seat adjustment NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 97 of 4801

BR-1

BRAKES

C

D E

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Brake System ....................................3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION ..............................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

6

NVH Troubleshooting Chart ................................ ......6

BASIC INSPECTION ....................................7

BRAKE PEDAL .............................................. .....7

Inspection ............................................................ ......7

BRAKE FLUID .....................................................8

Inspection ............................................................ ......8

BRAKE MASTER CYLINDER ........................ .....9

Inspection ............................................................ ......9

On Board Inspection .................................................9

BRAKE BOOSTER ............................................10

Inspection ............................................................ ....10

FRONT DISC BRAKE .................................... ....11

BRAKE PAD .......................................................... ....11

BRAKE PAD : Inspection ........................................11

DISC ROTOR ......................................................... ....11

DISC ROTOR : Inspection ......................................11

REAR DISC BRAKE .........................................12

BRAKE PAD .......................................................... ....12

BRAKE PAD : Inspection .........................................12

DISC ROTOR ......................................................... ....12

DISC ROTOR : Inspection .......................................12

PERIODIC MAINTENANCE ........................13

BRAKE PEDAL ................................ .................13

Inspection and Adjustment .................................. ....13

BRAKE FLUID ................................. .................14

Drain and Refill .................................................... ....14

Bleeding Brake System ...........................................14

FRONT DISC BRAKE .......................................16

Brake Burnishing ................................................. ....16

REAR DISC BRAKE .........................................17

Brake Burnishing ................................................. ....17

REMOVAL AND INSTALLATION ...............18

BRAKE PEDAL ................................ .................18

Exploded View ..................................................... ....18

Removal and Installation .........................................18

BRAKE PIPING ................................ .................20

FRONT ................................................................... ....20

FRONT : Exploded View .........................................20

FRONT : Hydraulic Piping .......................................21

FRONT : Removal and Installation ..........................21

REAR ..................................................................... ....23

REAR : Exploded View ............................................23

REAR : Hydraulic Piping ..........................................24

REAR : Removal and Installation ............................24

BRAKE MASTER CYLINDER ..........................26

Exploded View .........................................................26

Removal and Installation .........................................26

Revision: November 20132014 Altima NAM

Page 147 of 4801

BRC-1

BRAKES

C

D E

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

PRECAUTION ................ ...............................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Brake System ....................................4

Precaution for Brake Control .....................................5

Precaution for CAN System ................................ ......5

Precaution for Work ..................................................6

PREPARATION ............................................7

PREPARATION .............................................. .....7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................7

SYSTEM DESCRIPTION ..............................8

COMPONENT PARTS ................................... .....8

Component Parts Location .................................. ......8

Component Description .............................................9

ABS Actuator and Electric Unit (Control Unit) ...........9

Wheel Sensor and Sensor Rotor ............................10

Stop Lamp Switch ...................................................10

Steering Angle Sensor ............................................10

Brake Fluid Level Switch .........................................10

Vacuum Sensor .......................................................10

Parking Brake Switch ..............................................11

VDC OFF Switch .....................................................11

SYSTEM .............................................................12

VDC/TCS/ABS ....................................................... ....12

VDC/TCS/ABS : System Diagram ...........................12

VDC/TCS/ABS : System De scription ......................12

VDC/TCS/ABS : VDC Functi on ...............................23

VDC/TCS/ABS : TCS Functi on ...............................25

VDC/TCS/ABS : ABS Function ........................... ....27

VDC/TCS/ABS : EBD Functi on ...............................28

VDC/TCS/ABS : Fail-safe ... .....................................29

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

33

CONSULT Function (ABS) .................................. ....33

ECU DIAGNOSIS INFORMATION ..............38

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

38

Reference Value .................................................. ....38

Fail-safe ...................................................................41

DTC Inspection Priority Chart ..................................44

DTC Index ...............................................................45

WIRING DIAGRAM ......................................47

BRAKE CONTROL SYSTEM ...........................47

Wiring Diagram .................................................... ....47

BASIC INSPECTION ...................................55

DIAGNOSIS AND REPAIR WORK FLOW .......55

Work Flow ............................................................ ....55

Diagnostic Work Sheet ............................................56

ADDITIONAL SERVICE WHEN REPLACING

ABS ACTUATOR AND ELECTRIC UNIT

(CONTROL UNIT) .............................................

57

Description ........................................................... ....57

ADJUSTMENT OF STEERING ANGLE SEN-

SOR NEUTRAL POSITION ...............................

58

Description ........................................................... ....58

Work Procedure .......................................................58

CONFIGURATION [ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT)] ................

60

Work Procedure ................................................... ....60

CALIBRATION OF DECEL G SENSOR ...........62

Description ...............................................................62

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 773 of 4801

DLK-5

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

REAR DOOR LOCK ..............................................

..

204

REAR DOOR LOCK : Exploded View ...................204

REAR DOOR LOCK : Removal and Installation ...205

TRUNK LID ..................................................... ..206

TRUNK LID ASSEMBLY ...... ...................................206

TRUNK LID ASSEMBLY : Exploded View .......... ..206

TRUNK LID ASSEMBLY : Removal and Installa-

tion ...................................................................... ..

206

TRUNK LID ASSEMBLY : Adjustment ................ ..208

TRUNK LID HINGE ............................................... ..209

TRUNK LID HINGE : Removal and Installation ....209

TORSION BAR ...................................................... ..210

TORSION BAR : Removal and Installation ...........210

TRUNK LAMP SWITCH AND TRUNK RELEASE

SOLENOID ............................................................ ..

210

TRUNK LAMP SWITCH AND TRUNK RELEASE

SOLENOID : Removal and Installation .................

210

EMERGENCY LEVER ........................................... ..211

EMERGENCY LEVER : Removal and Installation ..211

TRUNK LID STRIKER ........................................... ..211

TRUNK LID STRIKER : Removal and Installation ..211

FUEL FILLER LID OPENER ............................213

Exploded View .................................................... ..213

FUEL FILLER LID ................................................. ..213

FUEL FILLER LID : Removal and Installation .......213

FUEL FILLER OPENER CABLE ........................... ..214

FUEL FILLER OPENER CABLE : Removal and

Installation ........................................................... ..

214

FUEL FILLER LID LOCK ...................................... ..215

FUEL FILLER LID LOCK : Removal and Installa-

tion ...................................................................... ..

215

KEY CYLINDER ...............................................217

GLOVE BOX LID KEY CYLINDER ....................... ..217

GLOVE BOX LID KEY CYLINDER : Removal and

Installation ........................................................... ..

217

SEATBACK LOCK KEY CYLINDER .................... ..218

SEATBACK LOCK KEY CYLINDER : Removal

and Installation .................................................... ..

218

DOOR SWITCH ................................................219

Removal and Installation .......................................219

INSIDE KEY ANTENNA ..................................220

CONSOLE .............................................................. ..220

CONSOLE : Removal and Installation ...................220

LUGGAGE ROOM ................................................. ..220

LUGGAGE ROOM : Removal and Installation ......220

OUTSIDE KEY ANTENNA ..............................221

DRIVER SIDE ......................................................... ..221

DRIVER SIDE : Removal and Installation .............221

PASSENGER SIDE ..................................................221

PASSENGER SIDE : Removal and Installation .. ..221

REAR BUMPER ..................................................... ..221

REAR BUMPER : Removal and Installation ..........221

DOOR REQUEST SWITCH ............................222

DRIVER SIDE ......................................................... ..222

DRIVER SIDE : Removal and Installation .............222

PASSENGER SIDE ..................................................222

PASSENGER SIDE : Removal and Installation .. ..222

INTELLIGENT KEY WARNING BUZZER .......223

Removal and Installation .......................................223

REMOTE KEYLESS ENTRY RECEIVER .......224

Removal and Installation .......................................224

INTELLIGENT KEY BATTERY .......................225

Removal and Installation .......................................225

TRUNK LID OPENER CANCEL SWITCH ......226

Removal and Installation .......................................226

TRUNK LID OPENER SWITCH ......................227

Removal and Installation .......................................227

TRUNK OPENER REQUEST SWITCH ..........228

Removal and Installation .......................................228

UNIT DISASSEMBLY AND ASSEMBLY ..229

FRONT DOOR .................................................229

Exploded View ..................................................... ..229

Disassembly and Assembly ...................................229

REAR DOOR ...................................................231

Exploded View .......................................................231

Disassembly and Assembly ...................................231

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 774 of 4801

DLK-6

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951560

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000009663378

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precaution for Servicing Doors and LocksINFOID:0000000009461762

WARNING:

Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should

contact the electric medical eq uipment manufacturer for the possible influences before use,

• After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

• Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

PIIB3706J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 935 of 4801

SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-167

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine rpm or

load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 945 of 4801

HOOD

DLK-177

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

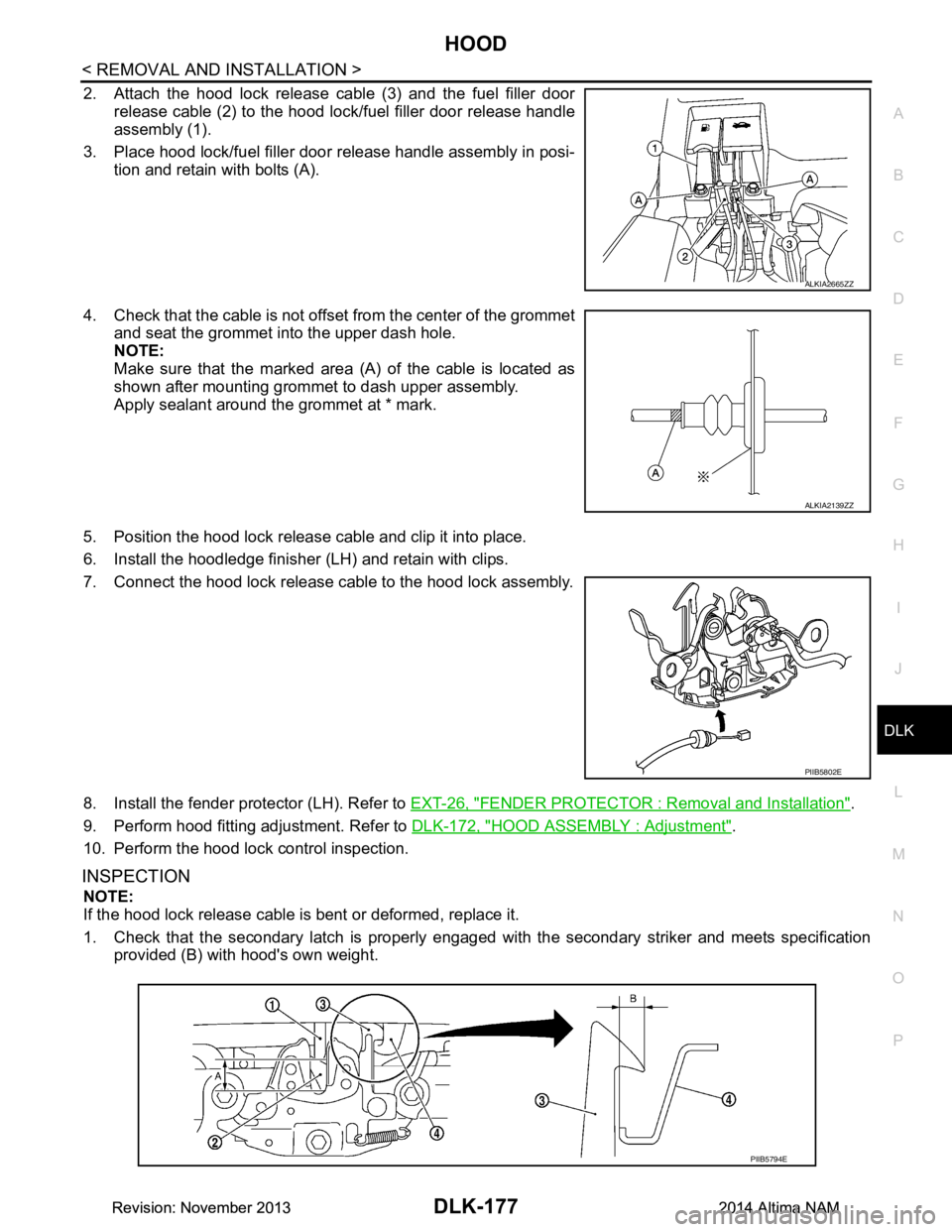

2. Attach the hood lock release cable (3) and the fuel filler door release cable (2) to the hood lock/fuel filler door release handle

assembly (1).

3. Place hood lock/fuel filler door release handle assembly in posi- tion and retain with bolts (A).

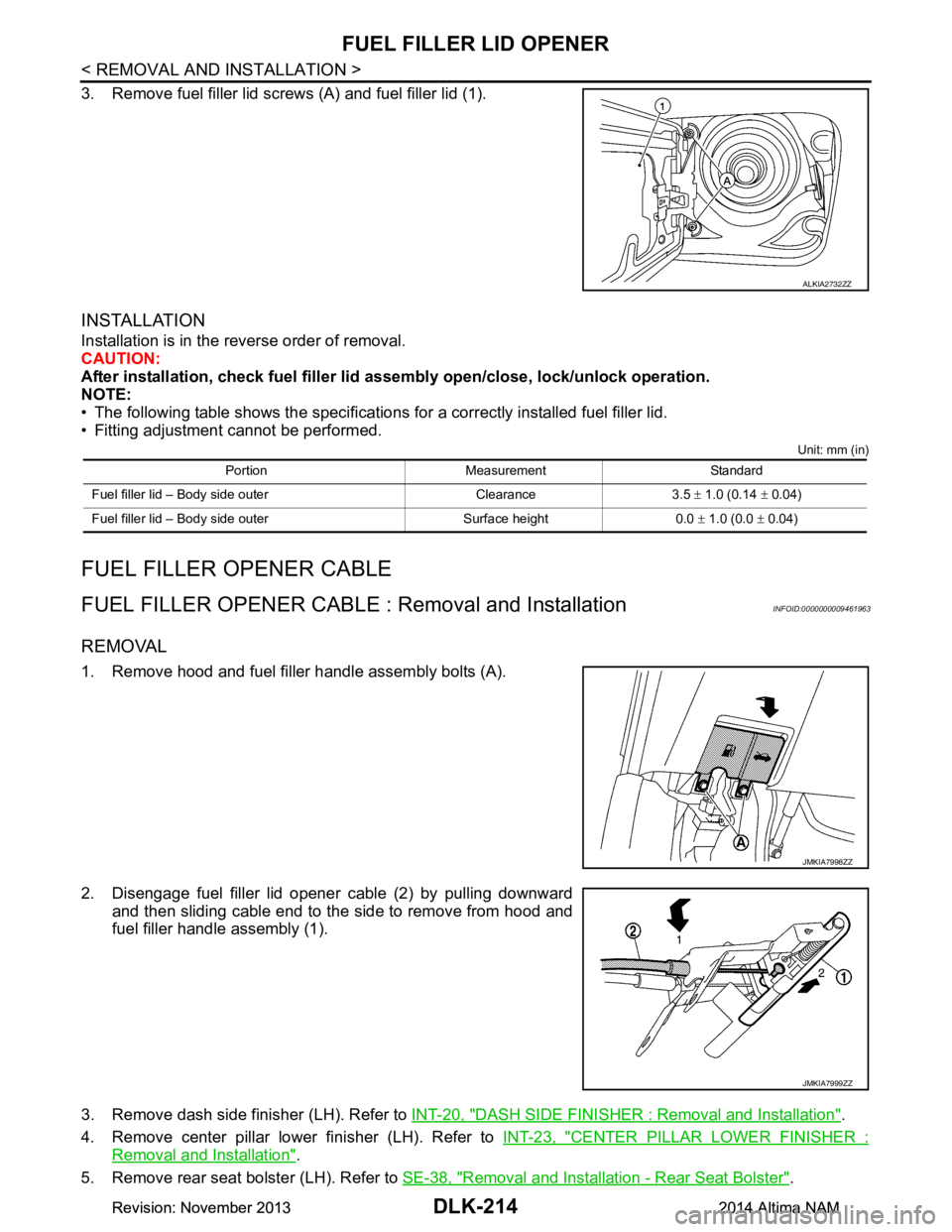

4. Check that the cable is not offset from the center of the grommet

and seat the grommet into the upper dash hole.

NOTE:

Make sure that the marked area (A) of the cable is located as

shown after mounting grommet to dash upper assembly.

Apply sealant around the grommet at * mark.

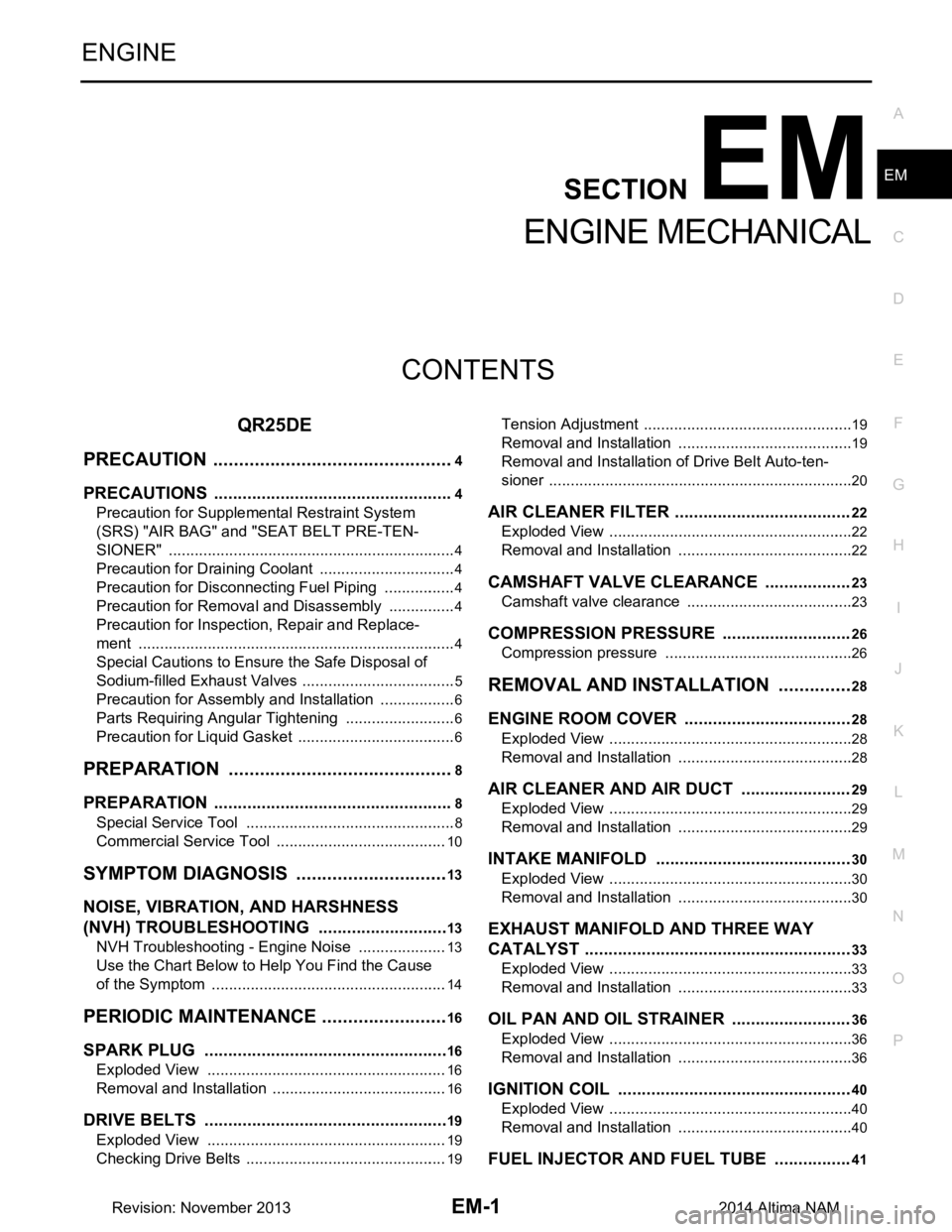

5. Position the hood lock release cable and clip it into place.

6. Install the hoodledge finisher (LH) and retain with clips.

7. Connect the hood lock release cable to the hood lock assembly.

8. Install the fender protector (LH). Refer to EXT-26, "FENDER PROTECTOR : Removal and Installation"

.

9. Perform hood fitting adjustment. Refer to DLK-172, "HOOD ASSEMBLY : Adjustment"

.

10. Perform the hood lock control inspection.

INSPECTION

NOTE:

If the hood lock release cable is bent or deformed, replace it.

1. Check that the secondary latch is properly engaged wi th the secondary striker and meets specification

provided (B) with hood's own weight.

ALKIA2665ZZ

ALKIA2139ZZ

PIIB5802E

PIIB5794E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 982 of 4801

DLK-214

< REMOVAL AND INSTALLATION >

FUEL FILLER LID OPENER

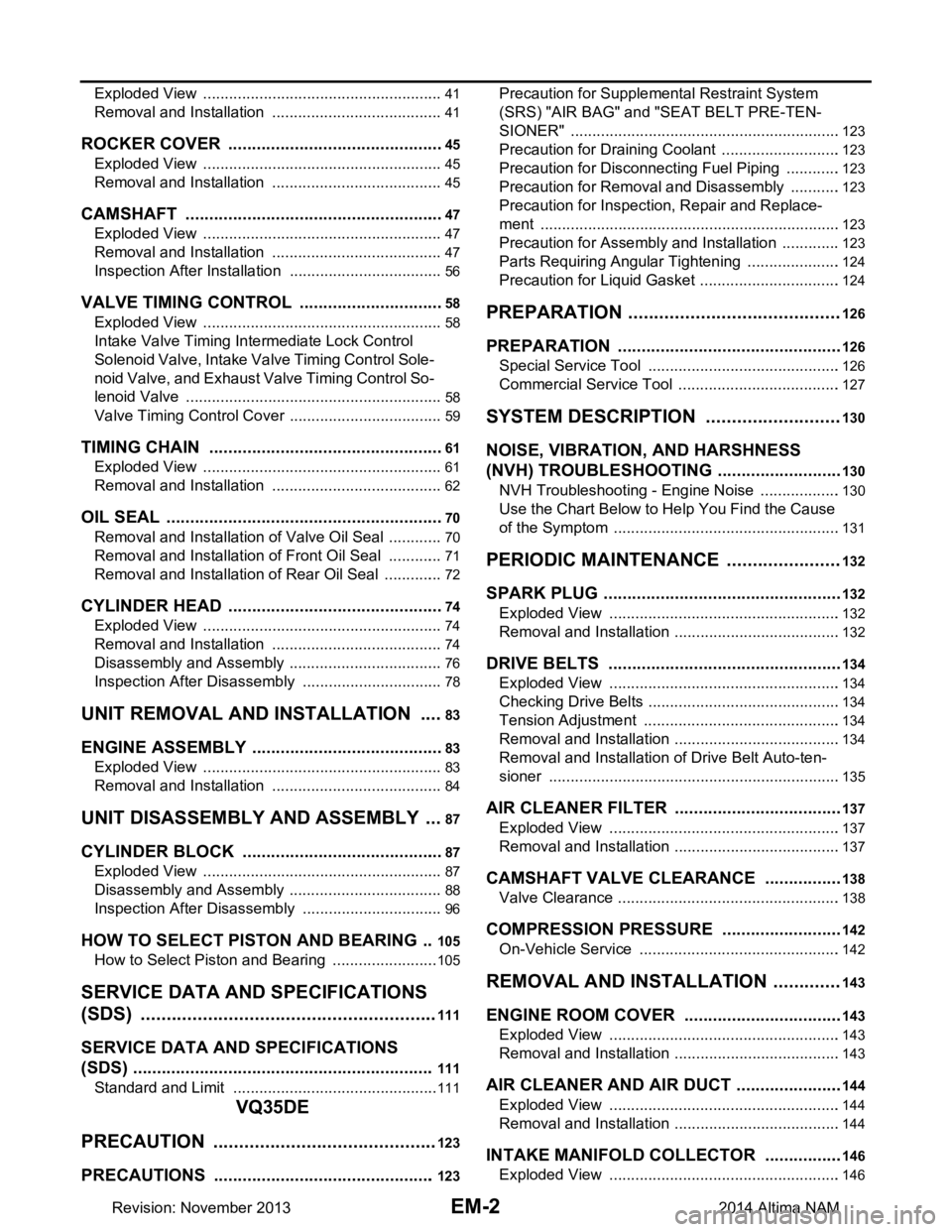

3. Remove fuel filler lid screws (A) and fuel filler lid (1).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

After installation, check fuel filler li d assembly open/close, lock/unlock operation.

NOTE:

• The following table shows the specifications for a correctly installed fuel filler lid.

• Fitting adjustment cannot be performed.

Unit: mm (in)

FUEL FILLER OP ENER CABLE

FUEL FILLER OPENER CABLE : Removal and InstallationINFOID:0000000009461963

REMOVAL

1. Remove hood and fuel filler handle assembly bolts (A).

2. Disengage fuel filler lid opener cable (2) by pulling downward and then sliding cable end to the side to remove from hood and

fuel filler handle assembly (1).

3. Remove dash side finisher (LH). Refer to INT-20, "DASH SIDE FINISHER : Removal and Installation"

.

4. Remove center pillar lower finisher (LH). Refer to INT-23, "CENTER PILLAR LOWER FINISHER :

Removal and Installation".

5. Remove rear seat bolster (LH). Refer to SE-38, "Removal and Installation - Rear Seat Bolster"

.

ALKIA2732ZZ

Portion Measurement Standard

Fuel filler lid – Body side outer Clearance 3.5 ± 1.0 (0.14 ± 0.04)

Fuel filler lid – Body side outer Surface height 0.0 ± 1.0 (0.0 ± 0.04)

JMKIA7998ZZ

JMKIA7999ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1999 of 4801

EM-1

ENGINE

C

D E

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

QR25DE

PRECAUTION ................ ...............................

4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Draining Coolant ................................4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment .................................................................... ......

4

Special Cautions to Ensure the Safe Disposal of

Sodium-filled Exhaust Valves .............................. ......

5

Precaution for Assembly and Installation ..................6

Parts Requiring Angular Tightening ..........................6

Precaution for Liquid Gasket ............................... ......6

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ........................................10

SYMPTOM DIAGNOSIS ..............................13

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

13

NVH Troubleshooting - Engine Noise ................. ....13

Use the Chart Below to Help You Find the Cause

of the Symptom ................................................... ....

14

PERIODIC MAINTENANCE .........................16

SPARK PLUG .. .............................................. ....16

Exploded View .................................................... ....16

Removal and Installation .........................................16

DRIVE BELTS ................................................ ....19

Exploded View .................................................... ....19

Checking Drive Belts ...............................................19

Tension Adjustment ............................................. ....19

Removal and Installation .........................................19

Removal and Installation of Drive Belt Auto-ten-

sioner ................................................................... ....

20

AIR CLEANER FILTER .....................................22

Exploded View .........................................................22

Removal and Installation .........................................22

CAMSHAFT VALVE CLEARANCE ..................23

Camshaft valve clearance .......................................23

COMPRESSION PRESSURE ...........................26

Compression pressure ............................................26

REMOVAL AND INSTALLATION ...............28

ENGINE ROOM COVER ...................................28

Exploded View ..................................................... ....28

Removal and Installation .........................................28

AIR CLEANER AND AIR DUCT .......................29

Exploded View .........................................................29

Removal and Installation .........................................29

INTAKE MANIFOLD .........................................30

Exploded View .........................................................30

Removal and Installation .........................................30

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

33

Exploded View ..................................................... ....33

Removal and Installation .........................................33

OIL PAN AND OIL STRAINER .........................36

Exploded View .........................................................36

Removal and Installation .........................................36

IGNITION COIL .................................................40

Exploded View .........................................................40

Removal and Installation .........................................40

FUEL INJECTOR AND FUEL TUBE ................41

Revision: November 20132014 Altima NAM

Page 2000 of 4801

EM-2

Exploded View ........................................................41

Removal and Installation ........................................41

ROCKER COVER ..............................................45

Exploded View ..................................................... ...45

Removal and Installation ........................................45

CAMSHAFT .......................................................47

Exploded View ..................................................... ...47

Removal and Installation ........................................47

Inspection After Installation ................................. ...56

VALVE TIMING CONTROL ............................ ...58

Exploded View ..................................................... ...58

Intake Valve Timing Intermediate Lock Control

Solenoid Valve, Intake Va lve Timing Control Sole-

noid Valve, and Exhaust Valve Timing Control So-

lenoid Valve ......................................................... ...

58

Valve Timing Control Cover ....................................59

TIMING CHAIN ............................................... ...61

Exploded View ..................................................... ...61

Removal and Installation ........................................62

OIL SEAL ...........................................................70

Removal and Installation of Valve Oil Seal .......... ...70

Removal and Installation of Front Oil Seal .............71

Removal and Installation of Rear Oil Seal ..............72

CYLINDER HEAD ..............................................74

Exploded View ..................................................... ...74

Removal and Installation ........................................74

Disassembly and Assembly ....................................76

Inspection After Disassembly .................................78

UNIT REMOVAL AND INSTALLATION .. ...83

ENGINE ASSEMBLY ...................................... ...83

Exploded View ..................................................... ...83

Removal and Installation ........................................84

UNIT DISASSEMBLY AND ASSEMBLY ....87

CYLINDER BLOCK ........................................ ...87

Exploded View ..................................................... ...87

Disassembly and Assembly ....................................88

Inspection After Disassembly .................................96

HOW TO SELECT PISTON AND BEARING .. .105

How to Select Piston and Bearing ....................... ..105

SERVICE DATA AND SPECIFICATIONS

(SDS) .............. ............................................

111

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................... .

111

Standard and Limit .............................................. ..111

VQ35DE

PRECAUTION .............. ..............................

123

PRECAUTIONS .............................................. .123

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

123

Precaution for Draining Coolant ............................123

Precaution for Disconnecting Fuel Piping .............123

Precaution for Removal and Disassembly ............123

Precaution for Inspection, Repair and Replace-

ment ..................................................................... .

123

Precaution for Assembly and Installation ..............123

Parts Requiring Angular Tightening ..................... .124

Precaution for Liquid Gasket .................................124

PREPARATION .........................................126

PREPARATION .............................................. ..126

Special Service Tool ............................................ .126

Commercial Service Tool ......................................127

SYSTEM DESCRIPTION ..........................130

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING ......................... ..

130

NVH Troubleshooting - Engine Noise .................. .130

Use the Chart Below to Help You Find the Cause

of the Symptom .................................................... .

131

PERIODIC MAINTENANCE ......................132

SPARK PLUG ... .............................................. ..132

Exploded View ..................................................... .132

Removal and Installation .......................................132

DRIVE BELTS ................................................ ..134

Exploded View ..................................................... .134

Checking Drive Belts .............................................134

Tension Adjustment ..............................................134

Removal and Installation .......................................134

Removal and Installation of Drive Belt Auto-ten-

sioner ................................................................... .

135

AIR CLEANER FILTER ....................................137

Exploded View ..................................................... .137

Removal and Installation .......................................137

CAMSHAFT VALVE CLEARANCE ............... ..138

Valve Clearance ................................................... .138

COMPRESSION PRESSURE ..........................142

On-Vehicle Service .............................................. .142

REMOVAL AND INSTALLATION .............143

ENGINE ROOM COVER ................................ ..143

Exploded View ..................................................... .143

Removal and Installation .......................................143

AIR CLEANER AND AIR DUCT ..................... ..144

Exploded View ..................................................... .144

Removal and Installation .......................................144

INTAKE MANIFOLD COLLECTOR ............... ..146

Exploded View ..................................................... .146

Revision: November 20132014 Altima NAM

Page 2388 of 4801

EXL-122

< PERIODIC MAINTENANCE >

HEADLAMP

PERIODIC MAINTENANCE

HEADLAMP

Aiming AdjustmentINFOID:0000000009463617

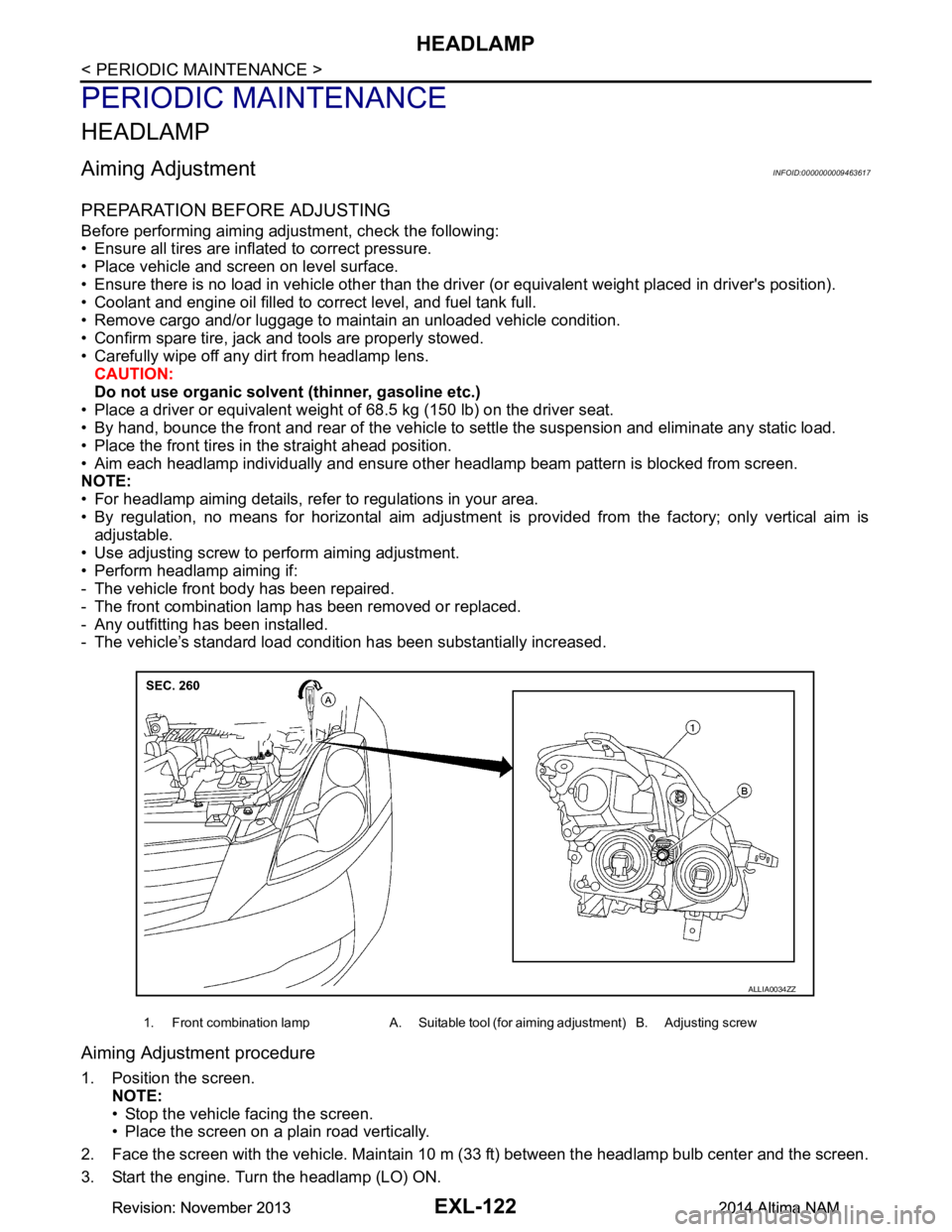

PREPARATION BEFORE ADJUSTING

Before performing aiming adjustment, check the following:

• Ensure all tires are inflated to correct pressure.

• Place vehicle and screen on level surface.

• Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position).

• Coolant and engine oil filled to correct level, and fuel tank full.

• Remove cargo and/or luggage to maintain an unloaded vehicle condition.

• Confirm spare tire, jack and tools are properly stowed.

• Carefully wipe off any dirt from headlamp lens. CAUTION:

Do not use organic solvent (thinner, gasoline etc.)

• Place a driver or equivalent weight of 68.5 kg (150 lb) on the driver seat.

• By hand, bounce the front and rear of the vehicle to settle the suspension and eliminate any static load.

• Place the front tires in the straight ahead position.

• Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

NOTE:

• For headlamp aiming details, refer to regulations in your area.

• By regulation, no means for horizontal aim adjustment is provided from the factory; only vertical aim is

adjustable.

• Use adjusting screw to perform aiming adjustment.

• Perform headlamp aiming if:

- The vehicle front body has been repaired.

- The front combination lamp has been removed or replaced.

- Any outfitting has been installed.

- The vehicle’s standard load condition has been substantially increased.

Aiming Adjustment procedure

1. Position the screen.

NOTE:

• Stop the vehicle facing the screen.

• Place the screen on a plain road vertically.

2. Face the screen with the vehicle. Maintain 10 m (33 ft) between the headlamp bulb center and the screen.

3. Start the engine. Turn the headlamp (LO) ON.

1. Front combination lamp A. Suitable tool (for aiming adjustment) B. Adjusting screw

ALLIA0034ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM