ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2350 of 5121

![NISSAN TEANA 2008 Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-321

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

88

(P)GroundWasher pump power sup-

plyOutput Ignition switch ON Ba NISSAN TEANA 2008 Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-321

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

88

(P)GroundWasher pump power sup-

plyOutput Ignition switch ON Ba](/img/5/57391/w960_57391-2349.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-321

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

88

(P)GroundWasher pump power sup-

plyOutput Ignition switch ON Battery voltage

89

(W)Ground Headlamp HI (RH) OutputIgnition

switch ON Lighting switch HI

Lighting switch PASSBattery voltage

Lighting switch OFF 0 V

90

(O)Ground Headlamp HI (LH) OutputIgnition

switch ON Lighting switch HI

Lighting switch PASSBattery voltage

Lighting switch OFF 0 V

91

(O)Ground Parking lamp (RH) OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

92

(L)Ground Parking lamp (LH) OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

93

(BR)GroundHeadlamp aiming motor

(RH)OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

94

(Y)GroundHeadlamp aiming motor

(LH)OutputIgnition

switch ONLighting switch 1ST Battery voltage

Lighting switch OFF 0 V

99

(W)Ground Ambient sensor ground Input Ignition switch ON 0 V

100

(SB)Ground Ambient sensor OutputIgnition switch ON

NOTE:

Changes depending to ambient tem-

perature

101

(GR)GroundRefrigerant pressure sen-

sor groundInputEngine

running Warm-up condition

Idle speed0 V

102

(R)GroundRefrigerant pressure sen-

sorInputEngine

running Warm-up condition

Both A/C switch and

blower fan motor switch

ON

(Compressor operates)1.0 - 4.0 V

103

(P)GroundRefrigerant pressure sen-

sor power supplyOutputIgnition switch OFF 0 V

Ignition switch ON 5.0 V

104

(LG)

Ground Hood switch OutputClose the hood Battery voltage

Open the hood 0 V Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +−

JSNIA0014GB

Page 2355 of 5121

![NISSAN TEANA 2008 Service Manual EXL-326

< ECU DIAGNOSIS >[HALOGEN TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM NISSAN TEANA 2008 Service Manual EXL-326

< ECU DIAGNOSIS >[HALOGEN TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM](/img/5/57391/w960_57391-2354.png)

EXL-326

< ECU DIAGNOSIS >[HALOGEN TYPE]

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to

alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop position by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 seconds activation and 20 seconds stop five times.

Control part Fail-safe operation

Cooling fan Turns ON the cooling fan relay-2 and the cooling fan relay-3 when ignition switch is

turned ON (Cooling fan operates at HI)

Turns OFF the cooling fan relay-1, the cooling fan relay-2 and the cooling fan relay-3

when the ignition switch is turned OFF (Cooling fan does not operate)

A/C compressor A/C relay OFF

Alternator Outputs the power generation command signal (PWM signal) 0%

Control part Fail-safe operation

Headlamp Turns ON the headlamp low relay when the ignition switch is turned ON

Turns OFF the headlamp low relay when the ignition switch is turned OFF

Headlamp high relay OFF

Parking lamps

License plate lamps

Illuminations

Tail lamps Turns ON the tail lamp relay when the ignition switch is turned ON

Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

The wiper is operated at LO speed until the ignition switch is turned OFF if the fail-

safe control is activated while the front wiper is set in the INT mode and the front wiper

motor is operating.

Front fog lamps Front fog lamp relay OFF

Horn Horn OFF

Ignition relay The status just before activation of fail-safe is maintained.

Starter motor Starter control relay OFF

Steering lock unit Steering lock relay OFF

Headlamp washer relay Headlamp washer relay OFF

Voltage judgment

IPDM E/R judgment Operation

Ignition relay contact sideIgnition relay excitation coil

side

ON ON Ignition relay ON normal —

OFF OFF Ignition relay OFF normal —

ON OFF Ignition relay ON stuck Detects DTC “B2098: IGN RELAY ON”

Turns ON the tail lamp relay for 10 min-

utes

OFF ON Ignition relay OFF stuck Detects DTC “B2099: IGN RELAY OFF”

Page 2356 of 5121

![NISSAN TEANA 2008 Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-327

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

NOTE:

This operation status can be confirmed on the IPDM E/R “Da NISSAN TEANA 2008 Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-327

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

NOTE:

This operation status can be confirmed on the IPDM E/R “Da](/img/5/57391/w960_57391-2355.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

EXL-327

< ECU DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

NOTE:

This operation status can be confirmed on the IPDM E/R “Data Monitor” that displays “BLOCK” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

DTC IndexINFOID:0000000003894353

NOTE:

The details of time display are as follows.

- CRNT: A malfunction is detected now

- PAST: A malfunction was detected in the past.

IGN counter is displayed on FFD (Freeze Frame data).

- The number is 0 when is detected now

- The number increases like 1 → 2 ··· 38 → 39 after returning to the normal condition whenever IGN OFF →

ON.

- The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

×: Applicable

Ignition switch Front wiper switch Front wiper auto stop signal

ONOFFThe front wiper auto stop signal (stop posi-

tion) cannot be input for 10 seconds.

ONThe front wiper auto stop signal does not

change for 10 seconds.

CONSULT display Fail-safe Refer to

No DTC is detected.

further testing

may be required.——

U1000: CAN COMM CIRCUIT×PCS-16

B2098: IGN RELAY ON×PCS-17

B2099: IGN RELAY OFF —PCS-18

B2108: STRG LCK RELAY ON —SEC-96

B2109: STRG LCK RELAY OFF —SEC-97

B210A: STRG LCK STATE SW —SEC-98

B210B: START CONT RLY ON —SEC-102

B210C: START CONT RLY OFF —SEC-103

B210D: STARTER RELAY ON —SEC-104

B210E: STARTER RELAY OFF —SEC-105

B210F: INTRLCK/PNP SW ON —SEC-107

B2110: INTRLCK/PNP SW OFF —SEC-109

Page 2357 of 5121

![NISSAN TEANA 2008 Service Manual EXL-328

< SYMPTOM DIAGNOSIS >[HALOGEN TYPE]

EXTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003811996

CAUTION:

Perform the self-diagnos NISSAN TEANA 2008 Service Manual EXL-328

< SYMPTOM DIAGNOSIS >[HALOGEN TYPE]

EXTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003811996

CAUTION:

Perform the self-diagnos](/img/5/57391/w960_57391-2356.png)

EXL-328

< SYMPTOM DIAGNOSIS >[HALOGEN TYPE]

EXTERIOR LIGHTING SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

EXTERIOR LIGHTING SYSTEM SYMPTOMS

Symptom TableINFOID:0000000003811996

CAUTION:

Perform the self-diagnosis with CONSULT-III before the symptom diagnosis. Perform the trouble diag-

nosis if any DTC is detected.

Symptom Possible cause Inspection item

Headlamp (HI) is not

turned ON.One sideFuse

Halogen bulb (HI)

Harness between IPDM E/R

and the headlamp high

IPDM E/RHeadlamp (HI) circuit

Refer to EXL-227

.

Both sides

Symptom diagnosis

“BOTH SIDE HEADLAMPS (HI) ARE NOT TURNED ON”

Refer to EXL-331

.

Headlamp (HI) is not

turned OFF.When ignition switch is

turned ON.

When ignition switch is

turned OFF.IPDM E/R —

High beam indicator lamp is not turned ON.

[Headlamp (HI) is turned ON.]Combination meter Combination meter

Data monitor “HI-BEAM IND”

BCM (HEAD LAMP)

Active test “HEADLAMP”

Headlamp (LO) is not

turned ON.One sideFuse

Halogen bulb (LO)

Harness between IPDM E/R

and the front combination lamp

IPDM E/RHeadlamp (LO) circuit

Refer to EXL-229

.

Both sides

Symptom diagnosis

“BOTH SIDE HEADLAMPS (LO) ARE NOT TURNED ON”

Refer to EXL-332

.

Headlamp (LO) is not

turned OFF.When ignition switch is

turned ON.

When ignition switch is

turned OFF.IPDM E/R —

Each lamps are not turned ON/OFF with lighting

switch AUTO. Combination switch

Harness between the combina-

tion switch and BCM

BCMCombination switch

Refer to BCS-76

.

Optical sensor

Harness between the optical

sensor and BCM

BCMOptical sensor circuit

Refer to EXL-238

.

Front fog lamp is not

turned ON.One side Front fog lamp bulb

Harness between IPDM E/R

and the front fog lamp

Front fog lamp

IPDM E/RFront fog lamp circuit

Refer to EXL-231

.

Both sidesSymptom diagnosis

“BOTH SIDE FRONT FOG LAMPS ARE NOT TURNED ON”

Refer to EXL-334

. Front fog lamp is not turned ON.

Front fog lamp indicator is not turned ON.

(Front fog lamp is turned ON.)Combination meter Combination meter

Data monitor “FR FOG IND”

BCM (HEAD LAMP)

Active test “FR FOG LAMP”

Page 2358 of 5121

![NISSAN TEANA 2008 Service Manual EXTERIOR LIGHTING SYSTEM SYMPTOMS

EXL-329

< SYMPTOM DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Parking lamp is not turned ON. Parking lamp bulb

Harness between IPDM E/R

and the fro NISSAN TEANA 2008 Service Manual EXTERIOR LIGHTING SYSTEM SYMPTOMS

EXL-329

< SYMPTOM DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Parking lamp is not turned ON. Parking lamp bulb

Harness between IPDM E/R

and the fro](/img/5/57391/w960_57391-2357.png)

EXTERIOR LIGHTING SYSTEM SYMPTOMS

EXL-329

< SYMPTOM DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Parking lamp is not turned ON. Parking lamp bulb

Harness between IPDM E/R

and the front combination lamp

Front combination lamp

IPDM E/RParking lamp circuit

Refer to EXL-233.

Tail lamp is not turned ON. Harness between IPDM E/R

and the rear combination lamp

Rear combination lampTail lamp circuit

Refer to EXL-243

.

License plate lamp is not turned ON. License plate lamp bulb

Harness between IPDM E/R

and the license plate lamp

License plate lampLicense plate lamp circuit

Refer to EXL-245

.

Tail lamp and the license plate lamp are not turned

ON.Fuse

Harness between IPDM E/R

and the rear combination lamp

IPDM E/RLicense plate lamp circuit

Refer to EXL-245

.

Parking lamp, the tail lamp and the license plate

lamp are not turned ON.

Parking lamp, the tail lamp and the license plate

lamp are not turned OFF.

(Each illumination is turned ON/OFF.)Symptom diagnosis

“PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED

ON”

Refer to EXL-333

.

Tail lamp indicator is not turned ON.

(Parking, tail lamps are turned ON.)Combination meter Combination meter

Data monitor “LIGHT IND”

BCM (HEAD LAMP)

Active test “TAIL LAMP”

Turn signal lamp does not

blink.Indicator lamp is nor-

mal.

(Applicable side per-

forms the high flasher

activation.) Harness between BCM and

each turn signal lamp

Turn signal lamp bulbTurn signal circuit

Refer to EXL-235

.

Indicator lamp is includ-

ed. Combination switch

Harness between the combina-

tion switch and BCM

BCMCombination switch

Refer to BCS-38

.

Turn signal indicator lamp

does not blink.

(Turn signal indicator

lamp is normal.)One side Combination meter —

Both sides

(Always) Turn signal indicator lamp sig-

nal

-BCM

Combination meter Combination meter

Data monitor “TURN IND”

BCM (FLASHER)

Active test “FLASHER”

Both sides

(Only when activating

hazard warning lamp

with the ignition switch

OFF) Combination meter power sup-

ply and the ground circuit

Combination meterCombination meter

Power supply and the ground circuit

Refer to MWI-42

.

Hazard warning lamp does not activate.

Hazard warning lamp continues activating.

(Turn signal is normal.) Hazard switch

Harness between the hazard

switch and BCM

BCMHazard switch

Refer to EXL-241

. Symptom Possible cause Inspection item

Page 2397 of 5121

EXT-8

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003841895

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003841896

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 2431 of 5121

PRECAUTIONS

FAX-3

< PRECAUTION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003890158

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003890159

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precautions for Drive ShaftINFOID:0000000003811071

CAUTION:

Note the following precautions when disassembling and assembling drive shaft.

Never disassemble joint sub-assembly because it is non-overhaul parts.

Perform work in a dust-free location.

Before disassembling and assembling, clean the parts.

Prevent the entry of foreign objects during disassembly of the service location.

Page 2465 of 5121

FL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

General PrecautionsINFOID:0000000003793245

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

Be sure to work in a well ventilated area and furnish workshop with a CO

2 fire extinguisher.

Never smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

Use gasoline required by the regulations for octane number. Refer to GI-29, "

Fuel".

Before removing fuel line parts, perform out the following procedures:

- Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-411, "

Inspection".

- Disconnect the battery cable from the negative terminal.

Always replace O-ring and clamps with new ones.

Never kink or twist tubes when they are being installed.

Never tighten hose clamps excessively to avoid damaging hoses.

After installing tubes, check there is no fuel leakage at connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch “ON” (with engine stopped). Then check

for fuel leakage at connections.

- Start engine and rev it up and check for fuel leakage at connections.

Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the

“MI” may come on.

For servicing “Evaporative Emission System” parts, refer to EC-76, "

System Diagram".

Page 2471 of 5121

FL-8

< ON-VEHICLE REPAIR >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

INSTALLATION

Note to the following, and install in the reverse order of removal.

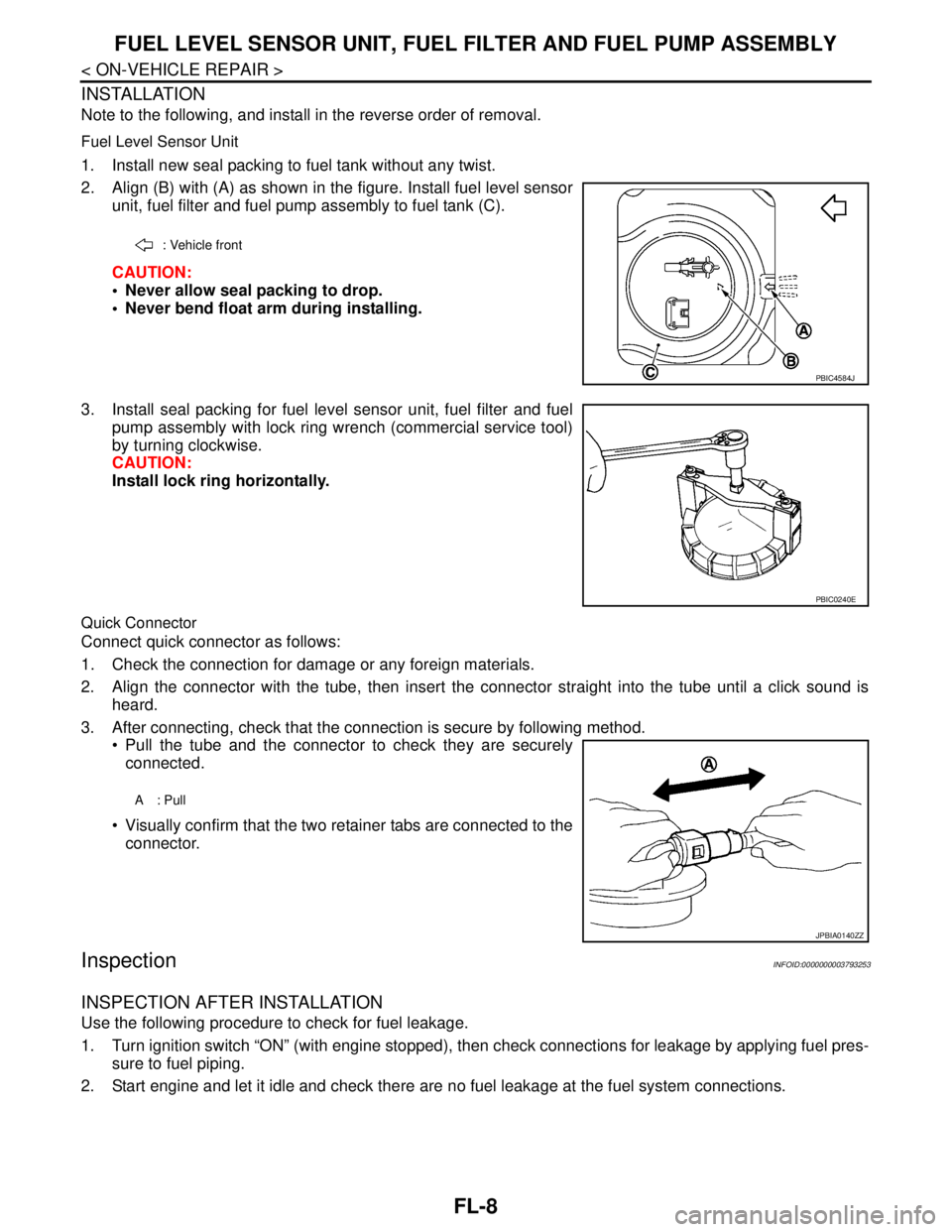

Fuel Level Sensor Unit

1. Install new seal packing to fuel tank without any twist.

2. Align (B) with (A) as shown in the figure. Install fuel level sensor

unit, fuel filter and fuel pump assembly to fuel tank (C).

CAUTION:

Never allow seal packing to drop.

Never bend float arm during installing.

3. Install seal packing for fuel level sensor unit, fuel filter and fuel

pump assembly with lock ring wrench (commercial service tool)

by turning clockwise.

CAUTION:

Install lock ring horizontally.

Quick Connector

Connect quick connector as follows:

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click sound is

heard.

3. After connecting, check that the connection is secure by following method.

Pull the tube and the connector to check they are securely

connected.

Visually confirm that the two retainer tabs are connected to the

connector.

InspectionINFOID:0000000003793253

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1. Turn ignition switch “ON” (with engine stopped), then check connections for leakage by applying fuel pres-

sure to fuel piping.

2. Start engine and let it idle and check there are no fuel leakage at the fuel system connections.

: Vehicle front

PBIC4584J

PBIC0240E

A: Pull

JPBIA0140ZZ

Page 2473 of 5121

FL-10

< ON-VEHICLE REPAIR >

FUEL TANK

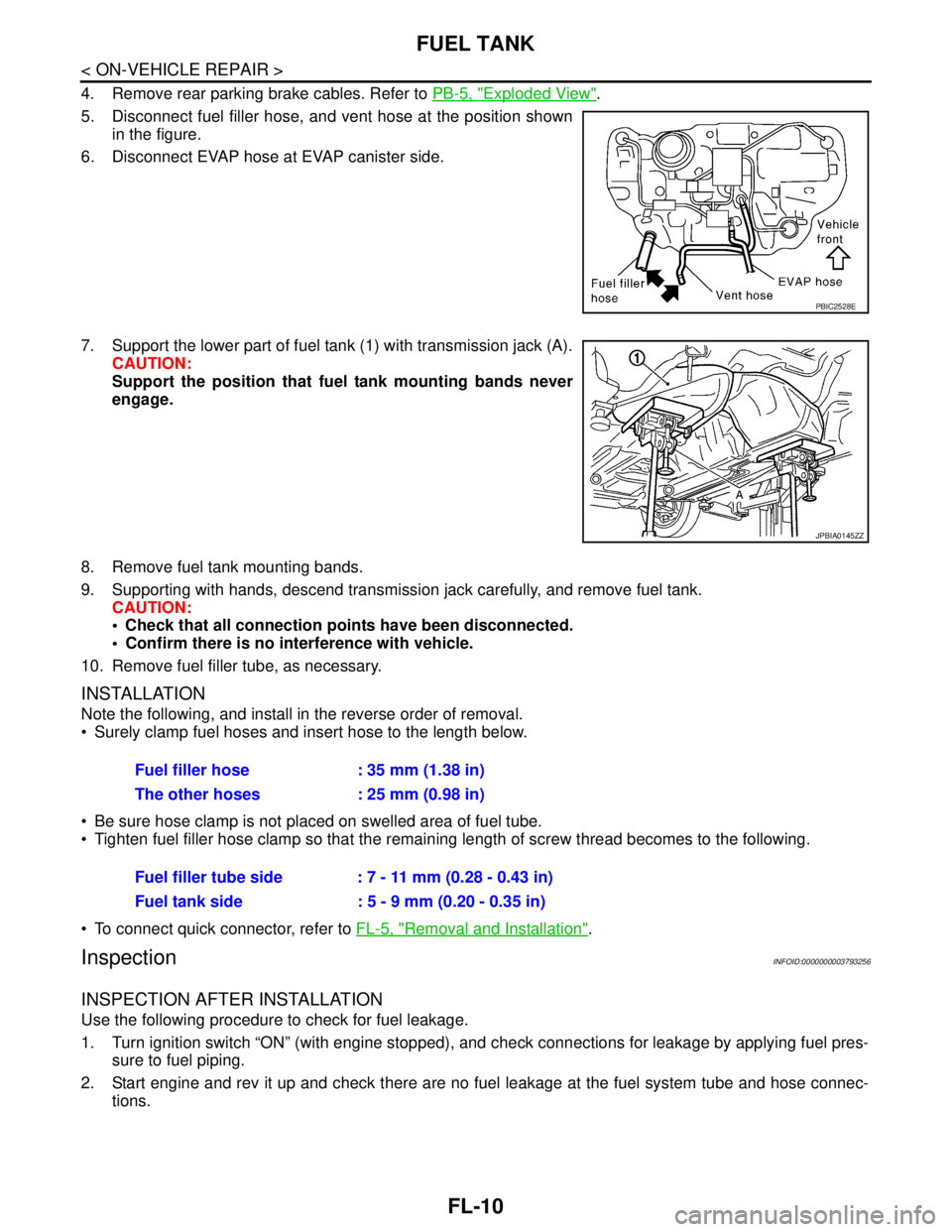

4. Remove rear parking brake cables. Refer to PB-5, "Exploded View".

5. Disconnect fuel filler hose, and vent hose at the position shown

in the figure.

6. Disconnect EVAP hose at EVAP canister side.

7. Support the lower part of fuel tank (1) with transmission jack (A).

CAUTION:

Support the position that fuel tank mounting bands never

engage.

8. Remove fuel tank mounting bands.

9. Supporting with hands, descend transmission jack carefully, and remove fuel tank.

CAUTION:

Check that all connection points have been disconnected.

Confirm there is no interference with vehicle.

10. Remove fuel filler tube, as necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

Surely clamp fuel hoses and insert hose to the length below.

Be sure hose clamp is not placed on swelled area of fuel tube.

Tighten fuel filler hose clamp so that the remaining length of screw thread becomes to the following.

To connect quick connector, refer to FL-5, "

Removal and Installation".

InspectionINFOID:0000000003793256

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leakage.

1. Turn ignition switch “ON” (with engine stopped), and check connections for leakage by applying fuel pres-

sure to fuel piping.

2. Start engine and rev it up and check there are no fuel leakage at the fuel system tube and hose connec-

tions.

PBIC2528E

JPBIA0145ZZ

Fuel filler hose : 35 mm (1.38 in)

The other hoses : 25 mm (0.98 in)

Fuel filler tube side : 7 - 11 mm (0.28 - 0.43 in)

Fuel tank side : 5 - 9 mm (0.20 - 0.35 in)