Key NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 993 of 4801

INTELLIGENT KEY BATTERYDLK-225

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY BATTERY

Removal and InstallationINFOID:0000000009461977

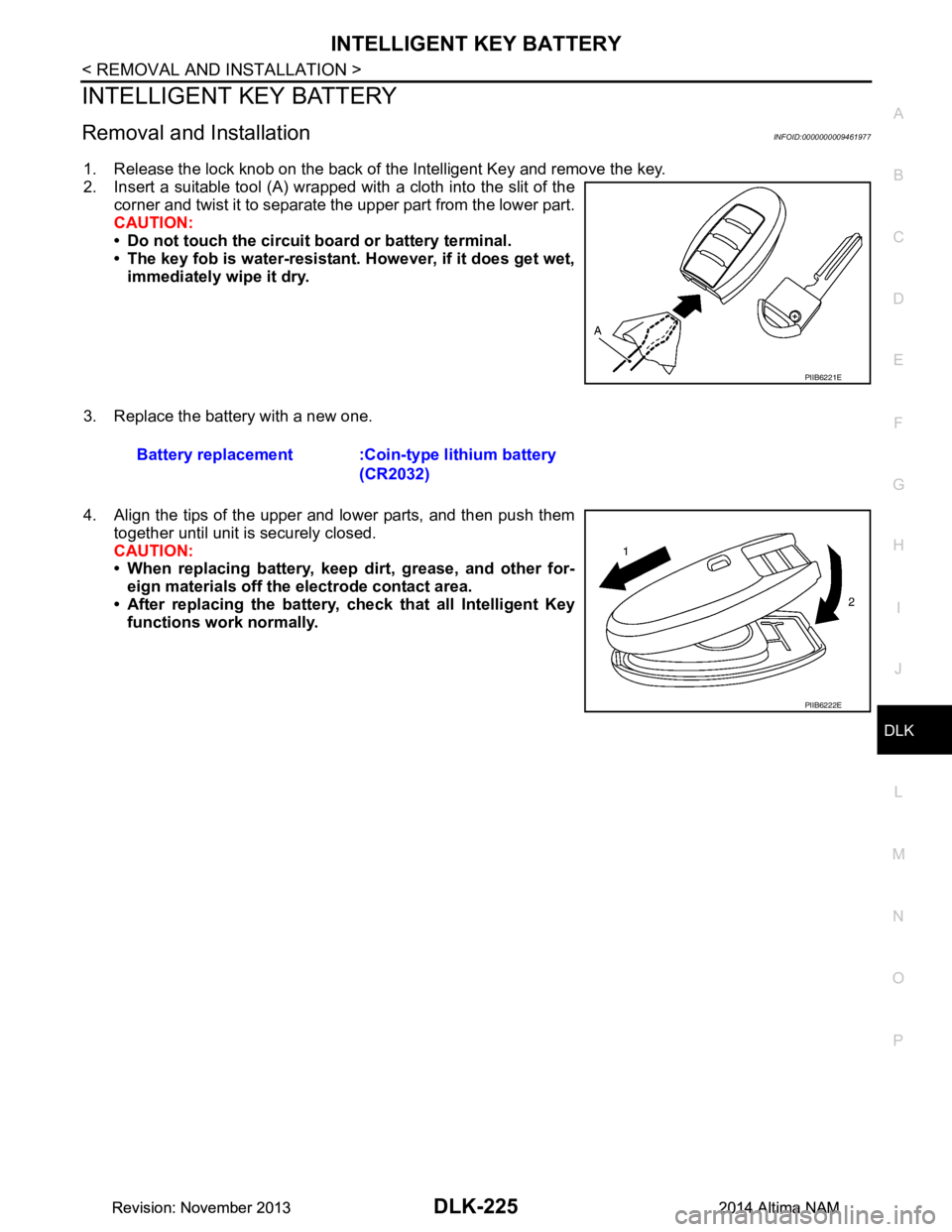

1. Release the lock knob on the back of the Intelligent Key and remove the key.

2. Insert a suitable tool (A) wrapped with a cloth into the slit of the corner and twist it to separate the upper part from the lower part.

CAUTION:

• Do not touch the circuit board or battery terminal.

• The key fob is water-resistant. However, if it does get wet,

immediately wipe it dry.

3. Replace the battery with a new one.

4. Align the tips of the upper and lower parts, and then push them together until unit is securely closed.

CAUTION:

• When replacing battery, keep dirt, grease, and other for-

eign materials off the electrode contact area.

• After replacing the battery, check that all Intelligent Key

functions work normally.

PIIB6221E

Battery replacement :Coin-type lithium battery

(CR2032)

PIIB6222E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1030 of 4801

![NISSAN TEANA 2014 Service Manual

EC-30

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid ValveINFOID:0000000009462066

Intake valve timing control sol NISSAN TEANA 2014 Service Manual

EC-30

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid ValveINFOID:0000000009462066

Intake valve timing control sol](/img/5/57390/w960_57390-1029.png)

EC-30

< SYSTEM DESCRIPTION >[QR25DE]

COMPONENT PARTS

ECM receives the signals as shown in the figure.

Intake Valve Timing Control Solenoid ValveINFOID:0000000009462066

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

Intake Valve Timing Intermediate Lock Control Solenoid ValveINFOID:0000000009462067

Intake valve timing intermediate lock control solenoid valve is acti-

vated by ON/OFF signals from the ECM.

The intake valve timing intermediate lock control solenoid valve

opens/closes the path of oil pressure acting on the lock key in the

camshaft sprocket (INT).

• When the solenoid valve becomes ON, oil pressure to the lock key

is trained to perform intermediate lock.

• When the solenoid valve becomes OFF, oil pressure is acted on the lock key to release the intermediate lock.

Exhaust Valve Timing Control Position SensorINFOID:0000000009462068

Exhaust valve timing control position sensor detects the protrusion of

the signal plate installed to the exhaust camshaft front end.

This sensor signal is used for sensing a position of the exhaust cam-

shaft.

The sensor consists of a permanent magnet and Hall IC.

When engine is running, the high and low parts of the teeth cause

the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

JMBIA0714GB

PBIB1842E

PBIB1842E

JPBIA5847ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1051 of 4801

![NISSAN TEANA 2014 Service Manual

SYSTEMEC-51

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The intake valve timing intermediate lock control improv

es the cleaning ability of exhaust gas at cold starting

by fixing NISSAN TEANA 2014 Service Manual

SYSTEMEC-51

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The intake valve timing intermediate lock control improv

es the cleaning ability of exhaust gas at cold starting

by fixing](/img/5/57390/w960_57390-1050.png)

SYSTEMEC-51

< SYSTEM DESCRIPTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

The intake valve timing intermediate lock control improv

es the cleaning ability of exhaust gas at cold starting

by fixing the camshaft sprocket (INT) with two lock keys and bringing the cam phase into intermediate phase.

Cam phase is fixed at the intermediate phase by two lock keys in the camshaft sprocket (INT). Lock key 1 con-

trols retard position and lock key 2 controls advance position.

ECM controls the intermediate phase lock by opening/clos ing the intake valve timing intermediate lock control

solenoid valve to control oil pressure acti ng on the lock key and locking/unlocking the lock key.

Lock/Unlock Activation

When ECM activates the intake valve timing intermediate lock control solenoid valve, oil pressure generated in

the oil pump is drained through the oil pressure path in t he control valve. Since oil pressure is not acted on the

lock key, the lock key position is fixed by the spri ng tension and the cam phase is fixed at the intermediate

phase.

When ECM deactivates the intake valve timing intermediate lock control solenoid valve, unlocking oil pressure

acts on each lock key. Lock key 1 is not released because it is under load due to sprocket rotational force. For

this reason, lock key 2 is released first by being pushed up by unlocking oil pressure. When lock key 2 is

released, some clearance is formed between lock key 1 and the rotor due to sprocket rotational force and

return spring force. Accordingly, lock key 1 is pushed up by unlocking oil pressure and the intermediated

phase lock is released.

When stopping the engine

When the ignition switch is turned from idle state to OFF, ECM receives an ignition switch signal from BCM via

CAN communication and activates the intake valve timing intermediate lock control solenoid valve and drains

oil pressure acting on the lock key before activating the intake valve timing control solenoid valve and operat-

ing the cam phase toward the advance position.

The cam phase is fixed by the lock key when shifting to the intermediated phase and ECM performs Lock

judgment to stop the engine.

When starting the engine

JPBIA6317GB

JPBIA5970GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1052 of 4801

![NISSAN TEANA 2014 Service Manual

EC-52

< SYSTEM DESCRIPTION >[QR25DE]

SYSTEM

When starting the engine by cold start, ECM judges the

locked/unlocked state when ignition switch is turned

ON. When judged as locked state (fixed at the NISSAN TEANA 2014 Service Manual

EC-52

< SYSTEM DESCRIPTION >[QR25DE]

SYSTEM

When starting the engine by cold start, ECM judges the

locked/unlocked state when ignition switch is turned

ON. When judged as locked state (fixed at the](/img/5/57390/w960_57390-1051.png)

EC-52

< SYSTEM DESCRIPTION >[QR25DE]

SYSTEM

When starting the engine by cold start, ECM judges the

locked/unlocked state when ignition switch is turned

ON. When judged as locked state (fixed at the intermedi ate phase), the intake valve timing intermediate lock

control solenoid valve is activated. Since oil pre ssure does not act on the lock key even when the engine is

started, the cam phase is fixed at the intermediate phas e and the intake valve timing control is not performed.

When the engine stops without locking the cam phase at the intermediate phase due to an engine stall and the

state is not judged as locked, the intake valve timing intermediate lock control solenoid valve and the intake

valve timing control solenoid valve are activated and the cam phase shifts to the advanced position to be

locked at the intermediate phase. Even when not locked in the intermediate lock phase due to no oil pressure

or low oil pressure, a ratchet structure of the camshaft sprocket (INT) rotor allows the conversion to the inter-

mediate phase in stages by engine vibration.

When engine coolant temperature is more than 60 °C, the intake valve timing is controlled by deactivating the

intake valve timing intermediate lock control so lenoid valve and releasing the intermediate phase lock.

When the engine is started after warming up, ECM releas es the intermediate phase lock immediately after the

engine start and controls the intake valve timing.

EXHAUST VALVE TIMING CONTROL

EXHAUST VALVE TIMING CONT ROL : System DescriptionINFOID:0000000009462097

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL CHART

JPBIA4761GB

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed and piston position

Exhaust valve

timing control Exhaust valve timing control

solenoid valve

Camshaft position sensor (PHASE)

Engine oil temperature sensor Engine oil temperature

Exhaust valve timing control position

sensor Exhaust valve timing signal

Combination meter CAN commu-

nication Vehicle speed signal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1171 of 4801

![NISSAN TEANA 2014 Service Manual

BASIC INSPECTIONEC-171

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 mi NISSAN TEANA 2014 Service Manual

BASIC INSPECTIONEC-171

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 mi](/img/5/57390/w960_57390-1170.png)

BASIC INSPECTIONEC-171

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Check idle speed.

For procedure, refer to EC-534, "Inspection"

.

For specification, refer to EC-541, "Idle Speed"

.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-177, "Work Procedure"

.

>> GO TO 5.

5.PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Perform EC-178, "Work Procedure"

.

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-179, "Work Procedure"

.

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 7.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.CHECK TARGET IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

For procedure, refer to EC-534, "Inspection"

.

For specification, refer to EC-541, "Idle Speed"

.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-329, "DTC Logic"

.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-326, "DTC Logic"

.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace. Then GO TO 4

9.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of NVIS (NATS) system and regi stration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

.

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

PBIA8513J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1173 of 4801

![NISSAN TEANA 2014 Service Manual

BASIC INSPECTIONEC-173

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refe NISSAN TEANA 2014 Service Manual

BASIC INSPECTIONEC-173

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refe](/img/5/57390/w960_57390-1172.png)

BASIC INSPECTIONEC-173

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

17.DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-329, "DTC Logic"

.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-326, "DTC Logic"

.

Is the inspection result normal?

YES >> GO TO 18.

NO >> Repair or replace. Then GO TO 4

18.CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM f unction. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of NVIS (NATS) system and regi stration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

.

>> GO TO 4.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1175 of 4801

![NISSAN TEANA 2014 Service Manual

ADDITIONAL SERVICE WHEN REPLACING ECMEC-175

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

• During programming, maintain the following conditions:

- Ignition switch: ON

- Electri NISSAN TEANA 2014 Service Manual

ADDITIONAL SERVICE WHEN REPLACING ECMEC-175

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

• During programming, maintain the following conditions:

- Ignition switch: ON

- Electri](/img/5/57390/w960_57390-1174.png)

ADDITIONAL SERVICE WHEN REPLACING ECMEC-175

< BASIC INSPECTION > [QR25DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

O

• During programming, maintain the following conditions:

- Ignition switch: ON

- Electric load: OFF

- Brake pedal: Not depressed

- Battery voltage: 12 – 13.5 V (Be sure to check the va lue of battery voltage by selecting “BATTERY VOLT” in

“Data monitor” of CONSULT.)

