load capacity NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1687 of 5121

![NISSAN TEANA 2008 Service Manual EC-226

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0420, P0430 THREE WAY CATALYST FUNCTION

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000003856631

DTC DETECTION LOGIC

The ECM monitors t NISSAN TEANA 2008 Service Manual EC-226

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0420, P0430 THREE WAY CATALYST FUNCTION

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000003856631

DTC DETECTION LOGIC

The ECM monitors t](/img/5/57391/w960_57391-1686.png)

EC-226

< COMPONENT DIAGNOSIS >[VQ25DE, VQ35DE]

P0420, P0430 THREE WAY CATALYST FUNCTION

P0420, P0430 THREE WAY CATALYST FUNCTION

DTC LogicINFOID:0000000003856631

DTC DETECTION LOGIC

The ECM monitors the switching frequency ratio of air fuel ratio (A/F)

sensor 1 and heated oxygen sensor 2.

A three way catalyst (manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of A/F sensor 1 and heated oxygen sensor

2 approaches a specified limit value, the three way catalyst (mani-

fold) malfunction is diagnosed.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Will CONSULT-III be used?

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 7.

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Do not hold engine speed for more than the specified minutes below.

>> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-I

With CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode with CONSULT-III.

2. Start engine and warm it up to the normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

5. Let engine idle for 1 minute.

6. Check that “COOLAN TEMP/S” indicates more than 70°C (158°F).

If not, warm up engine and go to next step when “COOLAN TEMP/S” indication reaches to 70°C (158°F).

7. Open engine hood.

8. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUPPORT” mode with CONSULT-III.

9. Rev engine between 2,000 and 3,000 rpm and hold it for 3 consecutive minutes then release the acceler-

ator pedal completely.

10. Check the indication of “CATALYST”.

Which is displayed on CONSULT-III screen?

PBIB2055E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420Catalyst system efficien-

cy below threshold

(bank 1) Three way catalyst (manifold) does not oper-

ate properly.

Three way catalyst (manifold) does not have

enough oxygen storage capacity. Three way catalyst (manifold)

Exhaust tube

Intake air leaks

Fuel injector

Fuel injector leaks

Spark plug

Improper ignition timing P0430Catalyst system efficien-

cy below threshold

(bank 2)

Page 1951 of 5121

EM-76

< DISASSEMBLY AND ASSEMBLY >

ENGINE STAND SETTING

DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000003802278

NOTE:

Explained here is how to disassemble with engine stand supporting transaxle surface. When using different

type of engine stand, note with difference in steps and etc.

1. Remove the engine assembly from the vehicle. Refer to EM-67, "

Exploded View".

2. Remove the parts that may restrict installation of engine to widely use engine stand.

NOTE:

The procedure is described assuming that you use a widely use engine stand holding the surface, to

which transmission is installed.

Remove drive plate. Fix crankshaft pulley with the pulley holder (commercial service tool), and remove

mounting bolts.

Loosen mounting bolts in diagonal order.

Check for deformation or damage drive plate.

CAUTION:

Never disassemble drive plate.

Never place drive plate with signal plate facing down.

When handling signal plate, take care not to damage or scratch it.

Handle signal plate in a manner that prevents it from becoming magnetized.

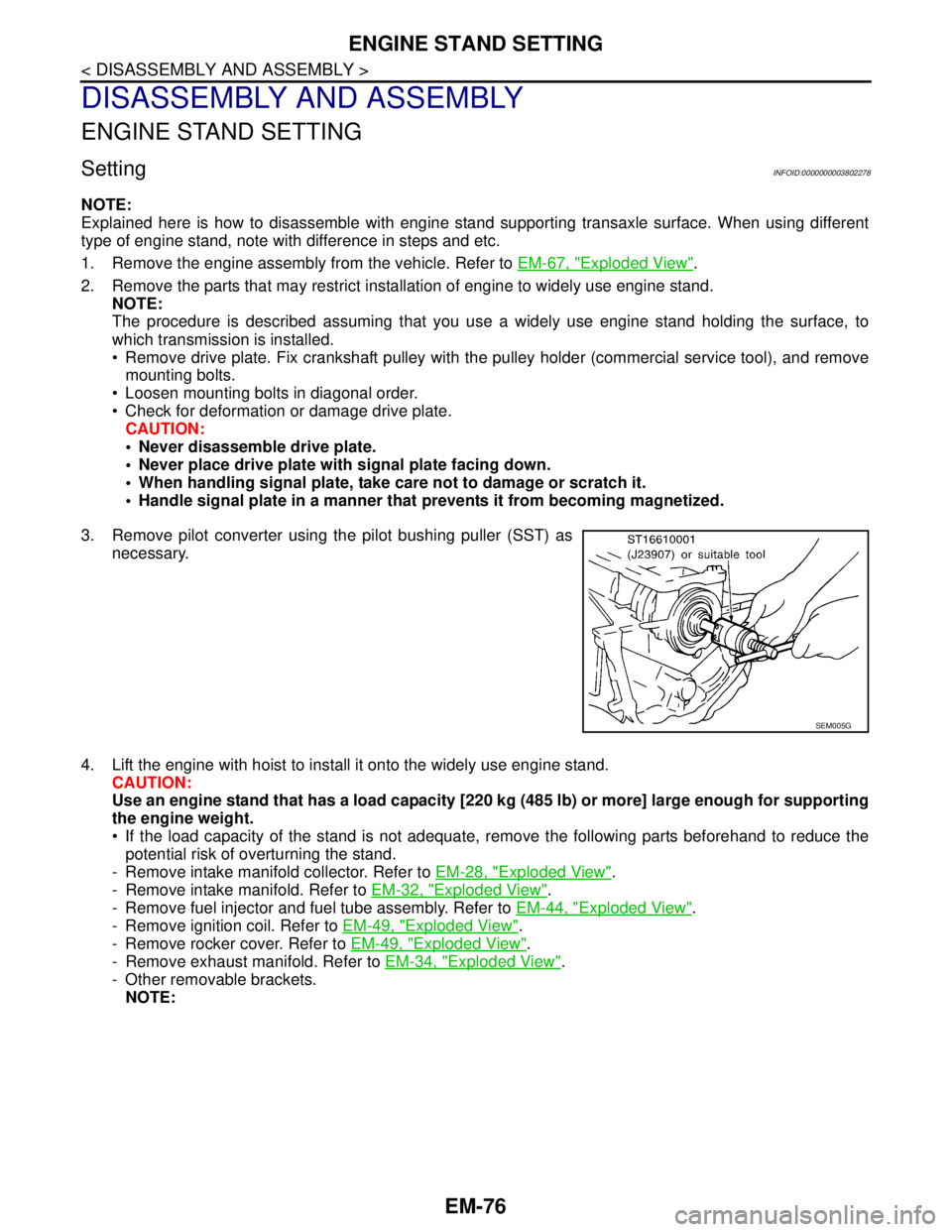

3. Remove pilot converter using the pilot bushing puller (SST) as

necessary.

4. Lift the engine with hoist to install it onto the widely use engine stand.

CAUTION:

Use an engine stand that has a load capacity [220 kg (485 lb) or more] large enough for supporting

the engine weight.

If the load capacity of the stand is not adequate, remove the following parts beforehand to reduce the

potential risk of overturning the stand.

- Remove intake manifold collector. Refer to EM-28, "

Exploded View".

- Remove intake manifold. Refer to EM-32, "

Exploded View".

- Remove fuel injector and fuel tube assembly. Refer to EM-44, "

Exploded View".

- Remove ignition coil. Refer to EM-49, "

Exploded View".

- Remove rocker cover. Refer to EM-49, "

Exploded View".

- Remove exhaust manifold. Refer to EM-34, "

Exploded View".

- Other removable brackets.

NOTE:

SEM005G

Page 3524 of 5121

![NISSAN TEANA 2008 Service Manual PG-6

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

BATTERY

3. If the difference between the max. and min. electrolyte level in cells is within 10 mm (0.39 in), it is OK.

Are these inspection resul NISSAN TEANA 2008 Service Manual PG-6

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

BATTERY

3. If the difference between the max. and min. electrolyte level in cells is within 10 mm (0.39 in), it is OK.

Are these inspection resul](/img/5/57391/w960_57391-3523.png)

PG-6

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

BATTERY

3. If the difference between the max. and min. electrolyte level in cells is within 10 mm (0.39 in), it is OK.

Are these inspection results normal?

YES >> GO TO 2.

NO >> Replace battery.

2.CHECKING SPECIFIC GRAVITY

Check specific gravity. Refer to PG-3, "

How to Handle Battery".

Inspection results

Above 1.220 (Test using battery checker)>>GO TO 3.

Above 1.220 (Test using load tester)>>GO TO 5.

1.100 - 1.220 (When performing quick charge)>>GO TO 7.

1.100 - 1.220 (When performing standard charge)>>GO TO 12.

Below 1.100>>GO TO 13.

3.CAPACITY TEST

Test using battery checker.

Is the battery usable, according to the manufacturer

’s instructions?

YES >> Ready for use. Mount battery again and check loose terminals. Also check other related circuits.

NO >> GO TO 4.

4.QUICK CHARGE

1. Perform quick charge. Time required: 45 min. Refer to PG-107, "

Quick Charge".

2. Test using battery checker.

Is the battery usable, according to the manufacturer

’s instructions?

YES >> Ready for use.

NO >> Replace battery.

5.CAPACITY TEST

1. Test using load tester.

2. Check battery type and determine the specified current using the table.

Discharging Current (Load Tester)

3. Read load tester voltage when specified discharging current flows through battery for 15 seconds.

Type Current (A)

28B19R(L) 90

34B19R(L) 99

46B24R(L)

135

55B24R(L)

50D23R(L) 150

55D23R(L) 180

80D23R(L)

195 65D26R(L)

80D26R(L)

75D31R(L) 210

95D31R(L)

240 115D31R(L)

025 [YUASA type code]

027 [YUASA type code] 285

110D26R(L)

300

95E41R(L)

067 [YUASA type code] 325

130E41R(L) 330

096 [YUASA type code] 375

Page 3525 of 5121

![NISSAN TEANA 2008 Service Manual PG

BATTERY

PG-7

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Is the voltage 9.6 V or more?

YES >> Ready for use.

NO >> GO TO 6.

6.QUICK CHARGE

1. Perform quick charg NISSAN TEANA 2008 Service Manual PG

BATTERY

PG-7

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Is the voltage 9.6 V or more?

YES >> Ready for use.

NO >> GO TO 6.

6.QUICK CHARGE

1. Perform quick charg](/img/5/57391/w960_57391-3524.png)

PG

BATTERY

PG-7

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

C

D

E

F

G

H

I

J

K

L B A

O

P N

Is the voltage 9.6 V or more?

YES >> Ready for use.

NO >> GO TO 6.

6.QUICK CHARGE

1. Perform quick charge. Time required: 45 min. Refer to PG-107, "

Quick Charge".

2. Test using load tester.

Is the voltage 9.6 V or more?

YES >> Ready for use.

NO >> Replace battery.

7. QUICK CHARGE

1. Perform quick charge. Refer to PG-107, "

Quick Charge".

2. Perform capacity test.

Test using battery checker.>>GO TO 8.

Test using load tester.>>GO TO 10.

8.CAPACITY TEST

Test using battery checker.

Is the battery usable, according to the manufacturer

’s instructions?

YES >> Ready for use.

NO >> GO TO 9.

9.CHECKING SPECIFIC GRAVITY

1. Check specific gravity. Refer to PG-3, "

How to Handle Battery".

2. Perform recharge. Refer to PG-107, "

Quick Charge".

NOTE:

If battery temperature rises above 55°C (131°F), stop charging. Always charge battery when its tempera-

ture is below 55°C (131°F).

3. Test using battery checker.

Is the battery usable, according to the manufacturer

’s instructions?

YES >> Ready for use.

NO >> Replace battery.

10.CAPACITY TEST

1. Test using load tester.

2. Check battery type and determine the specified current using the table.

Discharging Current (Load Tester)

Type Current (A)

28B19R(L) 90

34B19R(L) 99

46B24R(L)

135

55B24R(L)

50D23R(L) 150

55D23R(L) 180

80D23R(L)

195 65D26R(L)

80D26R(L)

75D31R(L) 210

95D31R(L)

240 115D31R(L)

025 [YUASA type code]

Page 3526 of 5121

![NISSAN TEANA 2008 Service Manual PG-8

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

BATTERY

3. Read load tester voltage when specified discharging current flows through battery for 15 seconds.

Is the voltage 9.6 V or more?

YES >> NISSAN TEANA 2008 Service Manual PG-8

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

BATTERY

3. Read load tester voltage when specified discharging current flows through battery for 15 seconds.

Is the voltage 9.6 V or more?

YES >>](/img/5/57391/w960_57391-3525.png)

PG-8

< BASIC INSPECTION >[POWER SUPPLY&GROUND CIRCUIT]

BATTERY

3. Read load tester voltage when specified discharging current flows through battery for 15 seconds.

Is the voltage 9.6 V or more?

YES >> Ready for use.

NO >> GO TO 11.

11 .CHECKING SPECIFIC GRAVITY

1. Check specific gravity. Refer to PG-3, "

How to Handle Battery".

2. Perform recharge. Refer to PG-107, "

Quick Charge".

NOTE:

If battery temperature rises above 55°C (131°F), stop charging. Always charge battery when its tempera-

ture is below 55°C (131°F).

3. Test using load tester.

Is the voltage 9.6 V or more?

YES >> Ready for use.

NO >> Replace battery.

12. STANDARD CHARGE

NOTE:

“STANDARD CHARGE” is recommended if the vehicle is in storage after charging.

1. Perform standard charge. Refer to PG-106, "

Standard Charge".

2. Perform capacity test.

Test using battery checker.>>GO TO 14.

Test using load tester.>>GO TO 15.

13. SLOW CHARGE

1. Perform slow charge. Refer to PG-105, "

Slow Charge".

2. Perform capacity test.

Test using battery checker.>>GO TO 14.

Test using load tester.>>GO TO 15.

14.CAPACITY TEST

Test using battery checker.

Is the battery usable, according to the manufacturer

’s instructions?

YES >> Ready for use.

NO >> Replace battery.

15.CAPACITY TEST

1. Test using load tester.

2. Check battery type and determine the specified current using the table.

Discharging Current (Load Tester)

027 [YUASA type code] 285

110D26R(L)

300

95E41R(L)

067 [YUASA type code] 325

130E41R(L) 330

096 [YUASA type code] 375Type Current (A)

Type Current (A)

28B19R(L) 90

34B19R(L) 99

46B24R(L)

135

55B24R(L)