clutch NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1399 of 5121

![NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-183

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

If the noise can be duplicated easily during the test drive, to help ide NISSAN TEANA 2008 Service Manual SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-183

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

If the noise can be duplicated easily during the test drive, to help ide](/img/5/57391/w960_57391-1398.png)

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DLK-183

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that is are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that is are suspected to be the cause of the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration by hand by touching the component(s) that is are suspected to be the cause of the

noise.

Placing a piece of paper between components that is are suspected to be the cause of the noise.

Looking for loose components and contact marks.

Refer to DLK-184, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. These insulators are available through the authorized Nissan Parts Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

URETHANE PADS

Insulates connectors, harness, etc.

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

INSULATOR (Light foam block)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

The following materials, not available through NISSAN Parts Department, can also be used to repair

squeaks and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is be visible or does not fit.

Note: Will only last a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Page 1519 of 5121

![NISSAN TEANA 2008 Service Manual EC-58

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Component Description

INFOID:0000000003856480

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel press NISSAN TEANA 2008 Service Manual EC-58

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Component Description

INFOID:0000000003856480

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel press](/img/5/57391/w960_57391-1518.png)

EC-58

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Component Description

INFOID:0000000003856480

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel pressure regulator 3. Fuel level sensor unit and fuel pump

: Vehicle front

JMBIA1385ZZ

Component Reference

ASCD steering switchEC-270, "

Description"

ASCD brake switchEC-273, "Description"

ASCD clutch switchEC-273, "Description"

Stop lamp switchEC-291, "Description"

Electric throttle control actuatorEC-302, "Description"

ASCD indicatorEC-323, "Description"

Page 1580 of 5121

![NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-119

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater det NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-119

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater det](/img/5/57391/w960_57391-1579.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-119

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals. HO2S2 HTR (B2)

I/P PULLY SPD rpm Indicates the engine speed computed from the

turbine revolution sensor signal.

VEHICLE SPEED km/h or mph The vehicle speed computed from the vehicle

speed signal sent from TCM is displayed.

IDL A/V LEARN YET/CMPLT Displays the condition of idle air volume learning

YET: Idle Air Volume Learning has not been per-

formed yet.

CMPLT: Idle Air Volume Learning has already

been performed successfully.

ENG OIL TEMP°C or °F The engine oil temperature (determined by the

signal voltage of the engine oil temperature sen-

sor) is displayed.

TRVL AFTER MIL km or mile Distance traveled while MI is activated.

A/F S1 HTR(B1)

% Air fuel ratio (A/F) sensor 1 heater control value

computed by ECM according to the input signals.

The current flow to the heater becomes larger as

the value increases. A/F S1 HTR(B2)

AC PRESS SEN V The signal voltage from the refrigerant pressure

sensor is displayed.

VHCL SPEED SE km/h or mph The vehicle speed computed from the vehicle

speed signal sent from combination meter is dis-

played.

SET VHCL SPD km/h or mph The preset vehicle speed is displayed.

MAIN SW ON/OFF Indicates [ON/OFF] condition from MAIN switch

signal.

CANCEL SW ON/OFF Indicates [ON/OFF] condition from CANCEL

switch signal.

RESUME/ACC SW ON/OFF Indicates [ON/OFF] condition from RESUME/AC-

CELERATE switch signal.

SET SW ON/OFF Indicates [ON/OFF] condition from SET/COAST

switch signal.

BRAKE SW1 ON/OFF Indicates [ON/OFF] condition from ASCD brake

switch signal or ASCD clutch switch.

BRAKE SW2 ON/OFF Indicates [ON/OFF] condition of stop lamp switch

signal.

VHCL SPD CUT NON/CUT Indicates the vehicle cruise condition.

NON: Vehicle speed is maintained at the ASCD

set speed.

CUT: Vehicle speed decreased to excessively

low compared with the ASCD set speed, and

ASCD operation is cut off.

LO SPEED CUT NON/CUT Indicates the vehicle cruise condition.

NON: Vehicle speed is maintained at the ASCD

set speed.

CUT: Vehicle speed decreased to excessively

low, and ASCD operation is cut off.

AT O D M O N I TO R O N / O F F Indicates [ON/OFF] condition of CVT O/D ac-

cording to the input signal from the TCM.

AT OD CANCEL ON/OFF Indicates [ON/OFF] condition of CVT O/D cancel

request signal.

