clock NISSAN TEANA 2008 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4224 of 5121

SR-10

< ON-VEHICLE REPAIR >

SPIRAL CABLE

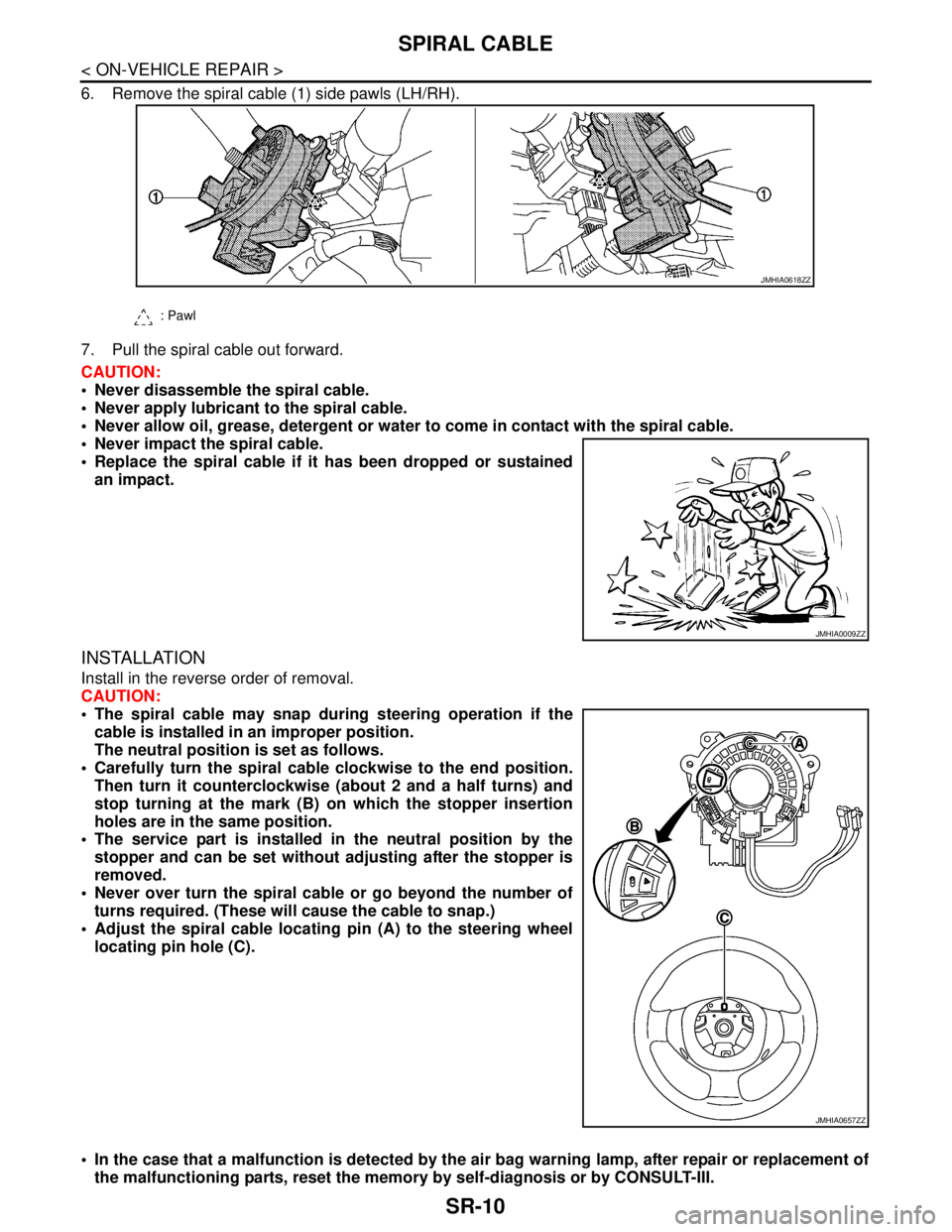

6. Remove the spiral cable (1) side pawls (LH/RH).

7. Pull the spiral cable out forward.

CAUTION:

Never disassemble the spiral cable.

Never apply lubricant to the spiral cable.

Never allow oil, grease, detergent or water to come in contact with the spiral cable.

