ABS NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3729 of 5121

RAX-4

< ON-VEHICLE REPAIR >

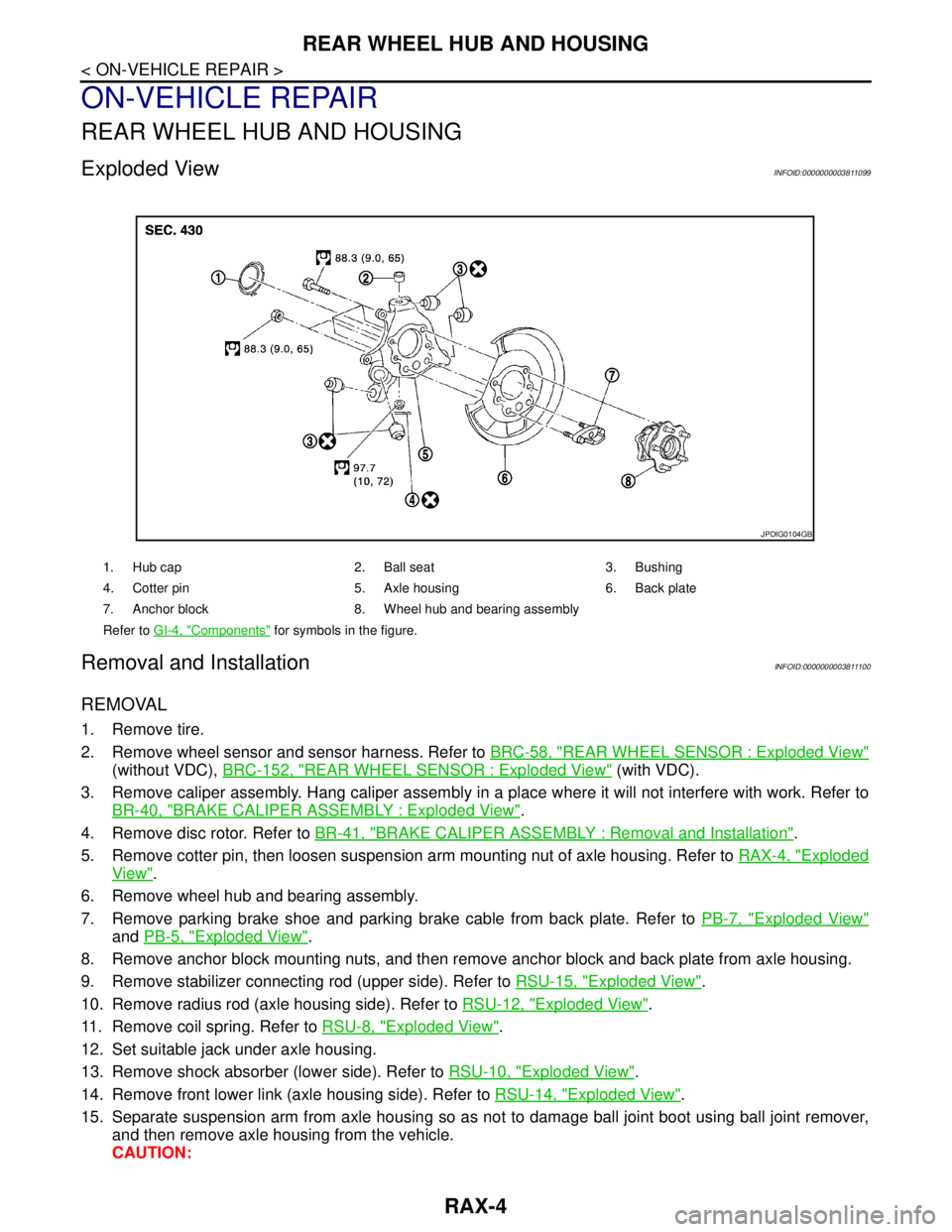

REAR WHEEL HUB AND HOUSING

ON-VEHICLE REPAIR

REAR WHEEL HUB AND HOUSING

Exploded ViewINFOID:0000000003811099

Removal and InstallationINFOID:0000000003811100

REMOVAL

1. Remove tire.

2. Remove wheel sensor and sensor harness. Refer to BRC-58, "

REAR WHEEL SENSOR : Exploded View"

(without VDC), BRC-152, "REAR WHEEL SENSOR : Exploded View" (with VDC).

3. Remove caliper assembly. Hang caliper assembly in a place where it will not interfere with work. Refer to

BR-40, "

BRAKE CALIPER ASSEMBLY : Exploded View".

4. Remove disc rotor. Refer to BR-41, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

5. Remove cotter pin, then loosen suspension arm mounting nut of axle housing. Refer to RAX-4, "

Exploded

View".

6. Remove wheel hub and bearing assembly.

7. Remove parking brake shoe and parking brake cable from back plate. Refer to PB-7, "

Exploded View"

and PB-5, "Exploded View".

8. Remove anchor block mounting nuts, and then remove anchor block and back plate from axle housing.

9. Remove stabilizer connecting rod (upper side). Refer to RSU-15, "

Exploded View".

10. Remove radius rod (axle housing side). Refer to RSU-12, "

Exploded View".

11. Remove coil spring. Refer to RSU-8, "

Exploded View".

12. Set suitable jack under axle housing.

13. Remove shock absorber (lower side). Refer to RSU-10, "

Exploded View".

14. Remove front lower link (axle housing side). Refer to RSU-14, "

Exploded View".

15. Separate suspension arm from axle housing so as not to damage ball joint boot using ball joint remover,

and then remove axle housing from the vehicle.

CAUTION:

1. Hub cap 2. Ball seat 3. Bushing

4. Cotter pin 5. Axle housing 6. Back plate

7. Anchor block 8. Wheel hub and bearing assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPDIG0104GB

Page 3781 of 5121

RF-50

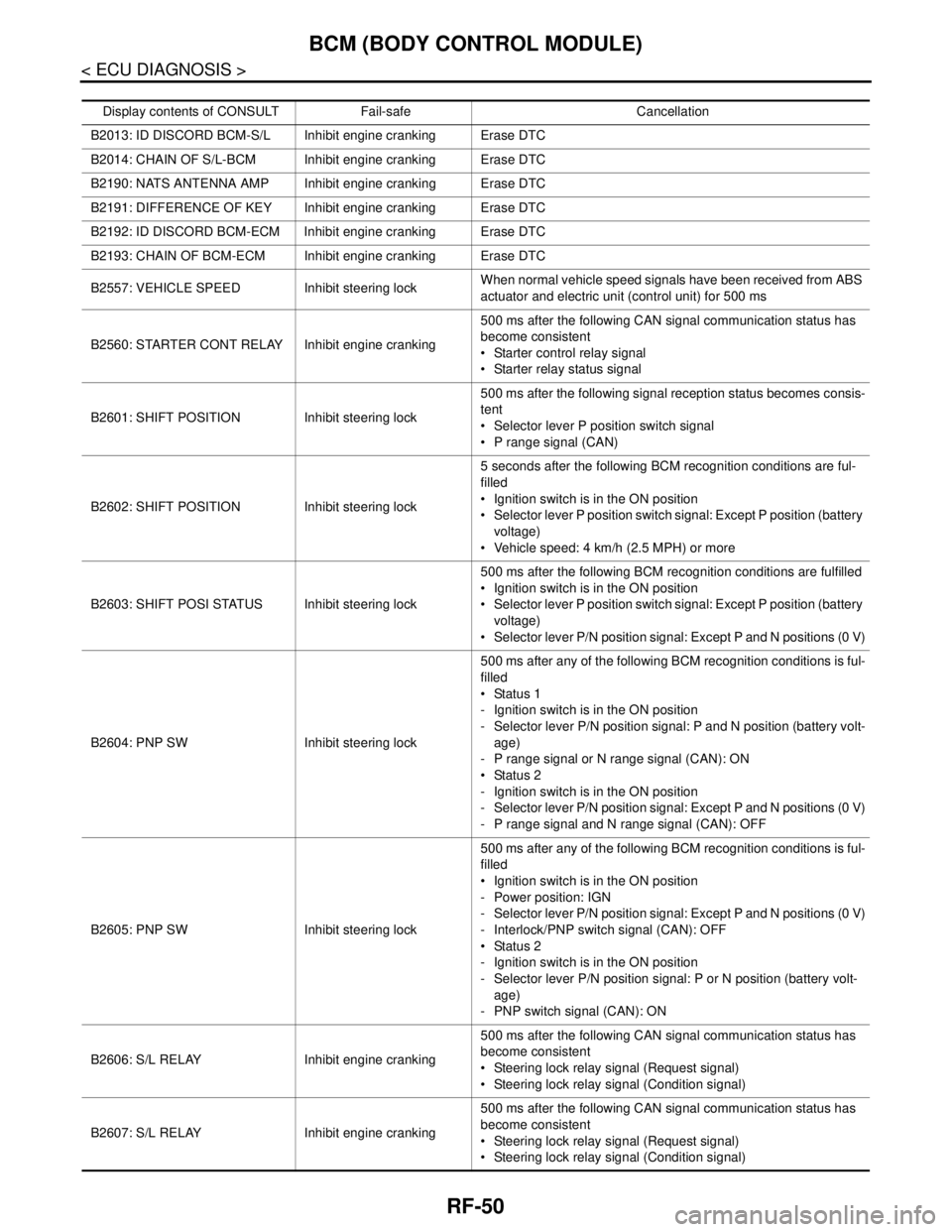

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITION Inhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITION Inhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 3833 of 5121

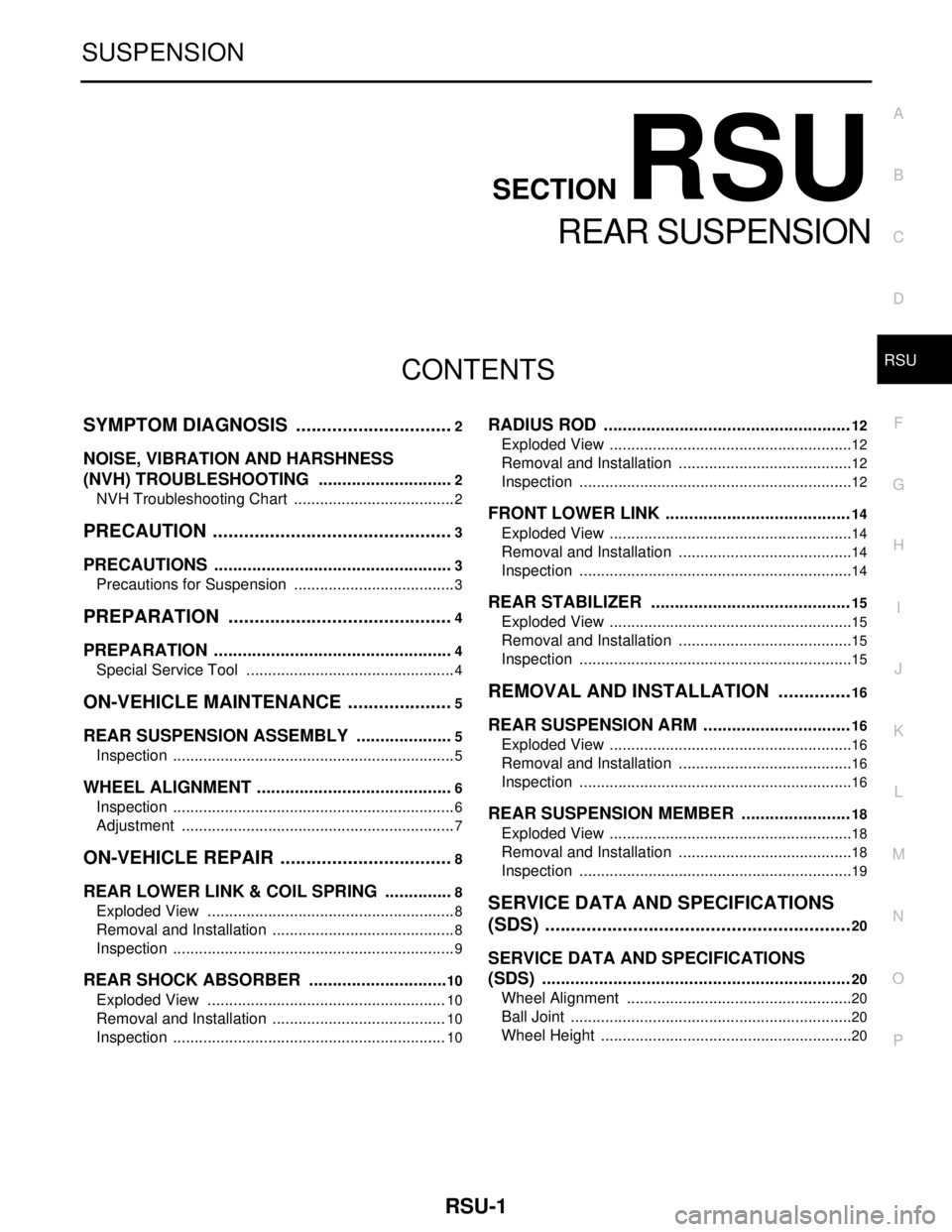

RSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION RSU

A

B

RSU

N

O PCONTENTS

REAR SUSPENSION

SYMPTOM DIAGNOSIS ..... ..........................2

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

2

NVH Troubleshooting Chart ................................ ......2

PRECAUTION ...............................................3

PRECAUTIONS .............................................. .....3

Precautions for Suspension ................................ ......3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

ON-VEHICLE MAINTENANCE .....................5

REAR SUSPENSION ASSEMBLY ................ .....5

Inspection ............................................................ ......5

WHEEL ALIGNMENT ..........................................6

Inspection ............................................................ ......6

Adjustment ................................................................7

ON-VEHICLE REPAIR ..................................8

REAR LOWER LINK & COIL SPRING .......... .....8

Exploded View .................................................... ......8

Removal and Installation ...........................................8

Inspection ..................................................................9

REAR SHOCK ABSORBER ..............................10

Exploded View .................................................... ....10

Removal and Installation .........................................10

Inspection ................................................................10

RADIUS ROD ................................... .................12

Exploded View ..................................................... ....12

Removal and Installation .........................................12

Inspection ................................................................12

FRONT LOWER LINK .......................................14

Exploded View .........................................................14

Removal and Installation .........................................14

Inspection ................................................................14

REAR STABILIZER ..........................................15

Exploded View .........................................................15

Removal and Installation .........................................15

Inspection ................................................................15

REMOVAL AND INSTALLATION ...............16

REAR SUSPENSION ARM ...............................16

Exploded View ..................................................... ....16

Removal and Installation .........................................16

Inspection ................................................................16

REAR SUSPENSION MEMBER .......................18

Exploded View ..................................................... ....18

Removal and Installation .........................................18

Inspection ................................................................19

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

20

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

20

Wheel Alignment ................................................. ....20

Ball Joint ..................................................................20

Wheel Height ...........................................................20

Page 3834 of 5121

RSU-2

< SYMPTOM DIAGNOSIS >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

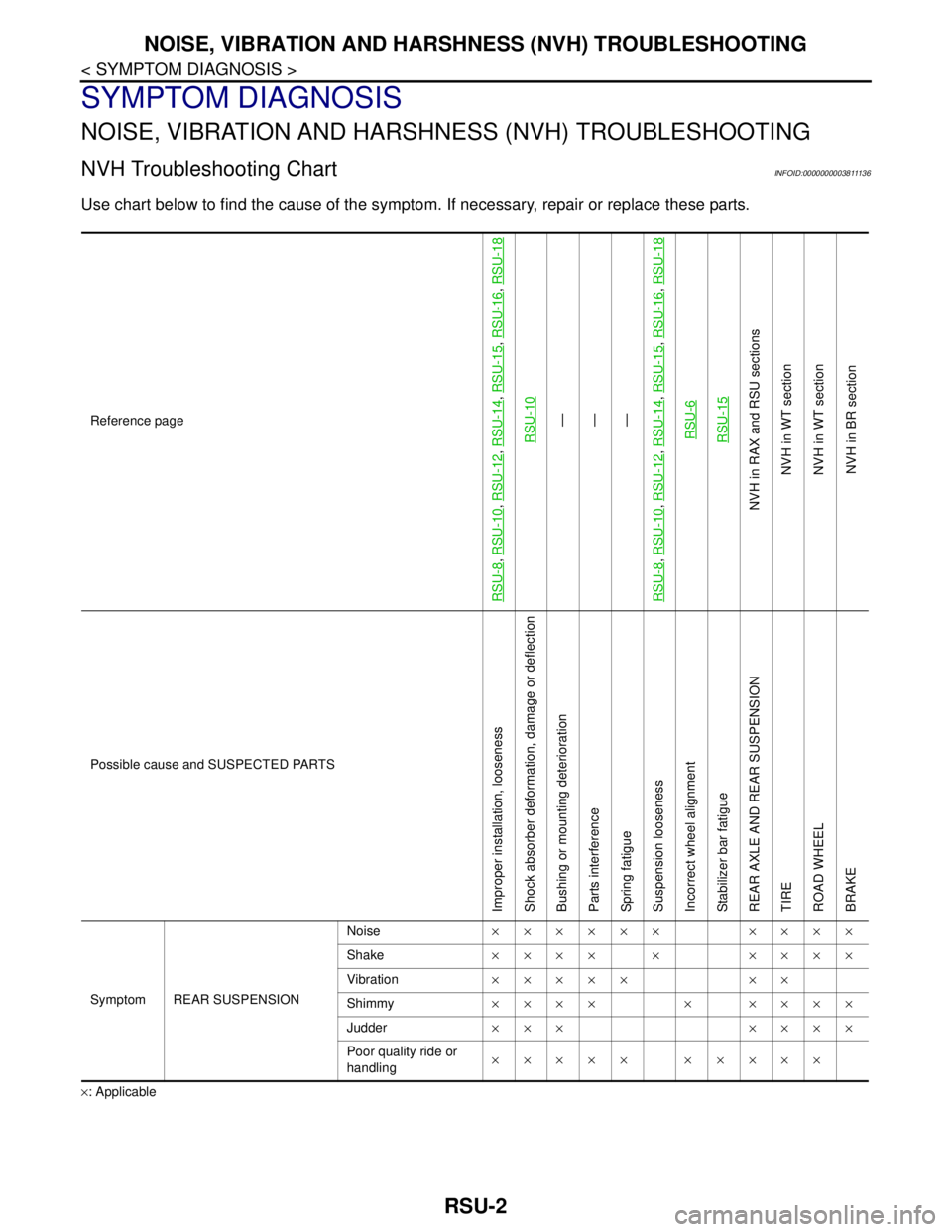

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003811136

Use chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-8

, RSU-10

, RSU-12

, RSU-14

, RSU-15

, RSU-16

, RSU-18

RSU-10

—

—

—

RSU-8

, RSU-10

, RSU-12

, RSU-14

, RSU-15

, RSU-16

, RSU-18

RSU-6RSU-15

NVH in RAX and RSU sections

NVH in WT section

NVH in WT section

NVH in BR section

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

REAR AXLE AND REAR SUSPENSION

TIRE

ROAD WHEEL

BRAKE

Symptom REAR SUSPENSIONNoise×××××× ××××

Shake×××× × ××××

Vibration××××× ××

Shimmy×××× × ××××

Judder ××× ××××

Poor quality ride or

handling××××× ×××××

Page 3837 of 5121

REAR SUSPENSION ASSEMBLY

RSU-5

< ON-VEHICLE MAINTENANCE >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

InspectionINFOID:0000000003811139

MOUNTING INSPECTION

Make sure the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

SHOCK ABSORBER

Check for oil leakage and damage. Replace if necessary.

Page 3838 of 5121

RSU-6

< ON-VEHICLE MAINTENANCE >

WHEEL ALIGNMENT

WHEEL ALIGNMENT

InspectionINFOID:0000000003813442

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout: refer to WT-2, "

Inspection".

Wheel bearing axial end play: refer to RAX-3, "

Inspection".

Shock absorber operation

Each mounting point of axle and suspension for looseness and deformation

Each of lower link, upper link, rear suspension member, suspension arm and shock absorber for cracks,

deformation, and other damage

Vehicle height (posture)

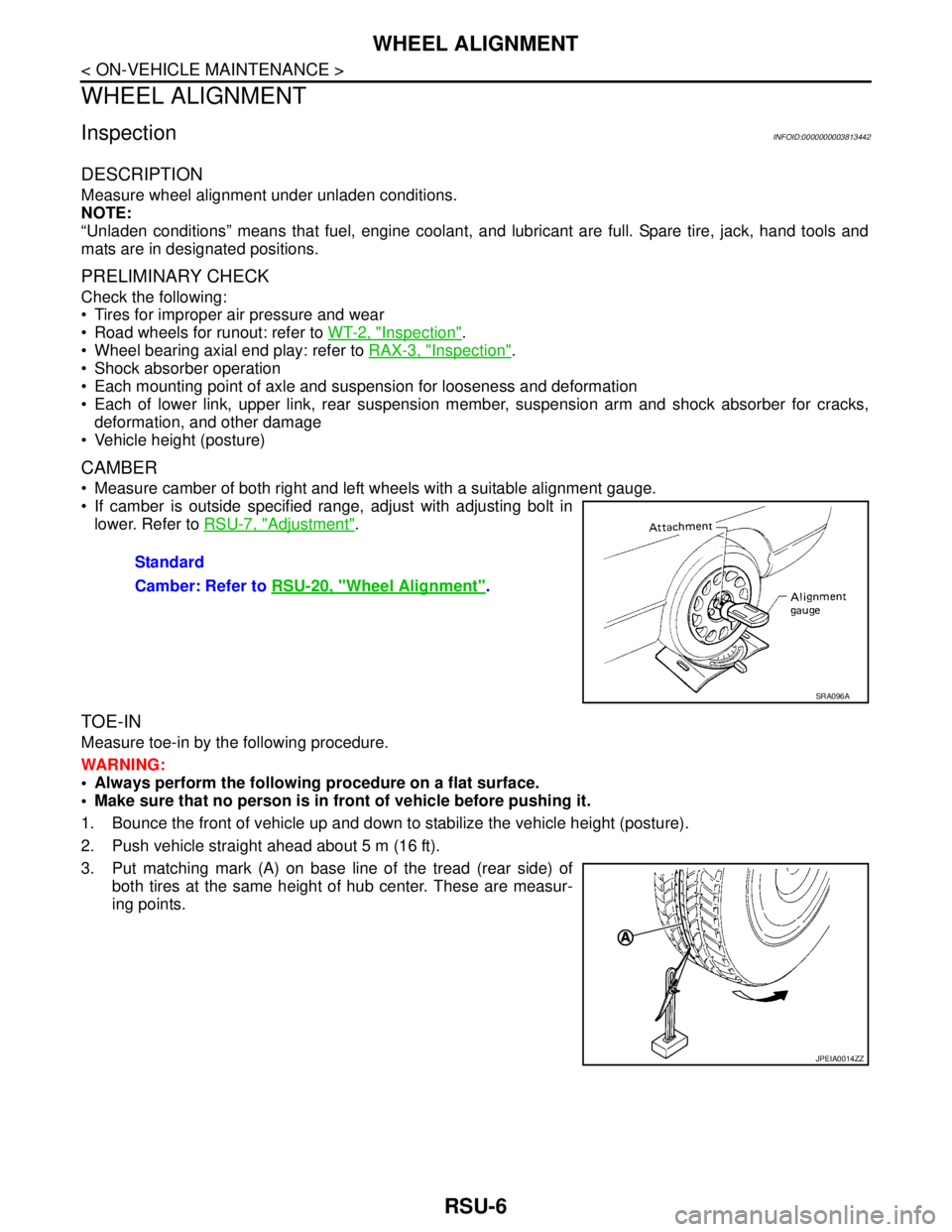

CAMBER

Measure camber of both right and left wheels with a suitable alignment gauge.

If camber is outside specified range, adjust with adjusting bolt in

lower. Refer to RSU-7, "

Adjustment".

TOE-IN

Measure toe-in by the following procedure.

WARNING:

Always perform the following procedure on a flat surface.

Make sure that no person is in front of vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft).

3. Put matching mark (A) on base line of the tread (rear side) of

both tires at the same height of hub center. These are measur-

ing points.Standard

Camber: Refer to RSU-20, "

Wheel Alignment".

SRA096A

JPEIA0014ZZ

Page 3840 of 5121

RSU-8

< ON-VEHICLE REPAIR >

REAR LOWER LINK & COIL SPRING

ON-VEHICLE REPAIR

REAR LOWER LINK & COIL SPRING

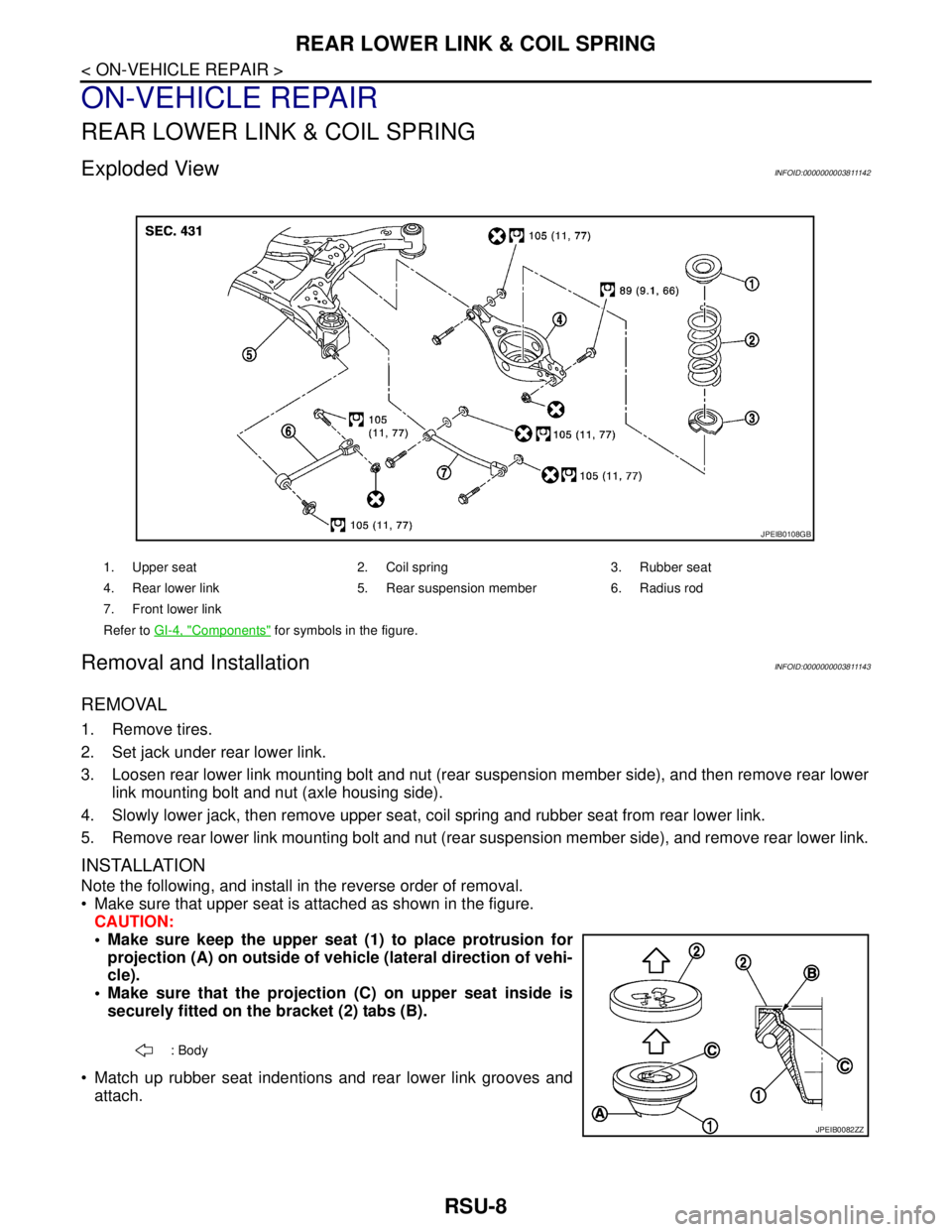

Exploded ViewINFOID:0000000003811142

Removal and InstallationINFOID:0000000003811143

REMOVAL

1. Remove tires.

2. Set jack under rear lower link.

3. Loosen rear lower link mounting bolt and nut (rear suspension member side), and then remove rear lower

link mounting bolt and nut (axle housing side).

4. Slowly lower jack, then remove upper seat, coil spring and rubber seat from rear lower link.

5. Remove rear lower link mounting bolt and nut (rear suspension member side), and remove rear lower link.

INSTALLATION

Note the following, and install in the reverse order of removal.

Make sure that upper seat is attached as shown in the figure.

CAUTION:

Make sure keep the upper seat (1) to place protrusion for

projection (A) on outside of vehicle (lateral direction of vehi-

cle).

Make sure that the projection (C) on upper seat inside is

securely fitted on the bracket (2) tabs (B).

Match up rubber seat indentions and rear lower link grooves and

attach.

1. Upper seat 2. Coil spring 3. Rubber seat

4. Rear lower link 5. Rear suspension member 6. Radius rod

7. Front lower link

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0108GB

: Body

JPEIB0082ZZ

Page 3842 of 5121

RSU-10

< ON-VEHICLE REPAIR >

REAR SHOCK ABSORBER

REAR SHOCK ABSORBER

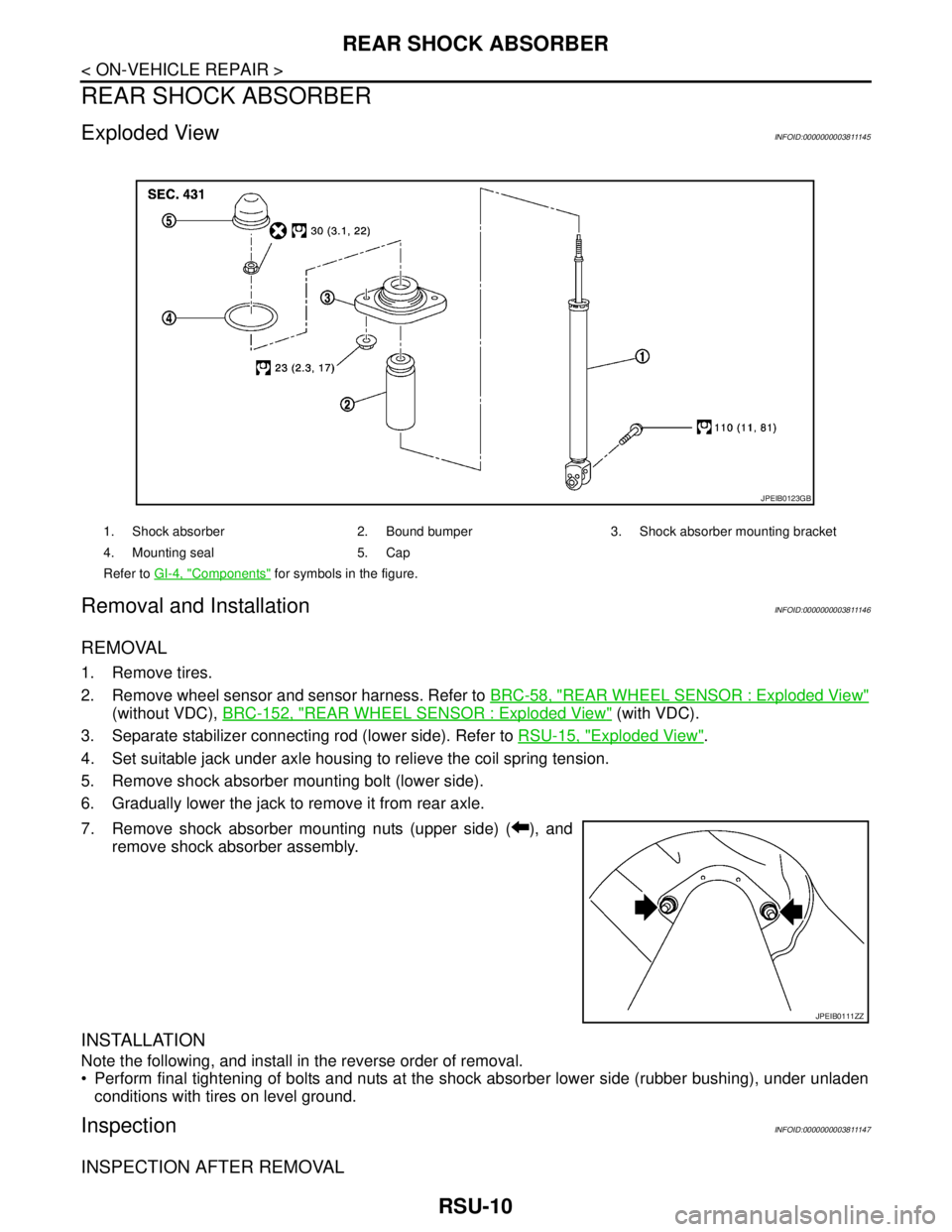

Exploded ViewINFOID:0000000003811145

Removal and InstallationINFOID:0000000003811146

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-58, "

REAR WHEEL SENSOR : Exploded View"

(without VDC), BRC-152, "REAR WHEEL SENSOR : Exploded View" (with VDC).

3. Separate stabilizer connecting rod (lower side). Refer to RSU-15, "

Exploded View".

4. Set suitable jack under axle housing to relieve the coil spring tension.

5. Remove shock absorber mounting bolt (lower side).

6. Gradually lower the jack to remove it from rear axle.

7. Remove shock absorber mounting nuts (upper side) ( ), and

remove shock absorber assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

Perform final tightening of bolts and nuts at the shock absorber lower side (rubber bushing), under unladen

conditions with tires on level ground.

InspectionINFOID:0000000003811147

INSPECTION AFTER REMOVAL

1. Shock absorber 2. Bound bumper 3. Shock absorber mounting bracket

4. Mounting seal 5. Cap

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0123GB

JPEIB0111ZZ

Page 3843 of 5121

REAR SHOCK ABSORBER

RSU-11

< ON-VEHICLE REPAIR >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

Check the following items, and replace the if necessary.

Shock absorber for deformation, cracks, damage.

Welded and sealed areas for oil leakage.

Piston rod for damage, uneven wear or distortion.

Seal of shock absorber mounting bracket for cracks, damage and come off.

INSPECTION AFTER INSTALLATION

Check wheel sensor harness for proper connection. Refer to BRC-58, "REAR WHEEL SENSOR : Exploded

View" (without VDC), BRC-152, "REAR WHEEL SENSOR : Exploded View" (with VDC).

Page 3844 of 5121

RSU-12

< ON-VEHICLE REPAIR >

RADIUS ROD

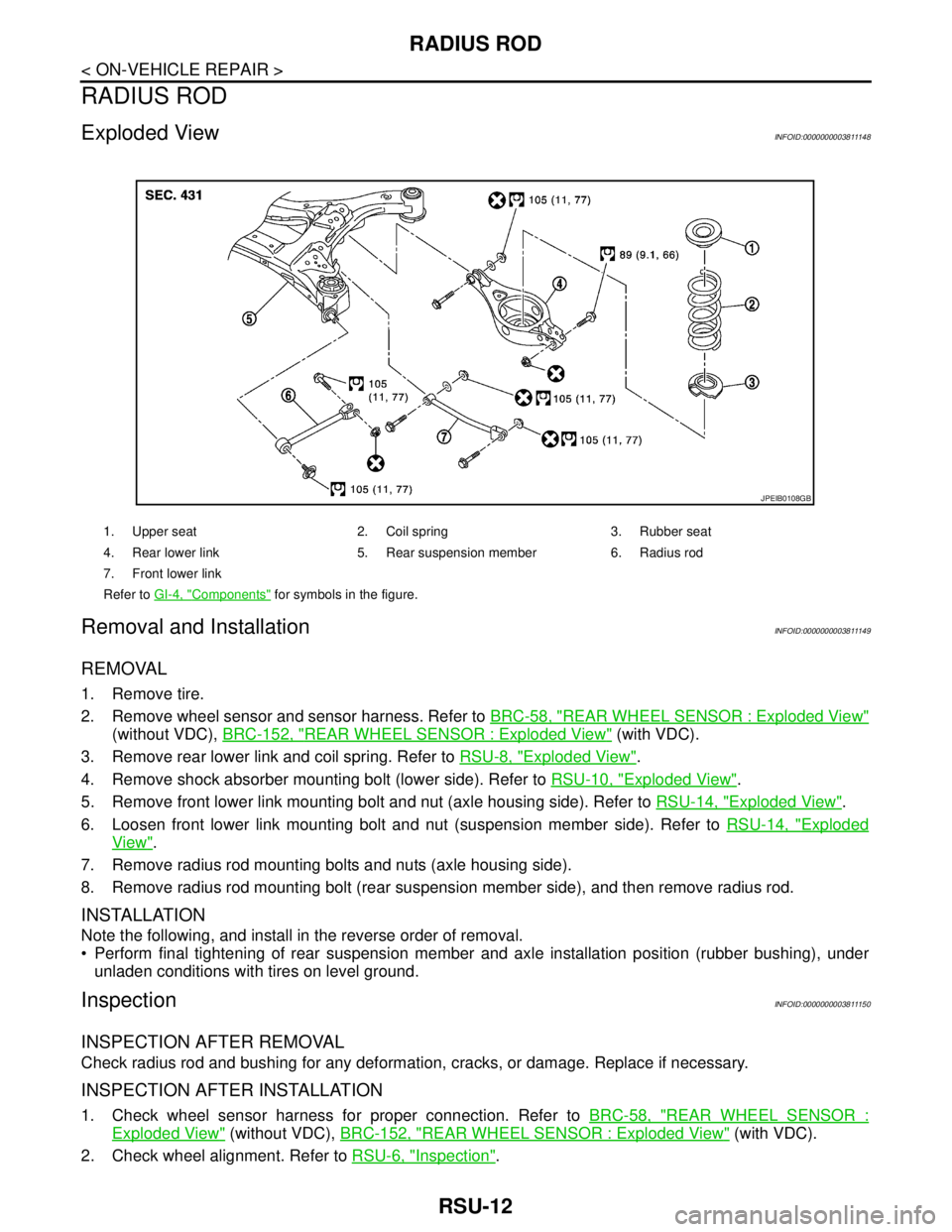

RADIUS ROD

Exploded ViewINFOID:0000000003811148

Removal and InstallationINFOID:0000000003811149

REMOVAL

1. Remove tire.

2. Remove wheel sensor and sensor harness. Refer to BRC-58, "

REAR WHEEL SENSOR : Exploded View"

(without VDC), BRC-152, "REAR WHEEL SENSOR : Exploded View" (with VDC).

3. Remove rear lower link and coil spring. Refer to RSU-8, "

Exploded View".

4. Remove shock absorber mounting bolt (lower side). Refer to RSU-10, "

Exploded View".

5. Remove front lower link mounting bolt and nut (axle housing side). Refer to RSU-14, "

Exploded View".

6. Loosen front lower link mounting bolt and nut (suspension member side). Refer to RSU-14, "

Exploded

View".

7. Remove radius rod mounting bolts and nuts (axle housing side).

8. Remove radius rod mounting bolt (rear suspension member side), and then remove radius rod.

INSTALLATION

Note the following, and install in the reverse order of removal.

Perform final tightening of rear suspension member and axle installation position (rubber bushing), under

unladen conditions with tires on level ground.

InspectionINFOID:0000000003811150

INSPECTION AFTER REMOVAL

Check radius rod and bushing for any deformation, cracks, or damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to BRC-58, "REAR WHEEL SENSOR :

Exploded View" (without VDC), BRC-152, "REAR WHEEL SENSOR : Exploded View" (with VDC).

2. Check wheel alignment. Refer to RSU-6, "

Inspection".

1. Upper seat 2. Coil spring 3. Rubber seat

4. Rear lower link 5. Rear suspension member 6. Radius rod

7. Front lower link

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0108GB