average vehicle speed displayed on the information display is uploaded in approximately 30-second

intervals.

NOTE:

When turning ON the ignition switch after triggering a reset or removing/installing the battery, “−−−−” is indi-

cated until 30 seconds/500 m (0.31 miles) of driving.

TRAVEL TIME

Measures the time while the ignition switch is ON through the combination meter.

TRAVEL DISTANCE

The combination meter receives the vehicle speed signal from the ABS actuator and electric unit (control

unit) via CAN communication.

The combination meter calculates the vehicle distance according to the vehicle speed signal. The vehicle

distance is displayed.

POSSIBLE DRIVING DISTANCE

The combination meter calculates possible driving distance according to the vehicle speed signal and fuel

consumption monitor signal transmitted via CAN communication and the fuel level sensor signal transmitted

from the fuel level sensor.

NOTE:

When turning ON the ignition switch after removing/installing the battery, “−−−−” is indicated until 30 sec-

onds.

The indicated values may not match each other when refueling with the ignition switch ON. Refer to MWI-

124, "INFORMATION DISPLAY : Description".

AMBIENT AIR TEMPERATURE

The combination meter receives the ambient sensor signal from the ambient sensor.

The combination meter calculates the ambient temperature according to the ambient sensor signal.

The indicated temperature does not increase if the vehicle speed is less than 20 km/h (12 MPH).

Page 3286 of 5121

MWI-32

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

DIAGNOSIS SYSTEM (METER)

Diagnosis DescriptionINFOID:0000000003792550

SELF-DIAGNOSIS MODE

Information display LCD segment operation can be checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

1. Turn ignition switch ON, and switch the trip meter to “trip A” or “trip B”.

NOTE:

If the diagnosis function is activated with “trip A” displayed, the mileage on “trip A” is reset to “0000.0”.

(The same way for “trip B”.)

2. Turn ignition switch OFF.

3. While pressing the trip reset switch (1), turn ignition switch ON

again.

4. Make sure that the trip meter displays “0000.0”.

5. Press the trip reset switch at least 3 times. (Within 7 seconds

after the ignition switch is turned ON.)

6. The unified meter control unit is turned to self-diagnosis mode.

The segment dots of the information display LCD (1) blink

alternately.

Water temperature gauge and fuel gauge return to zero, simul-

taneously.

NOTE:

Check combination meter power supply and ground circuit when the self-diagnosis mode of the combi-

nation meter does not start. Replace combination meter if abnormal.

If any of the segments are not displayed, replace combination meter.

JPNIA1020ZZ

JPNIA0766ZZ

Page 3291 of 5121

MWI

U1000 CAN COMM CIRCUIT

MWI-37

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003792552

CAN (Controller Area Network) is a serial communication system for real time application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent error detectability. Many

electronic control units are equipped onto vehicles, and each control unit shares information and links with

other control units during operation (not independent). In CAN communication, control units are connected

with two communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with

less wiring. Each control unit transmits/receives data but selectively reads required data only.

CAN Communication Signal Chart. Refer to LAN-13, "

How to Use CAN Communication Signal Chart".

DTC LogicINFOID:0000000003792553

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003792554

1.PERFORM SELF DIAGNOSTIC

1. Turn ignition switch ON and wait for 2 seconds or more.

2. Check “Self Diagnostic Result” of “METER/M&A”.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Refer to LAN-14, "Trouble Diagnosis Flow Chart".

NO >> Refer to GI-35, "

Intermittent Incident".

DTCDisplay contents of

CONSULT-IIIDiagnostic item is detected when ... Probable malfunction location

U1000 CAN COMM CIRCUITWhen combination meter is not transmitting or

receiving CAN communication signal for 2

seconds or more.CAN communication system

Page 3296 of 5121

MWI-42

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

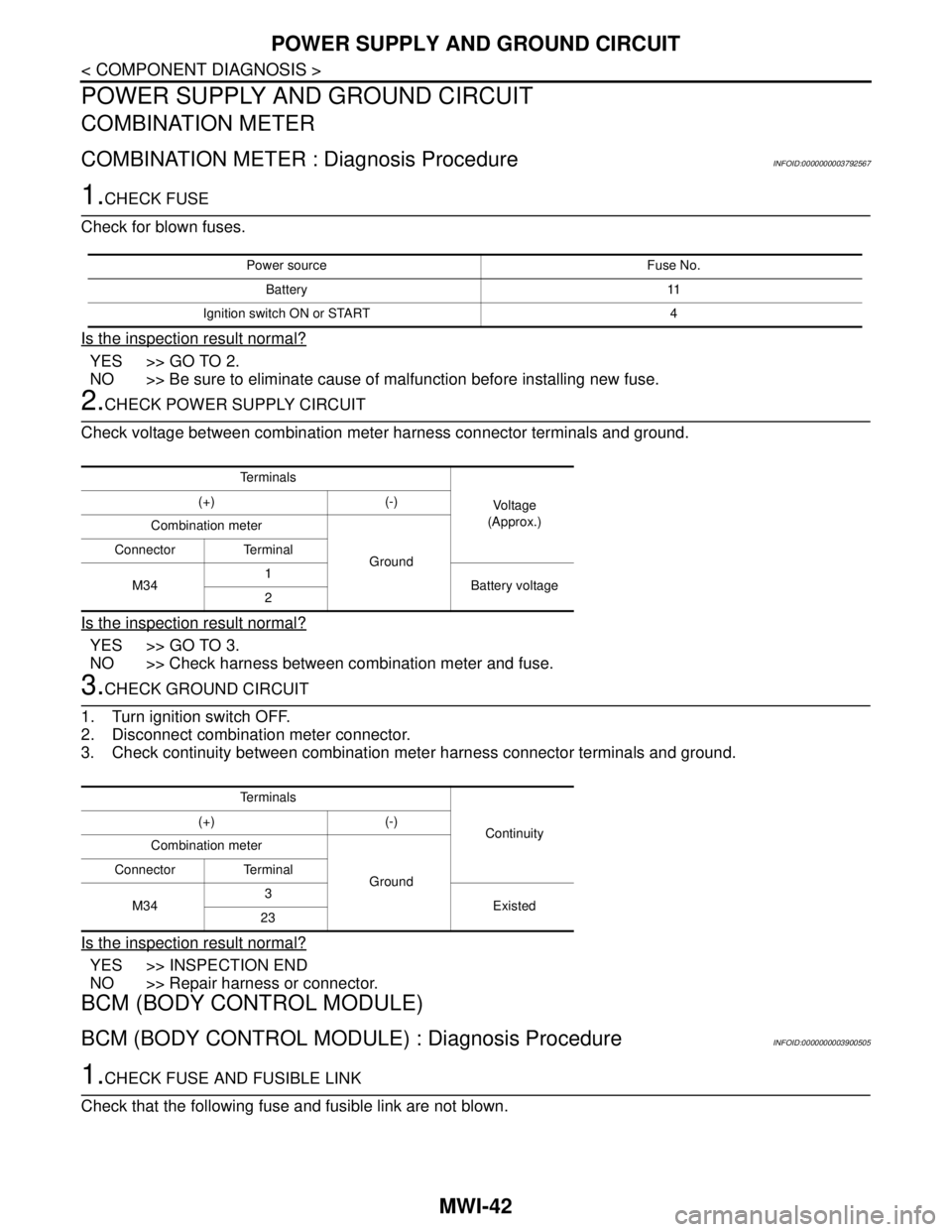

COMBINATION METER : Diagnosis ProcedureINFOID:0000000003792567

1.CHECK FUSE

Check for blown fuses.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between combination meter harness connector terminals and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Check harness between combination meter and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector.

3. Check continuity between combination meter harness connector terminals and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair harness or connector.

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000003900505

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Power source Fuse No.

Battery 11

Ignition switch ON or START 4

Te r m i n a l s

Vol tag e

(Approx.) (+) (-)

Combination meter

Ground Connector Terminal

M341

Battery voltage

2

Te r m i n a l s

Continuity (+) (-)

Combination meter

Ground Connector Terminal

M343

Existed

23