check engine NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4947 of 5121

WCS

DIAGNOSIS SYSTEM (BCM)

WCS-17

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

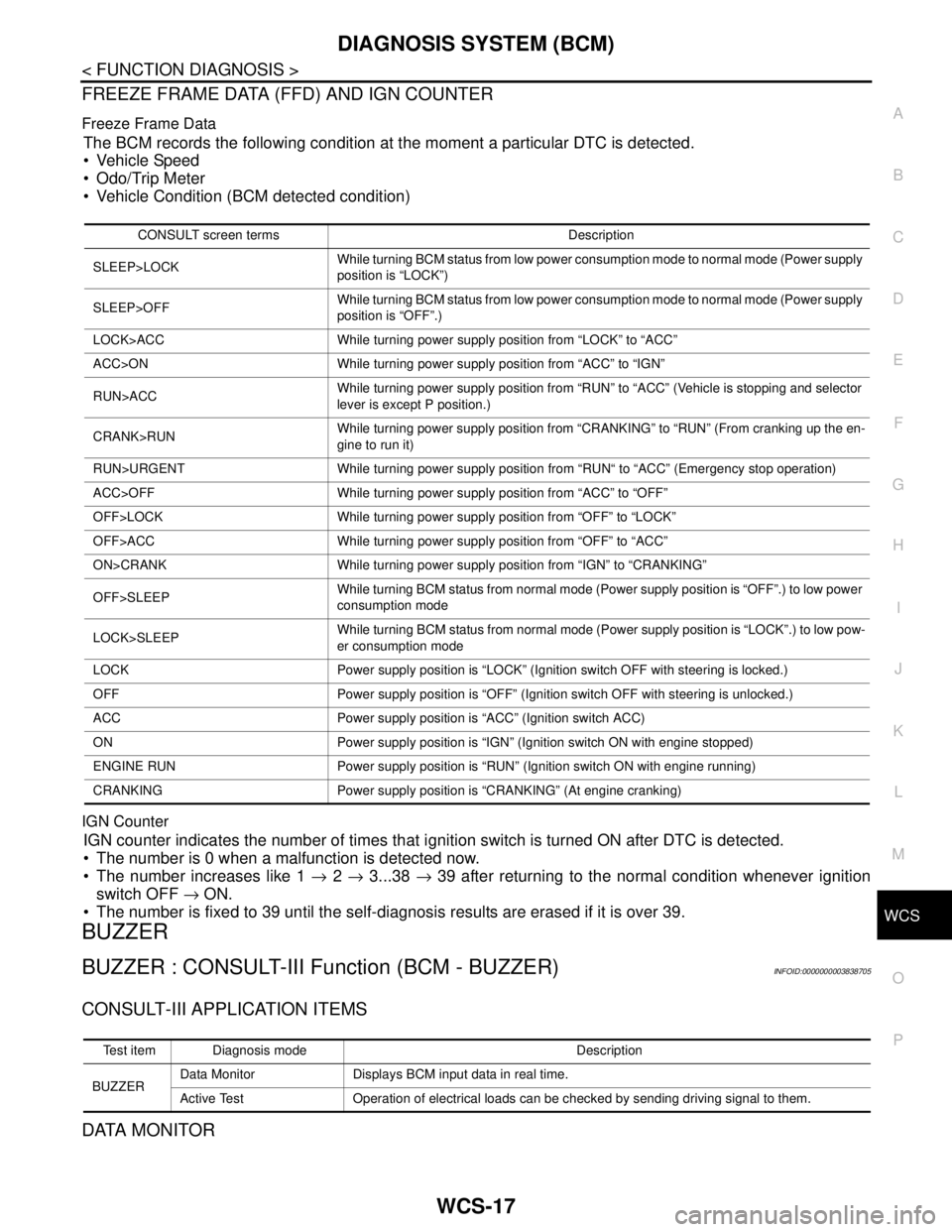

FREEZE FRAME DATA (FFD) AND IGN COUNTER

Freeze Frame Data

The BCM records the following condition at the moment a particular DTC is detected.

Vehicle Speed

Odo/Trip Meter

Vehicle Condition (BCM detected condition)

IGN Counter

IGN counter indicates the number of times that ignition switch is turned ON after DTC is detected.

The number is 0 when a malfunction is detected now.

The number increases like 1 → 2 → 3...38 → 39 after returning to the normal condition whenever ignition

switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

BUZZER

BUZZER : CONSULT-III Function (BCM - BUZZER)INFOID:0000000003838705

CONSULT-III APPLICATION ITEMS

DATA MONITOR

CONSULT screen terms Description

SLEEP>LOCKWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “LOCK”)

SLEEP>OFFWhile turning BCM status from low power consumption mode to normal mode (Power supply

position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACCWhile turning power supply position from “RUN” to “ACC” (Vehicle is stopping and selector

lever is except P position.)

CRANK>RUNWhile turning power supply position from “CRANKING” to “RUN” (From cranking up the en-

gine to run it)

RUN>URGENT While turning power supply position from “RUN“ to “ACC” (Emergency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning power supply position from “IGN” to “CRANKING”

OFF>SLEEPWhile turning BCM status from normal mode (Power supply position is “OFF”.) to low power

consumption mode

LOCK>SLEEPWhile turning BCM status from normal mode (Power supply position is “LOCK”.) to low pow-

er consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steering is locked.)

OFF Power supply position is “OFF” (Ignition switch OFF with steering is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine stopped)

ENGINE RUN Power supply position is “RUN” (Ignition switch ON with engine running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

Test item Diagnosis mode Description

BUZZERData Monitor Displays BCM input data in real time.

Active Test Operation of electrical loads can be checked by sending driving signal to them.

Page 5005 of 5121

WCS

THE PARKING BRAKE RELEASE WARNING CONTINUES SOUNDING, OR

DOES NOT SOUND

WCS-75

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

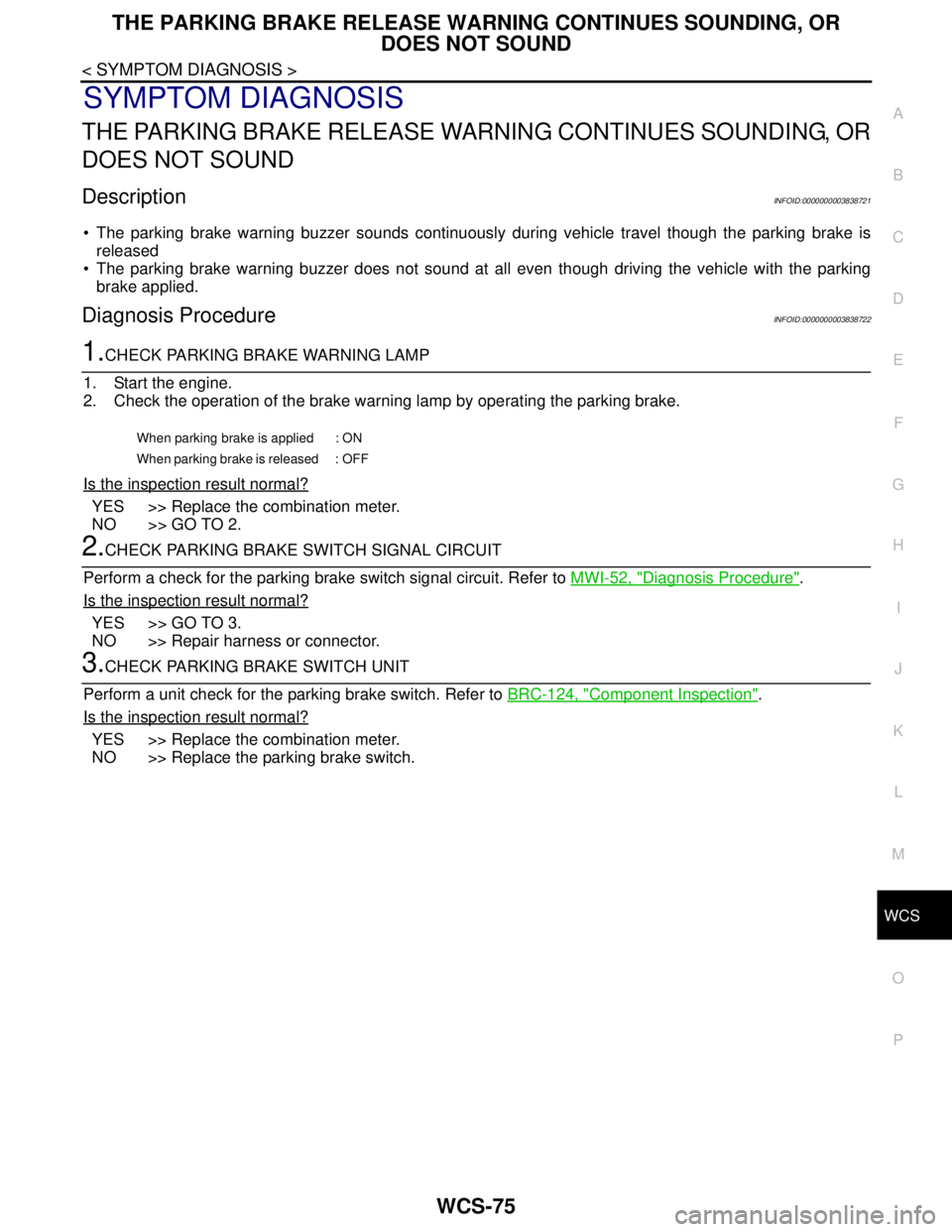

SYMPTOM DIAGNOSIS

THE PARKING BRAKE RELEASE WARNING CONTINUES SOUNDING, OR

DOES NOT SOUND

DescriptionINFOID:0000000003838721

The parking brake warning buzzer sounds continuously during vehicle travel though the parking brake is

released

The parking brake warning buzzer does not sound at all even though driving the vehicle with the parking

brake applied.

Diagnosis ProcedureINFOID:0000000003838722

1.CHECK PARKING BRAKE WARNING LAMP

1. Start the engine.

2. Check the operation of the brake warning lamp by operating the parking brake.

Is the inspection result normal?

YES >> Replace the combination meter.

NO >> GO TO 2.

2.CHECK PARKING BRAKE SWITCH SIGNAL CIRCUIT

Perform a check for the parking brake switch signal circuit. Refer to MWI-52, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK PARKING BRAKE SWITCH UNIT

Perform a unit check for the parking brake switch. Refer to BRC-124, "

Component Inspection".

Is the inspection result normal?

YES >> Replace the combination meter.

NO >> Replace the parking brake switch.

When parking brake is applied : ON

When parking brake is released : OFF

Page 5013 of 5121

WW-1

DRIVER CONTROLS

C

D

E

F

G

H

I

J

K

M

SECTION WW

A

B

WW

N

O

P

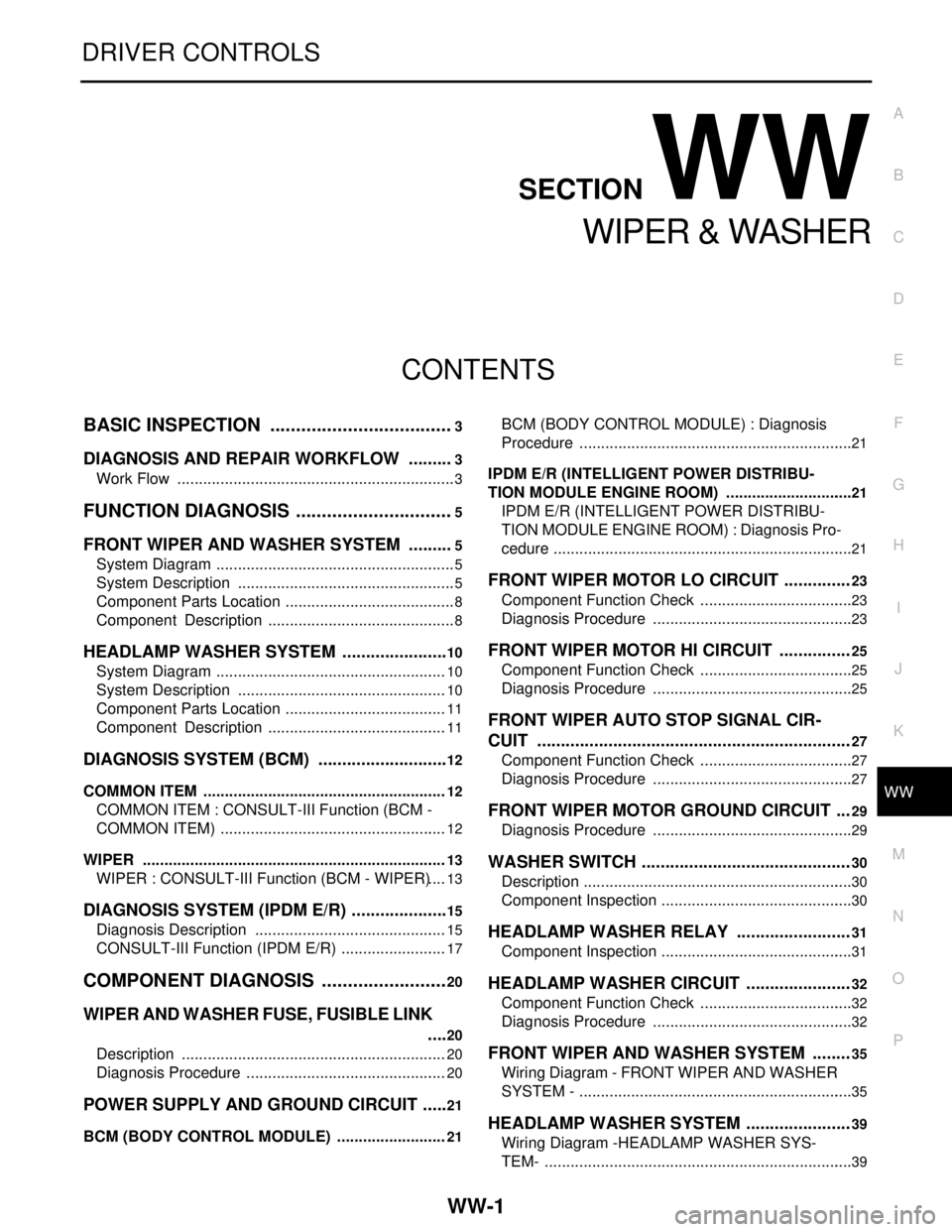

CONTENTS

WIPER & WASHER

BASIC INSPECTION ....................................3

DIAGNOSIS AND REPAIR WORKFLOW ..........3

Work Flow .................................................................3

FUNCTION DIAGNOSIS ...............................5

FRONT WIPER AND WASHER SYSTEM ..........5

System Diagram ........................................................5

System Description ...................................................5

Component Parts Location ........................................8

Component Description ............................................8

HEADLAMP WASHER SYSTEM .......................10

System Diagram ......................................................10

System Description .................................................10

Component Parts Location ......................................11

Component Description ..........................................11

DIAGNOSIS SYSTEM (BCM) ............................12

COMMON ITEM .........................................................12

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

12

WIPER .......................................................................13

WIPER : CONSULT-III Function (BCM - WIPER) ....13

DIAGNOSIS SYSTEM (IPDM E/R) .....................15

Diagnosis Description .............................................15

CONSULT-III Function (IPDM E/R) .........................17

COMPONENT DIAGNOSIS .........................20

WIPER AND WASHER FUSE, FUSIBLE LINK

....

20

Description ..............................................................20

Diagnosis Procedure ...............................................20

POWER SUPPLY AND GROUND CIRCUIT ......21

BCM (BODY CONTROL MODULE) ..........................21

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ................................................................

21

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) ..............................

21

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure ......................................................................

21

FRONT WIPER MOTOR LO CIRCUIT ..............23

Component Function Check ....................................23

Diagnosis Procedure ...............................................23

FRONT WIPER MOTOR HI CIRCUIT ...............25

Component Function Check ....................................25

Diagnosis Procedure ...............................................25

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ..................................................................

27

Component Function Check ....................................27

Diagnosis Procedure ...............................................27

FRONT WIPER MOTOR GROUND CIRCUIT ...29

Diagnosis Procedure ...............................................29

WASHER SWITCH ............................................30

Description ...............................................................30

Component Inspection .............................................30

HEADLAMP WASHER RELAY ........................31

Component Inspection .............................................31

HEADLAMP WASHER CIRCUIT ......................32

Component Function Check ....................................32

Diagnosis Procedure ...............................................32

FRONT WIPER AND WASHER SYSTEM ........35

Wiring Diagram - FRONT WIPER AND WASHER

SYSTEM - ................................................................

35

HEADLAMP WASHER SYSTEM ......................39

Wiring Diagram -HEADLAMP WASHER SYS-

TEM- ........................................................................

39

Page 5027 of 5121

DIAGNOSIS SYSTEM (IPDM E/R)

WW-15

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

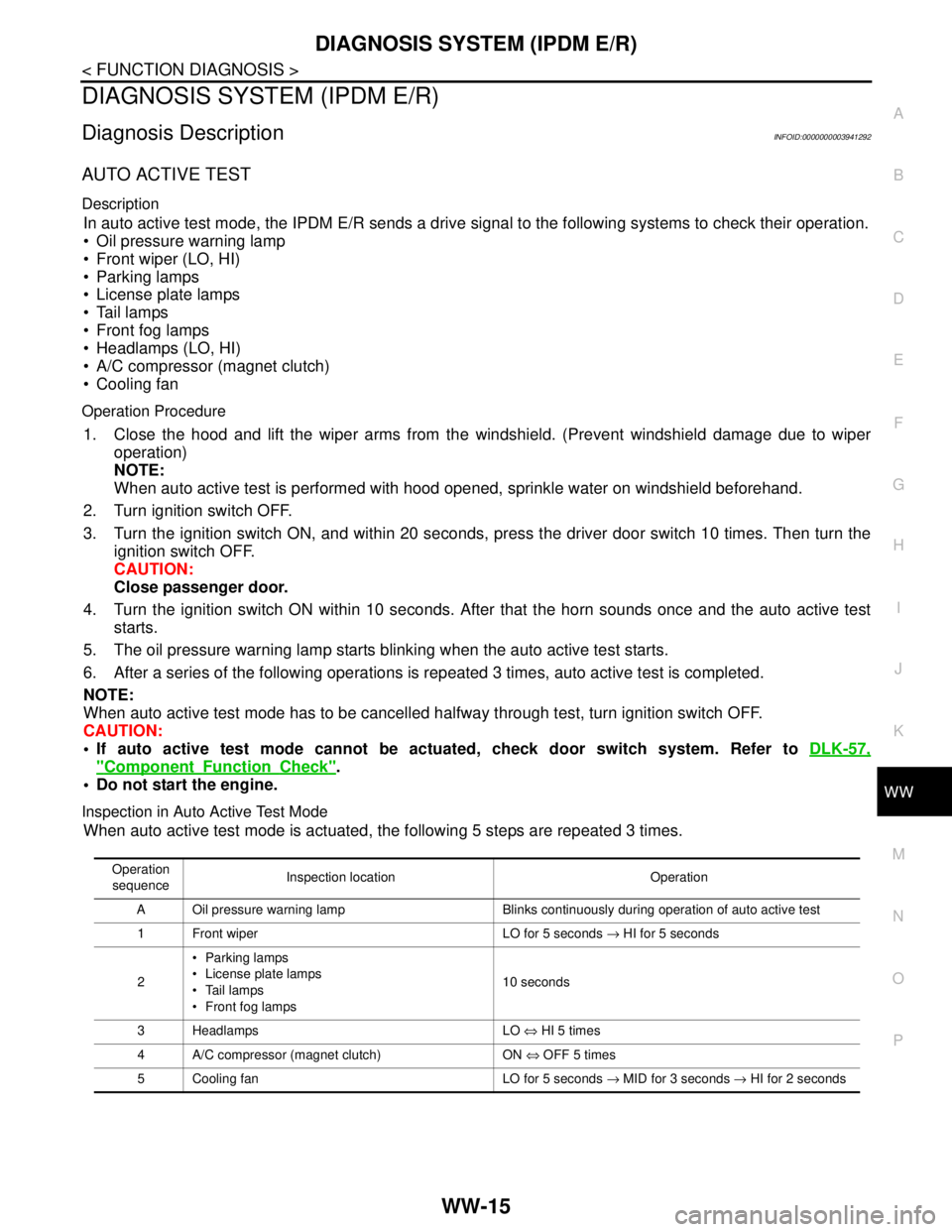

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003941292

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Front wiper (LO, HI)

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamps (LO, HI)

A/C compressor (magnet clutch)

Cooling fan

Operation Procedure

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to DLK-57,

"ComponentFunctionCheck".

Do not start the engine.

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

Operation

sequenceInspection location Operation

A Oil pressure warning lamp Blinks continuously during operation of auto active test

1 Front wiper LO for 5 seconds → HI for 5 seconds

2Parking lamps

License plate lamps

Tail lamps

Front fog lamps10 seconds

3 Headlamps LO ⇔ HI 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Page 5033 of 5121

POWER SUPPLY AND GROUND CIRCUIT

WW-21

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

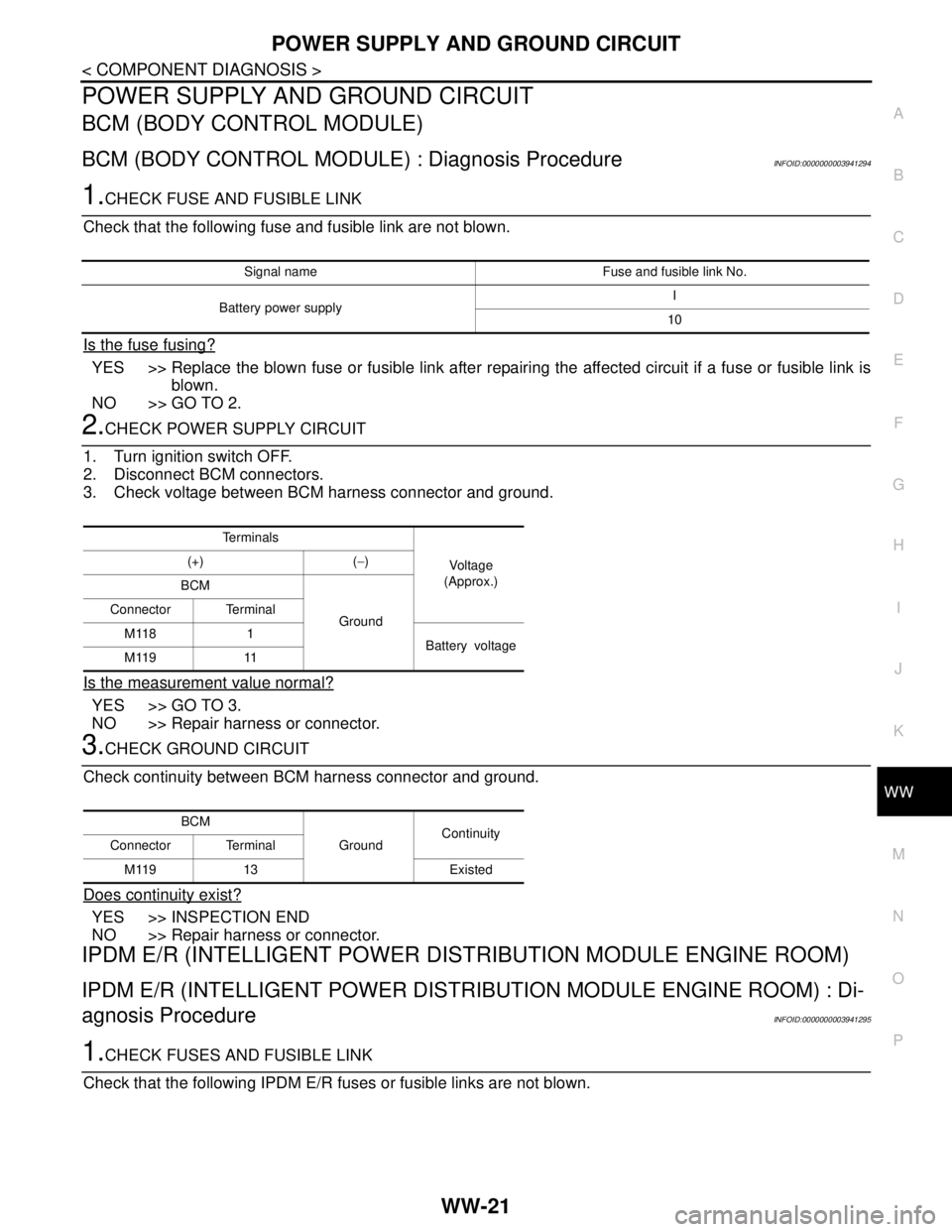

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000003941294

1.CHECK FUSE AND FUSIBLE LINK

Check that the following fuse and fusible link are not blown.

Is the fuse fusing?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit if a fuse or fusible link is

blown.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connectors.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair harness or connector.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000003941295

1.CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible links are not blown.

Signal name Fuse and fusible link No.

Battery power supplyI

10

Te r m i n a l s

Vo l ta g e

(Approx.) (+) (−)

BCM

Ground Connector Terminal

M118 1

Battery voltage

M119 11

BCM

GroundContinuity

Connector Terminal

M119 13 Existed