Never impact the spiral cable.

Replace the spiral cable if it has been dropped or sustained

an impact.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

The spiral cable may snap during steering operation if the

cable is installed in an improper position.

The neutral position is set as follows.

Carefully turn the spiral cable clockwise to the end position.

Then turn it counterclockwise (about 2 and a half turns) and

stop turning at the mark (B) on which the stopper insertion

holes are in the same position.

The service part is installed in the neutral position by the

stopper and can be set without adjusting after the stopper is

removed.

Never over turn the spiral cable or go beyond the number of

turns required. (These will cause the cable to snap.)

Adjust the spiral cable locating pin (A) to the steering wheel

locating pin hole (C).

In the case that a malfunction is detected by the air bag warning lamp, after repair or replacement of

the malfunctioning parts, reset the memory by self-diagnosis or by CONSULT-III.

: Pawl

JMHIA0618ZZ

JMHIA0009ZZ

JMHIA0657ZZ

Page 4414 of 5121

ST-24

< ON-VEHICLE REPAIR >

STEERING GEAR AND LINKAGE

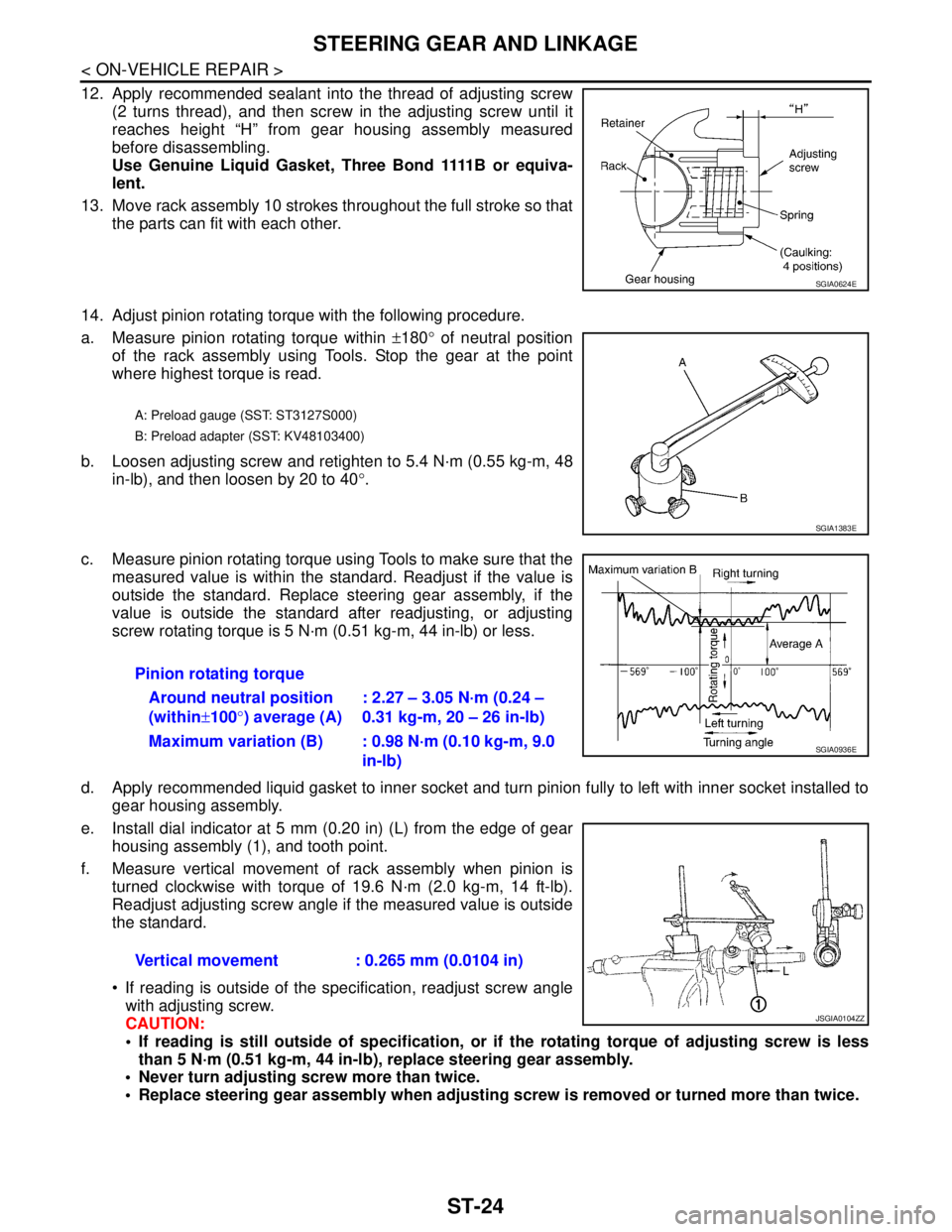

12. Apply recommended sealant into the thread of adjusting screw

(2 turns thread), and then screw in the adjusting screw until it

reaches height “H” from gear housing assembly measured

before disassembling.

Use Genuine Liquid Gasket, Three Bond 1111B or equiva-

lent.

13. Move rack assembly 10 strokes throughout the full stroke so that

the parts can fit with each other.

14. Adjust pinion rotating torque with the following procedure.

a. Measure pinion rotating torque within ±180° of neutral position

of the rack assembly using Tools. Stop the gear at the point

where highest torque is read.

b. Loosen adjusting screw and retighten to 5.4 N·m (0.55 kg-m, 48

in-lb), and then loosen by 20 to 40°.

c. Measure pinion rotating torque using Tools to make sure that the

measured value is within the standard. Readjust if the value is

outside the standard. Replace steering gear assembly, if the

value is outside the standard after readjusting, or adjusting

screw rotating torque is 5 N·m (0.51 kg-m, 44 in-lb) or less.

d. Apply recommended liquid gasket to inner socket and turn pinion fully to left with inner socket installed to

gear housing assembly.

e. Install dial indicator at 5 mm (0.20 in) (L) from the edge of gear

housing assembly (1), and tooth point.

f. Measure vertical movement of rack assembly when pinion is

turned clockwise with torque of 19.6 N·m (2.0 kg-m, 14 ft-lb).

Readjust adjusting screw angle if the measured value is outside

the standard.

If reading is outside of the specification, readjust screw angle

with adjusting screw.

CAUTION:

If reading is still outside of specification, or if the rotating torque of adjusting screw is less

than 5 N·m (0.51 kg-m, 44 in-lb), replace steering gear assembly.

Never turn adjusting screw more than twice.

Replace steering gear assembly when adjusting screw is removed or turned more than twice.

SGIA0624E

A: Preload gauge (SST: ST3127S000)

B: Preload adapter (SST: KV48103400)

SGIA1383E

Pinion rotating torque

Around neutral position

(within±100°) average (A): 2.27 – 3.05 N·m (0.24 –

0.31 kg-m, 20 – 26 in-lb)

Maximum variation (B) : 0.98 N·m (0.10 kg-m, 9.0

in-lb)

Vertical movement : 0.265 mm (0.0104 in)

SGIA0936E

JSGIA0104ZZ

Page 4586 of 5121

![NISSAN TEANA 2008 Repair Manual TCM

TM-113

< ECU DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

* Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-139, "ATFTEMP COU NISSAN TEANA 2008 Repair Manual TCM

TM-113

< ECU DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

* Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-139, "ATFTEMP COU](/img/5/57391/w960_57391-4585.png)

TCM

TM-113

< ECU DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

* Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-139, "ATFTEMP COUNT

Conversion Table".

TERMINAL LAYOUT

PHYSICAL VALUES

ABS ONABS operate On

Other conditions Off

RANGESelector lever in “N” and “P” positions. N·P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “L” position. L Item name Condition Display value (Approx.)

SCIA6679J

Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

+ - Signal name Input/Output

1

(P/B)Ground PNP switch 2 Input

Ignition switch ONSelector lever in “N” and “D” and

“L” positions0 V

Selector lever in other positions10.0 V –

Battery

voltage

2

(P/L)Ground PNP switch 3 InputSelector lever in “D” and “L” po-

sitions0 V

Selector lever in other positions10.0 V –

Battery

voltage

3

(G/O)Ground PNP switch 4 InputSelector lever in “R” and “D” po-

sitions0 V

Selector lever in other positions10.0 V –

Battery

voltage

4

(GR)Ground PNP switch 3 (monitor) InputSelector lever in “D” and “L” po-

sitions0 V

Selector lever in other positions10.0 V –

Battery

voltage

5

(B)Ground Ground Output Always 0 V

6

(O)Ground K-LINE Input/Output — —

7

(W)Ground Sensor ground Output Always 0 V

8

(G/W)— CLOCK (SEL2) — — —

Page 4610 of 5121

![NISSAN TEANA 2008 Repair Manual PRECAUTIONS

TM-137

< PRECAUTION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Rotate bayonet ring counterclockwise. Pull out CVT unit harness

connector upward and remove it.

INSTALLATION

1. Align � NISSAN TEANA 2008 Repair Manual PRECAUTIONS

TM-137

< PRECAUTION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Rotate bayonet ring counterclockwise. Pull out CVT unit harness

connector upward and remove it.

INSTALLATION

1. Align �](/img/5/57391/w960_57391-4609.png)

PRECAUTIONS

TM-137

< PRECAUTION >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Rotate bayonet ring counterclockwise. Pull out CVT unit harness

connector upward and remove it.

INSTALLATION

1. Align ∆ marking on CVT unit harness connector terminal body

with o marking on bayonet ring. Insert CVT unit harness connec-

tor. Then rotate bayonet ring clockwise.

2. Rotate bayonet ring clockwise until ∆ marking on CVT unit har-

ness connector terminal body is aligned with the slit on bayonet

ring as shown in the figure (correctly fitting condition). Install

CVT unit harness connector to CVT unit harness connector ter-

minal body.

CAUTION:

Securely align ∆ marking on CVT unit harness connector

terminal body with bayonet ring slit. Then, be careful not

to make a half fit condition as shown in the figure.

Never mistake the slit of bayonet ring for other dent por-

tion.

SCIA2096E

SCIA2097E

SCIA2098E

SCIA2099E

Page 4643 of 5121

![NISSAN TEANA 2008 Repair Manual TM-170

< REMOVAL AND INSTALLATION >[CVT: RE0F09B]

TRANSAXLE ASSEMBLY

When using the drive plate location guide (commercial service tool:

31197CA000) (A), set it to the stud bolts which is used to in NISSAN TEANA 2008 Repair Manual TM-170

< REMOVAL AND INSTALLATION >[CVT: RE0F09B]

TRANSAXLE ASSEMBLY

When using the drive plate location guide (commercial service tool:

31197CA000) (A), set it to the stud bolts which is used to in](/img/5/57391/w960_57391-4642.png)

TM-170

< REMOVAL AND INSTALLATION >[CVT: RE0F09B]

TRANSAXLE ASSEMBLY

When using the drive plate location guide (commercial service tool:

31197CA000) (A), set it to the stud bolts which is used to install it

to the torque converter.

When not using drive plate location guide, rotate torque converter

so that the stud bolt (B) for mounting the drive plate location guide

of torque converter aligns with the mounting position of service

hole.

Rotate crankshaft so that the hole (A) for inserting drive plate loca-

tion guide of drive plate aligns with the service hole (B).

NOTE:

When not using drive plate location guide, insert stud bolt of torque

converter into the hole (C) of drive plate, aligning the drive plate

hole position and torque converter.

CAUTION:

Be careful not to strike the drive plate when installing the

torque converter stud bolt.

Align the position of tightening nuts ( ) for drive plate with those

of the torque converter, and temporarily tighten the nuts. Then,

tighten the bolts to the specified torque.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

When tightening the nuts for the torque converter after fixing

the crankshaft pulley bolts, confirm the tightening torque of

the crankshaft pulley mounting bolts. Refer to EM-79,

"Exploded View".

Rotate crankshaft several turns and check that transaxle rotates freely without binding after con-

verter is installed to drive plate.

Never reuse O-ring.

Apply petroleum jelly to O-ring.

InspectionINFOID:0000000003849110

INSPECTION BEFORE INSTALLATION

After inserting a torque converter to transaxle assembly, check that

distance (A) is within the reference value limit.

INSPECTION AFTER INSTALLATION

Check the following items.

JPDIA0607ZZ

JPDIA0603ZZ

: 51 N·m (5.2 kg-m,38 ft-lb)

SCIA1861E

B: Scale

C : Straightedge

Distance A : Refer to TM-175, "Torque Converter".

JPDIA0620ZZ

Page 4750 of 5121

![NISSAN TEANA 2008 Repair Manual TCM

TM-277

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

PPHYSICAL VALUES

SCIA6679J

Te r m i n a l N o .

(wire color)Description

ConditionVa l u e

(Approx.)

+−Signal name Input/Ou NISSAN TEANA 2008 Repair Manual TCM

TM-277

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

PPHYSICAL VALUES

SCIA6679J

Te r m i n a l N o .

(wire color)Description

ConditionVa l u e

(Approx.)

+−Signal name Input/Ou](/img/5/57391/w960_57391-4749.png)

TCM

TM-277

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

PPHYSICAL VALUES

SCIA6679J

Te r m i n a l N o .

(wire color)Description

ConditionVa l u e

(Approx.)

+−Signal name Input/Output

1

(P/B)Ground R RANGE SW Input

Ignition switch ONSelector lever in “R” positionBattery

voltage

Other than the above position 0 V

2

(P/L)Ground N RANGE SW InputSelector lever in “N” positionBattery

voltage

Other than the above position 0 V

3

(G/O)Ground D RANGE SW InputSelector lever in “D” positionsBattery

voltage

Other than the above position 0 V

4

(GR)Ground L RANGE SW InputSelector lever in “L” positionBattery

voltage

Other than the above position 0 V

5

(B)Ground Ground Output Always 0 V

6

(O)Ground K-LINE Input/Output — —

7

(W)Ground Sensor ground Input Always 0 V

8

(G/W)— CLOCK (SEL2) — — —

9

(L/R)— CHIP SELECT (SEL1) — — —

10

(BR/R)— DATA I/O (SEL3) — — —

11

(BR/W)Ground P RANGE SW Input Ignition switch ONSelector lever in “P” positionBattery

voltage

Other than the above position 0 V

13

(V)GroundCVT fluid temperature sen-

sor Input Ignition switch ONWhen CVT fluid temperature is

20°C (68°F)2.0 V

When CVT fluid temperature is

80°C (176°F)1.0 V

15

(V/W)GroundTransmission fluid pres-

sure sensor A (Secondary

pressure sensor)Input “N” position idle 1.0 V

25

(W/R)Ground Sensor ground Input Always 0 V

Page 4772 of 5121

![NISSAN TEANA 2008 Repair Manual PRECAUTIONS

TM-299

< PRECAUTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Rotate bayonet ring (1) counterclockwise. Pull out CVT unit harness

connector (2) upward and remove it.

INSTALLATION

1. NISSAN TEANA 2008 Repair Manual PRECAUTIONS

TM-299

< PRECAUTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Rotate bayonet ring (1) counterclockwise. Pull out CVT unit harness

connector (2) upward and remove it.

INSTALLATION

1.](/img/5/57391/w960_57391-4771.png)

PRECAUTIONS

TM-299

< PRECAUTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Rotate bayonet ring (1) counterclockwise. Pull out CVT unit harness

connector (2) upward and remove it.

INSTALLATION

1. Align ∆ marking on CVT unit harness connector terminal body

with o marking on bayonet ring. Insert CVT unit harness connec-

tor. Then rotate bayonet ring clockwise.

2. Rotate bayonet ring clockwise until ∆ marking on CVT unit har-

ness connector terminal body is aligned with the slit on bayonet

ring as shown in the figure (correctly fitting condition). Install

CVT unit harness connector to CVT unit harness connector ter-

minal body.

CAUTION:

Securely align ∆ marking on CVT unit harness connector

terminal body with bayonet ring slit. Then, be careful not

to make a half fit condition as shown in the figure.

Never mistake the slit of bayonet ring for other dent por-

tion.

PrecautionINFOID:0000000003806499

NOTE:

If any malfunction occurs in the RE0F10A model transaxle, replace the entire transaxle assembly.

SCIA6685J

SCIA2097E

SCIA2098E

SCIA2099E

Page 4806 of 5121

![NISSAN TEANA 2008 Repair Manual TRANSAXLE ASSEMBLY

TM-333

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. Remove rear plate. Refer to EM-38, "Exploded View".

8. Turn crankshaft, and remove the four tigh NISSAN TEANA 2008 Repair Manual TRANSAXLE ASSEMBLY

TM-333

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. Remove rear plate. Refer to EM-38, "Exploded View".

8. Turn crankshaft, and remove the four tigh](/img/5/57391/w960_57391-4805.png)

TRANSAXLE ASSEMBLY

TM-333

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

7. Remove rear plate. Refer to EM-38, "Exploded View".

8. Turn crankshaft, and remove the four tightening bolts ( ) for

drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

9. Remove transaxle assembly fixing bolts with power tool.

10. Remove transaxle assembly from engine assembly with a hoist.

11. Remove CVT fluid cooler tube from transaxle assembly. Refer to

TM-329, "

Exploded View".

INSTALLATION

Note following, and install in the reverse order of removal.

CAUTION:

Never reuse O-ring.

Apply petroleum jelly to O-ring.

Check fitting of dowel pin ( ) when installing transaxle

assembly to engine assembly.

When installing transaxle assembly to the engine assembly, attach

the fixing bolts in accordance with the following.

SCIA1861E

JPDIA0598ZZ

JPDIA0602ZZ

JPDIA0737ZZ

Page 4807 of 5121

![NISSAN TEANA 2008 Repair Manual TM-334

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

TRANSAXLE ASSEMBLY

Align the position of tightening bolts ( ) for drive plate with those

of the torque converter, and temporarily tighten the bolts. NISSAN TEANA 2008 Repair Manual TM-334

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

TRANSAXLE ASSEMBLY

Align the position of tightening bolts ( ) for drive plate with those

of the torque converter, and temporarily tighten the bolts.](/img/5/57391/w960_57391-4806.png)

TM-334

< REMOVAL AND INSTALLATION >[CVT: RE0F10A]

TRANSAXLE ASSEMBLY

Align the position of tightening bolts ( ) for drive plate with those

of the torque converter, and temporarily tighten the bolts. Then,

tighten the bolts to the specified torque.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

When tightening the tightening bolts for the torque converter

after fixing the crankshaft pulley bolts, confirm the tightening

torque of the crankshaft pulley mounting bolts. Refer to EM-

53, "Removal and Installation".

After converter is installed to drive plate, rotate crankshaft

several turns and check that transaxle rotates freely without

binding.

InspectionINFOID:0000000003806553

INSPECTION BE FORE INSTALLATION

After inserting a torque converter to the CVT, check that distance

(A) within the reference value limit.

INSPECTION AFTER INSTALLATION

After completing installation, check the following item.

- CVT fluid leakage and CVT fluid level. Refer to TM-304, "

Inspection".

- CVT position. Refer to TM-314, "

Inspection and Adjustment".

Insertion direction Transaxle assembly to engine assembly Engine assembly to transaxle assembly

Bolt position A B C D

Number of bolts 2 1 1 4

Bolt length mm (in) 55 (2.17) 35 (1.38) 55 (2.17) 40 (1.57)

Tightening torque N·m (kg-m, ft-lb) 75 (7.7, 55) 50 (5.1, 37)

SCIA1861E

B: Scale

C : Straightedge

Distance A : Refer to TM-338, "Torque Converter".

JPDIA0740ZZ

Page 4823 of 5121

![NISSAN TEANA 2008 Repair Manual VTL-12

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for ser-

vice hoses NISSAN TEANA 2008 Repair Manual VTL-12

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for ser-

vice hoses](/img/5/57391/w960_57391-4822.png)

VTL-12

< PRECAUTION >[WITHOUT 7 INCH DISPLAY]

PRECAUTIONS

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2″-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must equip positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite to the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers do

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. The hose fitting must

be 1/2″-16 ACME if the scale controls refrigerant flow electronically.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale each three month.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset” and “Enter” at the same time.

2. Press “8787”. “A1” is displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”. “0.00” is displayed and change to “A2”.

SHA533D

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D