instrument cluster NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 181 of 5121

![NISSAN TEANA 2008 Service Manual AV

AUDIO UNIT

AV-37

< ON-VEHICLE REPAIR >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ON-VEHICLE REPAIR

AUDIO UNIT

Exploded ViewINFOID:0000000003765611

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEM NISSAN TEANA 2008 Service Manual AV

AUDIO UNIT

AV-37

< ON-VEHICLE REPAIR >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ON-VEHICLE REPAIR

AUDIO UNIT

Exploded ViewINFOID:0000000003765611

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEM](/img/5/57391/w960_57391-180.png)

AV

AUDIO UNIT

AV-37

< ON-VEHICLE REPAIR >[AUDIO SYSTEM]

C

D

E

F

G

H

I

J

K

L

MB A

O

P

ON-VEHICLE REPAIR

AUDIO UNIT

Exploded ViewINFOID:0000000003765611

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

Removal and InstallationINFOID:0000000003765612

REMOVAL

1. Remove instrument finisher C. Refer to IP-12, "Removal and Installation".

2. Remove cluster lid D. Refer to IP-12, "

Removal and Installation".

3. Remove audio unit with an A/C auto amp. as a single unit from the body.

4. Remove bracket screws, and then remove audio unit.

INSTALLATION

Install in the reverse order of removal.

1. Audio unit 2. Bracket LH 3. A/C auto amp.

4. Bracket RH

JPNIA1027ZZ

Page 314 of 5121

![NISSAN TEANA 2008 Service Manual AV-170

< ON-VEHICLE REPAIR >[BASE AUDIO AND DISPLAY SYSTEM]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003940154

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

NISSAN TEANA 2008 Service Manual AV-170

< ON-VEHICLE REPAIR >[BASE AUDIO AND DISPLAY SYSTEM]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003940154

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY](/img/5/57391/w960_57391-313.png)

AV-170

< ON-VEHICLE REPAIR >[BASE AUDIO AND DISPLAY SYSTEM]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003940154

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

Removal and InstallationINFOID:0000000003940155

REMOVAL

1. Remove instrument finisher C. Refer to IP-12, "Removal and Installation".

2. Remove cluster lid D. Refer to IP-12, "

Removal and Installation".

3. Remove AV control unit with A/C amp. as a single unit from the body.

4. Remove bracket screws, and then remove AV control unit.

INSTALLATION

Installation is the reverse order of removal.

1. AV control unit 2. Bracket LH 3. A/C auto amp.

4. Bracket RH

JPNIA1034ZZ

Page 522 of 5121

![NISSAN TEANA 2008 Service Manual AV-378

< ON-VEHICLE REPAIR >[BOSE AUDIO WITHOUT NAVIGATION]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003838325

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

NISSAN TEANA 2008 Service Manual AV-378

< ON-VEHICLE REPAIR >[BOSE AUDIO WITHOUT NAVIGATION]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003838325

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY](/img/5/57391/w960_57391-521.png)

AV-378

< ON-VEHICLE REPAIR >[BOSE AUDIO WITHOUT NAVIGATION]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003838325

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

Removal and InstallationINFOID:0000000003838326

REMOVAL

1. Remove instrument finisher C. Refer to IP-12, "Removal and Installation".

2. Remove cluster lid D. Refer to IP-12, "

Removal and Installation".

3. Remove AV control unit with A/C amp. as a single unit from the body.

4. Remove bracket screws, and then remove AV control unit.

INSTALLATION

Installation is the reverse order of removal.

1. AV control unit 2. Bracket LH 3. A/C auto amp.

4. Bracket RH

JPNIA1034ZZ

Page 792 of 5121

![NISSAN TEANA 2008 Service Manual AV-648

< ON-VEHICLE REPAIR >[BOSE AUDIO WITH NAVIGATION]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003765981

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

Rem NISSAN TEANA 2008 Service Manual AV-648

< ON-VEHICLE REPAIR >[BOSE AUDIO WITH NAVIGATION]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003765981

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

Rem](/img/5/57391/w960_57391-791.png)

AV-648

< ON-VEHICLE REPAIR >[BOSE AUDIO WITH NAVIGATION]

AV CONTROL UNIT

ON-VEHICLE REPAIR

AV CONTROL UNIT

Exploded ViewINFOID:0000000003765981

REMOVAL

Refer to IP-11, "Exploded View".

DISASSEMBLY

Removal and InstallationINFOID:0000000003765982

REMOVAL

1. Remove instrument finisher C. Refer to IP-12, "Removal and Installation".

2. Remove cluster lid D. Refer to IP-12, "

Removal and Installation".

3. Remove AV control unit with A/C amp. as a single unit from the body.

4. Remove bracket screws, and then remove AV control unit.

INSTALLATION

Installation is the reverse order of removal.

1. AV control unit 2. Bracket LH 3. A/C auto amp.

4. Bracket RH

JPNIA1034ZZ

Page 1400 of 5121

![NISSAN TEANA 2008 Service Manual DLK-184

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Inspection Procedure

INFOID:0000000003941378

Refer to Table of Contents for specific component removal an NISSAN TEANA 2008 Service Manual DLK-184

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Inspection Procedure

INFOID:0000000003941378

Refer to Table of Contents for specific component removal an](/img/5/57391/w960_57391-1399.png)

DLK-184

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Inspection Procedure

INFOID:0000000003941378

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insulated with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

Page 2393 of 5121

EXT-4

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Check that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000003941540

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. Usually insulate the areas with felt cloth tape or insulator foam blocks to repair the

noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 2547 of 5121

GW-4

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000003943093

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insulated with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 3000 of 5121

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INT-23

< SYMPTOM DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

INT

N

O

P

Inspection ProcedureINFOID:0000000003887244

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insulated with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

Page 3044 of 5121

IP-4

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000003939974

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insulated with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 3052 of 5121

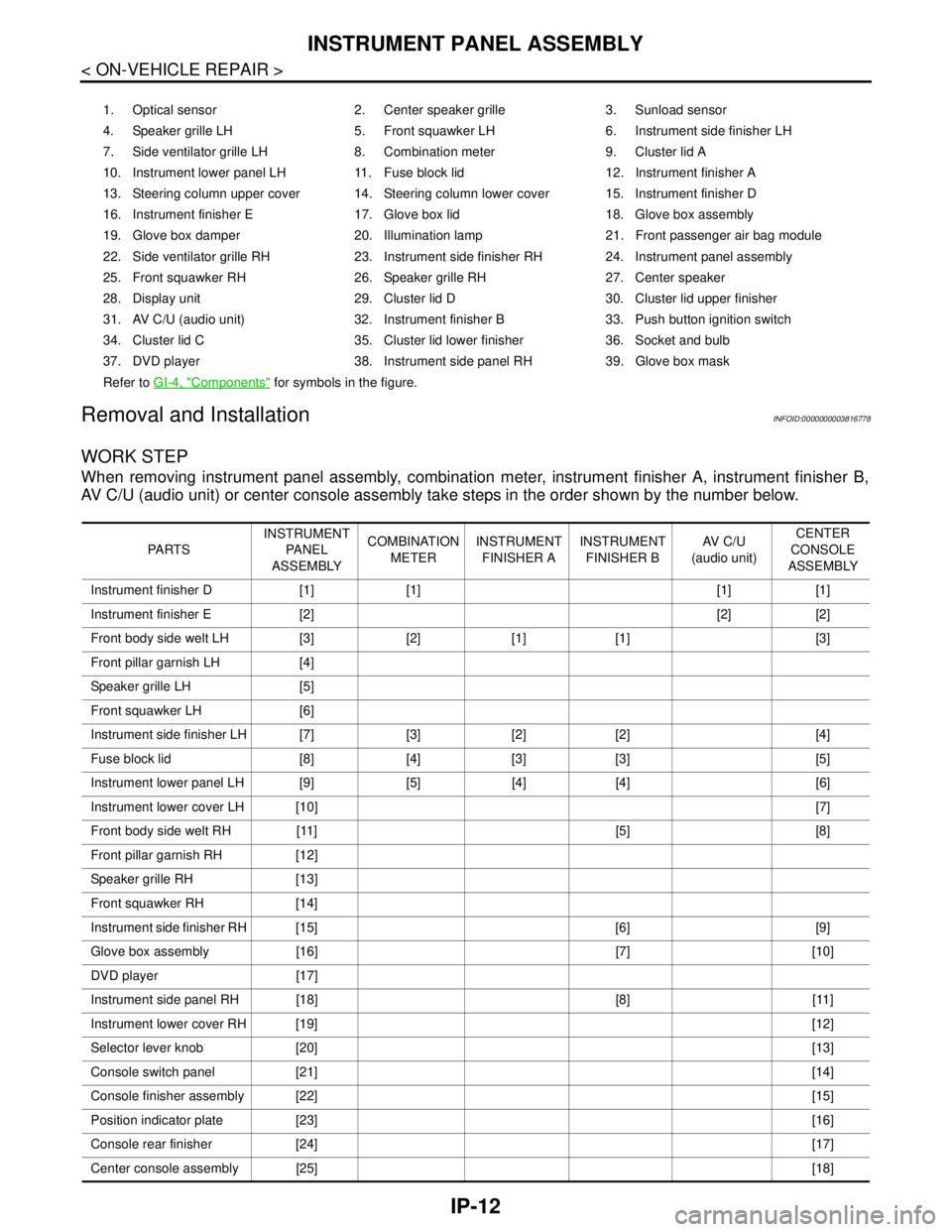

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000003816778

WORK STEP

When removing instrument panel assembly, combination meter, instrument finisher A, instrument finisher B,

AV C/U (audio unit) or center console assembly take steps in the order shown by the number below.

1. Optical sensor 2. Center speaker grille 3. Sunload sensor

4. Speaker grille LH 5. Front squawker LH 6. Instrument side finisher LH

7. Side ventilator grille LH 8. Combination meter 9. Cluster lid A

10. Instrument lower panel LH 11. Fuse block lid 12. Instrument finisher A

13. Steering column upper cover 14. Steering column lower cover 15. Instrument finisher D

16. Instrument finisher E 17. Glove box lid 18. Glove box assembly

19. Glove box damper 20. Illumination lamp 21. Front passenger air bag module

22. Side ventilator grille RH 23. Instrument side finisher RH 24. Instrument panel assembly

25. Front squawker RH 26. Speaker grille RH 27. Center speaker

28. Display unit 29. Cluster lid D 30. Cluster lid upper finisher

31. AV C/U (audio unit) 32. Instrument finisher B 33. Push button ignition switch

34. Cluster lid C 35. Cluster lid lower finisher 36. Socket and bulb

37. DVD player 38. Instrument side panel RH 39. Glove box mask

Refer to GI-4, "

Components" for symbols in the figure.

PA R T SINSTRUMENT

PA N E L

ASSEMBLYCOMBINATION

METERINSTRUMENT

FINISHER AINSTRUMENT

FINISHER BAV C / U

(audio unit)CENTER

CONSOLE

ASSEMBLY

Instrument finisher D [1] [1] [1] [1]

Instrument finisher E [2] [2] [2]

Front body side welt LH [3] [2] [1] [1] [3]

Front pillar garnish LH [4]

Speaker grille LH [5]

Front squawker LH [6]

Instrument side finisher LH [7] [3] [2] [2] [4]

Fuse block lid [8] [4] [3] [3] [5]

Instrument lower panel LH [9] [5] [4] [4] [6]

Instrument lower cover LH [10][7]

Front body side welt RH [11] [5] [8]

Front pillar garnish RH [12]

Speaker grille RH [13]

Front squawker RH [14]

Instrument side finisher RH [15] [6] [9]

Glove box assembly [16] [7] [10]

DVD player [17]

Instrument side panel RH [18] [8] [11]

Instrument lower cover RH [19][12]

Selector lever knob [20][13]

Console switch panel [21][14]

Console finisher assembly [22][15]

Position indicator plate [23][16]

Console rear finisher [24][17]

Center console assembly [25][18]