sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 812 of 4801

DLK-44

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

* : Initial setting

INTELLIGENT KEY

INTELLIGENT KEY : CONSULT Function (BCM - INTELLIGENT KEY)INFOID:0000000009952502

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and a no-start condition.

SELF DIAGNOSTIC RESULT

Refer to BCS-52, "DTC Index".

DATA MONITOR

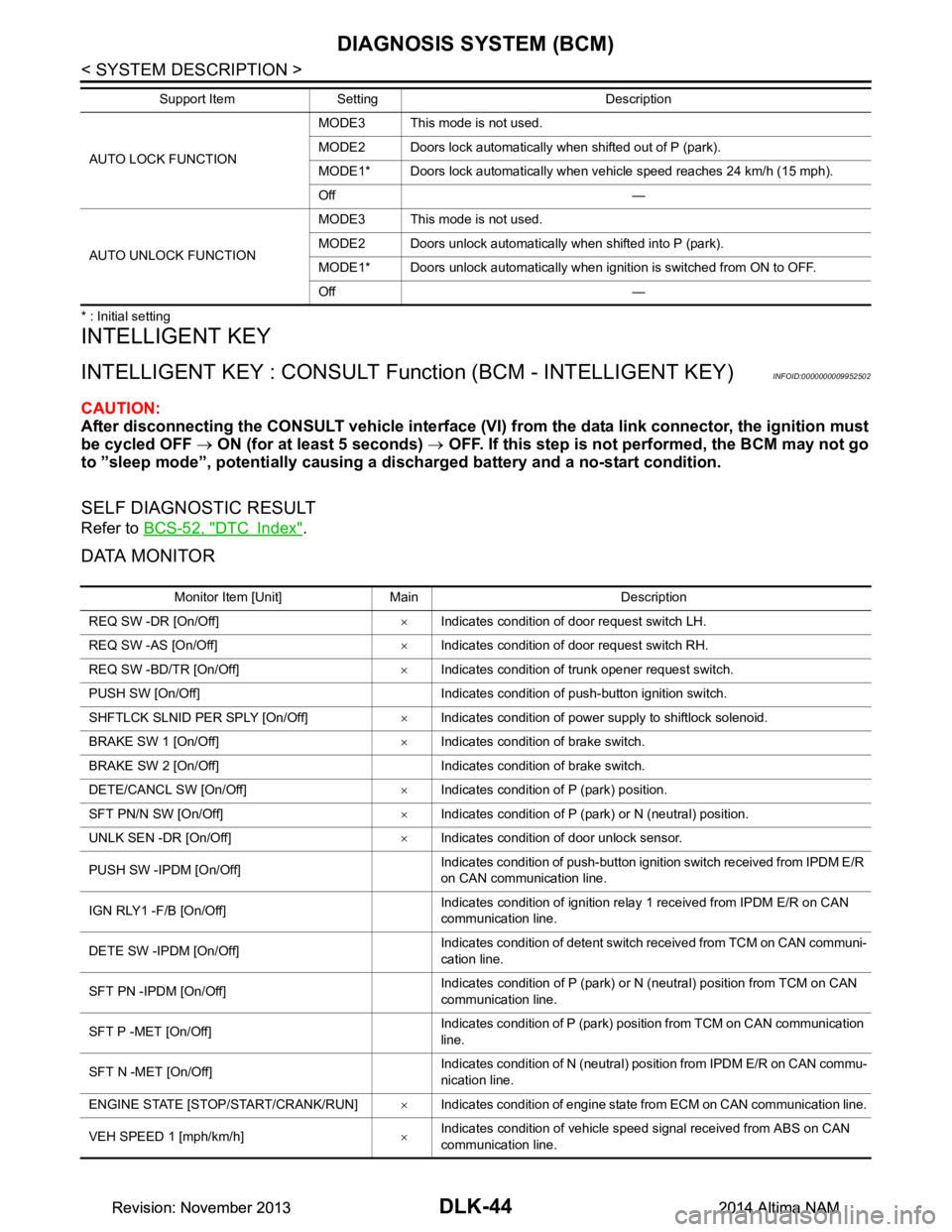

AUTO LOCK FUNCTION MODE3 This mode is not used.

MODE2 Doors lock automatically when shifted out of P (park).

MODE1* Doors lock automatically when vehicle speed reaches 24 km/h (15 mph).

Off —

AUTO UNLOCK FUNCTION MODE3 This mode is not used.

MODE2 Doors unlock automatically when shifted into P (park).

MODE1* Doors unlock automatically when ignition is switched from ON to OFF.

Off —

Support Item Setting Description

Monitor Item [Unit] Main Description

REQ SW -DR [On/Off] ×Indicates condition of door request switch LH.

REQ SW -AS [On/Off] ×Indicates condition of door request switch RH.

REQ SW -BD/TR [On/Off] ×Indicates condition of trunk opener request switch.

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

SHFTLCK SLNID PER SPLY [On/Off] ×Indicates condition of power supply to shiftlock solenoid.

BRAKE SW 1 [On/Off] ×Indicates condition of brake switch.

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW [On/Off] ×Indicates condition of P (park) position.

SFT PN/N SW [On/Off] ×Indicates condition of P (park) or N (neutral) position.

UNLK SEN -DR [On/Off] ×Indicates condition of door unlock sensor.

PUSH SW -IPDM [On/Off] Indicates condition of push-button ignition switch received from IPDM E/R

on CAN communication line.

IGN RLY1 -F/B [On/Off] Indicates condition of ignition relay 1 received from IPDM E/R on CAN

communication line.

DETE SW -IPDM [On/Off] Indicates condition of detent switch received from TCM on CAN communi-

cation line.

SFT PN -IPDM [On/Off] Indicates condition of P (park) or N (neutral) position from TCM on CAN

communication line.

SFT P -MET [On/Off] Indicates condition of P (park) position from TCM on CAN communication

line.

SFT N -MET [On/Off] Indicates condition of N (neutral) position from IPDM E/R on CAN commu-

nication line.

ENGINE STATE [STOP/START/CRANK/RUN] ×Indicates condition of engine state from ECM on CAN communication line.

VEH SPEED 1 [mph/km/h] ×Indicates condition of vehicle speed signal received from ABS on CAN

communication line.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 815 of 4801

DIAGNOSIS SYSTEM (BCM)DLK-47

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

*: Initial Setting

TRUNK

TRUNK : CONSULT Function (BCM - TRUNK)INFOID:0000000009952503

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentiall y causing a discharged battery and a no-start condition.

DATA MONITOR

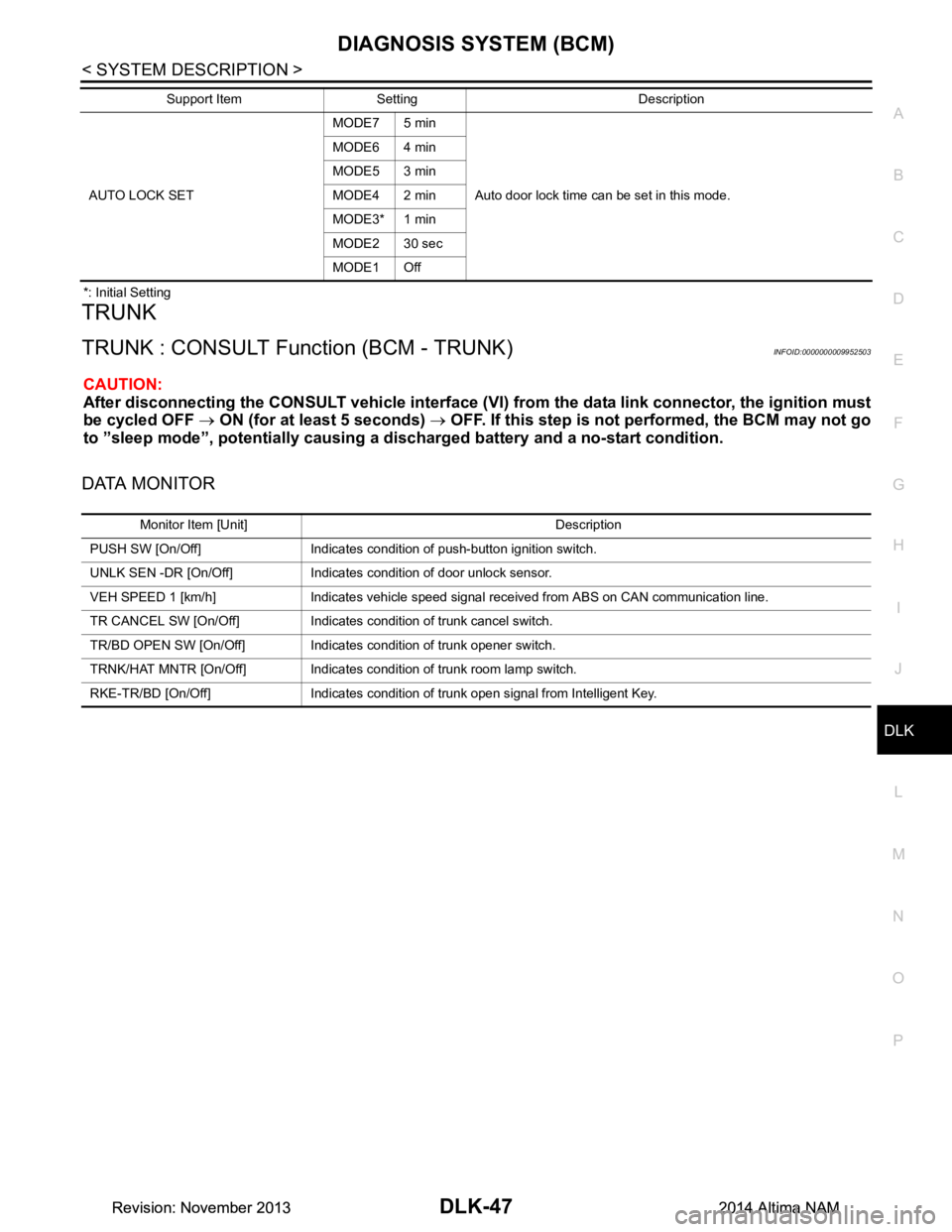

AUTO LOCK SET MODE7 5 min

Auto door lock time can be set in this mode.

MODE6 4 min

MODE5 3 min

MODE4 2 min

MODE3* 1 min

MODE2 30 sec

MODE1 Off

Support Item Setting Description

Monitor Item [Unit] Description

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

UNLK SEN -DR [On/Off] Indicates condition of door unlock sensor.

VEH SPEED 1 [km/h] Indicates vehicle speed signal received from ABS on CAN communication line.

TR CANCEL SW [On/Off] Indicates condition of trunk cancel switch.

TR/BD OPEN SW [On/Off] Indicates condition of trunk opener switch.

TRNK/HAT MNTR [On/Off] Indicates condition of trunk room lamp switch.

RKE-TR/BD [On/Off] Indicates condition of trunk open signal from Intelligent Key.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 887 of 4801

UNLOCK SENSORDLK-119

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

UNLOCK SENSOR

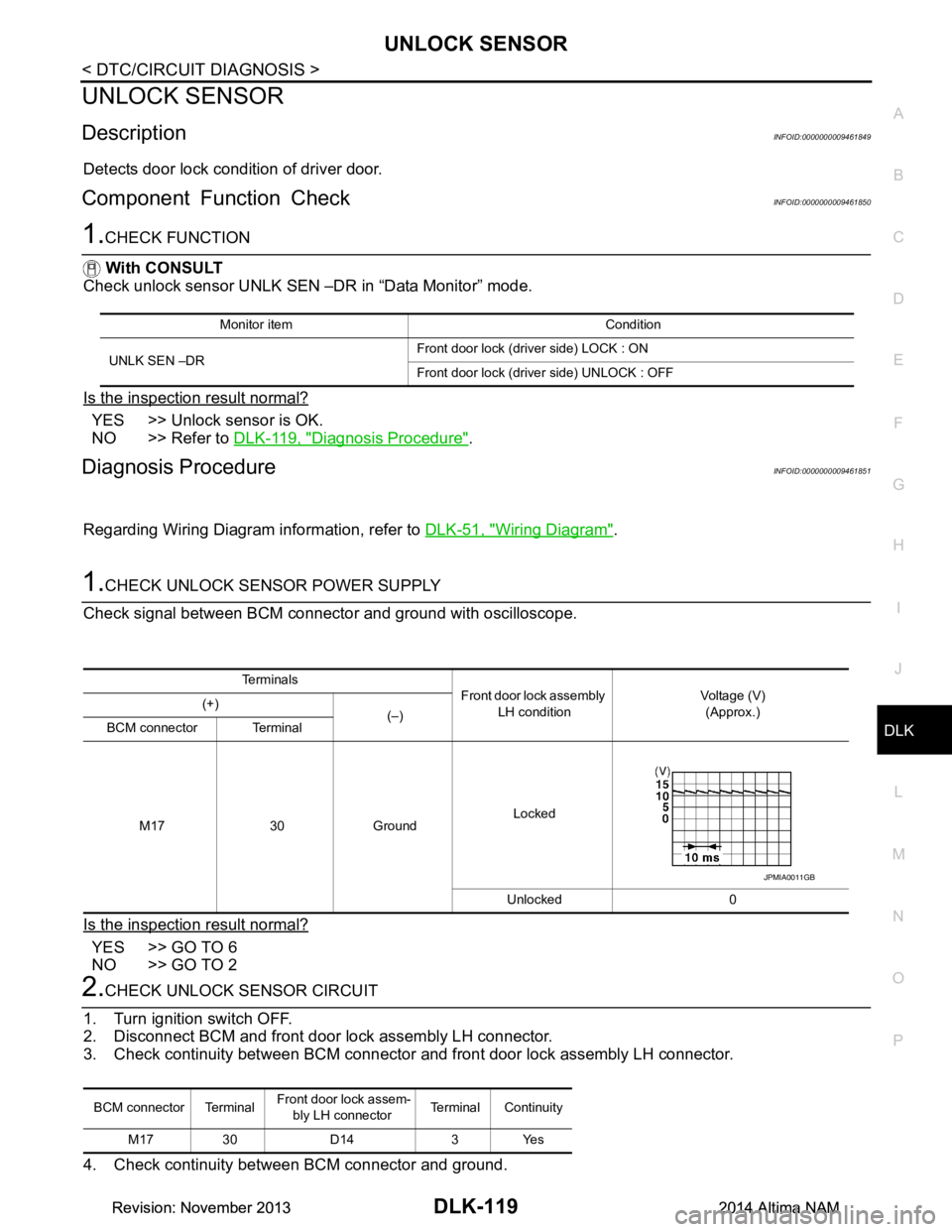

DescriptionINFOID:0000000009461849

Detects door lock condition of driver door.

Component Function CheckINFOID:0000000009461850

1.CHECK FUNCTION

With CONSULT

Check unlock sensor UNLK SEN –DR in “Data Monitor” mode.

Is the inspection result normal?

YES >> Unlock sensor is OK.

NO >> Refer to DLK-119, "Diagnosis Procedure"

.

Diagnosis ProcedureINFOID:0000000009461851

Regarding Wiring Diagram information, refer to DLK-51, "Wiring Diagram".

1.CHECK UNLOCK SENSOR POWER SUPPLY

Check signal between BCM connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 6

NO >> GO TO 2

2.CHECK UNLOCK SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM and front door lock assembly LH connector.

3. Check continuity between BCM connector and front door lock assembly LH connector.

4. Check continuity between BCM connector and ground.

Monitor item Condition

UNLK SEN –DR Front door lock (driver side) LOCK : ON

Front door lock (dri ver side) UNLOCK : OFF

Te r m i n a l s

Front door lock assembly

LH condition Voltage (V)

(Approx.)

(+)

(–)

BCM connector Terminal

M17 30 Ground Locked

Unlocked 0

JPMIA0011GB

BCM connector Terminal Front door lock assem-

bly LH connector Terminal Continuity

M17 30 D14 3 Yes

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 888 of 4801

DLK-120

< DTC/CIRCUIT DIAGNOSIS >

UNLOCK SENSOR

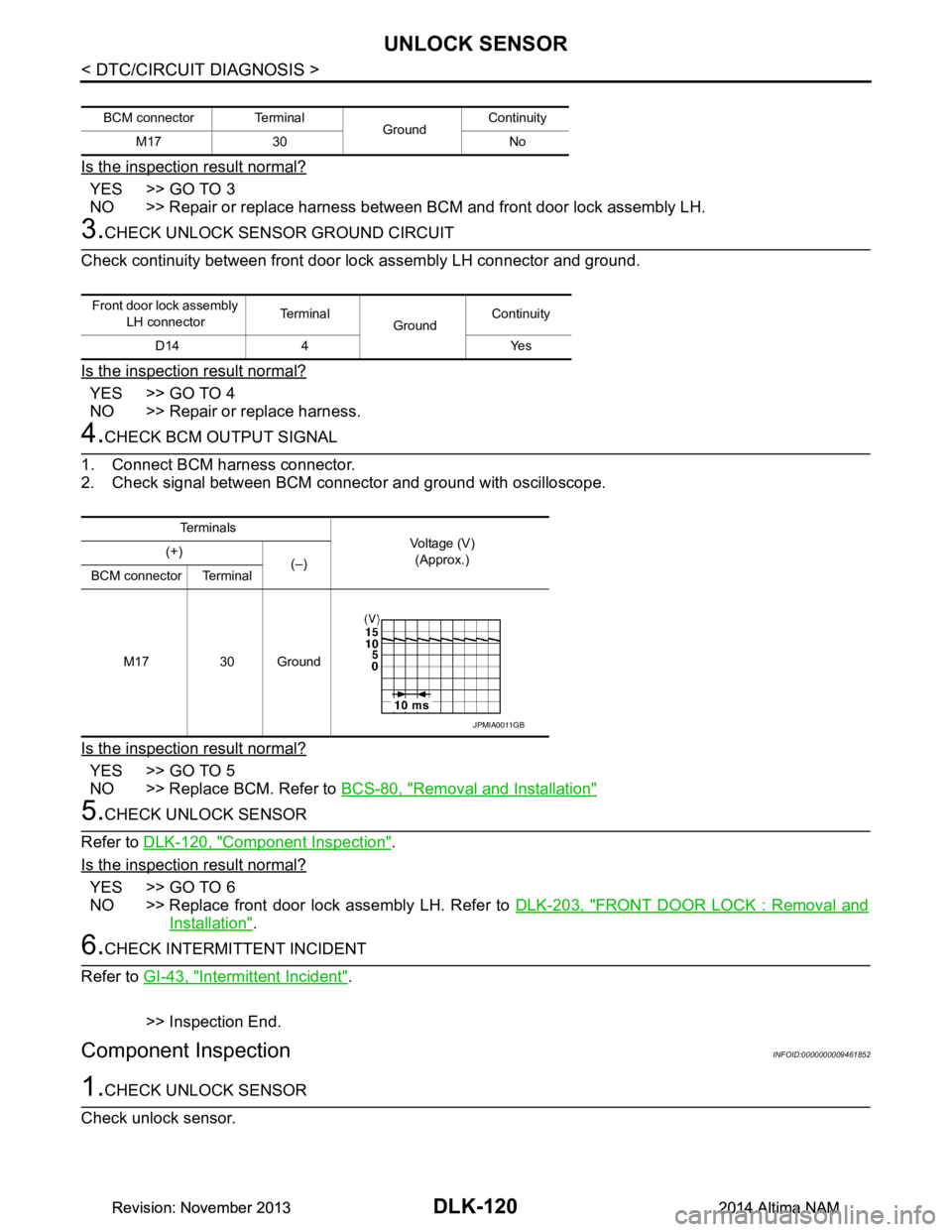

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair or replace harness between BCM and front door lock assembly LH.

3.CHECK UNLOCK SENSOR GROUND CIRCUIT

Check continuity between front door lock assembly LH connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM harness connector.

2. Check signal between BCM connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 5

NO >> Replace BCM. Refer to BCS-80, "Removal and Installation"

5.CHECK UNLOCK SENSOR

Refer to DLK-120, "Component Inspection"

.

Is the inspection result normal?

YES >> GO TO 6

NO >> Replace front door lock assembly LH. Refer to DLK-203, "FRONT DOOR LOCK : Removal and

Installation".

6.CHECK INTERMITTENT INCIDENT

Refer to GI-43, "Intermittent Incident"

.

>> Inspection End.

Component InspectionINFOID:0000000009461852

1.CHECK UNLOCK SENSOR

Check unlock sensor.

BCM connector Terminal GroundContinuity

M17 30 No

Front door lock assembly LH connector Te r m i n a l

GroundContinuity

D14 4 Yes

Te r m i n a l s Voltage (V)

(Approx.)

