sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4157 of 4801

STC-6

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

HYDRAULIC PUMP ELECTRIC POWER STEERING SYSTEM

HYDRAULIC PUMP ELECTRIC POWER ST EERING SYSTEM : System Description

INFOID:0000000009460344

• The system is composed primarily of the power steeri ng oil pump assembly (power steering control module,

power steering motor, power steering oil pump, and reservoir tank), hydraulic pipes, and steering gear

assembly.

• The power steering control module controls the speed of the power steering motor according to the vehicle

speed and steering angle speed. By changing the power st eering oil pump flow, the power steering control

module controls the steering assist force.

• According to the power steering motor control, the sy stem hydraulic pressure is transmitted from the power

steering motor to power steering oil pump. The power steering oil pump is driven by the system hydraulic

pressure.

• After engine start, the hydraulic pump electric power steering system performs control.

• When a malfunction occurs in the system, the fail-safe function stops the hydraulic pump electric power

steering system (manual steering state) or restricts it s operation (certain steering assist force). Refer to STC-

8, "HYDRAULIC PUMP ELECTRIC POWER STEERING SYSTEM : Fail-safe".

• When the power steering function is used continuously in an extreme manner, the protective function

reduces the output to the power steering motor. Refer to STC-9, "HYDRAULIC PUMP ELECTRIC POWER

STEERING SYSTEM : Protection Function".

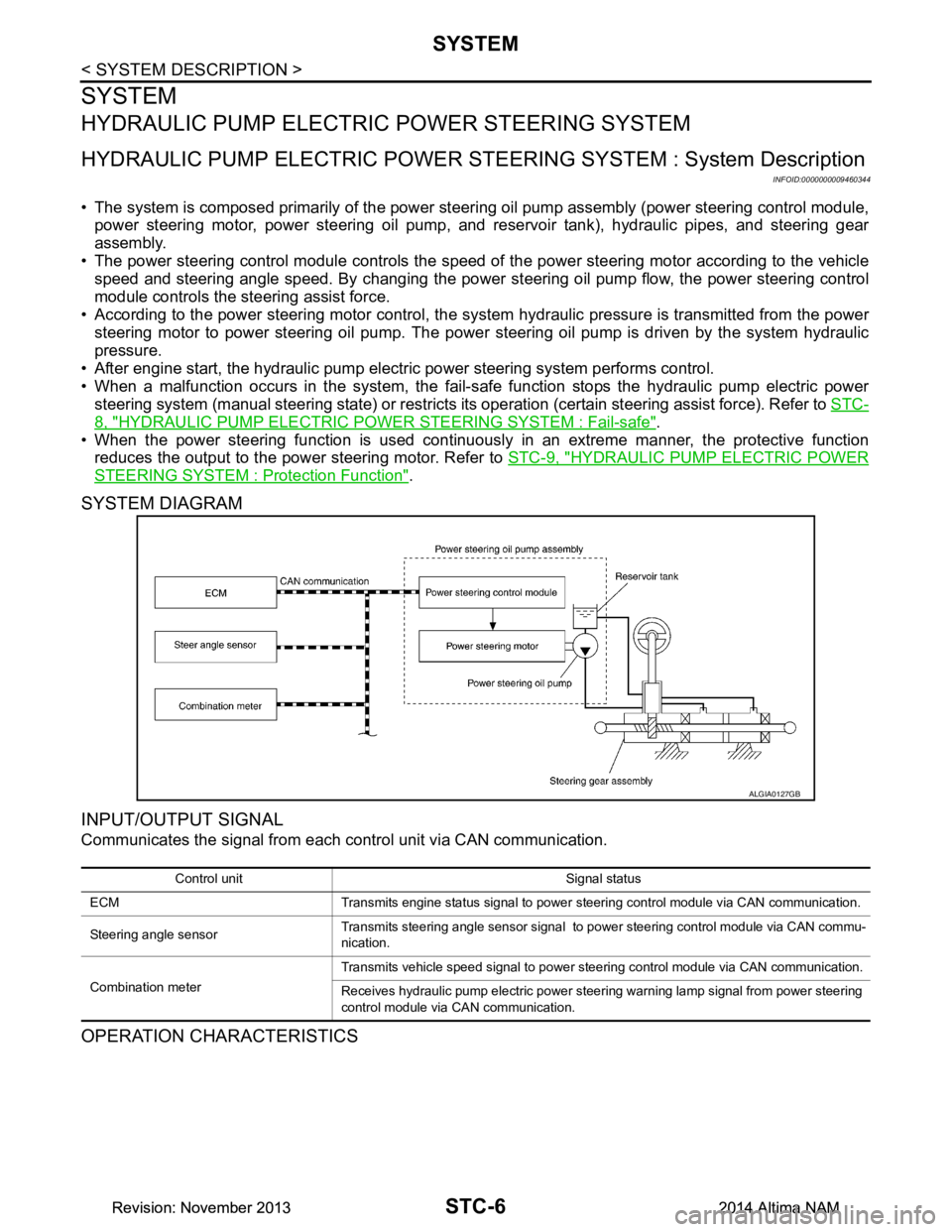

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL

Communicates the signal from each control unit via CAN communication.

OPERATION CHARACTERISTICS

ALGIA0127GB

Control unit Signal status

ECM Transmits engine status signal to power steering control module via CAN communication.

Steering angle sensor Transmits steering angle sensor signal to power steering control module via CAN commu-

nication.

Combination meter Transmits vehicle speed signal to power steering control module via CAN communication.

Receives hydraulic pump electric power steering warning lamp signal from power steering

control module via CAN communication.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4173 of 4801

STC-22

< DTC/CIRCUIT DIAGNOSIS >

C1143 STEERING ANGLE SENSOR

DTC/CIRCUIT DIAGNOSIS

C1143 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009460356

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC CONFIRMATION PROCEDURE has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With CONSULT

1. Turn the ignition switch OFF to ON.

2. Perform PS self-diagnosis.

Is DTC C1143 detected?

YES >> Proceed to diagnosis procedure. Refer to STC-22, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009460357

1.CHECK STEERING ANGLE SENSOR CIRCUIT

Check steering angle sensor circuit. Refer to BRC-88, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace malfunctioning component.

2.CHECK TERMINALS AND HARNESS CONNECTORS

Check the power steering control module pin termi nals for damage or loose connection with harness connec-

tor.

Is the inspection result normal?

YES >> Power steering control module is malfunctioni ng. Replace power steering oil pump assembly.

Refer to ST-38, "Removal and Installation"

.

NO >> Repair or replace malfunctioning component.

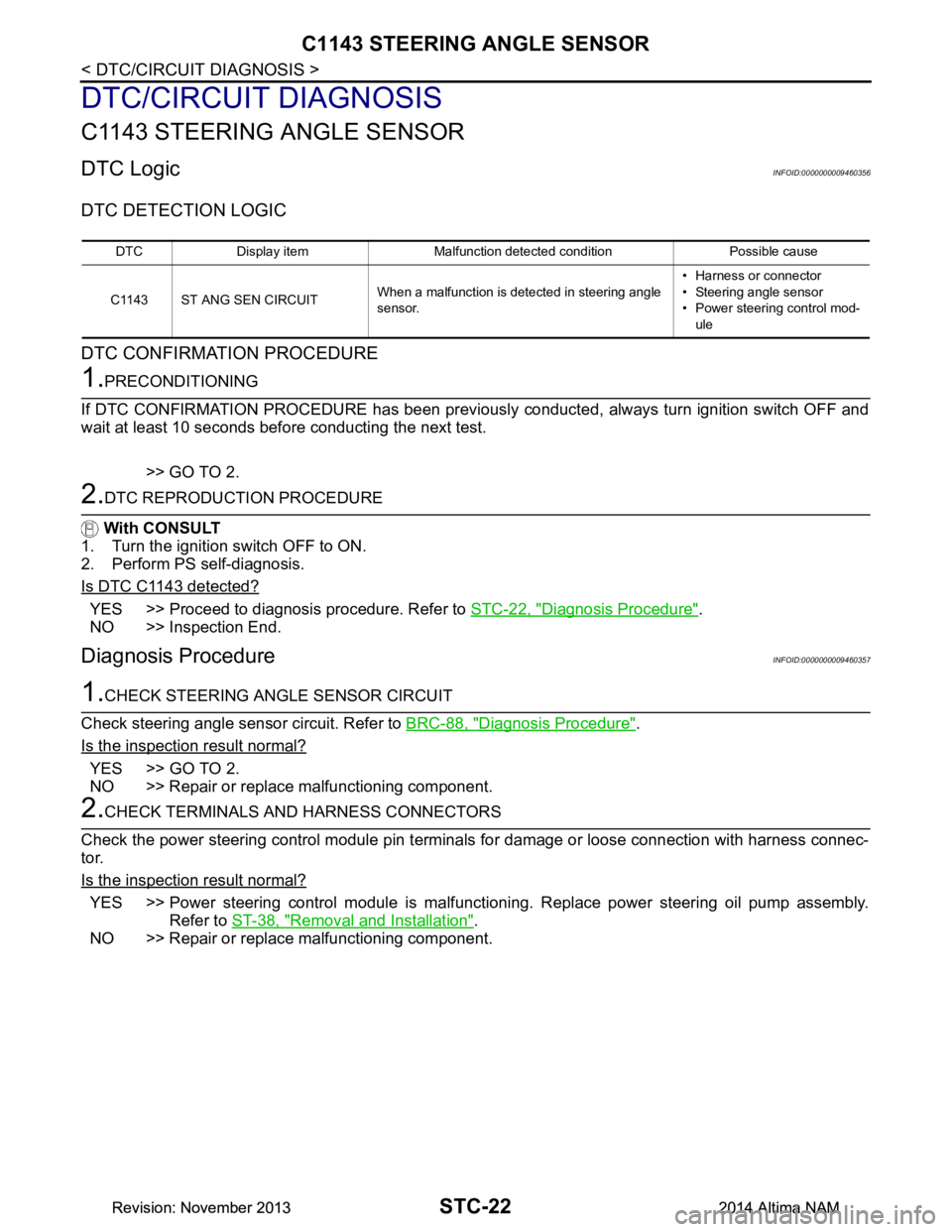

DTC Display item Malfunction detected condition Possible cause

C1143 ST ANG SEN CIRCUIT When a malfunction is detected in steering angle

sensor. • Harness or connector

• Steering angle sensor

• Power steering control mod-

ule

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4186 of 4801

STEERING WHEEL TURNING FORCE IS HEAVY OR LIGHTSTC-35

< SYMPTOM DIAGNOSIS >

C

D E

F

H I

J

K L

M A

B

STC

N

O P

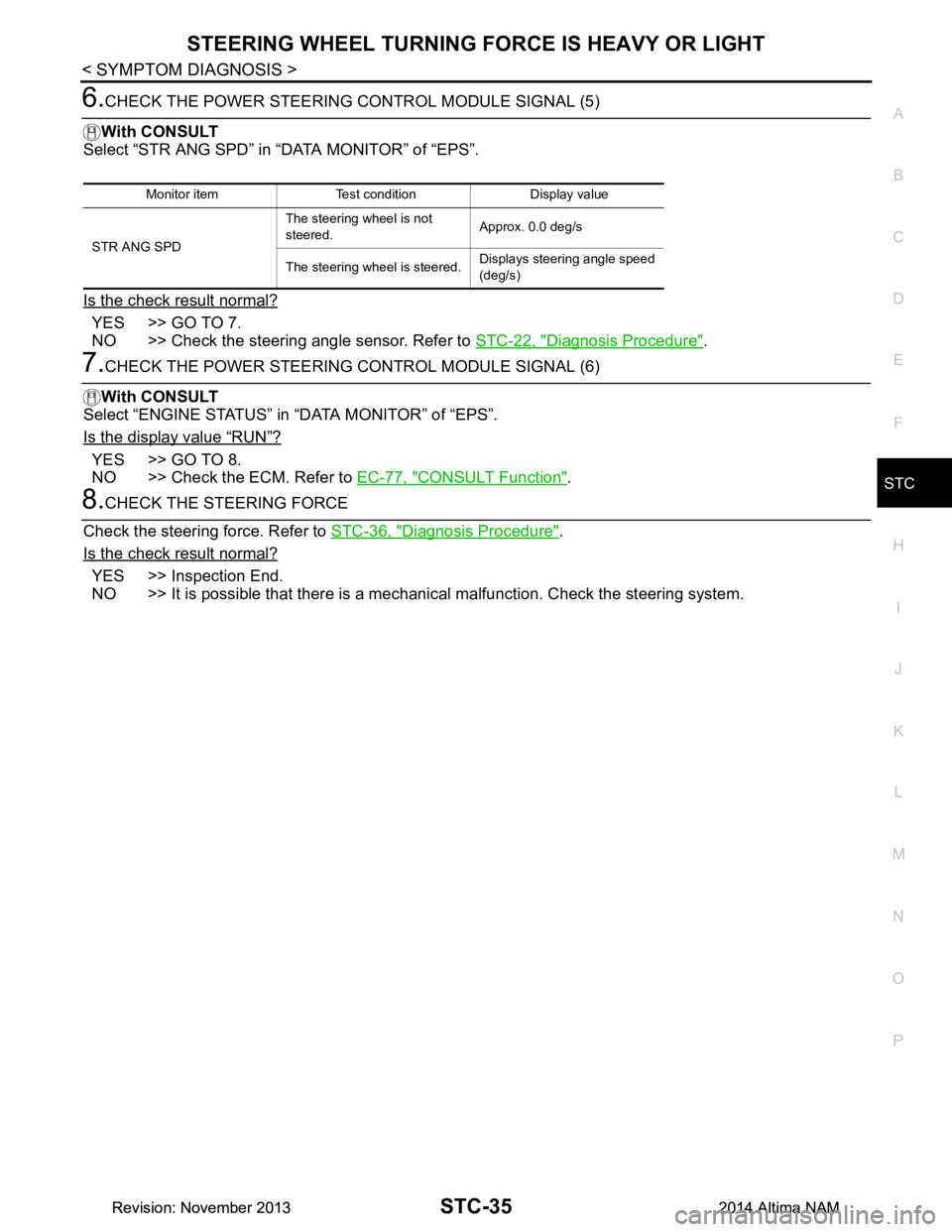

6.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (5)

With CONSULT

Select “STR ANG SPD” in “DATA MONITOR” of “EPS”.

Is the check result normal?

YES >> GO TO 7.

NO >> Check the steering angle sensor. Refer to STC-22, "Diagnosis Procedure"

.

7.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (6)

With CONSULT

Select “ENGINE STATUS” in “DATA MONITOR” of “EPS”.

Is the display value

“RUN”?

YES >> GO TO 8.

NO >> Check the ECM. Refer to EC-77, "CONSULT Function"

.

8.CHECK THE STEERING FORCE

Check the steering force. Refer to STC-36, "Diagnosis Procedure"

.

Is the check result normal?

YES >> Inspection End.

NO >> It is possible that there is a mechani cal malfunction. Check the steering system.

Monitor item Test condition Display value

STR ANG SPD The steering wheel is not

steered. Approx. 0.0 deg/s

The steering wheel is steered. Displays steering angle speed

(deg/s)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4189 of 4801

STC-38

< SYMPTOM DIAGNOSIS >

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

NO >> Check the combination meter, ABS actuator and electric unit (control unit). Refer to MWI-18,

"CONSULT Function (METER/M&A)" and BRC-33, "CONSULT Function (ABS)".

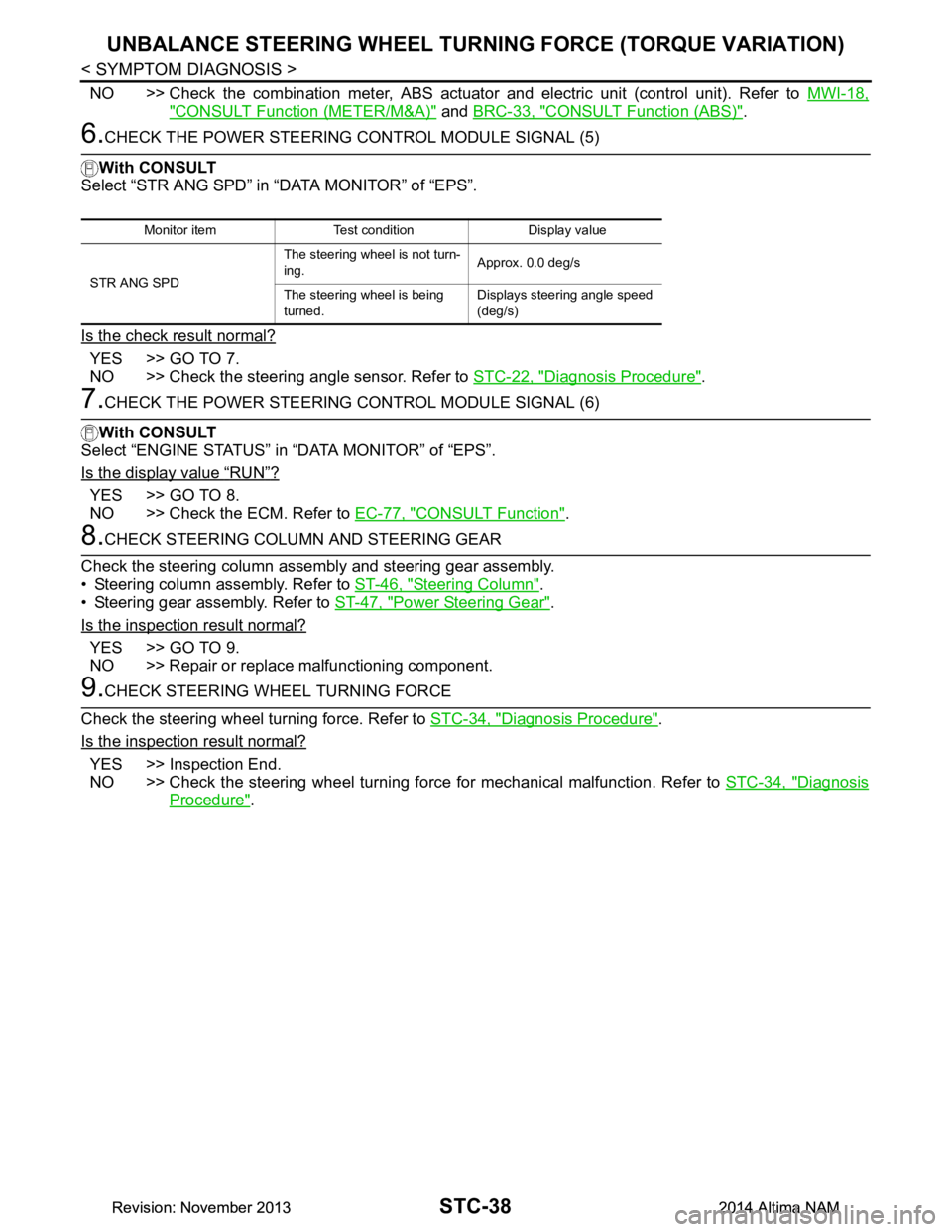

6.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (5)

With CONSULT

Select “STR ANG SPD” in “DATA MONITOR” of “EPS”.

Is the check result normal?

YES >> GO TO 7.

NO >> Check the steering angle sensor. Refer to STC-22, "Diagnosis Procedure"

.

7.CHECK THE POWER STEERING CONTROL MODULE SIGNAL (6)

With CONSULT

Select “ENGINE STATUS” in “DATA MONITOR” of “EPS”.

Is the display value

“RUN”?

YES >> GO TO 8.

NO >> Check the ECM. Refer to EC-77, "CONSULT Function"

.

8.CHECK STEERING COLUMN AND STEERING GEAR

Check the steering column assembly and steering gear assembly.

• Steering column assembly. Refer to ST-46, "Steering Column"

.

• Steering gear assembly. Refer to ST-47, "Power Steering Gear"

.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace malfunctioning component.

9.CHECK STEERING WHEEL TURNING FORCE

Check the steering wheel turning force. Refer to STC-34, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> Inspection End.

NO >> Check the steering wheel turning force for mechanical malfunction. Refer to STC-34, "Diagnosis

Procedure".

Monitor item Test condition Display value

STR ANG SPD The steering wheel is not turn-

ing. Approx. 0.0 deg/s

The steering wheel is being

turned. Displays steering angle speed

(deg/s)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4192 of 4801

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951694

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4216 of 4801

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

CONTENTS

TRANSAXLE & TRANSMISSION

CVT: RE0F10D

PRECAUTION ................ ...............................

9

PRECAUTIONS .............................................. .....9

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

9

Precaution for Procedure without Cowl Top Cover ......9

Precaution for TCM and Transaxle Assembly Re-

placement ............................................................ ......

9

General Precautions ...............................................10

On Board Diagnosis (OBD) System of CVT and

Engine ................................................................. ....

11

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ....

11

PREPARATION ...........................................13

PREPARATION .............................................. ....13

Special Service Tools .......................................... ....13

Commercial Service Tools ......................................13

SYSTEM DESCRIPTION .............................14

COMPONENT PARTS ................................... ....14

CVT CONTROL SYSTEM .........................................14

CVT CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ....

14

CVT CONTROL SYSTEM : TCM ............................16

CVT CONTROL SYSTEM : Transmission Range

Switch .................................................................. ....

16

CVT CONTROL SYSTEM : Primary Speed Sen-

sor ....................................................................... ....

16

CVT CONTROL SYSTEM : Output Speed Sensor ....16

CVT CONTROL SYSTEM : In put Speed Sensor ....17

CVT CONTROL SYSTEM : CVT Fluid Tempera-

ture Sensor .......................................................... ....

17

CVT CONTROL SYSTEM : Primary Pressure

Sensor ................................................................. ....

18

CVT CONTROL SYSTEM : Secondary Pressure

Sensor ................................................................. ....

18

CVT CONTROL SYSTEM : Primary Pressure So-

lenoid Valve ......................................................... ....

19

CVT CONTROL SYSTEM : Secondary Pressure

Solenoid Valve ..................................................... ....

19

CVT CONTROL SYSTEM : Select Solenoid Valve

....

19

CVT CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ....

19

CVT CONTROL SYSTEM : Line Pressure Sole-

noid Valve ............................................................ ....

20

CVT CONTROL SYSTEM : Overdrive Control

Switch .................................................................. ....

20

CVT CONTROL SYSTEM : O/D OFF Indicator

Lamp .................................................................... ....

20

CVT CONTROL SYSTEM : Shift Position Indica-

tor ........................................................................ ....

20

SHIFT LOCK SYSTEM ..............................................20

SHIFT LOCK SYSTEM : Component Parts Loca-

tion ....................................................................... ....

21

STRUCTURE AND OPERATION .....................22

TRANSAXLE .......................................................... ....22

TRANSAXLE : Cross-Sectional View ......................22

TRANSAXLE : Operation Stat us .............................23

TRANSAXLE : Transaxle Me chanism .....................23

TRANSAXLE : Oil Pressure System .......................26

TRANSAXLE : Component De scription ...................27

FLUID COOLER & FLUID WARMER SYSTEM .... ....27

FLUID COOLER & FLUID WARMER SYSTEM :

System Description .............................................. ....

28

SHIFT LOCK SYSTEM ..............................................28

SHIFT LOCK SYSTEM : Syst em Description ..........28

SYSTEM ...................... ......................................30

CVT CONTROL SYSTEM ..... .....................................30

CVT CONTROL SYSTEM : S ystem Description .....30

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4217 of 4801

TM-2

CVT CONTROL SYSTEM : Fail-safe .................. ...31

CVT CONTROL SYSTEM : Protection Control ... ...34

LINE PRESSURE CONTROL ................................ ...35

LINE PRESSURE CONTROL : System Descrip-

tion ....................................................................... ...

35

SHIFT CONTROL ................................................... ...35

SHIFT CONTROL : System Description .................36

SELECT CONTROL ............................................... ...37

SELECT CONTROL : System Description .............38

LOCK-UP CONTROL ............................................. ...38

LOCK-UP CONTROL : System Description ...........38

ON BOARD DIAGNOSTIC (OBD) SYSTEM .....40

Description ........................................................... ...40

Function of OBD .....................................................40

DIAGNOSIS SYSTEM (TCM) ............................41

DIAGNOSIS DESCRIPTION .................................. ...41

DIAGNOSIS DESCRIPTION : 1 Trip Detection Di-

agnosis and 2 Trip Detection Diagnosis .............. ...

41

DIAGNOSIS DESCRIPTION : DTC and DTC of

1st Trip ................................................................. ...

41

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ...

41

DIAGNOSIS DESCRIPTION : Counter System .....41

CONSULT Function ................................................43

ECU DIAGNOSIS INFORMATION ..............49

TCM ................................................................. ...49

Reference Value .................................................. ...49

Fail-safe ..................................................................56

Protection Control ...................................................59

DTC Inspection Priority Chart .................................59

DTC Index ..............................................................60

WIRING DIAGRAM .....................................62

CVT CONTROL SYSTEM ............................... ...62

Wiring diagram .................................................... ...62

CVT SHIFT LOCK SYSTEM ........................... ...73

Wiring diagram .................................................... ...73

BASIC INSPECTION ...................................77

DIAGNOSIS AND REPAIR WORK FLOW ..... ...77

Flowchart of Trouble Diagnosis ........................... ...77

Question sheet .......................................................78

ADDITIONAL SERVICE WHEN REPLACING

TCM ................................................................. ...

80

Description ........................................................... ...80

Work Procedure ......................................................80

ADDITIONAL SERVICE WHEN REPLACING

TRANSAXLE ASSEMBLY ............................. ...

81

Description ........................................................... ...81

Work Procedure ................................................... ...81

CVT FLUID ........................................................83

Replacement ........................................................ ...83

Adjustment ..............................................................84

STALL TEST .....................................................86

Work Procedure ................................................... ...86

CVT POSITION ..................................................87

Inspection ............................................................. ...87

Adjustment ..............................................................87

DTC/CIRCUIT DIAGNOSIS ........................88

U0073 COMMUNICATION BUS A OFF ......... ...88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

U0100 LOST COMMUNICATION (ECM A) .......89

DTC Logic ............................................................ ...89

Diagnosis Procedure ...............................................89

U0140 LOST COMMUNICATION (BCM) ..........90

DTC Logic ............................................................ ...90

Diagnosis Procedure ...............................................90

U0141 LOST COMMUNICATION (BCM A) ......91

DTC Logic ............................................................ ...91

Diagnosis Procedure ...............................................91

U0155 LOST COMMUNICATION (IPC) ............92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

U0300 CAN COMMUNICATION DATA ............93

DTC Logic ............................................................ ...93

Diagnosis Procedure ...............................................93

U1000 CAN COMM CIRCUIT ............................94

Description ........................................................... ...94

DTC Logic ...............................................................94

Diagnosis Procedure ...............................................94

U1117 LOST COMMUNICATION (ABS) ...........95

DTC Logic ............................................................ ...95

Diagnosis Procedure ...............................................95

P062F EEPROM ................................................96

Description ........................................................... ...96

DTC Logic ...............................................................96

Diagnosis Procedure ...............................................96

P0705 TRANSMISSION RANGE SENSOR A ...97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

Component Inspection ..........................................101

P0706 TRANSMISSION RANGE SENSOR A ..103

DTC Logic ............................................................ .103

Diagnosis Procedure .............................................103

Component Inspection ..........................................105

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4218 of 4801

TM-3

CEF

G H

I

J

K L

M A

B

TM

N

O P

P0711 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A .......................................... ..

106

DTC Logic ........................................................... ..106

Diagnosis Procedure .............................................107

P0712 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A .......................................... ..

110

DTC Logic ........................................................... ..110

Diagnosis Procedure .............................................110

Component Inspection ..........................................110

P0713 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A .......................................... ..

112

DTC Logic ........................................................... ..112

Diagnosis Procedure .............................................112

Component Inspection ..........................................113

P0715 INPUT SPEED SENSOR A ...................114

DTC Logic ........................................................... ..114

Diagnosis Procedure .............................................115

P0717 INPUT SPEED SENSOR A ...................117

DTC Logic ........................................................... ..117

Diagnosis Procedure .............................................118

P0740 TORQUE CONVERTER ........................120

DTC Logic ........................................................... ..120

Diagnosis Procedure .............................................121

P0743 TORQUE CONVERTER ........................122

DTC Logic ........................................................... ..122

Diagnosis Procedure .............................................123

P0744 TORQUE CONVERTER ........................124

DTC Logic ........................................................... ..124

Diagnosis Procedure .............................................125

P0746 PRESSURE CONTROL SOLENOID A ..126

DTC Logic ........................................................... ..126

Diagnosis Procedure .............................................127

P0776 PRESSURE CONTROL SOLENOID B ..128

DTC Logic ........................................................... ..128

Diagnosis Procedure .............................................129

P0778 PRESSURE CONTROL SOLENOID B ..130

DTC Logic ........................................................... ..130

Diagnosis Procedure .............................................130

P0779 PRESSURE CONTROL SOLENOID B ..132

DTC Logic ........................................................... ..132

Diagnosis Procedure .............................................132

P0841 TRANSMISSION FLUID PRESSURE

SEN/SW A ...................................................... ..

134

DTC Logic ........................................................... ..134

Diagnosis Procedure .............................................134

P0847 TRANSMISSION FLUID PRESSURE

SEN/SW B ...................................................... ..

135

DTC Logic ........................................................... ..135

Diagnosis Procedure ........................................... ..135

P0848 TRANSMISSION FLUID PRESSURE

SEN/SW B .......................................................

137

DTC Logic ............................................................ ..137

Diagnosis Procedure .............................................137

P084C TRANSMISSION FLUID PRESSURE

SEN/SW H .......................................................

139

DTC Logic ............................................................ ..139

Diagnosis Procedure .............................................139

P084D TRANSMISSION FLUID PRESSURE

SEN/SW H .......................................................

141

DTC Logic ............................................................ ..141

Diagnosis Procedure .............................................141

P0863 TCM COMMUNICATION .....................143

DTC Logic ..............................................................143

Diagnosis Procedure .............................................143

P0890 TCM ......................................................144

DTC Logic ..............................................................144

Diagnosis Procedure .............................................144

P0962 PRESSURE CONTROL SOLENOID A .145

DTC Logic ............................................................ ..145

Diagnosis Procedure .............................................145

P0963 PRESSURE CONTROL SOLENOID A .147

DTC Logic ............................................................ ..147

Diagnosis Procedure .............................................147

P0965 PRESSURE CONTROL SOLENOID B .149

DTC Logic ............................................................ ..149

Diagnosis Procedure .............................................150

P0966 PRESSURE CONTROL SOLENOID B .151

DTC Logic ............................................................ ..151

Diagnosis Procedure .............................................151

P0967 PRESSURE CONTROL SOLENOID B .153

DTC Logic ............................................................ ..153

Diagnosis Procedure .............................................153

P2765 INPUT SPEED SENSOR B ..................155

DTC Logic ..............................................................155

Diagnosis Procedure .............................................156

P2813 SELECT SOLENOID ...........................158

DTC Logic ..............................................................158

Diagnosis Procedure .............................................159

P2814 SELECT SOLENOID ...........................160

DTC Logic ..............................................................160

Diagnosis Procedure .............................................160

P2815 SELECT SOLENOID ...........................162

DTC Logic ..............................................................162

Diagnosis Procedure .............................................162

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4219 of 4801

TM-4

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ................................................................ .

164

Diagnosis Procedure ........................................... ..164

OVERDRIVE CONTROL SWITCH ..................166

Component Function Check ................................ ..166

Diagnosis Procedure .............................................166

Component Inspection ...........................................167

OD OFF INDICATOR LAMP ............................168

Component Function Check ................................ ..168

Diagnosis Procedure .............................................168

SHIFT POSITION INDICATOR CIRCUIT ........169

Component Parts Function Inspection ................ ..169

Diagnosis Procedure .............................................169

SHIFT LOCK SYSTEM ................................... .170

Component Function Check ................................ ..170

Diagnosis Procedure .............................................170

Component Inspection (Shift Lock Solenoid) ........172

Component Inspection (Park Position Switch) ......172

Component Inspection (Stop Lamp Switch) ..........173

SYMPTOM DIAGNOSIS ............................174

CVT CONTROL SYSTEM ............................... .174

Symptom Table ................................................... ..174

PERIODIC MAINTENANCE ..................... ..178

CVT FLUID ...................................................... .178

Inspection ............................................................ ..178

REMOVAL AND INSTALLATION ..............179

CVT SHIFT SELECTOR ................................. .179

Exploded View ..................................................... ..179

Removal and Installation .......................................179

Inspection ..............................................................180

CONTROL CABLE ..........................................181

Exploded View ..................................................... ..181

Removal and Installation .......................................181

Inspection and Adjustment ....................................182

TCM ..................................................................183

Exploded View ..................................................... ..183

Removal and Installation .......................................183

Adjustment .............................................................184

AIR BREATHER HOSE ...................................185

Removal and Installation ..................................... ..185

CONTROL VALVE ...........................................186

Exploded View ..................................................... ..186

Removal and Installation .......................................187

Inspection ..............................................................191

INPUT SPEED SENSOR .................................192

Exploded View ..................................................... ..192

Removal and Installation .......................................192

Inspection and Adjustment ................................... .192

PRIMARY SPEED SENSOR .......................... ..194

Exploded View ..................................................... .194

Removal and Installation .......................................194

Inspection and Adjustment ................................... .194

OUTPUT SPEED SENSOR ..............................196

Exploded View ..................................................... .196

Removal and Installation .......................................196

Inspection and Adjustment ................................... .196

DIFFERENTIAL SIDE OIL SEAL .....................197

Exploded View ..................................................... .197

Removal and Installation .......................................197

Inspection and Adjustment ................................... .198

CVT OIL WARMER SYSTEM ...........................199

WATER HOSE ........................................................ .199

WATER HOSE : Exploded View ...........................199

WATER HOSE : Removal and Installation ...........199

WATER HOSE : Inspection ..................................201

CVT FLUID COOLER HOSE .................................. .201

CVT FLUID COOLER HOSE : Exploded View .....201

CVT FLUID COOLER HOSE : Removal and In-

stallation ............................................................... .

202

CVT FLUID COOLER HOSE : Inspection .............203

CVT OIL WARMER ................................................ .203

CVT OIL WARMER : Exploded View ....................203

CVT OIL WARMER : Removal and Installation ....203

CVT OIL WARMER : Inspection .......................... .204

PLUG ................................................................205

Description ........................................................... .205

Exploded View ......................................................205

Removal and Installation .......................................205

Inspection and Adjustment ................................... .205

UNIT REMOVAL AND INSTALLATION ...206

TRANSAXLE ASSEMBLY ............................. ..206

Exploded View ..................................................... .206

Removal and Installation .......................................206

Inspection and Adjustment ................................... .208

UNIT DISASSEMBLY AND ASSEMBLY ..209

TORQUE CONVERTER AND CONVERTER

HOUSING OIL SEAL ...................................... ..

209

Exploded View ..................................................... .209

Disassembly ..........................................................209

Assembly ..............................................................209

Inspection ..............................................................210

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..........................................

212

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

212

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4220 of 4801

TM-5

CEF

G H

I

J

K L

M A

B

TM

N

O P

General Specification ..........................................

..

212

Shift Characteristics ..............................................212

Stall Speed ............................................................212

Torque Converter ..................................................212

Heater Thermostat ................................................212

CVT: RE0F10E

PRECAUTION ................ ............................

213

PRECAUTIONS .............................................. ..213

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

213

Precaution for Procedure without Cowl Top Cover ..213

Precaution for TCM and Transaxle Assembly Re-

placement ............................................................ ..

213

General Precautions .............................................214

On Board Diagnosis (OBD) System of CVT and

Engine ................................................................. ..

215

Removal and Installation Procedure for CVT Unit

Connector ............................................................ ..

215

PREPARATION .........................................217

PREPARATION .............................................. ..217

Special Service Tools .......................................... ..217

Commercial Service Tools ....................................217

SYSTEM DESCRIPTION ...........................218

COMPONENT PARTS ................................... ..218

CVT CONTROL SYSTEM .......................................218

CVT CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ..

218

CVT CONTROL SYSTEM : TCM ..........................219

CVT CONTROL SYSTEM : Transmission Range

Switch .................................................................. ..

219

CVT CONTROL SYSTEM : Primary Speed Sen-

sor ....................................................................... ..

219

CVT CONTROL SYSTEM : Output Speed Sensor ..220

CVT CONTROL SYSTEM : Input Speed Sensor ..220

CVT CONTROL SYSTEM : CVT Fluid Tempera-

ture Sensor .......................................................... ..

221

CVT CONTROL SYSTEM : Primary Pressure

Sensor ................................................................. ..

221

CVT CONTROL SYSTEM : Secondary Pressure

Sensor ................................................................. ..

222

CVT CONTROL SYSTEM : Primary Pressure So-

lenoid Valve ......................................................... ..

222

CVT CONTROL SYSTEM : Secondary Pressure

Solenoid Valve .................................................... ..

222

CVT CONTROL SYSTEM : Select Solenoid Valve

..

223

CVT CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ..

223

CVT CONTROL SYSTEM : Line Pressure Sole-

noid Valve ........................................................... ..

223

CVT CONTROL SYSTEM : Paddle Shifter ...........223

CVT CONTROL SYSTEM : Shift Position Indica-

tor ........................................................................ ..

223

SHIFT LOCK SYSTEM ............................................223

SHIFT LOCK SYSTEM : Component Parts Loca-

tion ....................................................................... ..

224

STRUCTURE AND OPERATION ...................225

TRANSAXLE .......................................................... ..225

TRANSAXLE : Cross-Sectional View ....................225

TRANSAXLE : Operation Stat us ...........................226

TRANSAXLE : Transaxle Me chanism ...................226

TRANSAXLE : Oil Pressure System .....................228

TRANSAXLE : Component De scription .................229

FLUID COOLER & FLUID WARMER SYSTEM .... ..229

FLUID COOLER & FLUID WARMER SYSTEM :

System Description .............................................. ..

230

SHIFT LOCK SYSTEM ............................................230

SHIFT LOCK SYSTEM : Syst em Description ........230

SYSTEM ...................... ....................................232

CVT CONTROL SYSTEM ..... ...................................232

CVT CONTROL SYSTEM : S ystem Description ...232

CVT CONTROL SYSTEM : Fa il-safe ....................233

CVT CONTROL SYSTEM : Pr otection Control .....236

LINE PRESSURE CONTROL ......................... .........237

LINE PRESSURE CONTROL : System Descrip-

tion ....................................................................... ..

237

SHIFT CONTROL .................................................. ..237

SHIFT CONTROL : System Description ................238

SELECT CONTROL ............................................... ..239

SELECT CONTROL : System Description ............239

LOCK-UP CONTROL ............................................ ..240

LOCK-UP CONTROL : System Description ..........240

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..242

Description .............................................................242

Function of OBD ....................................................242

DIAGNOSIS SYSTEM (TCM) ..........................243

DIAGNOSIS DESCRIPTION .................................. ..243

DIAGNOSIS DESCRIPTION : 1 Trip Detection Di-

agnosis and 2 Trip Detection Diagnosis .............. ..

243

DIAGNOSIS DESCRIPTION : DTC and DTC of

1st Trip ................................................................. ..

243

DIAGNOSIS DESCRIPTION : Malfunction Indica-

tor Lamp (MIL) ..................................................... ..

243

DIAGNOSIS DESCRIPTION : Counter System ....243

CONSULT Function ............................................. ..245

ECU DIAGNOSIS INFORMATION ............251

TCM .................................................................251

Reference Value .................................................. ..251

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM