ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4770 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

TM-297

< PRECAUTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI NISSAN TEANA 2008 Service Manual PRECAUTIONS

TM-297

< PRECAUTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI](/img/5/57391/w960_57391-4769.png)

PRECAUTIONS

TM-297

< PRECAUTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003901473

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003901477

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 4771 of 5121

![NISSAN TEANA 2008 Service Manual TM-298

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003901480

When performing the procedure after removing cowl top cover, cover

the lower end NISSAN TEANA 2008 Service Manual TM-298

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003901480

When performing the procedure after removing cowl top cover, cover

the lower end](/img/5/57391/w960_57391-4770.png)

TM-298

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003901480

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000003806496

The ECM has an on board diagnostic system. It will light up the Malfunction Indicator Lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal

before any repair or inspection work. The open/short circuit of related switches, sensors, solenoid

valves, etc. will cause the MIL to light up.

Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EVAP system or fuel injection system, etc.

Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Precaution for TCM and CVT Assembly ReplacementINFOID:0000000003806497

CAUTION:

Check if new data (Unit ID) are entered correctly after replacing CVT assembly and erasing data in

TCM. (Connect CONSULT-III, and then turn ignition switch OFF.)

When replacing CVT assembly or TCM, refer to the pattern table below and erase the EEPROM in the

TCM if necessary.

EEPROM ERASING PATTERNS

Removal and Installation Procedure for CVT Unit ConnectorINFOID:0000000003806498

REMOVAL

PIIB3706J

CVT assembly TCM Erasing EEPROM in TCM Remarks

Replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state. (CVT assembly must be replaced

first.)

Not replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state.

Replaced Not replaced RequiredRequired because data has been written in the EE-

PROM in the TCM and because the TCM cannot write

data from the ROM assembly in the transmission.

Page 4773 of 5121

![NISSAN TEANA 2008 Service Manual TM-300

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Turn ignition switch OFF and disconnect negative battery

cable before connecting or disconnecting the TCM harness

connector. Because battery voltage is NISSAN TEANA 2008 Service Manual TM-300

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Turn ignition switch OFF and disconnect negative battery

cable before connecting or disconnecting the TCM harness

connector. Because battery voltage is](/img/5/57391/w960_57391-4772.png)

TM-300

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Turn ignition switch OFF and disconnect negative battery

cable before connecting or disconnecting the TCM harness

connector. Because battery voltage is applied to TCM even if

ignition switch is turned OFF.

When connecting or disconnecting pin connectors into or

from TCM, do not damage pin terminals (bend or break).

Check that there are not any bends or breaks on TCM pin ter-

minal, when connecting pin connectors.

Perform TCM input/output signal inspection and check

whether TCM functions normally or not before replacing TCM.

Refer to TM-275, "

Reference Value".

Perform “DTC Confirmation Procedure” after performing each

TROUBLE DIAGNOSIS.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

Always use the specified brand of CVT fluid. Refer to MA-11, "

Flu-

ids and Lubricants".

Use lint-free paper, not cloth rags, during work.

Dispose of the waste oil using the methods prescribed by law, ordi-

nance, etc. after replacing the CVT fluid.

Service Notice or PrecautionINFOID:0000000003806500

OBD SELF-DIAGNOSIS

CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the Malfunction Indicator (MI). Refer to the table on TM-204, "

CONSULT-III Function

(TRANSMISSION)" for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MI are automatically stored in both the ECM and TCM memories.

Always perform the procedure on TM-202, "

Diagnosis Description" to complete the repair and avoid

unnecessary blinking of the MIL.

For details of OBD, refer to EC-102, "

Diagnosis Description".

SEF289H

SEF291H

MEF040DA

SAT652J

Page 4783 of 5121

![NISSAN TEANA 2008 Service Manual TM-310

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

ROAD TEST

ROAD TEST

DescriptionINFOID:0000000003806508

DESCRIPTION

The purpose of the test is to determine the overall performance of

CVT and analyze NISSAN TEANA 2008 Service Manual TM-310

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

ROAD TEST

ROAD TEST

DescriptionINFOID:0000000003806508

DESCRIPTION

The purpose of the test is to determine the overall performance of

CVT and analyze](/img/5/57391/w960_57391-4782.png)

TM-310

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

ROAD TEST

ROAD TEST

DescriptionINFOID:0000000003806508

DESCRIPTION

The purpose of the test is to determine the overall performance of

CVT and analyze causes of problems.

The road test consists of the following three parts:

1. “Check Before Engine Is Started” TM-310

.

2. “Check at Idle” TM-311

.

3. “Cruise Test” TM-312

.

Before the road test, familiarize yourself with all test procedures

and items to check.

Perform tests for all the check items until a malfunction phenome-

non is detected. Perform diagnosis for NG items after the comple-

tion of road tests.

CONSULT-III SETTING PROCEDURE

Using CONSULT-III, perform a cruise test and record the result.

Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “Data Monitor” on “Direct Diagnostic Mode” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to TM-312, "

Cruise Test".

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out.

Check before Engine Is StartedINFOID:0000000003806509

1.CHECK SHIFT POSITION INDICATOR

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Never start engine.)

Has shift position indicator been turned ON for about 2 seconds?

YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.

Refer to TM-204, "

CONSULT-III Function (TRANSMISSION)".

3. Go to TM-311, "

Check at Idle".

SAT786A

SAT496G

Page 4784 of 5121

![NISSAN TEANA 2008 Service Manual ROAD TEST

TM-311

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

NO >> Stop “Road Test”. Refer to TM-286, "Symptom Table".

Check at IdleINFOID:0000000003806510

1.CHECK STA NISSAN TEANA 2008 Service Manual ROAD TEST

TM-311

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

NO >> Stop “Road Test”. Refer to TM-286, "Symptom Table".

Check at IdleINFOID:0000000003806510

1.CHECK STA](/img/5/57391/w960_57391-4783.png)

ROAD TEST

TM-311

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

NO >> Stop “Road Test”. Refer to TM-286, "Symptom Table".

Check at IdleINFOID:0000000003806510

1.CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch to “START” position.

Is engine started?

YES >> GO TO 2.

NO >> Stop “Road Test”. Refer to TM-286, "

Symptom Table".

2.CHECK STARTING THE ENGINE

1. Turn ignition switch ON.

2. Move selector lever to “D”, “L” or “R” position.

3. Turn ignition switch to “START” position.

Is engine started?

YES >> Stop “Road Test”. Refer to TM-286, "Symptom Table".

NO >> GO TO 3.

3.CHECK “P” POSITION FUNCTION

1. Move selector lever to “P” position.

2. Turn ignition switch OFF.

3. Release parking brake.

4. Push vehicle forward or backward.

5. Apply parking brake.

Does vehicle move forward or backward?

YES >> Refer to TM-286, "Symptom Table". GO TO 4.

NO >> GO TO 4.

4.CHECK “N” POSITION FUNCTION

1. Start engine.

2. Move selector lever to “N” position.

3. Release parking brake.

Does vehicle move forward or backward?

YES >> Refer to TM-286, "Symptom Table". GO TO 5.

NO >> GO TO 5.

5.CHECK SHIFT SHOCK

1. Apply foot brake.

2. Move selector lever to “R” position.

Is there large shock when changing from

“N” to “R” position?

YES >> Refer to TM-286, "Symptom Table". GO TO 6.

NO >> GO TO 6.

6.CHECK “R” POSITION FUNCTION

Release foot brake for several seconds.

Does vehicle creep backward when foot brake is released?

YES >> GO TO 7.

NO >> Refer to TM-286, "

Symptom Table". GO TO 7.

7.CHECK “D” POSITION FUNCTION

Move selector lever to “D” position and check if vehicle creeps forward.

Does vehicle creep forward in all positions?

YES >> Go to TM-312, "Cruise Test".

NO >> Stop “Road Test”. Refer to TM-286, "

Symptom Table".

Page 4787 of 5121

![NISSAN TEANA 2008 Service Manual TM-314

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003806512

INSPECTION

1. Place selector lever in “P” position, and turn ignition swi NISSAN TEANA 2008 Service Manual TM-314

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003806512

INSPECTION

1. Place selector lever in “P” position, and turn ignition swi](/img/5/57391/w960_57391-4786.png)

TM-314

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003806512

INSPECTION

1. Place selector lever in “P” position, and turn ignition switch ON (engine stop).

2. Check that selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

check that selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move the selector lever and check for excessive effort, sticking, noise or rattle.

4. Check that selector lever stops at each position with the feel of engagement when it is moved through all

the positions. Check that the actual position of the selector lever matches the position shown by the shift

position indicator and the manual lever on the transaxle.

5. The method of operating the selector lever to individual posi-

tions correctly should be as shown.

6. When selector button is pressed in “P”, “R”, “N”, “D” or “L” posi-

tion without applying forward/backward force to selector lever,

check button operation for sticking.

7. Check that back-up lamps illuminate only when selector lever is

placed in the “R” position.

8. When in “R” position, check that back-up lamps illuminate even

when the selector lever is pushed toward the “P” position.

CAUTION:

Check the lighting without pressing shift button.

9. Check that the back-up lamps do not illuminate when selector lever is pushed toward the “R” position

when in the “P” or “N” position.

CAUTION:

Check the lighting without pressing shift button.

10. Check that the engine can only be started with the selector lever in the “P” and “N” positions.

11. Check that transaxle is locked completely in “P” position.

ADJUSTMENT

1. Place selector lever in “ P” position.

CAUTION:

Turn wheels more than 1/4 rotations and apply the park lock.

2. Loosen nut (A) and place manual lever (B) in “P” position.

CAUTION:

Never apply any force to the manual lever.

3. Tighten nut. Refer to TM-319, "

Exploded View".

CAUTION:

Fix the manual lever when tightening.

JPDIA0343GB

JPDIA0780ZZ

Page 4818 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

VTL-7

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIO NISSAN TEANA 2008 Service Manual PRECAUTIONS

VTL-7

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIO](/img/5/57391/w960_57391-4817.png)

PRECAUTIONS

VTL-7

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003845339

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003845340

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 4875 of 5121

![NISSAN TEANA 2008 Service Manual VTL-64

< PRECAUTION >[WITH 7 INCH DISPLAY]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003894443

The Su NISSAN TEANA 2008 Service Manual VTL-64

< PRECAUTION >[WITH 7 INCH DISPLAY]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003894443

The Su](/img/5/57391/w960_57391-4874.png)

VTL-64

< PRECAUTION >[WITH 7 INCH DISPLAY]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003894443

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003894445

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 4935 of 5121

WCS

WARNING CHIME SYSTEM

WCS-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

FUNCTION DIAGNOSIS

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM

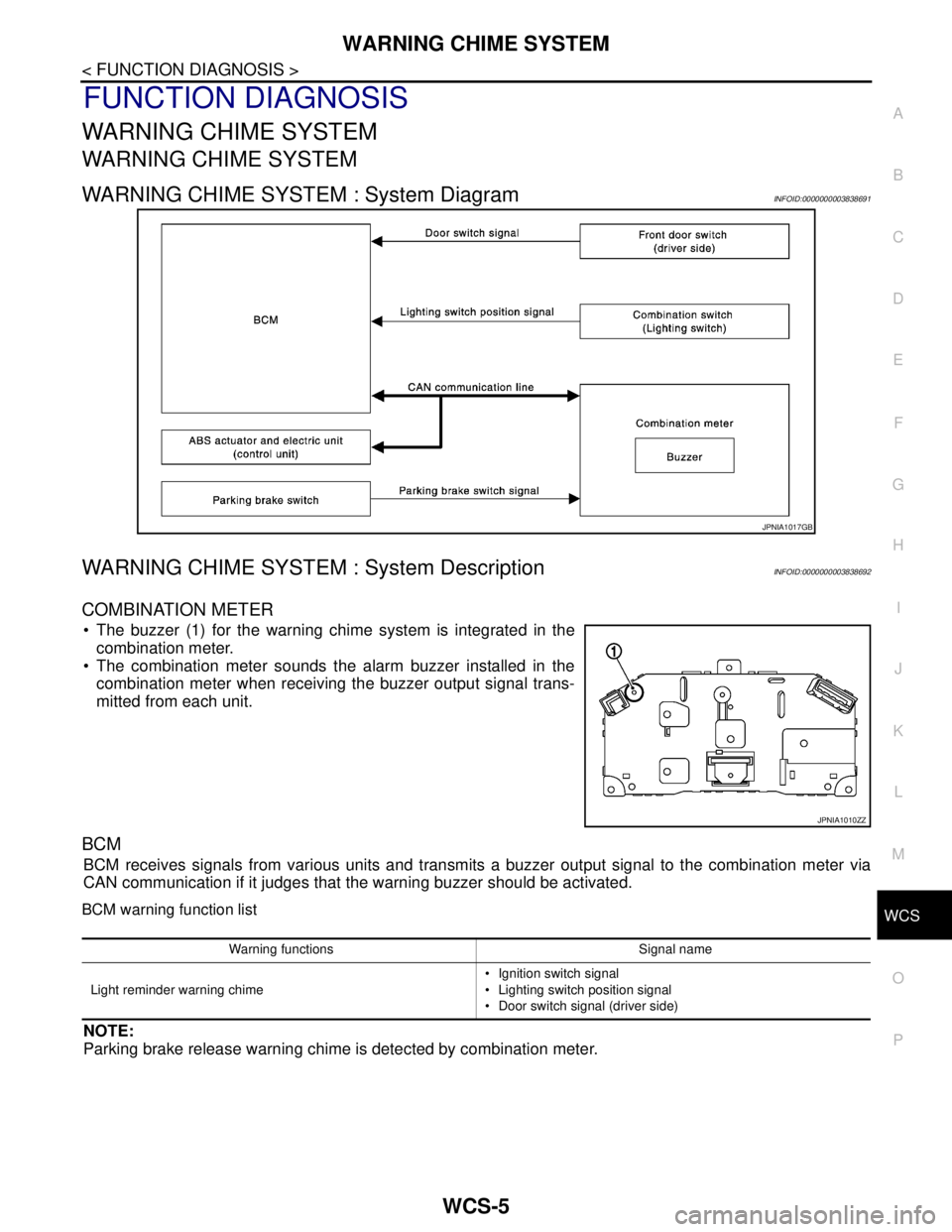

WARNING CHIME SYSTEM : System DiagramINFOID:0000000003838691

WARNING CHIME SYSTEM : System DescriptionINFOID:0000000003838692

COMBINATION METER

The buzzer (1) for the warning chime system is integrated in the

combination meter.

The combination meter sounds the alarm buzzer installed in the

combination meter when receiving the buzzer output signal trans-

mitted from each unit.

BCM

BCM receives signals from various units and transmits a buzzer output signal to the combination meter via

CAN communication if it judges that the warning buzzer should be activated.

BCM warning function list

NOTE:

Parking brake release warning chime is detected by combination meter.

JPNIA1017GB

JPNIA1010ZZ

Warning functions Signal name

Light reminder warning chime Ignition switch signal

Lighting switch position signal

Door switch signal (driver side)

Page 4937 of 5121

WCS

WARNING CHIME SYSTEM

WCS-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

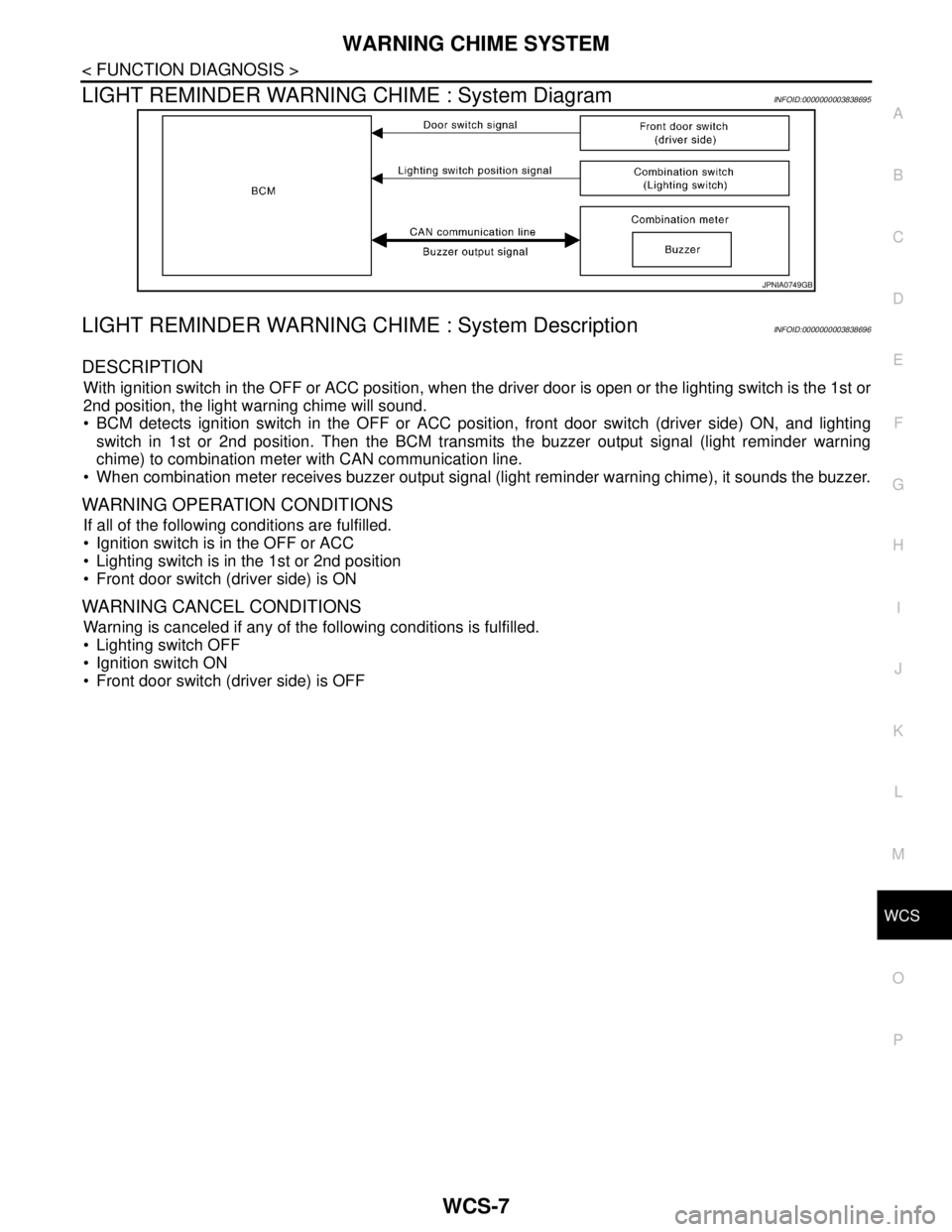

LIGHT REMINDER WARNING CHIME : System DiagramINFOID:0000000003838695

LIGHT REMINDER WARNING CHIME : System DescriptionINFOID:0000000003838696

DESCRIPTION

With ignition switch in the OFF or ACC position, when the driver door is open or the lighting switch is the 1st or

2nd position, the light warning chime will sound.

BCM detects ignition switch in the OFF or ACC position, front door switch (driver side) ON, and lighting

switch in 1st or 2nd position. Then the BCM transmits the buzzer output signal (light reminder warning

chime) to combination meter with CAN communication line.

When combination meter receives buzzer output signal (light reminder warning chime), it sounds the buzzer.

WARNING OPERATION CONDITIONS

If all of the following conditions are fulfilled.

Ignition switch is in the OFF or ACC

Lighting switch is in the 1st or 2nd position

Front door switch (driver side) is ON

WARNING CANCEL CONDITIONS

Warning is canceled if any of the following conditions is fulfilled.

Lighting switch OFF

Ignition switch ON

Front door switch (driver side) is OFF

JPNIA0749GB