CRUISE LAMP ON/OFF Indicates [ON/OFF] condition of CRUISE lamp

determined by the ECM according to the input

signals. Monitored item Unit Description Remarks

Page 2061 of 5121

![NISSAN TEANA 2008 Service Manual EXL-32

< FUNCTION DIAGNOSIS >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003894259

AUTO ACTIVE TEST

Description

In auto active test mode, th NISSAN TEANA 2008 Service Manual EXL-32

< FUNCTION DIAGNOSIS >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003894259

AUTO ACTIVE TEST

Description

In auto active test mode, th](/img/5/57391/w960_57391-2060.png)

EXL-32

< FUNCTION DIAGNOSIS >[XENON TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003894259

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Front wiper (LO, HI)

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamps (LO, HI)

A/C compressor (magnet clutch)

Cooling fan

Operation Procedure

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

If auto active test mode cannot be actuated, check door switch system. Refer to DLK-57,

"ComponentFunctionCheck".

Do not start the engine.

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

Operation

sequenceInspection location Operation

A Oil pressure warning lamp Blinks continuously during operation of auto active test

1 Front wiper LO for 5 seconds → HI for 5 seconds

2 Parking lamps

License plate lamps

Tail lamps

Front fog lamps10 seconds

3 Headlamps LO ⇔ HI 5 times

4A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Page 2062 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (IPDM E/R)

EXL-33

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals t NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (IPDM E/R)

EXL-33

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals t](/img/5/57391/w960_57391-2061.png)

DIAGNOSIS SYSTEM (IPDM E/R)

EXL-33

< FUNCTION DIAGNOSIS >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

JPMIA1016GB

Symptom Inspection contents Possible cause

Any of the following components do not operate

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamp (HI, LO)

Front wiperPerform auto active test.

Does the applicable system

operate?YES BCM signal input circuit

NO Lamp or motor

Lamp or motor ground cir-

cuit

Harness or connector be-

tween IPDM E/R and appli-

cable system

IPDM E/R

A/C compressor does not operatePerform auto active test.

Does the magnet clutch oper-

ate?YES A/C amp. signal input circuit

CAN communication signal

between A/C amp. and

ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnet clutch

Harness or connector be-

tween IPDM E/R and mag-

net clutch

IPDM E/R

Oil pressure warning lamp does not operatePerform auto active test.

Does the oil pressure warning

lamp blink?YES Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Page 2248 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (IPDM E/R)

EXL-219

< FUNCTION DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003894312

AUTO ACTIVE TEST

Desc NISSAN TEANA 2008 Service Manual DIAGNOSIS SYSTEM (IPDM E/R)

EXL-219

< FUNCTION DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003894312

AUTO ACTIVE TEST

Desc](/img/5/57391/w960_57391-2247.png)

DIAGNOSIS SYSTEM (IPDM E/R)

EXL-219

< FUNCTION DIAGNOSIS >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000003894312

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM E/R sends a drive signal to the following systems to check their operation.

Oil pressure warning lamp

Front wiper (LO, HI)

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamps (LO, HI)

A/C compressor (magnet clutch)

Cooling fan

Operation Procedure

1. Close the hood and lift the wiper arms from the windshield. (Prevent windshield damage due to wiper

operation)

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON, and within 20 seconds, press the driver door switch 10 times. Then turn the

ignition switch OFF.

CAUTION:

Close passenger door.

4. Turn the ignition switch ON within 10 seconds. After that the horn sounds once and the auto active test

starts.

5. The oil pressure warning lamp starts blinking when the auto active test starts.

6. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

If auto active test mode cannot be actuated, check door switch system. Refer to DLK-57,

"ComponentFunctionCheck".

Do not start the engine.

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 5 steps are repeated 3 times.

Operation

sequenceInspection location Operation

A Oil pressure warning lamp Blinks continuously during operation of auto active test

1 Front wiper LO for 5 seconds → HI for 5 seconds

2Parking lamps

License plate lamps

Tail lamps

Front fog lamps10 seconds

3 Headlamps LO ⇔ HI 5 times

4 A/C compressor (magnet clutch) ON ⇔ OFF 5 times

5 Cooling fan LO for 5 seconds → MID for 3 seconds → HI for 2 seconds

Page 2249 of 5121

![NISSAN TEANA 2008 Service Manual EXL-220

< FUNCTION DIAGNOSIS >[HALOGEN TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN comm NISSAN TEANA 2008 Service Manual EXL-220

< FUNCTION DIAGNOSIS >[HALOGEN TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN comm](/img/5/57391/w960_57391-2248.png)

EXL-220

< FUNCTION DIAGNOSIS >[HALOGEN TYPE]

DIAGNOSIS SYSTEM (IPDM E/R)

Concept of auto active test

IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

JPMIA1016GB

Symptom Inspection contents Possible cause

Any of the following components do not operate

Parking lamps

License plate lamps

Tail lamps

Front fog lamps

Headlamp (HI, LO)

Front wiperPerform auto active test.

Does the applicable system

operate?YES BCM signal input circuit

NO Lamp or motor

Lamp or motor ground cir-

cuit

Harness or connector be-

tween IPDM E/R and appli-

cable system

IPDM E/R

A/C compressor does not operatePerform auto active test.

Does the magnet clutch oper-

ate?YES A/C amp. signal input circuit

CAN communication signal

between A/C amp. and

ECM

CAN communication signal

between ECM and IPDM E/

R

NO Magnet clutch

Harness or connector be-

tween IPDM E/R and mag-

net clutch

IPDM E/R

Oil pressure warning lamp does not operatePerform auto active test.

Does the oil pressure warning

lamp blink?YES Harness or connector be-

tween IPDM E/R and oil

pressure switch

Oil pressure switch

IPDM E/R

NO CAN communication signal

between IPDM E/R and

BCM

CAN communication signal

between BCM and combi-

nation meter

Combination meter

Page 2392 of 5121

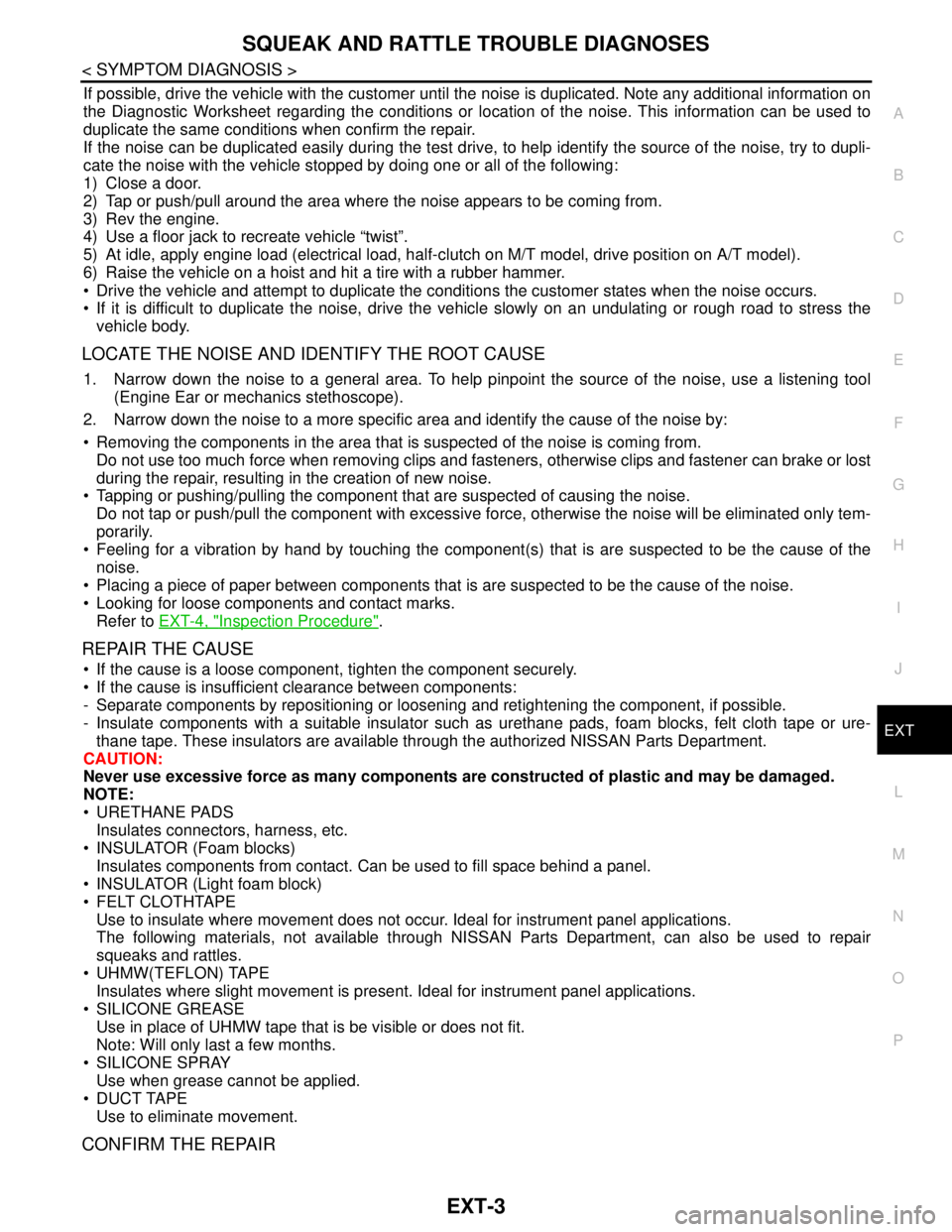

SQUEAK AND RATTLE TROUBLE DIAGNOSES

EXT-3

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the components in the area that is suspected of the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can brake or lost

during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component that are suspected of causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

Feeling for a vibration by hand by touching the component(s) that is are suspected to be the cause of the

noise.

Placing a piece of paper between components that is are suspected to be the cause of the noise.

Looking for loose components and contact marks.

Refer to EXT-4, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. These insulators are available through the authorized NISSAN Parts Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

URETHANE PADS

Insulates connectors, harness, etc.

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

INSULATOR (Light foam block)

FELT CLOTHTAPE

Use to insulate where movement does not occur. Ideal for instrument panel applications.

The following materials, not available through NISSAN Parts Department, can also be used to repair

squeaks and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Use in place of UHMW tape that is be visible or does not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Page 2510 of 5121

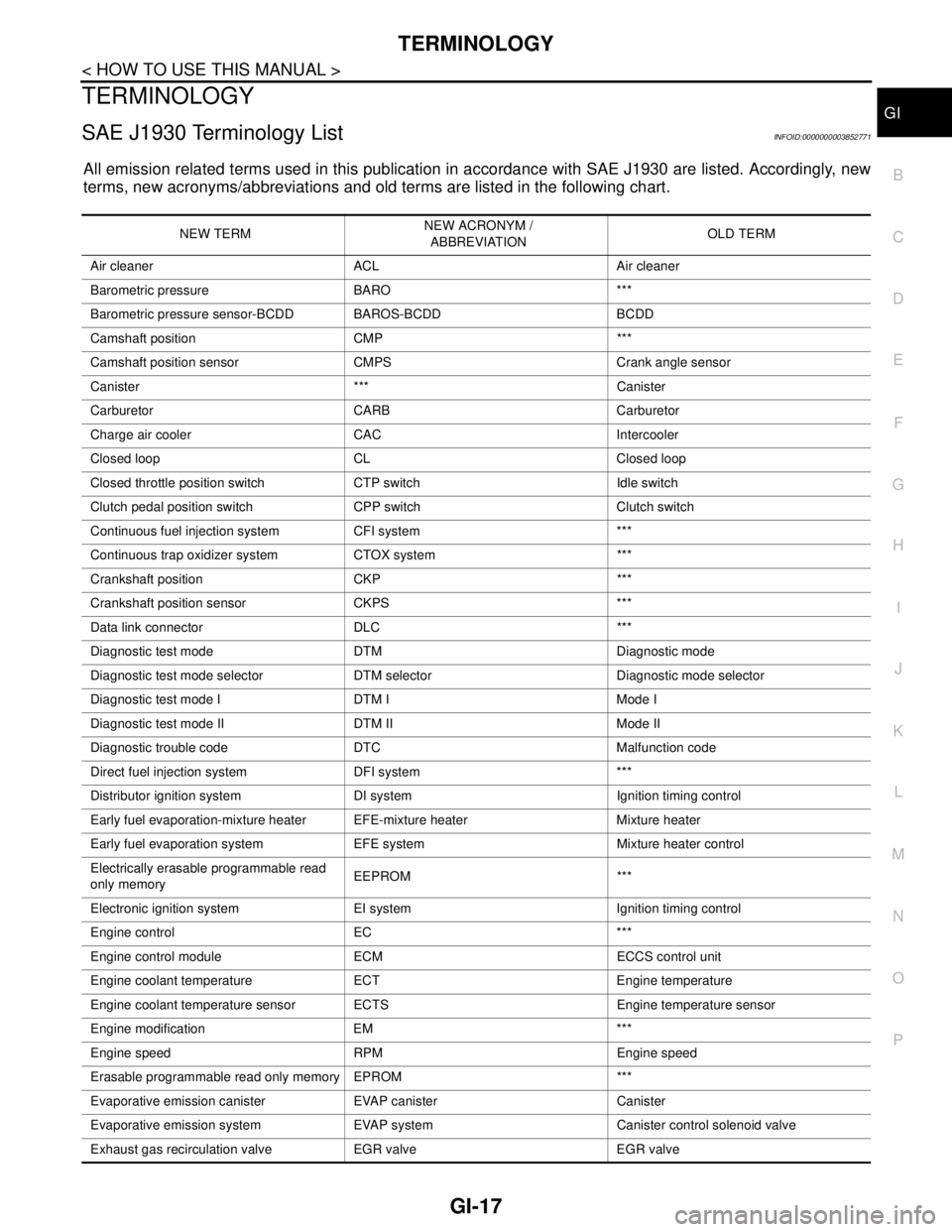

TERMINOLOGY

GI-17

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PTERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000003852771

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

Page 2512 of 5121

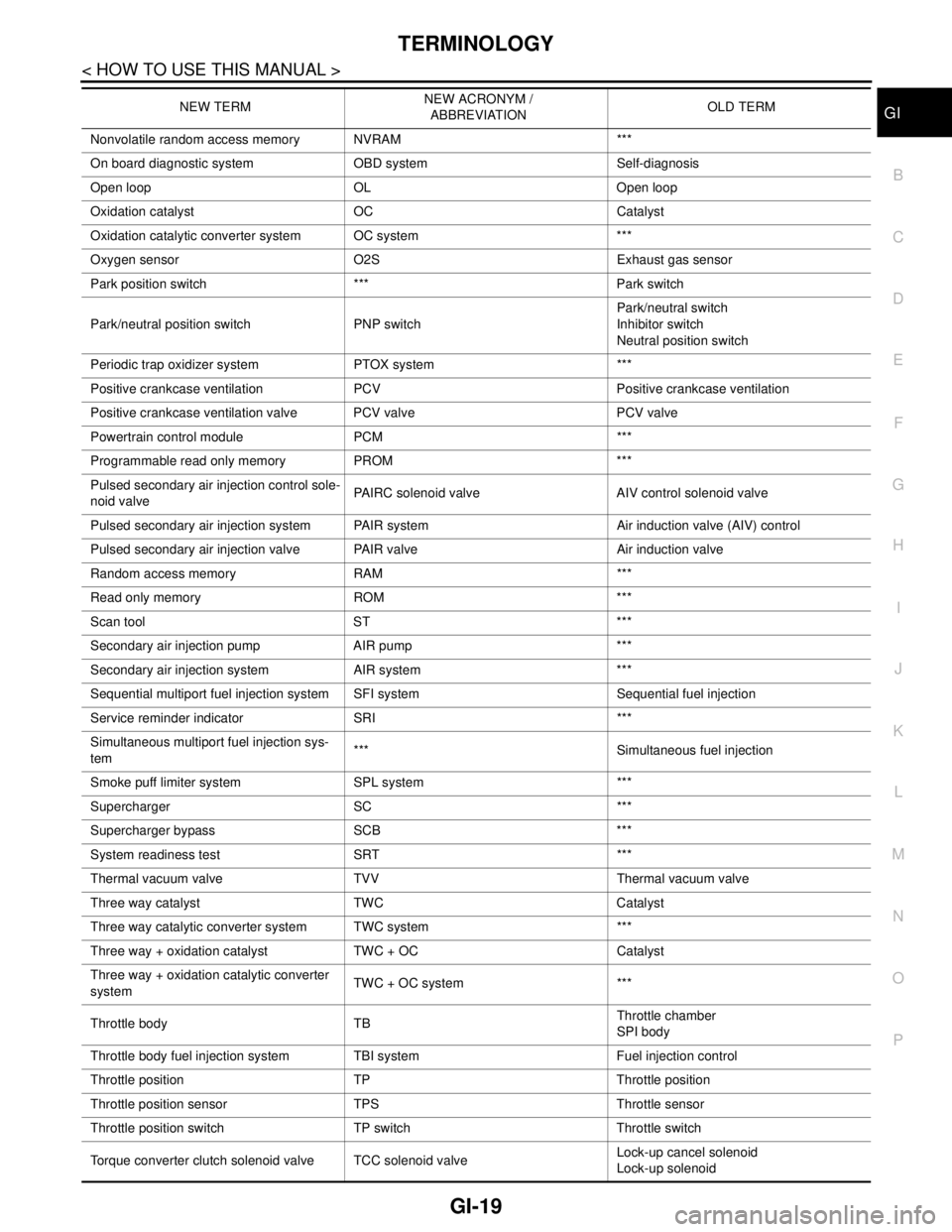

TERMINOLOGY

GI-19

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switchPark/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TBThrottle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valveLock-up cancel solenoid

Lock-up solenoid NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM