ESP NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 4425 of 4801

![NISSAN TEANA 2014 Service Manual

TM-210

< UNIT DISASSEMBLY AND ASSEMBLY >[CVT: RE0F10D]

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEAL

Drive converter housing oil seal (1) evenly using a drift (A) (com-

mercial service tool) so th NISSAN TEANA 2014 Service Manual

TM-210

< UNIT DISASSEMBLY AND ASSEMBLY >[CVT: RE0F10D]

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEAL

Drive converter housing oil seal (1) evenly using a drift (A) (com-

mercial service tool) so th](/img/5/57390/w960_57390-4424.png)

TM-210

< UNIT DISASSEMBLY AND ASSEMBLY >[CVT: RE0F10D]

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEAL

Drive converter housing oil seal (1) evenly using a drift (A) (com-

mercial service tool) so that converter housing oil seal protrudes by

the dimension (B) respectively.

Unit: mm (in)

Unit: mm (in)

NOTE:

Converter housing oil seal pulling direction is used as the refer-

ence.

• After completing installation, check for CVT fluid leaks and CVT

fluid level. Refer to TM-178, "Inspection"

.

• Attach the pawl (A) of the torque converter to the drive sprocket hole (B) on the transaxle assembly side.

CAUTION:

• Rotate the torque converter fo r installing torque converter.

• Do not damage the bushing in side the torque converter

sleeve when installing the converter housing oil seal.

InspectionINFOID:0000000009464166

INSPECTION AFTER INSTALLATION

Commercial service tool: (A) Outer diameter: 65 (2.56)

Inner diameter: 60 (2.36)

(2) : Transaxle assembly

SCIA7908J

Dimension (B) 1.0 ± 0.5 (0.039 ± 0.020)

SCIA7909J

SCIA7907J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4444 of 4801

![NISSAN TEANA 2014 Service Manual

STRUCTURE AND OPERATIONTM-229

< SYSTEM DESCRIPTION > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TRANSAXLE : Component DescriptionINFOID:0000000009464201

FLUID COOLER & FLUID WARMER SYSTEM

Part n NISSAN TEANA 2014 Service Manual

STRUCTURE AND OPERATIONTM-229

< SYSTEM DESCRIPTION > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TRANSAXLE : Component DescriptionINFOID:0000000009464201

FLUID COOLER & FLUID WARMER SYSTEM

Part n](/img/5/57390/w960_57390-4443.png)

STRUCTURE AND OPERATIONTM-229

< SYSTEM DESCRIPTION > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TRANSAXLE : Component DescriptionINFOID:0000000009464201

FLUID COOLER & FLUID WARMER SYSTEM

Part name Function

Torque converter Increases engine torque and transmits it to the transaxle.

Oil pump Utilizes a vane-type oil pump that is driven by the engine through the oil pump drive chain in order to

increase efficiency of pump discharge volume in low-speed zone and optimize pump discharge volume

in high-speed zone. Discharged oil from oil pump is tr ansmitted to control valve. It is used as the oil of

primary and secondary pulley operation, the oil of clutch operation, and the lubricant for each part.

Forward clutch The forward clutch is wet and multiple plate type clutch that consists of clutch drum, piston, drive plate,

and driven plate. It is a clutch to move the vehicle forward by activating piston hydraulically, engaging

plates, and directly connecting sun gear and input shaft.

Reverse brake The reverse brake is a wet multiple-plate type brake that consists of transaxle case, piston, drive plate,

and driven plate. It is a brake to move the vehicle in reverse by activating piston hydraulically, engaging

plates, and fixing planetary gear.

Internal gear The internal gear is directly connected to forward clutch drum. It is a gear that moves the outer edge of

pinion planet of planet carrier. It transmits power to move the vehicle in reverse when the planet carrier

is fixed.

Planet carrier Composed of a carrier, pinion planet, and pinion shaft. This gear fixes and releases the planet carrier in

order to switch between forward and reverse driving.

Sun gear Sun gear is a set part with planet carrier and internal gear. It transmits transmitted force to primary fixed

sheave. It rotates in forward or reverse direction according to activation of either forward clutch or re-

verse brake.

Input shaft The input shaft is directly connected to forward clutch drum and transmits traction force from torque con-

verter. In shaft center, there are holes for hydraulic distribution to primary pulley and hydraulic distribution

for lockup ON/OFF.

Primary pulley It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the chain belt. The groove width changes according to wrapping radius of steel belt and pulley from low status to

overdrive status continuously with non-step. It is controlled with the oil pressures of primary pulley and

secondary pulley.

Secondary pulley

Chain belt

Manual shaft When the manual shaft is in the P position, the parking rod that is linked to the manual shaft rotates the

parking pole. When the parking pole rotates, it engages with the parking gear, fixing the parking gear. As

a result, the secondary pulley that is integrated with the parking gear is fixed.

Parking rod

Parking pawl

Parking gear

Output gear

The deceleration gears are composed of 2 stages: primary deceleration (output gear, idler gear pair) and

secondary deceleration (reduction gear, final gear pair). All of these gears are helical gears.

Idler gear

Reduction gear

Differential

Torque converter regulator

valve Adjusts the feed pressure to the torque converter to the optimum pressure corresponding to the driving

condition.

Pressure regulator valve Adjusts the discharge pressure from the oil pump to the optimum pressure (line pressure) corresponding

to the driving condition.

Torque converter clutch

control valve Adjusts the torque converter engage and disengage pressures.

Manual valve Distributes the clutch operation pressure to each circuit according to the selector lever position.

Secondary reducing valve Reduces line pressure and adjusts secondary pressure.

Primary reducing valve Reduces line pressure and adjusts primary pressure.

Pilot valve A Reduces line pressure and adjusts pilot pressure to the solenoid valves listed below.

• Primary pressure solenoid valve

• Secondary pressure solenoid valve

• Select solenoid valve

• Line pressure solenoid valve

Pilot valve B Reduces pilot pressure and adjusts pilot pressure to the torque converter clutch solenoid valve.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4445 of 4801

![NISSAN TEANA 2014 Service Manual

TM-230

< SYSTEM DESCRIPTION >[CVT: RE0F10E]

STRUCTURE AND OPERATION

FLUID COOLER & FLUID WARMER SYSTEM : System Description

INFOID:0000000009464202

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

NISSAN TEANA 2014 Service Manual

TM-230

< SYSTEM DESCRIPTION >[CVT: RE0F10E]

STRUCTURE AND OPERATION

FLUID COOLER & FLUID WARMER SYSTEM : System Description

INFOID:0000000009464202

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION](/img/5/57390/w960_57390-4444.png)

TM-230

< SYSTEM DESCRIPTION >[CVT: RE0F10E]

STRUCTURE AND OPERATION

FLUID COOLER & FLUID WARMER SYSTEM : System Description

INFOID:0000000009464202

CVT FLUID COOLER SCHEMATIC

COMPONENT DESCRIPTION

CVT Oil Warmer

• The CVT oil warmer (1) is installed on the front part of transaxle

assembly.

• When engine is started while engine and CVT are cold, engine coolant temperature rises more quickly than CVT fluid tempera-

ture. CVT oil warmer is provided with two circuits for CVT and

engine coolant respectively so that warmed engine coolant warms

CVT quickly. This helps shorten CVT warming up time, improving

fuel economy.

• A cooling effect is obtained when CVT fluid temperature is high.

Heater Thermostat

• The heater thermostat (1) is insta lled on the front part of transaxle

assembly.

• The heater thermostat open and close with set temperature.

SHIFT LOCK SYSTEM

SHIFT LOCK SYSTEM : System DescriptionINFOID:0000000009464203

The shift lever cannot be shifted from the “P” positi on unless the brake pedal is depressed while the ignition

switch is set to ON. The shift lock is unlocked by turn ing the shift lock solenoid ON when the ignition switch is

set to ON, the park position switch is turned ON (selec tor lever is in “P” position), and the stop lamp switch is

turned ON (brake pedal is depressed) as shown in the oper ation chart in the figure. Therefore, the shift lock

solenoid receives no ON signal and the shift lock remains locked if all of the above conditions are not fulfilled.

However, selector operation is allowed if the shift lock release button is pressed.

JSDIA3787GB

JSDIA2280ZZ

JSDIA2585ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4614 of 4801

![NISSAN TEANA 2014 Service Manual

DIFFERENTIAL SIDE OIL SEALTM-399

< REMOVAL AND INSTALLATION > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Install each differential side oil seal evenly using Tool so that differ-

ential side oi NISSAN TEANA 2014 Service Manual

DIFFERENTIAL SIDE OIL SEALTM-399

< REMOVAL AND INSTALLATION > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Install each differential side oil seal evenly using Tool so that differ-

ential side oi](/img/5/57390/w960_57390-4613.png)

DIFFERENTIAL SIDE OIL SEALTM-399

< REMOVAL AND INSTALLATION > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Install each differential side oil seal evenly using Tool so that differ-

ential side oil seal protrudes by the dimension (C) and (D) respect-

fully.

NOTE:

The reference is the installation direction of the differential side oil seal.

Drift to be used:

Inspection and AdjustmentINFOID:0000000009464358

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-377, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-286, "Adjustment".

(A) : Differential side oil seal (LH)

(B) : Differential side oil seal (RH)

JSDIA1836ZZ

Dimension (C) :Height difference from case end surface is within 0 ± 0.5 mm (0.0 ± 0.020

in).

Dimension (D) :Height difference from case end surface is within 0 ± 0.5 mm (0.0 ± 0.020

in).

Location Commercial Service Tools

Transaxle case side Commercial service tool with outer dia. 56 mm (2.20 in) and in-

ner dia. 50 mm (1.97 in)

Converter housing side

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4626 of 4801

![NISSAN TEANA 2014 Service Manual

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEALTM-411

< UNIT DISASSEMBLY AND ASSEMBLY > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Drive converter housing oil seal evenly using a drift (A) NISSAN TEANA 2014 Service Manual

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEALTM-411

< UNIT DISASSEMBLY AND ASSEMBLY > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Drive converter housing oil seal evenly using a drift (A)](/img/5/57390/w960_57390-4625.png)

TORQUE CONVERTER AND CONVERTER HOUSING OIL SEALTM-411

< UNIT DISASSEMBLY AND ASSEMBLY > [CVT: RE0F10E]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Drive converter housing oil seal evenly using a drift (A) (com- mercial service tool) so that converter housing oil seal protrudes by

the dimension (B) respectively.

Unit: mm (in)

Unit: mm (in)

NOTE:

Converter housing oil seal pulling direction is used as the refer-

ence.

• Attach the pawl of the torque converter to the drive sprocket hole on the transaxle assembly side.

CAUTION:

• Rotate the torque converter fo r installing torque converter.

• Do not damage the bushing inside the torque converter

sleeve when installing the converter housing oil seal.

InspectionINFOID:0000000009464378

INSPECTION AFTER INSTALLATION

Commercial service tool: (A) Outer diameter: 65 (2.56)

Inner diameter: 60 (2.36)

: Transaxle assembly

SCIA7908J

Dimension (B) 1.0 ± 0.5 (0.039 ± 0.020)

SCIA7909J

SCIA7907J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4678 of 4801

PRECAUTIONSWT-3

< PRECAUTION >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951708

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Service Notice and Precautions for TPMSINFOID:0000000009464472

WARNING:

Radio waves could adversely affect electrical medi cal equipment. Those who use a pacemaker should

contact the electrical medical equipment manu facturer for possible influences before use.

• Low tire pressure warning lamp blinks for 1 minute, then turns ON when any malfunction occurs except low

tire pressure. Erase the self-diagnosis memories for Tire Pressure Monitoring System (TPMS), or register

the ID to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-25, "Work Procedure"

.

• ID registration is required when replacing or rotating wheels, replacing tire pressure sensor or BCM. Refer to WT-25, "Work Procedure"

.

• For easy fill tire alert function, refer to the following. WT-9, "Easy Fill Tire Alert Function"

- When inflating the tires, park the vehicle in the safe area and ensure the safety of the working area.

- Read and understand the easy fill tire alert function prior to use.

- Inflate the tires one at a time.

- If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

easy fill tire alert function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try again.

The air filler pressure may be weak or out of service area.

- Despite the high-precision TPMS pressure sensor, an i ndicated value may differ from that of the pressure

gauge.

- Air pressure is measured rather high due to the rise in tire air temperature after driving.

- If TPMS is malfunctioning, the easy fill tire alert is unusable.

• Replace grommet seal, valve core and valve cap of tire pressure sensor in TPMS when replacing each tire

by reaching the wear limit. Refer to WT-57, "Exploded View"

.

• Because the tire pressure sensor conforms to No rth America radio law, the following items must be

observed.

- The sensor may be used only in North America.

- It may not be used in any method other than the specified method.

- It must not be disassembled or modified.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 4684 of 4801

SYSTEMWT-9

< SYSTEM DESCRIPTION >

C

D

F

G H

I

J

K L

M A

B

WT

N

O P

System DescriptionINFOID:0000000009464484

When the vehicle has reached a speed of 40 km/h (25 MPH) or greater, the BCM receives a signal transmitted

from the tire pressure sensors/transmitters installed in each wheel. If the BCM detects low inflation pressure or

a system malfunction, it sends a signal to the combi nation meter via CAN communication to illuminate the low

tire pressure warning lamp. In addition, a warning message will be displayed in the vehicle information display.

Refer to the Owner’s Manual for additional information.

The tire pressure monitoring system (TPMS) has Easy fill ti re alert function to aid in tire inflation. Refer to WT-

9, "Easy Fill Tire Alert Function".

Low Tire Pressure Warning Lamp and Display Indications

Easy Fill Tire Alert FunctionINFOID:0000000009464485

NOTE:

When beginning tire inflation, it takes a few seconds for t he Easy fill tire alert to function. If there is no

response for approximately 15 seconds or more, cancel t he Easy fill tire alert function and move the vehicle

approximately 1 m (3.2 ft) backward or forward to try again.

• The Easy fill tire alert function operates only when t he select lever position is in P-range with the ignition

switch ON.

• This function informs the driver with a visual and audible indication that the recommended COLD tire pres-

sure has been reached.

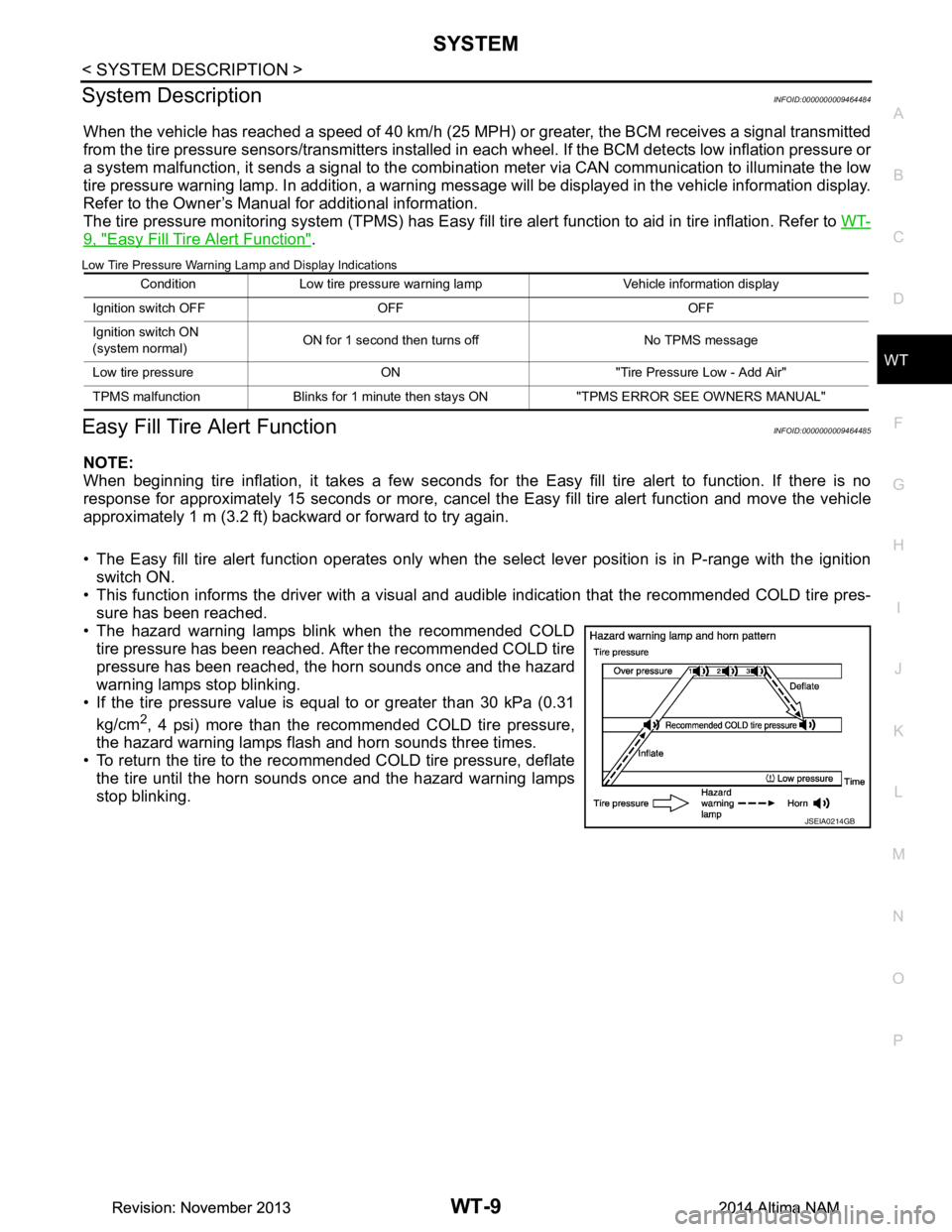

• The hazard warning lamps blink when the recommended COLD tire pressure has been reached. After the recommended COLD tire

pressure has been reached, the horn sounds once and the hazard

warning lamps stop blinking.

• If the tire pressure value is equal to or greater than 30 kPa (0.31

kg/cm

2, 4 psi) more than the recommended COLD tire pressure,

the hazard warning lamps flash and horn sounds three times.

• To return the tire to the recommended COLD tire pressure, deflate

the tire until the horn sounds once and the hazard warning lamps

stop blinking.

Condition Low tire pressure warning lamp Vehicle information display

Ignition switch OFF OFF OFF

Ignition switch ON

(system normal) ON for 1 second then turns off No TPMS message

Low tire pressure ON "Tire Pressure Low - Add Air"

TPMS malfunction Blinks for 1 minute th en stays ON "TPMS ERROR SEE OWNERS MANUAL"

JSEIA0214GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM