ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 5018 of 5121

WW-6

< FUNCTION DIAGNOSIS >

FRONT WIPER AND WASHER SYSTEM

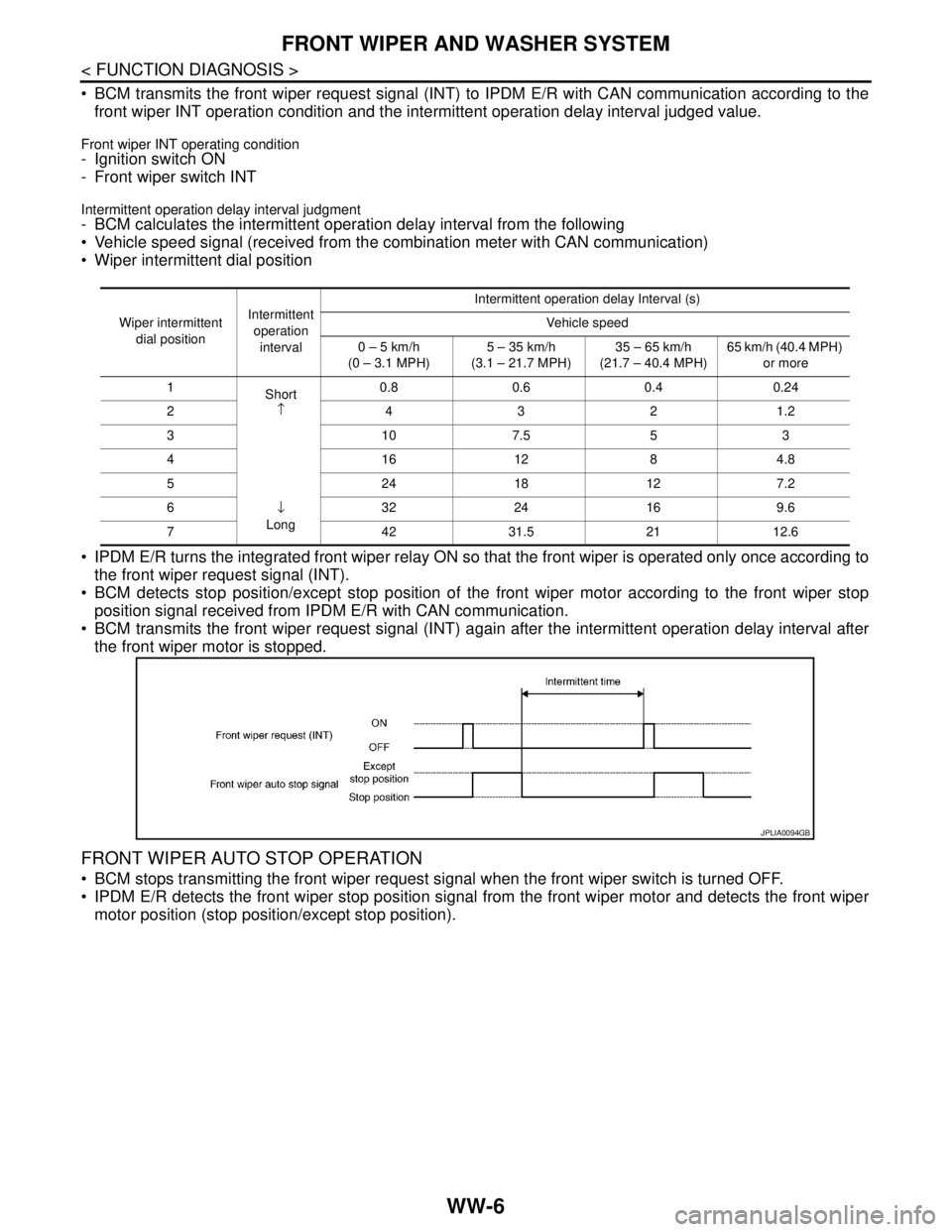

BCM transmits the front wiper request signal (INT) to IPDM E/R with CAN communication according to the

front wiper INT operation condition and the intermittent operation delay interval judged value.

Front wiper INT operating condition- Ignition switch ON

- Front wiper switch INT

Intermittent operation delay interval judgment- BCM calculates the intermittent operation delay interval from the following

Vehicle speed signal (received from the combination meter with CAN communication)

Wiper intermittent dial position

IPDM E/R turns the integrated front wiper relay ON so that the front wiper is operated only once according to

the front wiper request signal (INT).

BCM detects stop position/except stop position of the front wiper motor according to the front wiper stop

position signal received from IPDM E/R with CAN communication.

BCM transmits the front wiper request signal (INT) again after the intermittent operation delay interval after

the front wiper motor is stopped.

FRONT WIPER AUTO STOP OPERATION

BCM stops transmitting the front wiper request signal when the front wiper switch is turned OFF.

IPDM E/R detects the front wiper stop position signal from the front wiper motor and detects the front wiper

motor position (stop position/except stop position).

Wiper intermittent

dial positionIntermittent

operation

intervalIntermittent operation delay Interval (s)

Vehicle speed

0 – 5 km/h

(0 – 3.1 MPH)5 – 35 km/h

(3.1 – 21.7 MPH)35 – 65 km/h

(21.7 – 40.4 MPH)65 km/h (40.4 MPH)

or more

1

Short

↑

↓

Long0.8 0.6 0.4 0.24

24321.2

3107.553

4161284.8

5 2418127.2

6 3224169.6

7 4231.52112.6

JPLIA0094GB

Page 5019 of 5121

FRONT WIPER AND WASHER SYSTEM

WW-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

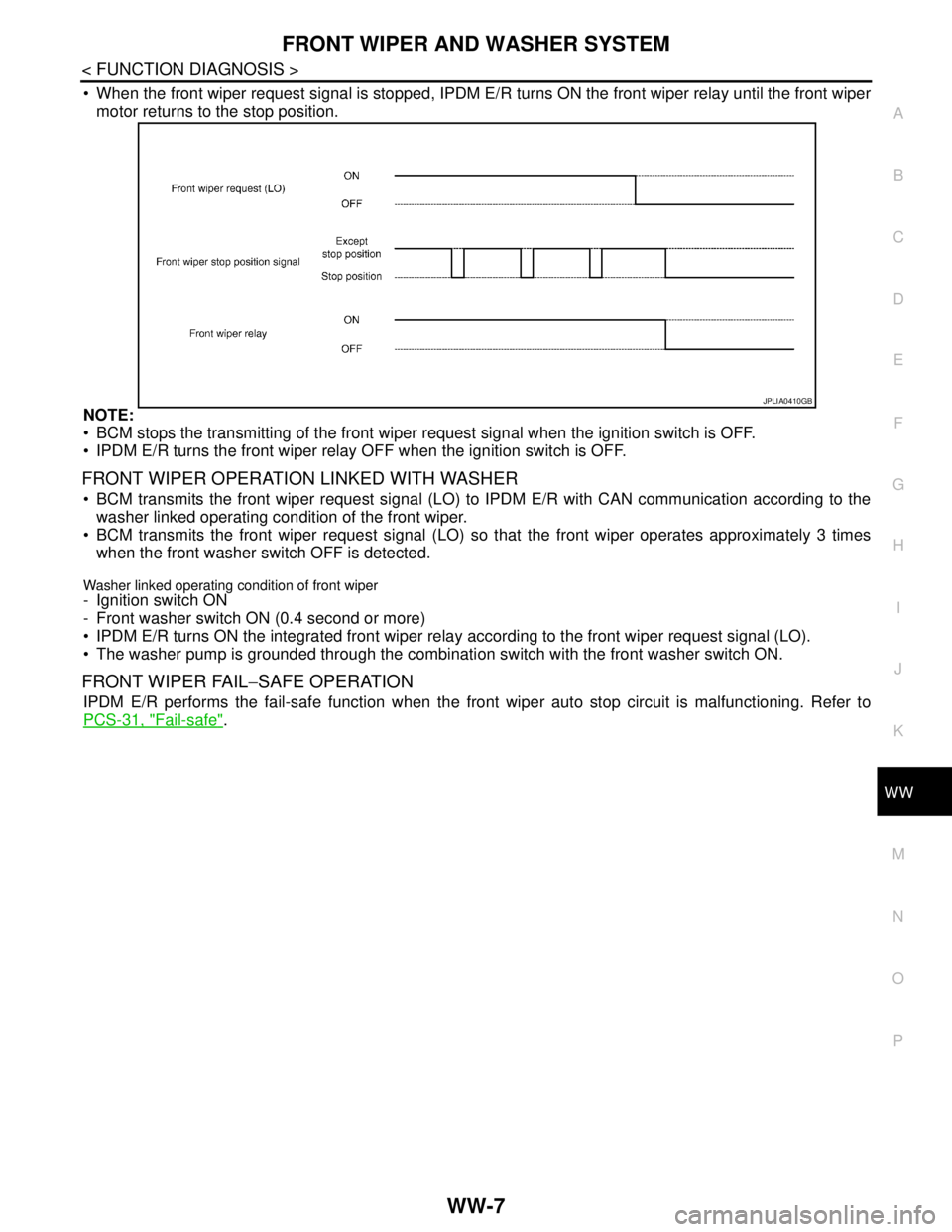

When the front wiper request signal is stopped, IPDM E/R turns ON the front wiper relay until the front wiper

motor returns to the stop position.

NOTE:

BCM stops the transmitting of the front wiper request signal when the ignition switch is OFF.

IPDM E/R turns the front wiper relay OFF when the ignition switch is OFF.

FRONT WIPER OPERATION LINKED WITH WASHER

BCM transmits the front wiper request signal (LO) to IPDM E/R with CAN communication according to the

washer linked operating condition of the front wiper.

BCM transmits the front wiper request signal (LO) so that the front wiper operates approximately 3 times

when the front washer switch OFF is detected.

Washer linked operating condition of front wiper

- Ignition switch ON

- Front washer switch ON (0.4 second or more)

IPDM E/R turns ON the integrated front wiper relay according to the front wiper request signal (LO).

The washer pump is grounded through the combination switch with the front washer switch ON.

FRONT WIPER FAIL−SAFE OPERATION

IPDM E/R performs the fail-safe function when the front wiper auto stop circuit is malfunctioning. Refer to

PCS-31, "

Fail-safe".

JPLIA0410GB

Page 5022 of 5121

WW-10

< FUNCTION DIAGNOSIS >

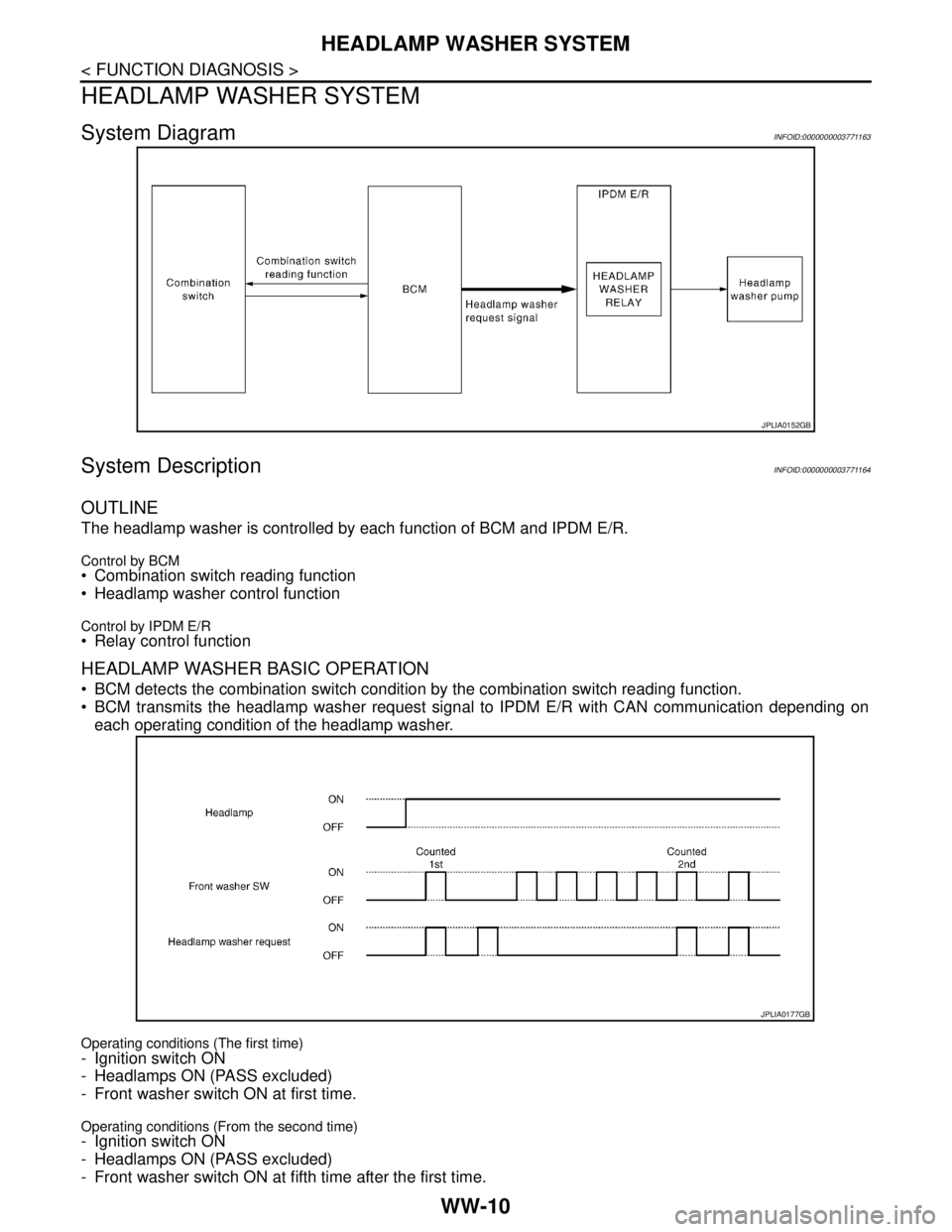

HEADLAMP WASHER SYSTEM

HEADLAMP WASHER SYSTEM

System DiagramINFOID:0000000003771163

System DescriptionINFOID:0000000003771164

OUTLINE

The headlamp washer is controlled by each function of BCM and IPDM E/R.

Control by BCM Combination switch reading function

Headlamp washer control function

Control by IPDM E/R Relay control function

HEADLAMP WASHER BASIC OPERATION

BCM detects the combination switch condition by the combination switch reading function.

BCM transmits the headlamp washer request signal to IPDM E/R with CAN communication depending on

each operating condition of the headlamp washer.

Operating conditions (The first time)

- Ignition switch ON

- Headlamps ON (PASS excluded)

- Front washer switch ON at first time.

Operating conditions (From the second time)- Ignition switch ON

- Headlamps ON (PASS excluded)

- Front washer switch ON at fifth time after the first time.

JPLIA0152GB

JPLIA0177GB

Page 5025 of 5121

DIAGNOSIS SYSTEM (BCM)

WW-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odo/Trip Meter

Vehicle Condition (BCM detected condition)

IGN Counter

IGN counter indicates the number of times that ignition switch is turned ON after DTC is detected.

The number is 0 when a malfunction is detected now.

The number increases like 1 → 2 → 3...38 → 39 after returning to the normal condition whenever ignition

switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000003761581

WORK SUPPORT

*:Factory setting

NOTE:

When performed “RESET SETTING VALUE” on “Work Support (BCM - BCM)”, set “WIPER SPEED SETTING” on “Work Support (BCM

-WIPER)” to “On”.CONSULT screen terms Description

SLEEP>LOCKWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “LOCK”.)

SLEEP>OFFWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACCWhile turning power supply position from “RUN” to “ACC” (Vehicle is stopping and selector

lever is except P position.)

CRANK>RUNWhile turning power supply position from “CRANKING” to “RUN” (From cranking up the en-

gine to run it)

RUN>URGENT While turning power supply position from “RUN“ to “ACC” (Emergency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEPWhile turning BCM status from normal mode (Power supply position is “OFF”.) to low power

consumption mode

LOCK>SLEEPWhile turning BCM status from normal mode (Power supply position is “LOCK”.) to low pow-

er consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steering is locked.)

OFF Power supply position is “OFF” (Ignition switch OFF with steering is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine stopped)

ENGINE RUN Power supply position is “RUN” (Ignition switch ON with engine running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

Service item Setting item Description

WIPER SPEED

SETTINGOn*With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wiper intermittent dial position)

OffWithout vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial position)

Page 5026 of 5121

![NISSAN TEANA 2008 Service Manual WW-14

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

Monitor Item

[Unit]Description

PUSH SW

[Off/On]The switch status input from push-button ignition switch.

VEH SPEED 1

[km/h] NISSAN TEANA 2008 Service Manual WW-14

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

Monitor Item

[Unit]Description

PUSH SW

[Off/On]The switch status input from push-button ignition switch.

VEH SPEED 1

[km/h]](/img/5/57391/w960_57391-5025.png)

WW-14

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

Monitor Item

[Unit]Description

PUSH SW

[Off/On]The switch status input from push-button ignition switch.

VEH SPEED 1

[km/h]Displays the value of the vehicle speed signal received from combination meter with CAN communication.

FR WIPER HI

[Off/On]

Status of each switch judged by BCM using the combination switch reading function FR WIPER LOW

[Off/On]

FR WASHER SW

[Off/On]

FR WIPER INT

[Off/On]

FR WIPER STOP

[Off/On]Displays the status of the front wiper stop position signal received from IPDM E/R with CAN communication.

INT VOLUME

[1 − 7] Status of each switch judged by BCM using the combination switch reading function

H/L WASH SW

[Off/On]Status of the switch input from headlamp washer switch

Test item Operation Description

FRONT WIPERHiTransmits the front wiper request signal (HI) to IPDM E/R with CAN communication to

operate the front wiper HI operation.

LoTransmits the front wiper request signal (LO) to IPDM E/R with CAN communication to

operate the front wiper LO operation.

INTTransmits the front wiper request signal (INT) to IPDM E/R with CAN communication to

operate the front wiper INT operation.

Off Stops transmitting the front wiper request signal to stop the front wiper operation.

HEADLAMP WASHER OnTransmits the headlamp washer request signal to IPDM E/R with CAN communication to

operate the headlamp washer operation.

Page 5027 of 5121

DIAGNOSIS SYSTEM (IPDM E/R)

WW-15

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003941292

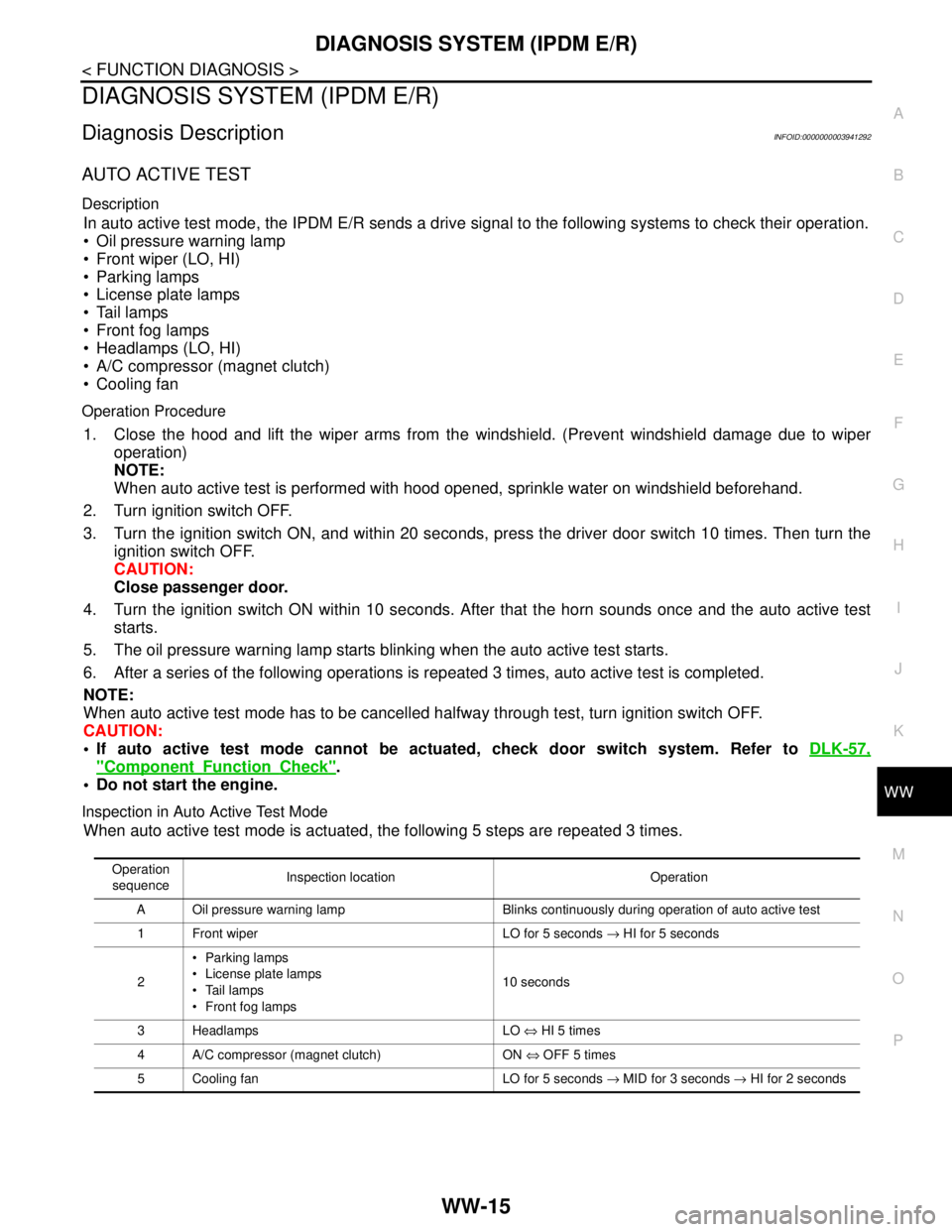

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Front wiper (LO, HI)

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamps (LO, HI)

A/C compressor (magnet clutch)

Cooling fan

Operation Procedure

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to DLK-57,

"ComponentFunctionCheck".

Do not start the engine.

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

Operation

sequenceInspection location Operation

A Oil pressure warning lamp Blinks continuously during operation of auto active test

1 Front wiper LO for 5 seconds → HI for 5 seconds

2Parking lamps

License plate lamps

Tail lamps

Front fog lamps10 seconds

3 Headlamps LO ⇔ HI 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Page 5029 of 5121

DIAGNOSIS SYSTEM (IPDM E/R)

WW-17

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

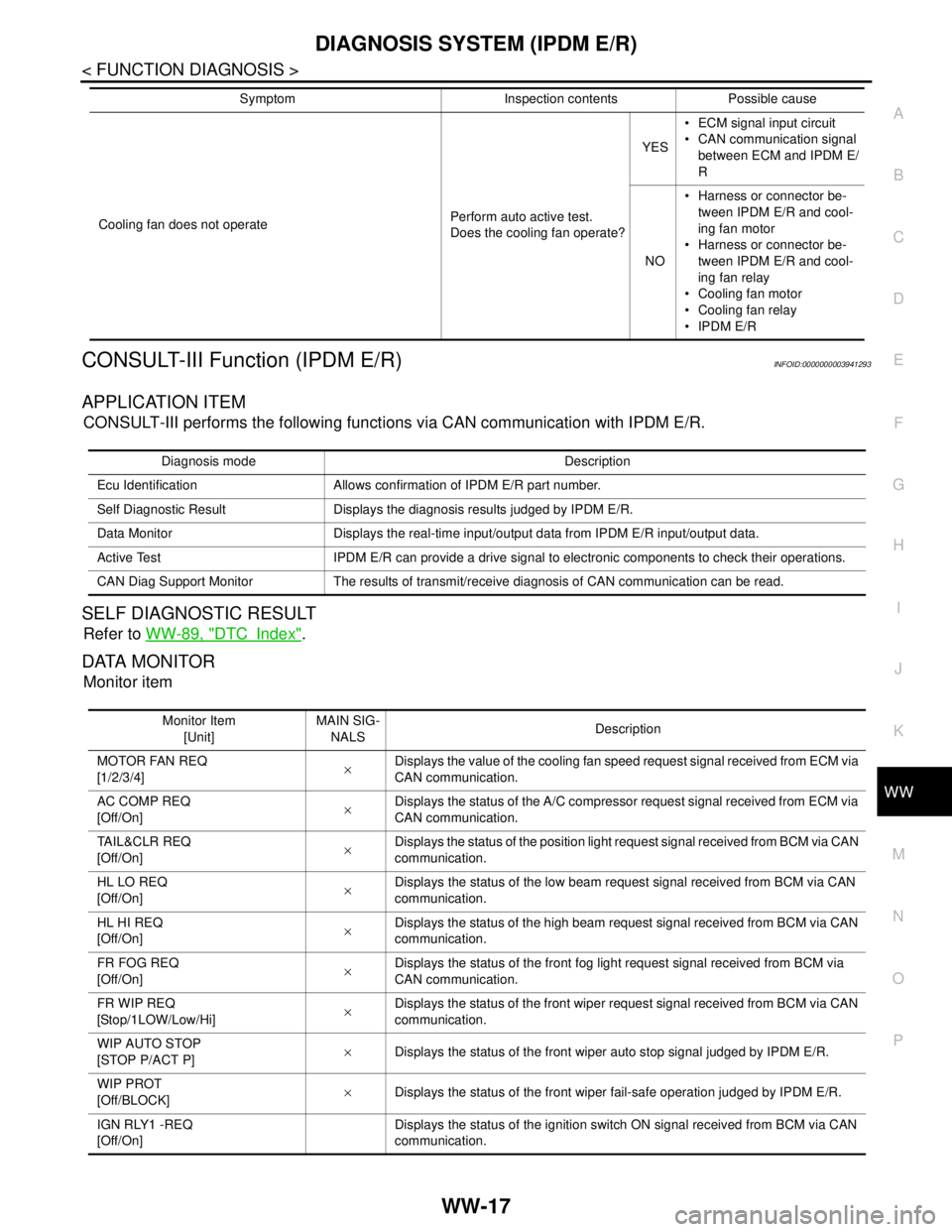

CONSULT-III Function (IPDM E/R)INFOID:0000000003941293

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with IPDM E/R.

SELF DIAGNOSTIC RESULT

Refer to WW-89, "DTCIndex".

DATA MONITOR

Monitor item

Cooling fan does not operatePerform auto active test.

Does the cooling fan operate?YES ECM signal input circuit

CAN communication signal

between ECM and IPDM E/

R

NO Harness or connector be-

tween IPDM E/R and cool-

ing fan motor

Harness or connector be-

tween IPDM E/R and cool-

ing fan relay

Cooling fan motor

Cooling fan relay

IPDM E/R Symptom Inspection contents Possible cause

Diagnosis mode Description

Ecu Identification Allows confirmation of IPDM E/R part number.

Self Diagnostic Result Displays the diagnosis results judged by IPDM E/R.

Data Monitor Displays the real-time input/output data from IPDM E/R input/output data.

Active Test IPDM E/R can provide a drive signal to electronic components to check their operations.

CAN Diag Support Monitor The results of transmit/receive diagnosis of CAN communication can be read.

Monitor Item

[Unit]MAIN SIG-

NALSDescription

MOTOR FAN REQ

[1/2/3/4]×Displays the value of the cooling fan speed request signal received from ECM via

CAN communication.

AC COMP REQ

[Off/On]×Displays the status of the A/C compressor request signal received from ECM via

CAN communication.

TAIL&CLR REQ

[Off/On]×Displays the status of the position light request signal received from BCM via CAN

communication.

HL LO REQ

[Off/On]×Displays the status of the low beam request signal received from BCM via CAN

communication.

HL HI REQ

[Off/On]×Displays the status of the high beam request signal received from BCM via CAN

communication.

FR FOG REQ

[Off/On]×Displays the status of the front fog light request signal received from BCM via

CAN communication.

FR WIP REQ

[Stop/1LOW/Low/Hi]×Displays the status of the front wiper request signal received from BCM via CAN

communication.

WIP AUTO STOP

[STOP P/ACT P]×Displays the status of the front wiper auto stop signal judged by IPDM E/R.

WIP PROT

[Off/BLOCK]×Displays the status of the front wiper fail-safe operation judged by IPDM E/R.

IGN RLY1 -REQ

[Off/On]Displays the status of the ignition switch ON signal received from BCM via CAN

communication.

Page 5030 of 5121

![NISSAN TEANA 2008 Service Manual WW-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

PUSH SW

[Off/On]Displays the status NISSAN TEANA 2008 Service Manual WW-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

PUSH SW

[Off/On]Displays the status](/img/5/57391/w960_57391-5029.png)

WW-18

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (IPDM E/R)

ACTIVE TEST

Te s t i t e m

IGN RLY

[Off/On]×Displays the status of the ignition relay judged by IPDM E/R.

PUSH SW

[Off/On]Displays the status of the push-button ignition switch judged by IPDM E/R.

INTER/NP SW

[Off/On]Displays the status of the shift position judged by IPDM E/R.

ST RLY CONT

[Off/On]Displays the status of the starter relay status signal received from BCM via CAN

communication.

IHBT RLY -REQ

[Off/On]Displays the status of the starter control relay signal received from BCM via CAN

communication.

ST/INHI RLY

[Off/ ST /INHI/UNKWN]Displays the status of the starter relay and starter control relay judged by IPDM

E/R.

DETENT SW

[Off/On]Displays the status of the control device (detention switch) judged by IPDM E/R.

S/L RLY -REQ

[Off/On]Displays the status of the steering lock relay signal received from BCM via CAN

communication.

S/L STATE

[LOCK/UNLOCK/UNKWN]Displays the status of the steering lock judged by IPDM E/R.

DTRL REQ

[Off]NOTE:

The item is indicated, but not monitored.

OIL P SW

[Open/Close]Displays the status of the oil pressure switch judged by IPDM E/R.

HOOD SW

[Off/On]Displays the status of the hood switch judged by IPDM E/R.

HL WASHER REQ

[Off]Display the status of the headlamp washer request signal received from BCM via

CAN communication.

THFT HRN REQ

[Off/On]Displays the status of the theft warning horn request signal received from BCM

via CAN communication.

HORN CHIRP

[Off/On]Displays the status of the horn reminder signal received from BCM via CAN com-

munication.

CRNRNG LMP REQ

[Off]NOTE:

The item is indicated, but not monitored. Monitor Item

[Unit]MAIN SIG-

NALSDescription

Test item Operation Description

CORNERING LAMPOff

NOTE:

The item is indicated, but cannot be tested. LH

RH

HORN On Operates horn relay for 20 ms.

FRONT WIPEROff OFF

Lo Operates the front wiper relay.

Hi Operates the front wiper relay and front wiper high relay.

MOTOR FAN1OFF

2 Operates the cooling fan relay-1.

3 Operates the cooling fan relay-2.

4 Operates the cooling fan relay-2 and cooling fan relay-3.

HEAD LAMP WASHER On Operates the headlamp washer relay for 1 s.

Page 5033 of 5121

POWER SUPPLY AND GROUND CIRCUIT

WW-21

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

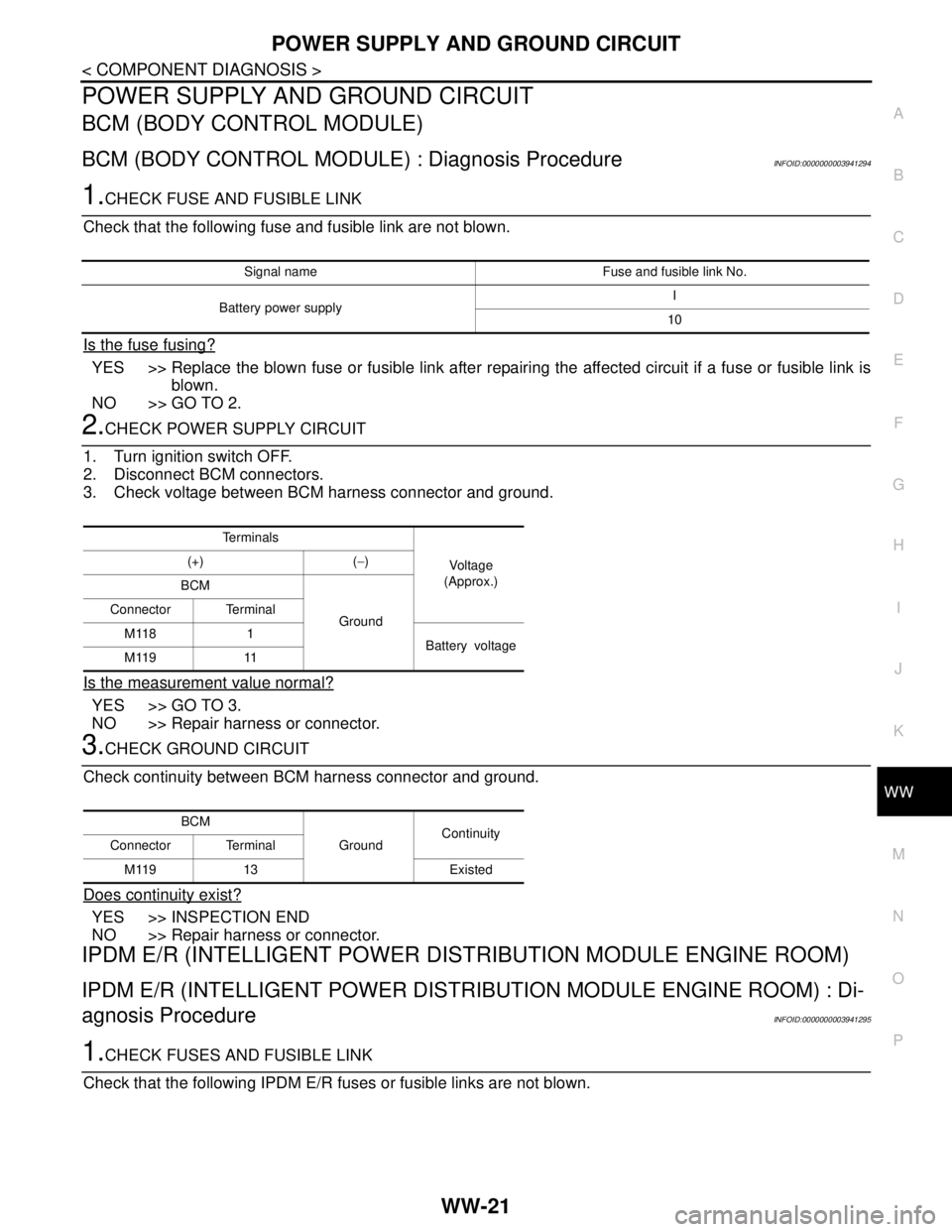

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000003941294

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000003941295

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Signal name Fuse and fusible link No.

Battery power supplyI

10

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (−)

BCM

Ground Connector Terminal

M118 1

Battery voltage

M119 11

BCM

GroundContinuity

Connector Terminal

M119 13 Existed

Page 5034 of 5121

WW-22

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

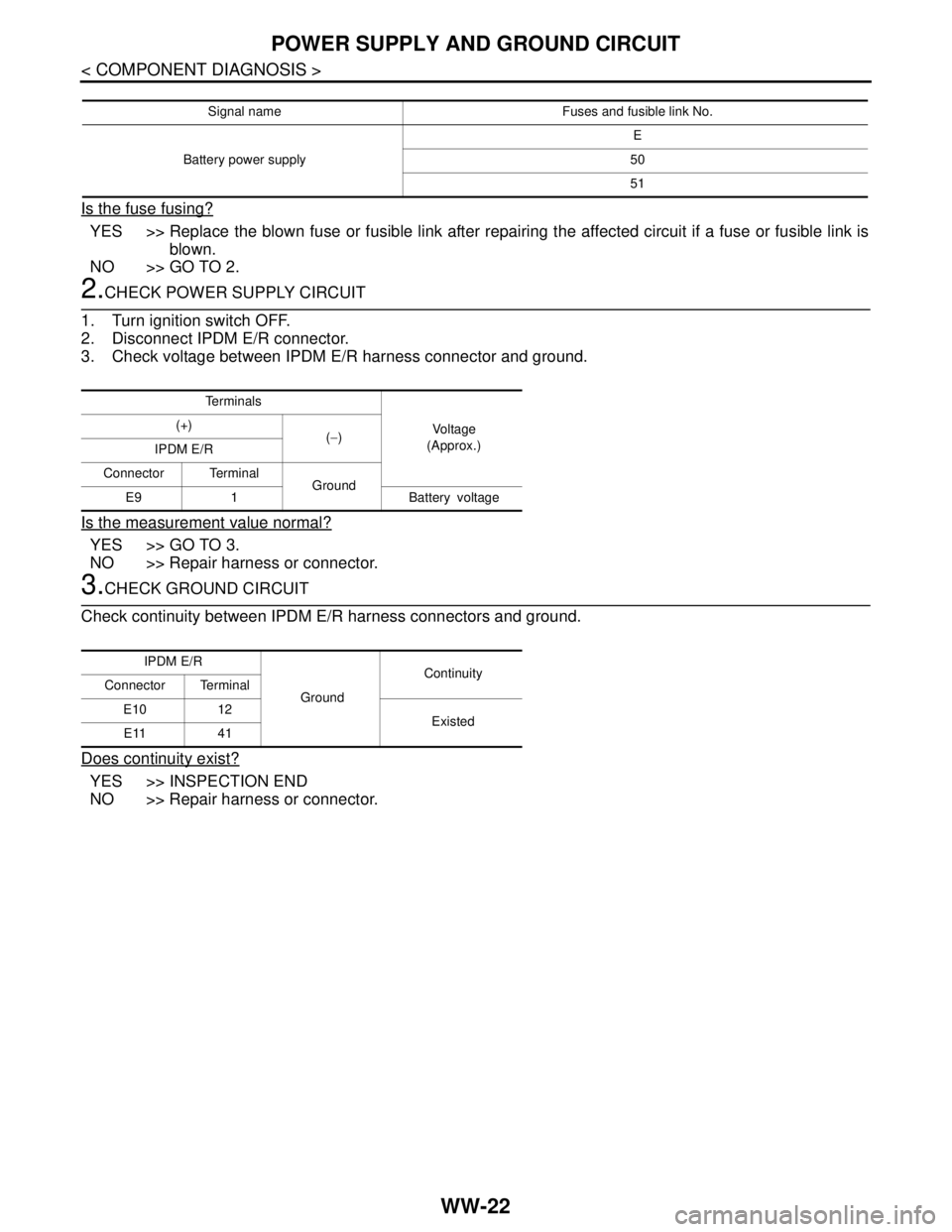

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between IPDM E/R harness connectors and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

Signal name Fuses and fusible link No.

Battery power supplyE

50

51

Te r m i n a l s

Vo l ta g e

(Approx.) (+)

(−)

IPDM E/R

Connector Terminal

Ground

E9 1 Battery voltage

IPDM E/R

GroundContinuity

Connector Terminal

E10 12

Existed

E11 41