>> GO TO 6.

5.REPLACE ECM

Replace ECM. Refer to EC-540, "Removal and Installation"

.

>> GO TO 6.

6.PERFORM INITIALIZATION OF NATS SYSTEM AND REGISTRATION OF ALL NATS IGNITION KEY IDS

Refer to SEC-66, "ECM : Work Procedure"

.

>> GO TO 7.

7.CHECK ECM DATA STATUS

Check if the data is successfully copied from the EC M at Step 1 (before replacement) and saved in CONSULT.

Is the data saved successfully?

YES >> GO TO 8.

NO >> GO TO 9.

8.WRITE ECM DATA

With CONSULT

1. Select “WRITING DATA FOR REPLC CPU” in “W ORK SUPPORT” mode of “ENGINE” using CONSULT.

2. Follow the instruction of CONSULT display.

NOTE:

The data saved by “SAVING DATA FOR REPLC CPU” is written to ECM.

>> GO TO 10.

9.PERFORM VIN REGISTRATION

Refer to EC-176, "Work Procedure"

.

>> GO TO 10.

10.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

Refer to EC-177, "Work Procedure"

.

>> GO TO 11.

11 .PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Refer to EC-178, "Work Procedure"

.

>> GO TO 12.

12.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-179, "Work Procedure"

.

>> END

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1633 of 4801

![NISSAN TEANA 2014 Service Manual

ECM

EC-633

< ECU DIAGNOSIS INFORMATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

OP0463 0463 FUEL LEVL SEN/CIRC — 2

×BEC-866

P0500 0500

VEH SPEED SEN/CIRC*8—2×BEC-867

P0506 0506 ISC SYSTEM — NISSAN TEANA 2014 Service Manual

ECM

EC-633

< ECU DIAGNOSIS INFORMATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

OP0463 0463 FUEL LEVL SEN/CIRC — 2

×BEC-866

P0500 0500

VEH SPEED SEN/CIRC*8—2×BEC-867

P0506 0506 ISC SYSTEM —](/img/5/57390/w960_57390-1632.png)

ECM

EC-633

< ECU DIAGNOSIS INFORMATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

EC

NP

OP0463 0463 FUEL LEVL SEN/CIRC — 2

×BEC-866

P0500 0500

VEH SPEED SEN/CIRC*8—2×BEC-867

P0506 0506 ISC SYSTEM — 2 ×BEC-869

P0507 0507 ISC SYSTEM — 2 ×BEC-871

P050A 050A COLD START CONTROL — 2 ×AEC-873

P050E 050E COLD START CONTROL — 2 ×AEC-873

P0520 0520 EOP SENSOR/SWITCH — 2 — — EC-875

P0524 0524 ENGINE OIL PRESSURE — 1 — —EC-878

P0603 0603 ECM BACK UP/CIRCUIT — 2×BEC-881

P0605 0605 ECM — 1 or 2 × or — B EC-883

P0607 0607 ECM — 1 ×BEC-884

P0643 0643 SENSOR POWER/CIRC — 1 ×BEC-885

P0850 0850 P-N POS SW/CIRCUIT — 2 ×BEC-887

P1148 1148 CLOSED LOOP-B1 — 1 ×AEC-890

P1168 1168 CLOSED LOOP-B2 — 1 ×AEC-890

P1212 1212 TCS/CIRC — 2 — — EC-891

P1217 1217 ENG OVER TEMP — 1×BEC-892

P1225 1225 CTP LEARNING-B1 — 2 — — EC-895

P1226 1226 CTP LEARNING-B1 — 2 — —EC-896

P1550 1550 BAT CURRENT SENSOR — 2 — —EC-897

P1551 1551 BAT CURRENT SENSOR — 2 — —EC-899

P1552 1552 BAT CURRENT SENSOR — 2 — —EC-899

P1553 1553 BAT CURRENT SENSOR — 2 — —EC-901

P1554 1554 BAT CURRENT SENSOR — 2 — —EC-903

P1556 1556 BAT TMP SEN/CIRC — 2 — —EC-906

P1557 1557 BAT TMP SEN/CIRC — 2 — —EC-906

P1564 1564 ASCD SW — 1 — —EC-908

P1572 1572 ASCD BRAKE SW — 1 — — EC-911

P1574 1574 ASCD VHL SPD SEN — 1 — —EC-918

P1610 1610 LOCK MODE — 2 — —SEC-68

P1611 1611 ID DISCORD, IMM-ECM — 2 — —SEC-69

P1612 1612 CHAIN OF ECM-IMMU — 2 — — SEC-70

P1614 1614 CHAIN OF IMMU-KEY — 2 — —SEC-71

P1800 1800 VIAS S/V-1 — 2 — — EC-920

P1801 1801 VIAS S/V-2 — 2 — —EC-922

P1805 1805 BRAKE SW/CIRCUIT — 2 — —EC-924

P2096 2096 A/F SENSOR1 (B1) — 2×AEC-927

P2097 2097 A/F SENSOR1 (B1) — 2 ×AEC-927

P2098 2098 A/F SENSOR1 (B2) — 2 ×AEC-927

P2099 2099 A/F SENSOR1 (B2) — 2 ×AEC-927

P2100 2100 ETC MOT PWR-B1 — 1 ×BEC-931

P2101 2101 ETC FNCTN/CIRC-B1 — 1 ×BEC-933

DTC*1

Items

(CONSULT screen terms) SRT

code Trip MIL Permanent

DTC group*4Refer-

ence page

CONSULT

GST

*2ECM*3

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1676 of 4801

![NISSAN TEANA 2014 Service Manual

EC-676

< BASIC INSPECTION >[VQ35DE]

BASIC INSPECTION

2. Rev engine (2,000 to 3,000 rpm) 2 or 3 times under no load,

then run engine at idle speed for approximately 1 minute.

3. Check idle speed.

For NISSAN TEANA 2014 Service Manual

EC-676

< BASIC INSPECTION >[VQ35DE]

BASIC INSPECTION

2. Rev engine (2,000 to 3,000 rpm) 2 or 3 times under no load,

then run engine at idle speed for approximately 1 minute.

3. Check idle speed.

For](/img/5/57390/w960_57390-1675.png)

EC-676

< BASIC INSPECTION >[VQ35DE]

BASIC INSPECTION

2. Rev engine (2,000 to 3,000 rpm) 2 or 3 times under no load,

then run engine at idle speed for approximately 1 minute.

3. Check idle speed.

For procedure, refer to EC-992, "Work Procedure"

.

For specification, refer to EC-998, "Idle Speed"

.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RE LEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-681, "Work Procedure"

.

>> GO TO 5.

5.PERFORM THROTTLE VALVE CL OSED POSITION LEARNING

Perform EC-682, "Work Procedure"

.

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Perform EC-683, "Work Procedure"

.

Is Idle Air Volume Learning carried out successfully?

YES >> GO TO 7.

NO >> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.CHECK IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

For procedure, refer to EC-992, "Work Procedure"

.

For specification, refer to EC-998, "Idle Speed"

.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 8.

8.DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor (PHASE) and circuit. Refer to EC-820, "Diagnosis Procedure"

.

• Check crankshaft position sensor (POS) and circuit. Refer to EC-817, "Diagnosis Procedure"

.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair or replace malfunctioning part. Then GO TO 4.

9.CHECK ECM FUNCTION

1. Substitute with a non-malfunctioning ECM to check EC M function. (ECM may be the cause of the incident,

although this is rare.)

2. Perform initialization of NVIS (NAT S) system and registration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

.

>> GO TO 4.

10.CHECK IGNITION TIMING

1. Run engine at idle.

2. Check ignition timing with a timing light.

For procedure, refer to EC-993, "Work Procedure"

.

PBIA8513J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1678 of 4801

![NISSAN TEANA 2014 Service Manual

EC-678

< BASIC INSPECTION >[VQ35DE]

BASIC INSPECTION

2. Perform initialization of NVIS (NAT

S) system and registration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

.

> NISSAN TEANA 2014 Service Manual

EC-678

< BASIC INSPECTION >[VQ35DE]

BASIC INSPECTION

2. Perform initialization of NVIS (NAT

S) system and registration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

.

>](/img/5/57390/w960_57390-1677.png)

EC-678

< BASIC INSPECTION >[VQ35DE]

BASIC INSPECTION

2. Perform initialization of NVIS (NAT

S) system and registration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

.

>> GO TO 4.

19.INSPECTION END

If ECM is replaced during this BASIC INSPECTION procedure, perform EC-679, "Work Procedure"

.

>> INSPECTION END

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM