ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2561 of 5121

GW-18

< ON-VEHICLE REPAIR >

FRONT DOOR GLASS

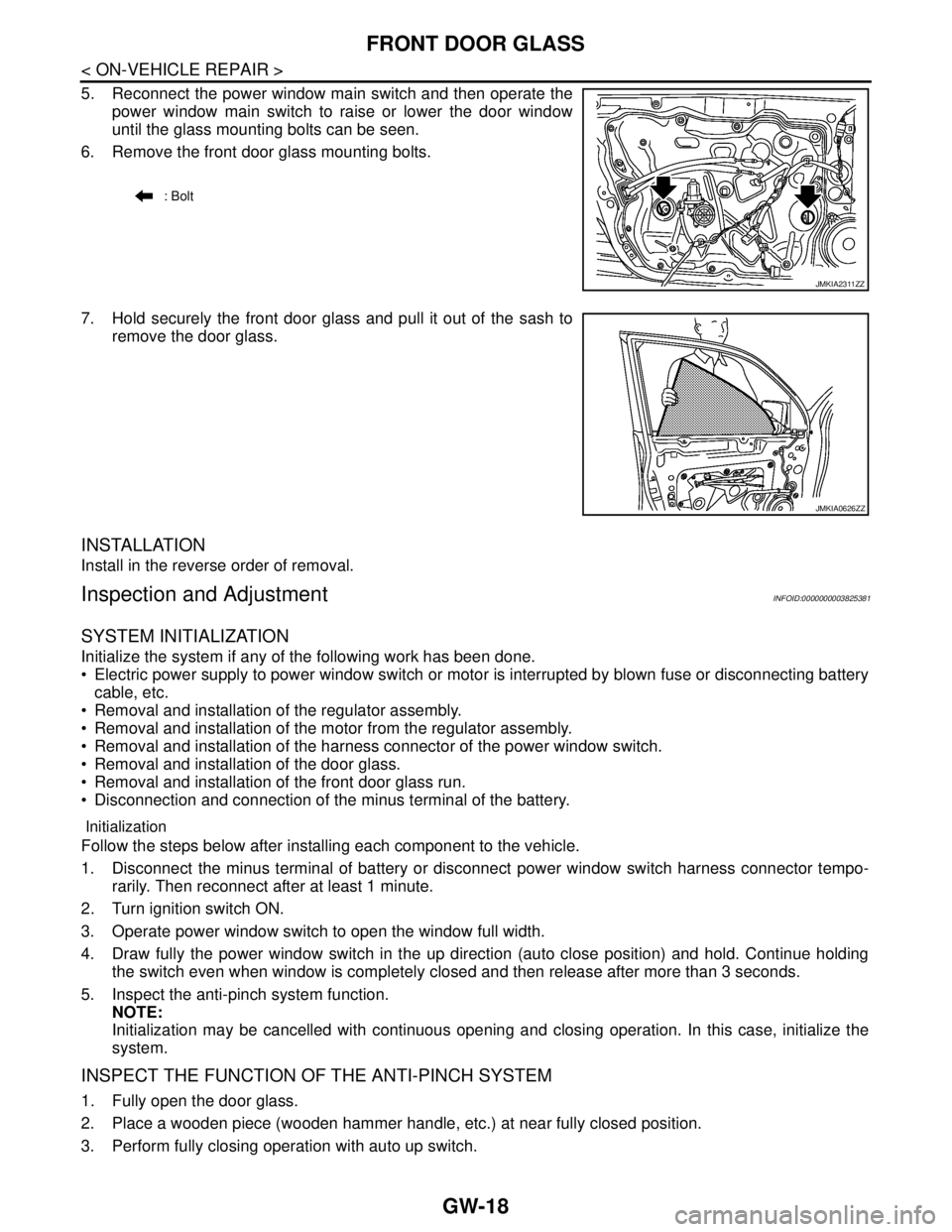

5. Reconnect the power window main switch and then operate the

power window main switch to raise or lower the door window

until the glass mounting bolts can be seen.

6. Remove the front door glass mounting bolts.

7. Hold securely the front door glass and pull it out of the sash to

remove the door glass.

INSTALLATION

Install in the reverse order of removal.

Inspection and AdjustmentINFOID:0000000003825381

SYSTEM INITIALIZATION

Initialize the system if any of the following work has been done.

Electric power supply to power window switch or motor is interrupted by blown fuse or disconnecting battery

cable, etc.

Removal and installation of the regulator assembly.

Removal and installation of the motor from the regulator assembly.

Removal and installation of the harness connector of the power window switch.

Removal and installation of the door glass.

Removal and installation of the front door glass run.

Disconnection and connection of the minus terminal of the battery.

Initialization

Follow the steps below after installing each component to the vehicle.

1. Disconnect the minus terminal of battery or disconnect power window switch harness connector tempo-

rarily. Then reconnect after at least 1 minute.

2. Turn ignition switch ON.

3. Operate power window switch to open the window full width.

4. Draw fully the power window switch in the up direction (auto close position) and hold. Continue holding

the switch even when window is completely closed and then release after more than 3 seconds.

5. Inspect the anti-pinch system function.

NOTE:

Initialization may be cancelled with continuous opening and closing operation. In this case, initialize the

system.

INSPECT THE FUNCTION OF THE ANTI-PINCH SYSTEM

1. Fully open the door glass.

2. Place a wooden piece (wooden hammer handle, etc.) at near fully closed position.

3. Perform fully closing operation with auto up switch.

: Bolt

JMKIA2311ZZ

JMKIA0626ZZ

Page 2564 of 5121

FRONT REGULATOR

GW-21

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

GW

N

O

P

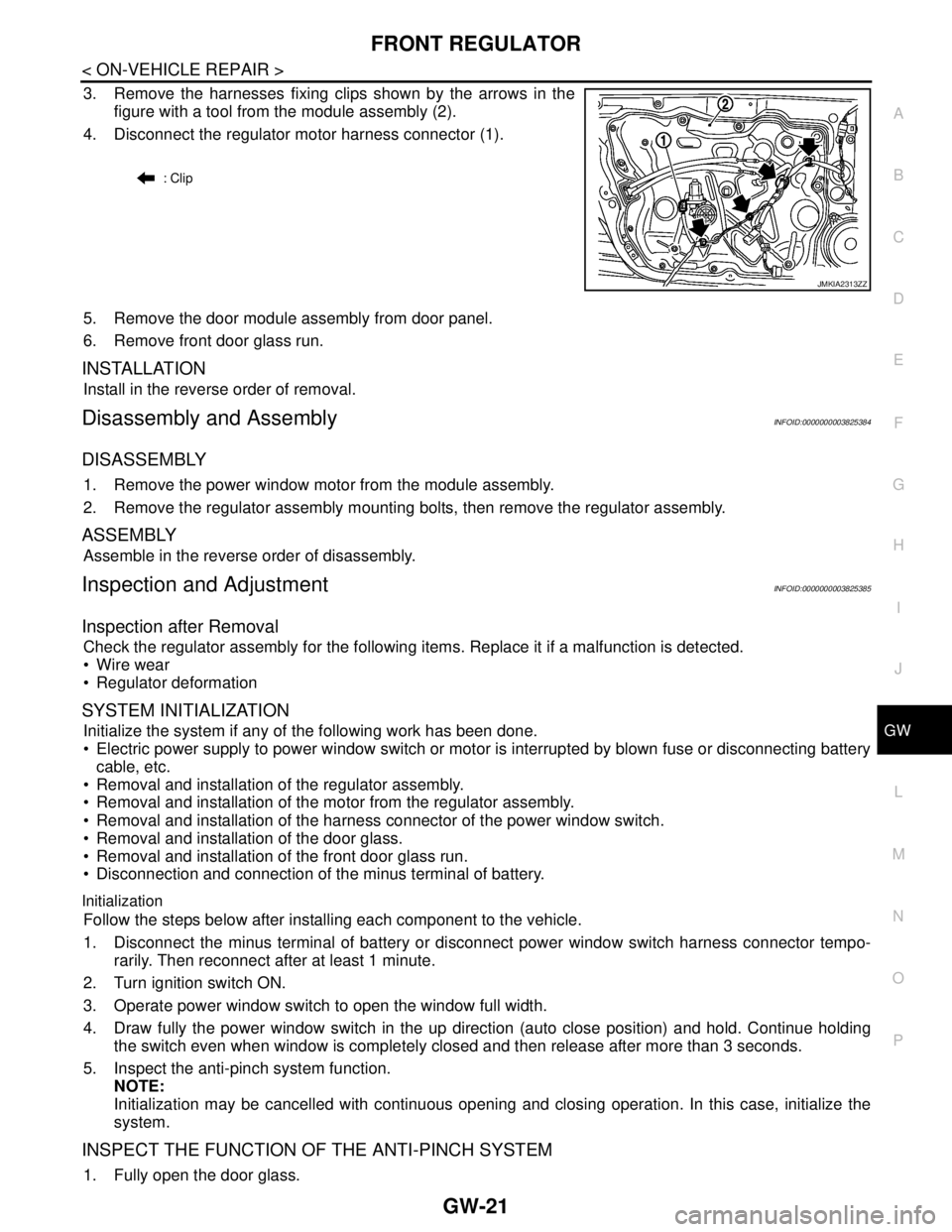

3. Remove the harnesses fixing clips shown by the arrows in the

figure with a tool from the module assembly (2).

4. Disconnect the regulator motor harness connector (1).

5. Remove the door module assembly from door panel.

6. Remove front door glass run.

INSTALLATION

Install in the reverse order of removal.

Disassembly and AssemblyINFOID:0000000003825384

DISASSEMBLY

1. Remove the power window motor from the module assembly.

2. Remove the regulator assembly mounting bolts, then remove the regulator assembly.

ASSEMBLY

Assemble in the reverse order of disassembly.

Inspection and AdjustmentINFOID:0000000003825385

Inspection after Removal

Check the regulator assembly for the following items. Replace it if a malfunction is detected.

Wire wear

Regulator deformation

SYSTEM INITIALIZATION

Initialize the system if any of the following work has been done.

Electric power supply to power window switch or motor is interrupted by blown fuse or disconnecting battery

cable, etc.

Removal and installation of the regulator assembly.

Removal and installation of the motor from the regulator assembly.

Removal and installation of the harness connector of the power window switch.

Removal and installation of the door glass.

Removal and installation of the front door glass run.

Disconnection and connection of the minus terminal of battery.

Initialization

Follow the steps below after installing each component to the vehicle.

1. Disconnect the minus terminal of battery or disconnect power window switch harness connector tempo-

rarily. Then reconnect after at least 1 minute.

2. Turn ignition switch ON.

3. Operate power window switch to open the window full width.

4. Draw fully the power window switch in the up direction (auto close position) and hold. Continue holding

the switch even when window is completely closed and then release after more than 3 seconds.

5. Inspect the anti-pinch system function.

NOTE:

Initialization may be cancelled with continuous opening and closing operation. In this case, initialize the

system.

INSPECT THE FUNCTION OF THE ANTI-PINCH SYSTEM

1. Fully open the door glass.

: Clip

JMKIA2313ZZ

Page 2581 of 5121

HA-12

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003844112

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003844113

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 2636 of 5121

![NISSAN TEANA 2008 Service Manual HAC-8

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Description & InspectionINFOID:0000000003846291

DESCRIPTION

The purpose of the operational check NISSAN TEANA 2008 Service Manual HAC-8

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Description & InspectionINFOID:0000000003846291

DESCRIPTION

The purpose of the operational check](/img/5/57391/w960_57391-2635.png)

HAC-8

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Description & InspectionINFOID:0000000003846291

DESCRIPTION

The purpose of the operational check is to check that the individual system operates normally.

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

1. Start the engine.

2. Operate the temperature control switch (driver side) and raise the temperature setting to 32°C (90°F).

3. Press the OFF switch.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

6. Press the AUTO switch.

7. Check that the temperature setting before turning the ignition switch OFF is stored.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Memory function malfunction: HAC-96, "

Inspection procedure".

2.CHECK BLOWER MOTOR SPEED

1. Start the engine.

2. Operate the fan control dial. Check that the fan speed changes. Check the operation for all fan speeds.

3. Set the fan speed to speed 7.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Blower motor system malfunction: HAC-68, "

Diagnosis Procedure".

3.CHECK DISCHARGE AIR

1. Press the MODE switch and the DEF switch.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-17, "

System

Description".

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

the FRE when DEF is selected.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Mode door system malfunction: HAC-61, "

Diagnosis Procedure". Conditions : Engine running at normal operating temperature

JPIIA0877GB

Page 2639 of 5121

![NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

HAC-11

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the batte NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

HAC-11

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the batte](/img/5/57391/w960_57391-2638.png)

INSPECTION AND ADJUSTMENT

HAC-11

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, trimmer operation is cancelled. Wind distribution rate set becomes that of initial condition.

Inlet Port Memory Function (FRE)INFOID:0000000003846294

DESCRIPTION

If the ignition switch is turned to the OFF position while the FRE switch is set to ON (fresh air intake), “Per-

form the memory” or “Do not perform the memory” of the FRE switch ON (fresh air intake) condition can be

selected.

If “Perform the memory” was set, the FRE switch will be ON (fresh air intake) when turning the ignition switch

to the ON position again.

If “Do not perform the memory” was set, the air inlets will be controlled automatically when turning the igni-

tion switch to the ON position again.

HOW TO SET

Using CONSULT-III, perform “FRE MEMORY SET” on “WORK SUPPORT” of HVAC.

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, the setting of the FRE switch memory function may be cancelled.

Inlet Port Memory Function (REC)INFOID:0000000003846295

DESCRIPTION

If the ignition switch is turned to the OFF position while the REC switch is set to ON (recirculation), “Perform

the memory” or “Do not perform the memory” of the REC switch ON (recirculation) condition can be

selected.

If “Perform the memory” was set, the REC switch will be ON (recirculation) when turning the ignition switch

to the ON position again.

If “Do not perform the memory” was set, the air inlets will be controlled automatically when turning the igni-

tion switch to the ON position again.

HOW TO SET

Using CONSULT-III, perform “REC MEMORY SET” on “WORK SUPPORT” of HVAC.

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, the setting of the REC switch memory function may be cancelled.

Work support items Display Setting

FRE MEMORY SETWITHOUT (initial status) Perform the memory of manual FRE

WITH Do not perform the memory of manual FRE (auto control)

Work support items Display Setting

REC MEMORY SETWITHOUT Perform the memory of manual REC

WITH (initial status) Do not perform the memory of manual REC (auto control)

Page 2659 of 5121

![NISSAN TEANA 2008 Service Manual AIR MIX DOOR CONTROL SYSTEM

HAC-31

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

When ignition switch is ON, the A/C auto amp. continuously and

automatically controls NISSAN TEANA 2008 Service Manual AIR MIX DOOR CONTROL SYSTEM

HAC-31

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

When ignition switch is ON, the A/C auto amp. continuously and

automatically controls](/img/5/57391/w960_57391-2658.png)

AIR MIX DOOR CONTROL SYSTEM

HAC-31

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

When ignition switch is ON, the A/C auto amp. continuously and

automatically controls temperatures regardless of air conditioner

operational condition. When setting a target temperature with the

temperature control switch, the A/C auto amp. corrects the set tem-

perature and decides a target air mix door opening angle. The A/C

auto amp. controls air mix door according to the target air mix door

opening angle and current air mix door opening angle, keeping an

optimum air mix door opening angle. When the temperature is set at

18°C (60°F), air mix door is set on full cold, and when the tempera-

ture is set at 32°C (90°F), it is set to full hot.

JPIIA0633GB

Page 2669 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (HVAC)

HAC-41

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the batte NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (HVAC)

HAC-41

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the batte](/img/5/57391/w960_57391-2668.png)

DIAGNOSIS SYSTEM (HVAC)

HAC-41

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, the setting of WORK SUPPORT may be cancelled.

FRE MEMORY SET If the ignition switch is turned to the OFF position while the FRE

switch is set to ON (fresh air intake), “Perform the memory” or

“Do not perform the memory” of the FRE switch ON (fresh air in-

take) condition can be selected.

If “Perform the memory” was set, the FRE switch will be ON

(fresh air intake) when turning the ignition switch to the ON posi-

tion again.

If “Do not perform the memory” was set, the air inlets will be con-

trolled automatically when turning the ignition switch to the ON

position again. HAC-11, "Inlet Port Mem-

ory Function (FRE)"

REC MEMORY SET If the ignition switch is turned to the OFF position while the REC

switch is set to ON (recirculation), “Perform the memory” or “Do

not perform the memory” of the REC switch ON (recirculation)

condition can be selected.

If “Perform the memory” was set, the REC switch will be ON (re-

circulation) when turning the ignition switch to the ON position

again.

If “Do not perform the memory” was set, the air inlets will be con-

trolled automatically when turning the ignition switch to the ON

position again. HAC-11, "Inlet Port Mem-

ory Function (REC)"

Work item Description Reference

Page 2670 of 5121

![NISSAN TEANA 2008 Service Manual HAC-42

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

U1000 CAN COMM CIRCUIT

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003846322

CAN (Controller Area Network) is a serial co NISSAN TEANA 2008 Service Manual HAC-42

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

U1000 CAN COMM CIRCUIT

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003846322

CAN (Controller Area Network) is a serial co](/img/5/57391/w960_57391-2669.png)

HAC-42

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

U1000 CAN COMM CIRCUIT

COMPONENT DIAGNOSIS

U1000 CAN COMM CIRCUIT

DescriptionINFOID:0000000003846322

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with two

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication Signal Chart. Refer to LAN-13, "

How to Use CAN Communication Signal Chart".

DTC LogicINFOID:0000000003846323

DTC DETECTION LOGIC

Diagnosis ProcedureINFOID:0000000003846324

1.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

1. Turn ignition switch ON and wait for 2 or more seconds.

2. Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC.

Is

“CAN COMM CIRCUIT” displayed?

YES >> Perform trouble diagnosis for the CAN communication system. Refer to LAN-14, "Trouble Diagno-

sis Flow Chart".

NO >> Perform the intermittent malfunction diagnosis. Refer to GI-35, "

Intermittent Incident".

DTCItems

(CONSULT-III screen terms)Diagnostic item is detected when... Possible cause

U1000 CAN COMM CIRCUITWhen A/C auto amp. is not transmitting

or receiving CAN communication signal

for 2 or more seconds.CAN communication system

Page 2673 of 5121

![NISSAN TEANA 2008 Service Manual B257B, B257C AMBIENT SENSOR

HAC-45

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC.

2. Check if any NISSAN TEANA 2008 Service Manual B257B, B257C AMBIENT SENSOR

HAC-45

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC.

2. Check if any](/img/5/57391/w960_57391-2672.png)

B257B, B257C AMBIENT SENSOR

HAC-45

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

1. Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC.

2. Check if any DTC is displayed in the self-diagnosis results.

NOTE:

If DTC is displayed along with DTC U1000 or U1010, first diagnose the DTC U1000 or U1010. Refer to HAC-

42, "DTC Logic" or HAC-43, "DTC Logic".

If there is an open circuit in the ambient sensor, A/C auto amp. registers extreme cold [−44°C (−47°F)] and

adjusts the temperature control warmer.

Is DTC

“B257B” or “B257C” displayed?

YES >> Perform trouble diagnosis for the ambient sensor. Refer to HAC-45, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003846330

1.CHECK VOLTAGE BETWEEN AMBIENT SENSOR AND GROUND

1. Disconnect ambient sensor connector.

2. Turn ignition switch ON.

3. Check voltage between ambient sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK CIRCUIT CONTINUITY BETWEEN AMBIENT SENSOR AND A/C AUTO AMP.

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector.

3. Check continuity between ambient sensor harness connector and A/C auto amp. harness connector.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK AMBIENT SENSOR

Check ambient sensor. Refer to HAC-46, "

Component Inspection".

Is the inspection result normal?

YES >> Replace A/C auto amp.

NO >> Replace ambient sensor.

4.CHECK CIRCUIT CONTINUITY BETWEEN AMBIENT SENSOR AND A/C AUTO AMP.

1. Turn ignition switch OFF.

2. Disconnect A/C auto amp. connector.

3. Check continuity between ambient sensor harness connector and A/C auto amp. harness connector.

4. Check continuity between ambient sensor harness connector and ground.

(+) (−)

Vo l ta g e Ambient sensor

—

Connector Terminal

E337 1 Ground Approx. 5 V

Ambient sensor A/C auto amp.

Continuity

Connector Terminal Connector Terminal

E337 2 M50 37 Existed

Ambient sensor A/C auto amp.

Continuity

Connector Terminal Connector Terminal

E337 1 M50 35 Existed

Page 2674 of 5121

![NISSAN TEANA 2008 Service Manual HAC-46

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

B257B, B257C AMBIENT SENSOR

Is the inspection result normal?

YES >> Replace A/C auto amp.

NO >> Repair harness or connector.

Component Inspection NISSAN TEANA 2008 Service Manual HAC-46

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

B257B, B257C AMBIENT SENSOR

Is the inspection result normal?

YES >> Replace A/C auto amp.

NO >> Repair harness or connector.

Component Inspection](/img/5/57391/w960_57391-2673.png)

HAC-46

< COMPONENT DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

B257B, B257C AMBIENT SENSOR

Is the inspection result normal?

YES >> Replace A/C auto amp.

NO >> Repair harness or connector.

Component InspectionINFOID:0000000003846331

1.CHECK AMBIENT SENSOR

1. Turn ignition switch OFF.

2. Disconnect ambient sensor connector. Refer to VTL-24, "

Exploded View".

3. Check resistance between ambient sensor terminals.

Is the inspection result normal?

YES >> END.

NO >> Replace ambient sensor.

Ambient sensor

—Continuity

Connector Terminal

E337 1 Ground Not existed

Te r m i n a lCondition

Resistance kΩ

Temperature °C (°F)

12−15 (5) 12.73

−10 (14) 9.92

−5 (23) 7.80

0 (32) 6.19

5 (41) 4.95

10 (50) 3.99

15 (59) 3.24

20 (68) 2.65

25 (77) 2.19

30 (86) 1.81

35 (95) 1.51

40 (104) 1.27

45 (113) 1.07