check engine NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 905 of 5121

BRAKE FLUID

BR-9

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE FLUID

InspectionINFOID:0000000003811173

BRAKE FLUID LEVEL

Check that the fluid level in the sub tank is within the specified

range (MAX – MIN lines).

Visually check for any brake fluid leakage around the sub tank,

reservoir tank and hose.

Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN).

Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake is released.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for fluid leakage by fully depressing brake pedal while

engine is running.

CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

DrainingINFOID:0000000003811174

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before draining.

1. Connect a vinyl tube to the bleed valve.

2. Depress the brake pedal and loosen the bleeder valve to gradu-

ally discharge brake fluid.

RefillingINFOID:0000000003811175

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) connec-

tor or the battery negative terminal before refilling.

1. Check that there is no foreign material in the sub tank, and refill with new brake fluid.

CAUTION:

Never reuse drained brake fluid.

JPFIA0007ZZ

SBR389C

BRA0007D

Page 908 of 5121

BR-12

< ON-VEHICLE MAINTENANCE >

BRAKE BOOSTER

BRAKE BOOSTER

InspectionINFOID:0000000003811178

OPERATION

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

AIR TIGHT

Idle the engine for 1 minute to apply vacuum to the brake booster,

and stop the engine. Then depress the brake pedal several times

at 5-second intervals until the accumulated vacuum is released to

atmospheric pressure. Check that the clearance between brake

pedal and dash lower panel gradually increases (A → B → C) each

time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal

for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due

to the brake system operation.

BRA0037D

JPFIA0043ZZ

JPFIA0044ZZ

Page 917 of 5121

BRAKE PIPINGBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT : Removal and InstallationINFOID:0000000003811188

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strong ly pull out the brake hoses and tubes.

Cover open end of brake tub es and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

FRONT : InspectionINFOID:0000000003811189

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80 kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

1. ABS actuator and electric unit (con-

trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0099ZZ

Page 919 of 5121

BRAKE PIPINGBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Removal and InstallationINFOID:0000000003811192

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never sharply bend, twist or strongly pull the brake hoses and tubes.

Cover the open end of brake tubes and hoses wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose from the vehicle.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse copper washer.

2. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

3. Connect the hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose

to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

REAR : InspectionINFOID:0000000003811193

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80

kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

1. ABS actuator and electric unit (con- trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0012ZZ

Page 925 of 5121

BRAKE BOOSTER

BR-29

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Replace the clevis pin if it is damaged. Refer to BR-18, "Inspection and Adjustment".

After installation, perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Inspection and AdjustmentINFOID:0000000003811200

INSPECTION AFTER REMOVAL

Output Rod Length Inspection

1. With a handy vacuum pump, apply vacuum pressure of −66.7

kPa (−500 mmHg, −19.70 inHg, –0.667 bar) to the brake

booster.

2. Check the output rod length (A).

Input Rod Length Inspection

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (B).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation

Depress the brake pedal several times at 5-second intervals with the

engine stopped. Start the engine with the brake pedal fully

depressed. Check that the clearance between brake pedal and dash

lower pane decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due to

the brake system operation.

Air Tight

Standard

A: Refer to BR-45, "

Brake Booster".

JPFIA0021ZZ

Standard

B: Refer to BR-45, "

Brake Booster".

JPFIA0020ZZ

BRA0037D

Page 926 of 5121

BR-30

< ON-VEHICLE REPAIR >

BRAKE BOOSTER

Idle the engine for 1 minute to apply vacuum to the brake booster,

and stop the engine. Then depress the brake pedal several times

at 5-second intervals until the accumulated vacuum is released to

atmospheric pressure. Check that the clearance between brake

pedal and dash lower panel gradually increases (A → B → C) each

time the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal

for 30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. This is a normal phenomenon due

to the brake system operation.

ADJUSTMENT AFTER INSTALLATION

Perform the brake pedal adjustment after installing the brake pedal assembly. Refer to BR-6, "Inspection and

Adjustment".

JPFIA0043ZZ

JPFIA0044ZZ

Page 927 of 5121

VACUUM LINES

BR-31

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

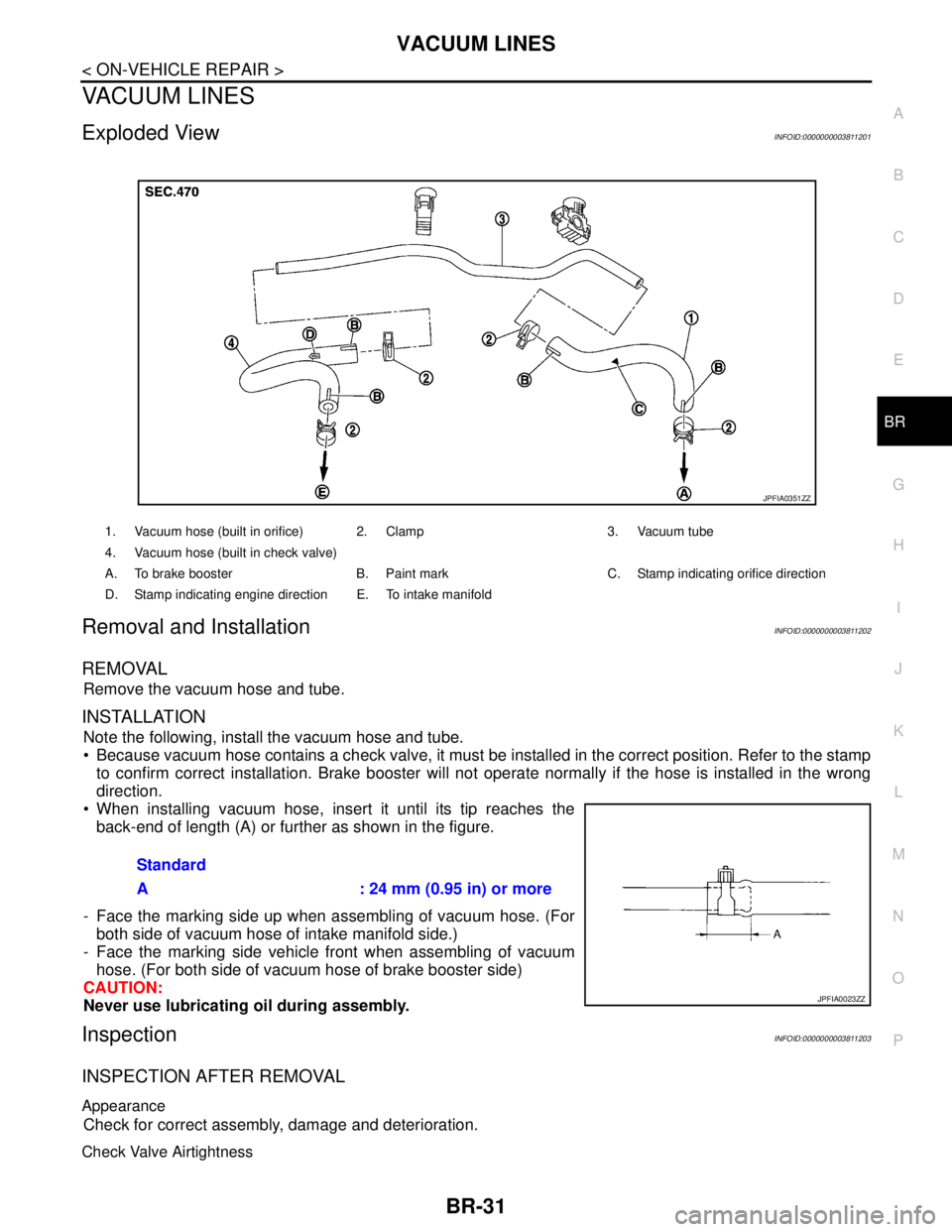

VACUUM LINES

Exploded ViewINFOID:0000000003811201

Removal and InstallationINFOID:0000000003811202

REMOVAL

Remove the vacuum hose and tube.

INSTALLATION

Note the following, install the vacuum hose and tube.

Because vacuum hose contains a check valve, it must be installed in the correct position. Refer to the stamp

to confirm correct installation. Brake booster will not operate normally if the hose is installed in the wrong

direction.

When installing vacuum hose, insert it until its tip reaches the

back-end of length (A) or further as shown in the figure.

- Face the marking side up when assembling of vacuum hose. (For

both side of vacuum hose of intake manifold side.)

- Face the marking side vehicle front when assembling of vacuum

hose. (For both side of vacuum hose of brake booster side)

CAUTION:

Never use lubricating oil during assembly.

InspectionINFOID:0000000003811203

INSPECTION AFTER REMOVAL

Appearance

Check for correct assembly, damage and deterioration.

Check Valve Airtightness

1. Vacuum hose (built in orifice) 2. Clamp 3. Vacuum tube

4. Vacuum hose (built in check valve)

A. To brake booster B. Paint mark C. Stamp indicating orifice direction

D. Stamp indicating engine direction E. To intake manifold

JPFIA0351ZZ

Standard

A : 24 mm (0.95 in) or more

JPFIA0023ZZ

Page 928 of 5121

BR-32

< ON-VEHICLE REPAIR >

VACUUM LINES

Use a handy vacuum pump (A) to check.

Replace vacuum hose assembly if vacuum hose and check valve

are malfunctioning.When connected to the brake booster side (B)

: Vacuum should decrease within 1.3 kPa (10 mmHg,

0.39 inHg, 0.013 bar) for 15 seconds under a vacuum

of −66.7 kPa (−500 mmHg, −19.70 inHg, −0.667 bar).

When connected to the engine side (C):

: Vacuum should not exist.

JPFIA0024ZZ

Page 957 of 5121

![NISSAN TEANA 2008 User Guide BRC-16

< COMPONENT DIAGNOSIS >[ABS]

C1101, C1102, C1103, C1104 WHEEL SENSOR

COMPONENT DIAGNOSIS

C1101, C1102, C1103, C1104 WHEEL SENSOR

DescriptionINFOID:0000000003766731

When the sensor rotor rotates NISSAN TEANA 2008 User Guide BRC-16

< COMPONENT DIAGNOSIS >[ABS]

C1101, C1102, C1103, C1104 WHEEL SENSOR

COMPONENT DIAGNOSIS

C1101, C1102, C1103, C1104 WHEEL SENSOR

DescriptionINFOID:0000000003766731

When the sensor rotor rotates](/img/5/57391/w960_57391-956.png)

BRC-16

< COMPONENT DIAGNOSIS >[ABS]

C1101, C1102, C1103, C1104 WHEEL SENSOR

COMPONENT DIAGNOSIS

C1101, C1102, C1103, C1104 WHEEL SENSOR

DescriptionINFOID:0000000003766731

When the sensor rotor rotates, the magnetic field changes. Wheel sensor converts the magnetic field changes

to current signals (rectangular wave) and transmits them to the ABS actuator and electric unit (control unit).

DTC LogicINFOID:0000000003766732

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC REPRODUCTION PROCEDURE

1. Start the engine and drive the vehicle at 30 km/h (19 MPH) or more for approximately 1 minute.

2. Perform ABS actuator and electric unit (control unit) self-diagnosis.

Is DTC

“C1101”, “C1102”, “C1103” or “C1104” detected?

YES >> Proceed to diagnosis. Refer to BRC-16, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003766733

CAUTION:

Do not check between wheel sensor terminals.

1.CHECK TIRES

Check air pressure, wear and size. Refer to WT-5, "

Tire Air Pressure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace damaged parts.

2.CHECK SENSOR AND SENSOR ROTOR

Check sensor rotor for damage.

Check wheel sensor for damage, disconnection or looseness.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair wheel sensor mount or replace sensor rotor. Then perform the self-diagnosis.

3.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) connector.

3. Disconnect malfunctioning wheel sensor connector.

4. Check terminal to see if it is deformed, disconnected, looseness, etc.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace damaged parts.

DTC Display item Malfunction detected condition Possible cause

C1101 RR RH SENSOR-1Circuit of rear RH wheel sensor is open. Or when the sen-

sor power voltage is outside the standard.

Harness or connector

Wheel sensor

ABS actuator and electric unit

(control unit) C1102 RR LH SENSOR-1Circuit of rear LH wheel sensor is open. Or when the sen-

sor power voltage is outside the standard.

C1103 FR RH SENSOR-1Circuit of front RH wheel sensor is open. Or when the

sensor power voltage is outside the standard.

C1104 FR LH SENSOR-1Circuit of front LH wheel sensor is open. Or when the

sensor power voltage is outside the standard.

Page 958 of 5121

![NISSAN TEANA 2008 User Guide C1101, C1102, C1103, C1104 WHEEL SENSOR

BRC-17

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4.CHECK WHEEL SENSOR HARNESS

1. Check the continuity between ABS actuator and electric unit NISSAN TEANA 2008 User Guide C1101, C1102, C1103, C1104 WHEEL SENSOR

BRC-17

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4.CHECK WHEEL SENSOR HARNESS

1. Check the continuity between ABS actuator and electric unit](/img/5/57391/w960_57391-957.png)

C1101, C1102, C1103, C1104 WHEEL SENSOR

BRC-17

< COMPONENT DIAGNOSIS >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4.CHECK WHEEL SENSOR HARNESS

1. Check the continuity between ABS actuator and electric unit (control unit) harness connector and wheel

sensor harness connector. (Also check continuity when steering wheel is turned right and left and when

sensor harness inside the wheel house is moved.)

Measurement terminal for power supply circuit

Measurement terminal for signal circuit

2. Check the continuity between ABS actuator and electric unit (control unit) harness connector.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK WHEEL SENSOR POWER SUPPLY CIRCUIT

1. Connect ABS actuator and electric unit (control unit) connector.

2. Turn the ignition switch ON.

CAUTION:

Never start the engine.

3. Check the voltage between wheel sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace damaged parts.

6.CHECK DATA MONITOR

1. Turn the ignition switch OFF.

2. Connect each wheel sensor connector.

ABS actuator and electric unit (control unit) Wheel sensor

Continuity

Connector Terminal Connector Terminal

E349 E39 (Front RH)

1 Existed 16 E22 (Front LH)

8 C4 (Rear RH)

6 C3 (Rear LH)

ABS actuator and electric unit (control unit) Wheel sensor

Continuity

Connector Terminal Connector Terminal

E3410 E39 (Front RH)

2 Existed 5 E22 (Front LH)

19 C4 (Rear RH)

17 C3 (Rear LH)

ABS actuator and electric unit (control unit)

Continuity

Connector Terminal Connector Terminal

E349, 10

E34 1, 4 Not existed 16, 5

8, 19

6, 17

Wheel sensor

—Voltage

Connector Terminal

E39 (Front RH)

1 Ground 8 V or more E22 (Front LH)

C4 (Rear RH)

C3 (Rear LH)