ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4726 of 5121

![NISSAN TEANA 2008 Service Manual P1722 ESTM VEHICLE SPEED SIGNAL

TM-253

< COMPONENT DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

P1722 ESTM VEHICLE SPEED SIGNAL

DescriptionINFOID:0000000003806455

The vehicle speed signal NISSAN TEANA 2008 Service Manual P1722 ESTM VEHICLE SPEED SIGNAL

TM-253

< COMPONENT DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

P1722 ESTM VEHICLE SPEED SIGNAL

DescriptionINFOID:0000000003806455

The vehicle speed signal](/img/5/57391/w960_57391-4725.png)

P1722 ESTM VEHICLE SPEED SIGNAL

TM-253

< COMPONENT DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

P1722 ESTM VEHICLE SPEED SIGNAL

DescriptionINFOID:0000000003806455

The vehicle speed signal is transmitted from ABS actuator and electric unit (control unit) to TCM via CAN com-

munication line.

DTC LogicINFOID:0000000003806456

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch

OFF. Then wait at least 10 seconds before performing the next test.

Perform the following procedure to confirm the malfunction is eliminated after the repair.

1.CHECK DTC DETECTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Data Monitor” mode for “TRANSMISSION”.

3. Start engine and maintain the following conditions for at least 5 consecutive seconds.

Is

“P1722 ESTM VEH SPD SIG” detected?

YES >> Go to TM-253, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-35, "

Intermittent Incident".

Diagnosis ProcedureINFOID:0000000003806457

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

With CONSULT-III

1. Turn ignition switch ON.

2. Select “Self Diagnostic Results” mode for “ABS”.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Check DTC detected item. Refer to BRC-48, "

DTC No. Index" (ABS), BRC-140, "DTC No. Index"

(VDC/TCS/ABS).

2.CHECK DTC WITH TCM

With CONSULT-III

Select “Self Diagnostic Results” mode for “TRANSMISSION”.

Is

“P1722 ESTM VEH SPD SIG” detected?

DTCItem

(CONSULT-III screen term)Malfunction is detected when... Possible cause

P1722 ESTM VEH SPD SIG CAN communication with the

ABS actuator and the electric

unit (control unit) is malfunc-

tioning.

There is a big difference be-

tween the vehicle speed sig-

nal from the ABS actuator

and the electric unit (control

unit), and the vehicle speed

sensor signal. Harness or connectors

(Sensor circuit is open or

shorted.)

ABS actuator and electric

unit (control unit)

ACC PEDAL OPEN : 1.0/8 or less

VEHICLE SPEED : 30 km/h (19 MPH) or more

Page 4749 of 5121

![NISSAN TEANA 2008 Service Manual TM-276

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

*Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-301, "ATFTEMP COUNT

Conversion Table".

TERMINAL LA NISSAN TEANA 2008 Service Manual TM-276

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

*Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-301, "ATFTEMP COUNT

Conversion Table".

TERMINAL LA](/img/5/57391/w960_57391-4748.png)

TM-276

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

*Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-301, "ATFTEMP COUNT

Conversion Table".

TERMINAL LAYOUT

D POSITION SWSelector lever in “D” position On

Other than the above position. Off

L POSITION SWSelector lever in “L” position On

Other than the above position. Off

BRAKE SWDepressed brake pedal On

Released brake pedal Off

FULL SWFully depressed accelerator pedal On

Released accelerator pedal Off

IDLE SWReleased accelerator pedal On

Fully depressed accelerator pedal Off

SPORT MODE SWWhile pushing sport mode switch On

Other conditions Off

INDLRNGSelector lever in “L” position On

When setting selector lever to other positions. Off

INDDRNGSelector lever in “D” position On

When setting selector lever to other positions. Off

INDNRNGSelector lever in “N“ position On

When setting selector lever to other positions. Off

INDRRNGSelector lever in “R” position On

When setting selector lever to other positions. Off

INDPRNGSelector lever in “P” position On

When setting selector lever to other positions. Off

SPORT MODE INDWhen sport mode On

Other conditions Off

SMCOIL A During driving Changes On ⇔ Off.

SMCOIL B During driving Changes On ⇔ Off.

SMCOIL C During driving Changes On ⇔ Off.

SMCOIL D During driving Changes On ⇔ Off.

LUSEL SOL OUTSelector lever in “P” and “N” positions On

Wait at least for 5 seconds with the selector lever in “R”

and “D” positionsOff

LUSEL SOL MONSelector lever in “P” and “N” positions On

Wait at least for 5 seconds with the selector lever in “R”

and “D” positionsOff

ABS ONABS operate On

Other conditions Off

RANGESelector lever in “N” and “P” position N·P

Selector lever in “R” position R

Selector lever in “D” position D

Selector lever in “L” position L Item name Condition Display value (Approx.)

Page 4819 of 5121

![NISSAN TEANA 2008 Service Manual VTL-8

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003802519

When performing the procedure after removing cowl top cover, cover

the NISSAN TEANA 2008 Service Manual VTL-8

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003802519

When performing the procedure after removing cowl top cover, cover

the](/img/5/57391/w960_57391-4818.png)

VTL-8

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003802519

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Xenon Headlamp ServiceINFOID:0000000003802520

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Working with HFC-134a (R-134a)INFOID:0000000003802521

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. Compressor malfunction is likely occur if the

refrigerants are mixed.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

- Cap (seal) immediately the component to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refrigerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed container. Reseal immediately containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

- Never allow lubricant (NISSAN A/C System Oil Type S) to come in contact with styrene foam parts.

Damage may result.

General Refrigerant PrecautionINFOID:0000000003802522

WARNING:

Never breath A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant.

PIIB3706J

Page 4876 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

VTL-65

< PRECAUTION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003894447

When performing the procedure after remov NISSAN TEANA 2008 Service Manual PRECAUTIONS

VTL-65

< PRECAUTION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003894447

When performing the procedure after remov](/img/5/57391/w960_57391-4875.png)

PRECAUTIONS

VTL-65

< PRECAUTION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003894447

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions For Xenon Headlamp ServiceINFOID:0000000003894448

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Working with HFC-134a (R-134a)INFOID:0000000003894449

CAUTION:

CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. Compressor malfunction is likely occur if the

refrigerants are mixed.

Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. Compressor malfunction is likely to occur if lubricant other than that specified is used.

The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

- Cap (seal) immediately the component to minimize the entry of moisture from the atmosphere when

removing refrigerant components from a vehicle.

- Never remove the caps (unseal) until just before connecting the components when installing refrig-

erant components to a vehicle. Connect all refrigerant loop components as quickly as possible to

minimize the entry of moisture into system.

- Use only the specified lubricant from a sealed container. Reseal immediately containers of lubricant.

Lubricant becomes moisture saturated and should not be used without proper sealing.

- Never allow lubricant (NISSAN A/C System Oil Type S) to come in contact with styrene foam parts.

Damage may result.

General Refrigerant PrecautionINFOID:0000000003894450

WARNING:

Never breath A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Use only approved recovery/recycling equipment to discharge HFC-134a (R-134a) refrigerant.

PIIB3706J

Page 4936 of 5121

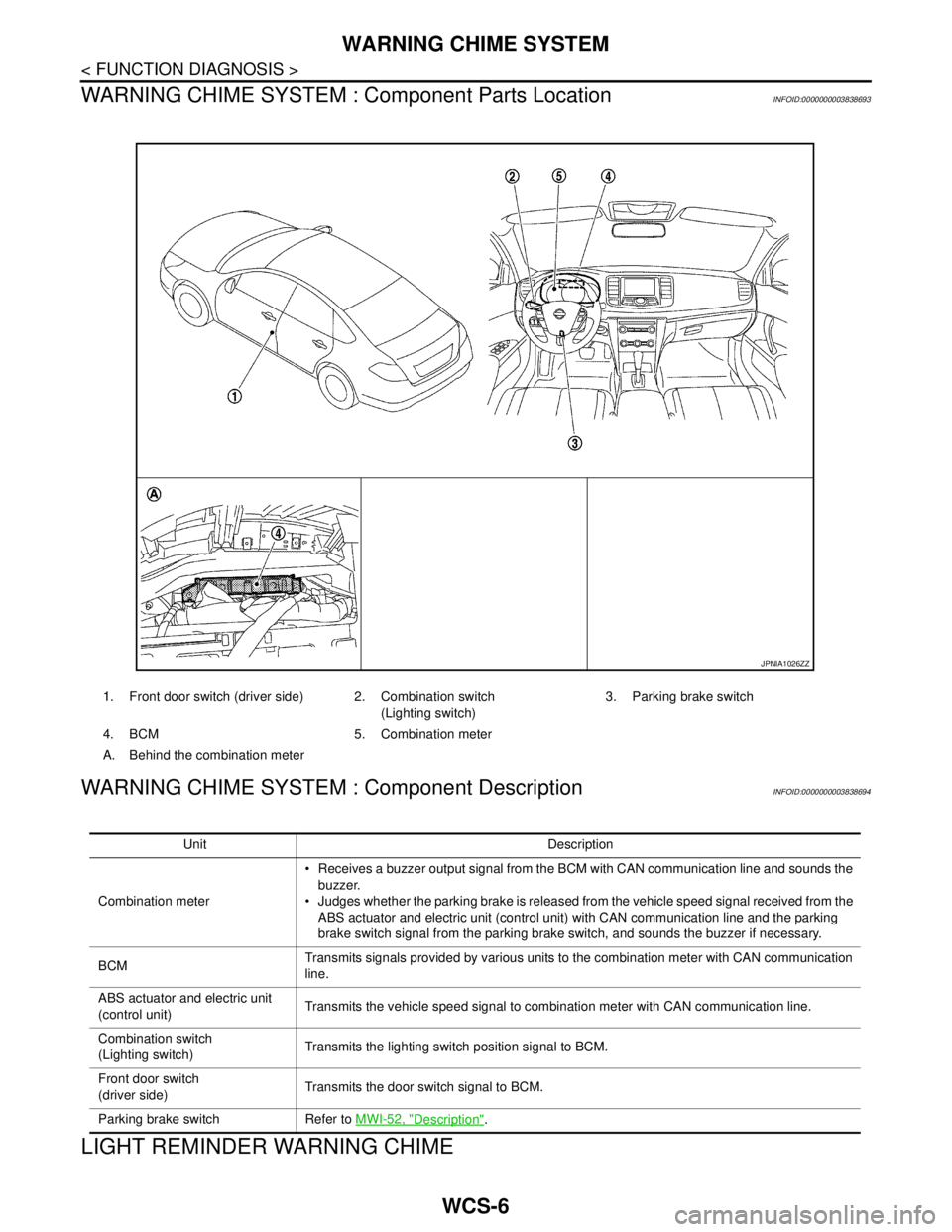

WCS-6

< FUNCTION DIAGNOSIS >

WARNING CHIME SYSTEM

WARNING CHIME SYSTEM : Component Parts Location

INFOID:0000000003838693

WARNING CHIME SYSTEM : Component DescriptionINFOID:0000000003838694

LIGHT REMINDER WARNING CHIME

1. Front door switch (driver side) 2. Combination switch

(Lighting switch)3. Parking brake switch

4. BCM 5. Combination meter

A. Behind the combination meter

JPNIA1026ZZ

Unit Description

Combination meter Receives a buzzer output signal from the BCM with CAN communication line and sounds the

buzzer.

Judges whether the parking brake is released from the vehicle speed signal received from the

ABS actuator and electric unit (control unit) with CAN communication line and the parking

brake switch signal from the parking brake switch, and sounds the buzzer if necessary.

BCMTransmits signals provided by various units to the combination meter with CAN communication

line.

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to combination meter with CAN communication line.

Combination switch

(Lighting switch)Transmits the lighting switch position signal to BCM.

Front door switch

(driver side)Transmits the door switch signal to BCM.

Parking brake switch Refer to MWI-52, "

Description".

Page 4939 of 5121

WCS

WARNING CHIME SYSTEM

WCS-9

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

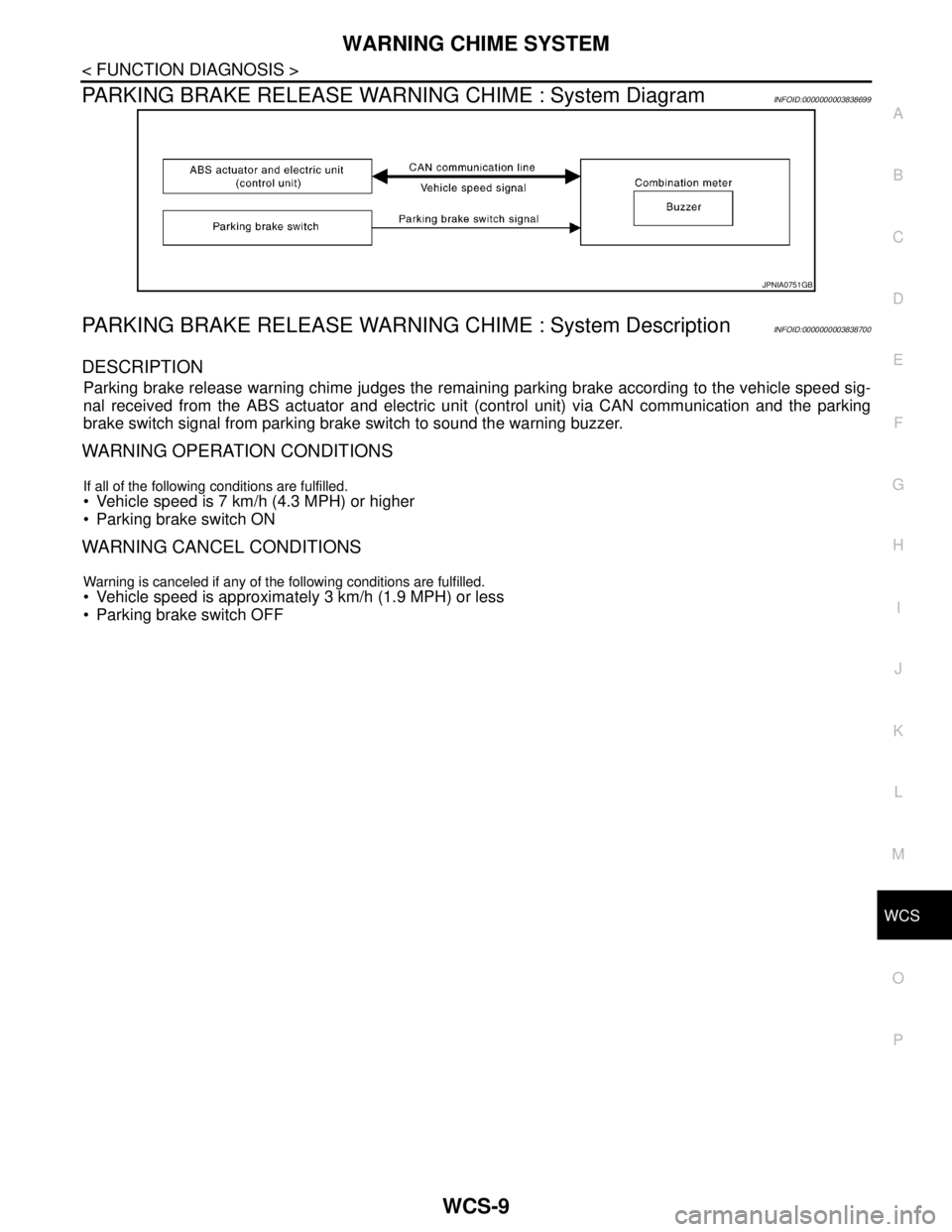

PARKING BRAKE RELEASE WARNING CHIME : System DiagramINFOID:0000000003838699

PARKING BRAKE RELEASE WARNING CHIME : System DescriptionINFOID:0000000003838700

DESCRIPTION

Parking brake release warning chime judges the remaining parking brake according to the vehicle speed sig-

nal received from the ABS actuator and electric unit (control unit) via CAN communication and the parking

brake switch signal from parking brake switch to sound the warning buzzer.

WARNING OPERATION CONDITIONS

If all of the following conditions are fulfilled. Vehicle speed is 7 km/h (4.3 MPH) or higher

Parking brake switch ON

WARNING CANCEL CONDITIONS

Warning is canceled if any of the following conditions are fulfilled.

Vehicle speed is approximately 3 km/h (1.9 MPH) or less

Parking brake switch OFF

JPNIA0751GB

Page 4940 of 5121

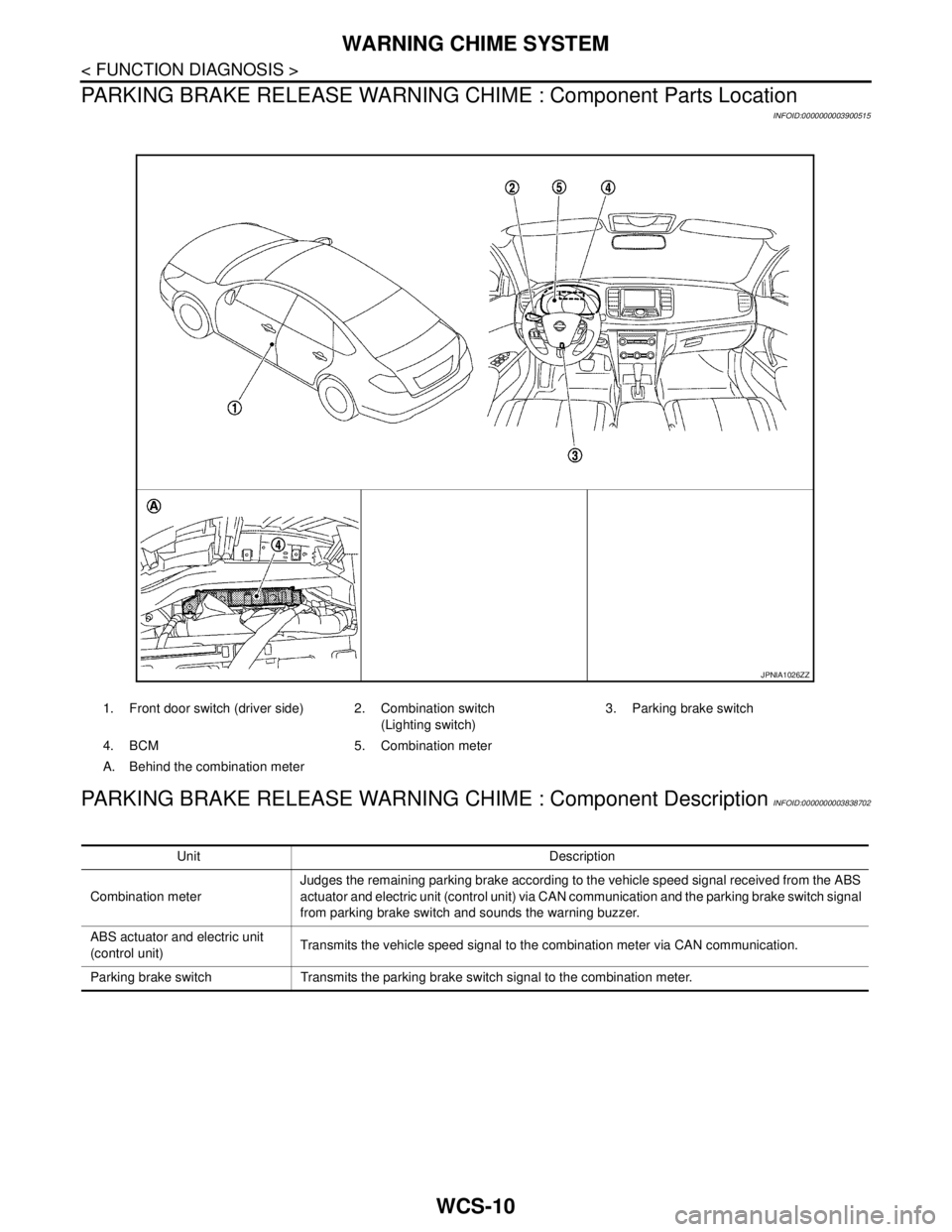

WCS-10

< FUNCTION DIAGNOSIS >

WARNING CHIME SYSTEM

PARKING BRAKE RELEASE WARNING CHIME : Component Parts Location

INFOID:0000000003900515

PARKING BRAKE RELEASE WARNING CHIME : Component DescriptionINFOID:0000000003838702

1. Front door switch (driver side) 2. Combination switch

(Lighting switch)3. Parking brake switch

4. BCM 5. Combination meter

A. Behind the combination meter

JPNIA1026ZZ

Unit Description

Combination meterJudges the remaining parking brake according to the vehicle speed signal received from the ABS

actuator and electric unit (control unit) via CAN communication and the parking brake switch signal

from parking brake switch and sounds the warning buzzer.

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to the combination meter via CAN communication.

Parking brake switch Transmits the parking brake switch signal to the combination meter.

Page 4942 of 5121

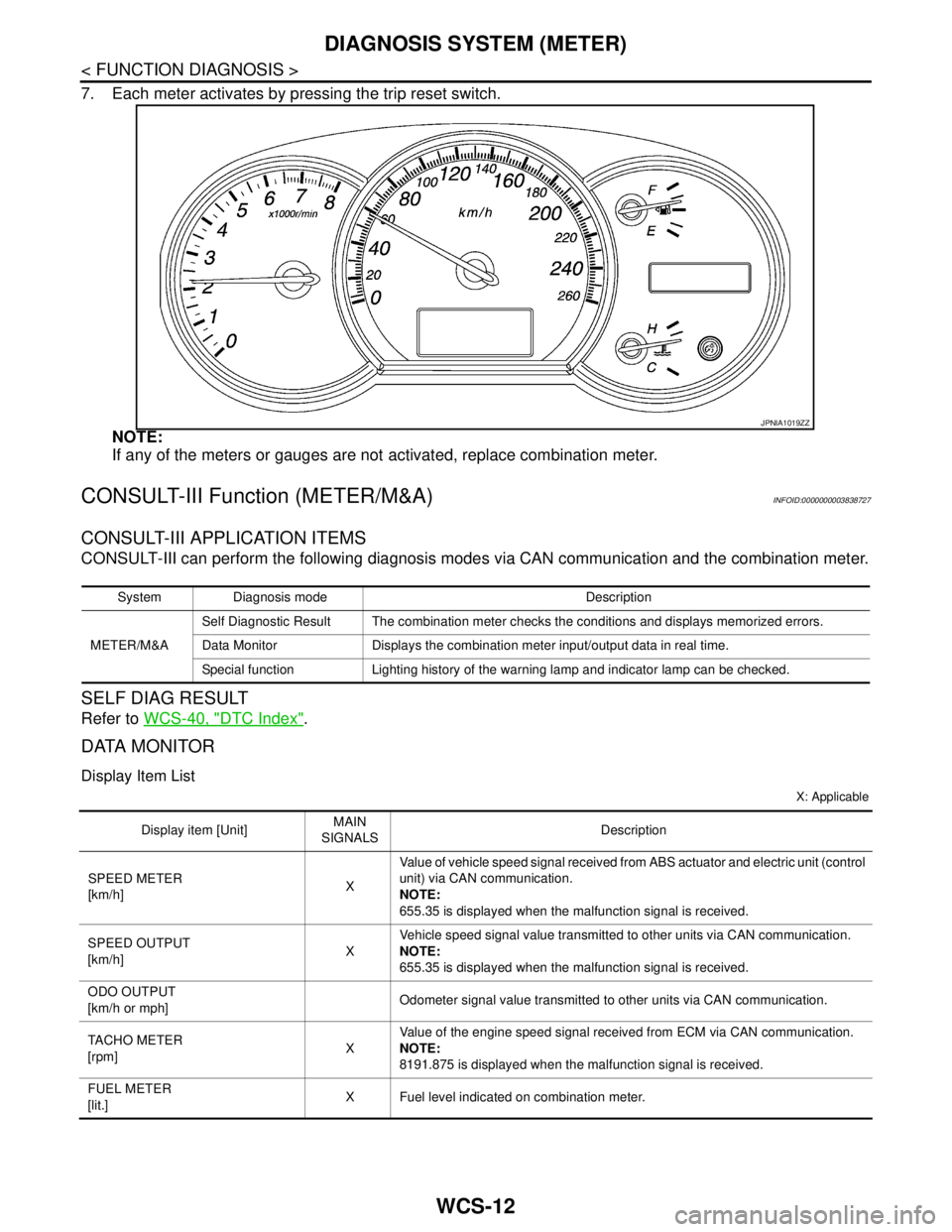

WCS-12

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

7. Each meter activates by pressing the trip reset switch.

NOTE:

If any of the meters or gauges are not activated, replace combination meter.

CONSULT-III Function (METER/M&A)INFOID:0000000003838727

CONSULT-III APPLICATION ITEMS

CONSULT-III can perform the following diagnosis modes via CAN communication and the combination meter.

SELF DIAG RESULT

Refer to WCS-40, "DTC Index".

DATA MONITOR

Display Item List

X: Applicable

JPNIA1019ZZ

System Diagnosis mode Description

METER/M&ASelf Diagnostic Result The combination meter checks the conditions and displays memorized errors.

Data Monitor Displays the combination meter input/output data in real time.

Special function Lighting history of the warning lamp and indicator lamp can be checked.

Display item [Unit]MAIN

SIGNALSDescription

SPEED METER

[km/h]XValue of vehicle speed signal received from ABS actuator and electric unit (control

unit) via CAN communication.

NOTE:

655.35 is displayed when the malfunction signal is received.

SPEED OUTPUT

[km/h]XVehicle speed signal value transmitted to other units via CAN communication.

NOTE:

655.35 is displayed when the malfunction signal is received.

ODO OUTPUT

[km/h or mph]Odometer signal value transmitted to other units via CAN communication.

TACHO METER

[rpm]XValue of the engine speed signal received from ECM via CAN communication.

NOTE:

8191.875 is displayed when the malfunction signal is received.

FUEL METER

[lit.]X Fuel level indicated on combination meter.

Page 4943 of 5121

![NISSAN TEANA 2008 Service Manual WCS

DIAGNOSIS SYSTEM (METER)

WCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

W TEMP METER

[°C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NO NISSAN TEANA 2008 Service Manual WCS

DIAGNOSIS SYSTEM (METER)

WCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

W TEMP METER

[°C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NO](/img/5/57391/w960_57391-4942.png)

WCS

DIAGNOSIS SYSTEM (METER)

WCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

W TEMP METER

[°C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NOTE:

215 is displayed when the malfunction signal is input.

ABS W/L

[On/Off]Status of ABS warning lamp detected from ABS warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

VDC/TCS IND

[On/Off]Status of VDC OFF indicator lamp detected from VDC OFF indicator lamp signal

is received from ABS actuator and electric unit (control unit) via CAN communica-

tion.

SLIP IND

[On/Off]Status of SLIP indicator lamp detected from slip indicator lamp signal received

from ABS actuator and electric unit (control unit) via CAN communication.

BRAKE W/L

[On/Off]Status of brake warning lamp detected from brake warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

NOTE:

Displays “Off” if the brake warning lamp is illuminated when the valve check starts,

the parking brake switch is turned ON or the brake fluid level switch is turned ON.

DOOR W/L

[On/Off]Status of door warning detected from door switch signal received from BCM via

CAN communication.

TRUNK/GLAS-H

[On/Off]Status of trunk warning detected from trunk switch signal received from BCM via

CAN communication.

HI-BEAM IND

[On/Off]Status of high beam indicator lamp detected from high beam request signal is re-

ceived from BCM via CAN communication.

TURN IND

[On/Off]Status of turn indicator lamp detected from turn indicator signal is received from

BCM via CAN communication.

FR FOG IND

[On/Off]Status of front fog light indicator lamp detected from front fog light request signal

is received from BCM via CAN communication.

RR FOG IND

[On/Off]Status of rear fog light indicator lamp detected from rear fog light request signal is

received from BCM via CAN communication.

LIGHT IND

[On/Off]Status of light indicator lamp detected from position light request signal is received

from BCM via CAN communication.

OIL W/L

[On/Off]Status of oil pressure warning lamp detected from oil pressure switch signal is re-

ceived from BCM via CAN communication.

MIL

[On/Off] Status of malfunction indicator lamp detected from malfunctioning indicator lamp

signal is received from ECM via CAN communication.

CRUISE IND

[On/Off]Status of CRUISE indicator detected from ASCD status signal is received from

ECM via CAN communication.

SPORT IND

[On/Off]Status of SPORT indicator detected from sport mode switch signal is received

from control device.

4WD W/L

[On/Off]This item is displayed, but cannot be monitored.

4WD LOCK IND

[On/Off]This item is displayed, but cannot be monitored.

FUEL W/L

[On/Off]Low-fuel warning lamp status detected by the identified fuel level.

WASHER W/L

[On/Off]This item is displayed, but cannot be monitored.

KEY G/Y W/L

[On/Off]Status of key warning lamp (G/Y) detected from key warning signal is received

from BCM via CAN communication.

AFS OFF IND

[On/Off]This item is displayed, but cannot be monitored.

LCD

[B&P N, B&P I, ID NG, ROTAT, SFT

P, INSRT, BATT, NO KY,OUTKY, LK

WN]Displays status of Intelligent Key system warning detected from meter display sig-

nal is received from BCM via CAN communication.

Display item [Unit]MAIN

SIGNALSDescription

Page 4945 of 5121

WCS

DIAGNOSIS SYSTEM (METER)

WCS-15

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

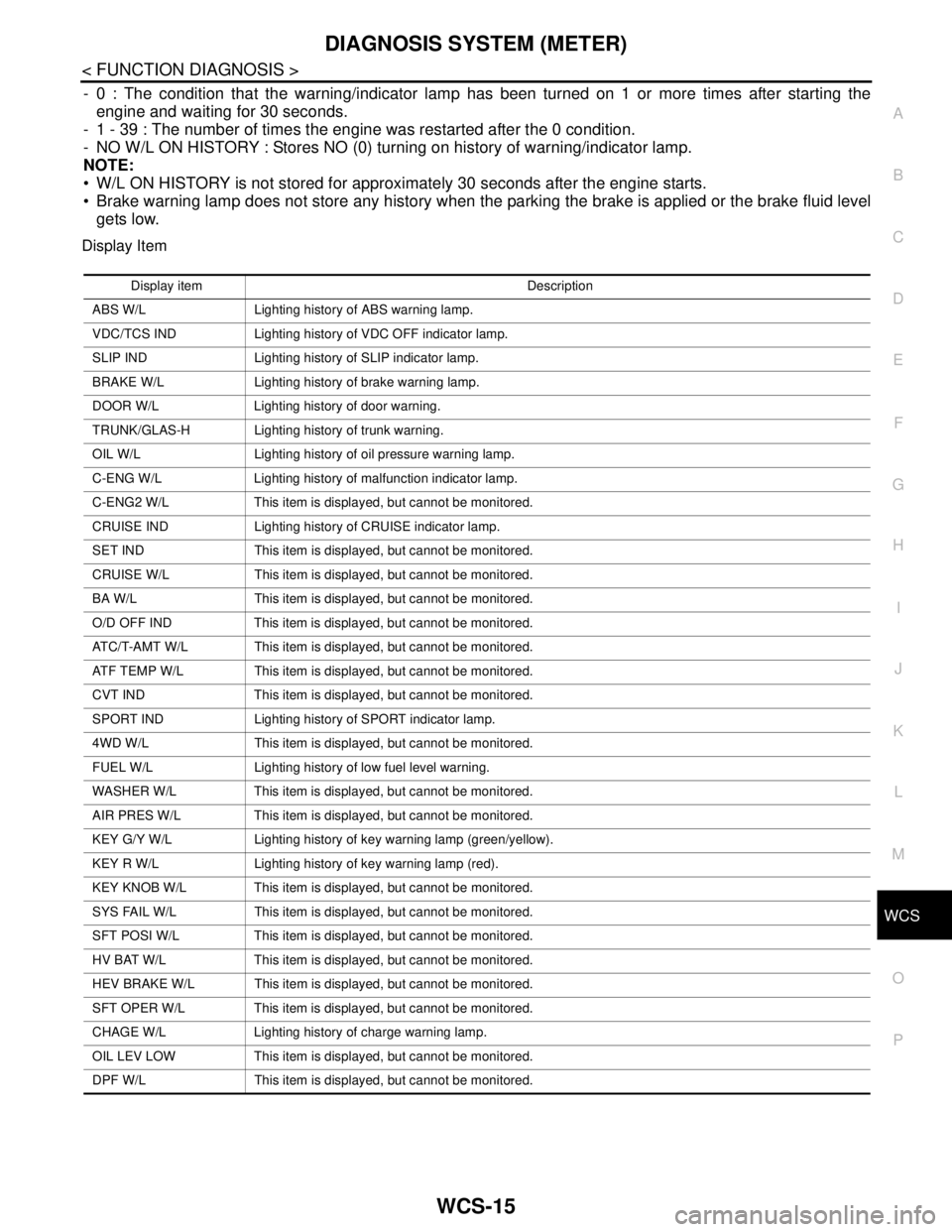

- 0 : The condition that the warning/indicator lamp has been turned on 1 or more times after starting the

engine and waiting for 30 seconds.

- 1 - 39 : The number of times the engine was restarted after the 0 condition.

- NO W/L ON HISTORY : Stores NO (0) turning on history of warning/indicator lamp.

NOTE:

W/L ON HISTORY is not stored for approximately 30 seconds after the engine starts.

Brake warning lamp does not store any history when the parking the brake is applied or the brake fluid level

gets low.

Display Item

Display item Description

ABS W/L Lighting history of ABS warning lamp.

VDC/TCS IND Lighting history of VDC OFF indicator lamp.

SLIP IND Lighting history of SLIP indicator lamp.

BRAKE W/L Lighting history of brake warning lamp.

DOOR W/L Lighting history of door warning.

TRUNK/GLAS-H Lighting history of trunk warning.

OIL W/L Lighting history of oil pressure warning lamp.

C-ENG W/L Lighting history of malfunction indicator lamp.

C-ENG2 W/L This item is displayed, but cannot be monitored.

CRUISE IND Lighting history of CRUISE indicator lamp.

SET IND This item is displayed, but cannot be monitored.

CRUISE W/L This item is displayed, but cannot be monitored.

BA W/L This item is displayed, but cannot be monitored.

O/D OFF IND This item is displayed, but cannot be monitored.

ATC/T-AMT W/L This item is displayed, but cannot be monitored.

ATF TEMP W/L This item is displayed, but cannot be monitored.

CVT IND This item is displayed, but cannot be monitored.

SPORT IND Lighting history of SPORT indicator lamp.

4WD W/L This item is displayed, but cannot be monitored.

FUEL W/L Lighting history of low fuel level warning.

WASHER W/L This item is displayed, but cannot be monitored.

AIR PRES W/L This item is displayed, but cannot be monitored.

KEY G/Y W/L Lighting history of key warning lamp (green/yellow).

KEY R W/L Lighting history of key warning lamp (red).

KEY KNOB W/L This item is displayed, but cannot be monitored.

SYS FAIL W/L This item is displayed, but cannot be monitored.

SFT POSI W/L This item is displayed, but cannot be monitored.

HV BAT W/L This item is displayed, but cannot be monitored.

HEV BRAKE W/L This item is displayed, but cannot be monitored.

SFT OPER W/L This item is displayed, but cannot be monitored.

CHAGE W/L Lighting history of charge warning lamp.

OIL LEV LOW This item is displayed, but cannot be monitored.

DPF W/L This item is displayed, but cannot be monitored.