(+)

(–)

BCM connector Terminal

M17 30 Ground

JPMIA0011GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 889 of 4801

UNLOCK SENSORDLK-121

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

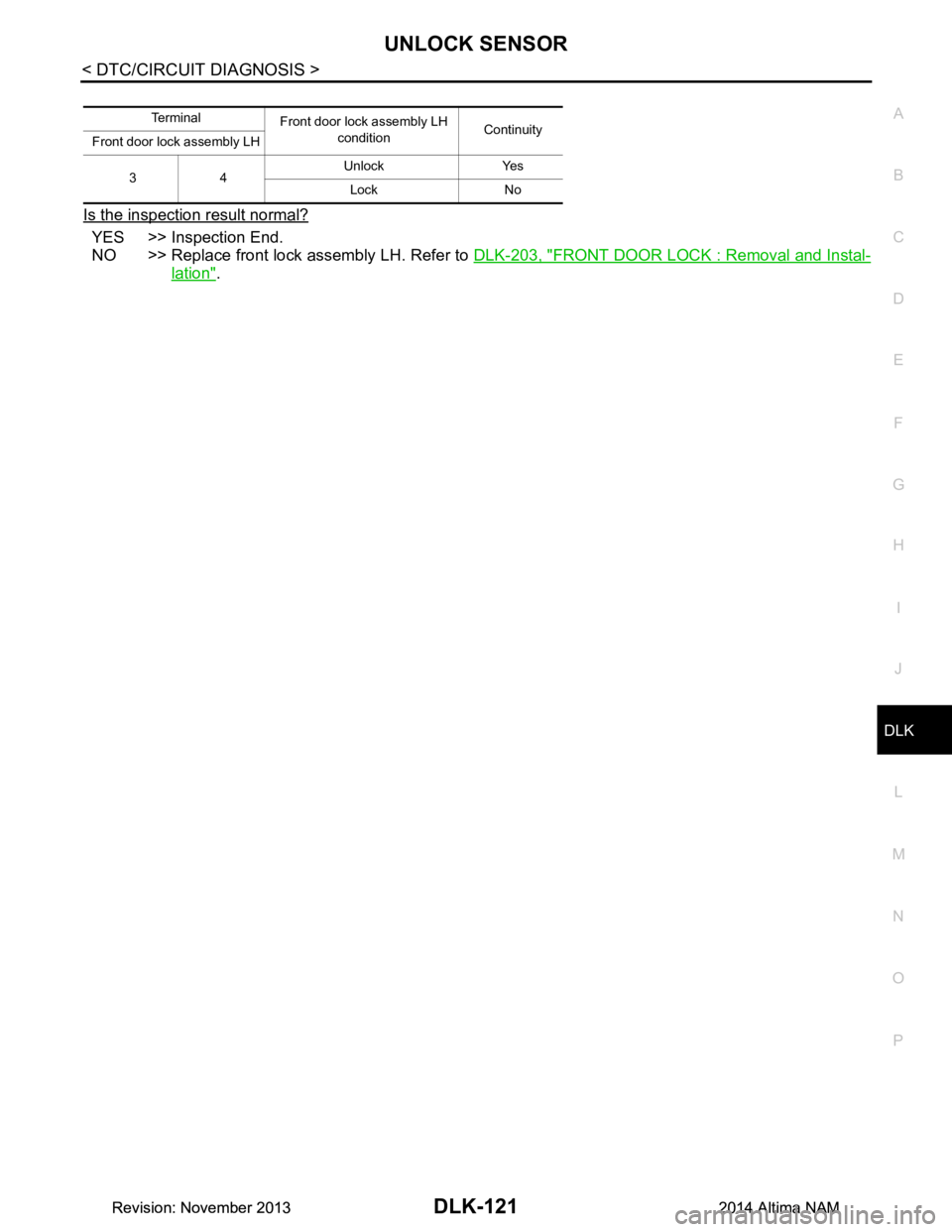

Is the inspection result normal?

YES >> Inspection End.

NO >> Replace front lock assembly LH. Refer to DLK-203, "FRONT DOOR LOCK : Removal and Instal-

lation".

Te r m i n a l

Front door lock assembly LH

condition Continuity

Front door lock assembly LH

34 Unlock Yes

Lock No

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 928 of 4801

DLK-160

< SYMPTOM DIAGNOSIS >

KEY REMINDER FUNCTION SYMPTOMS

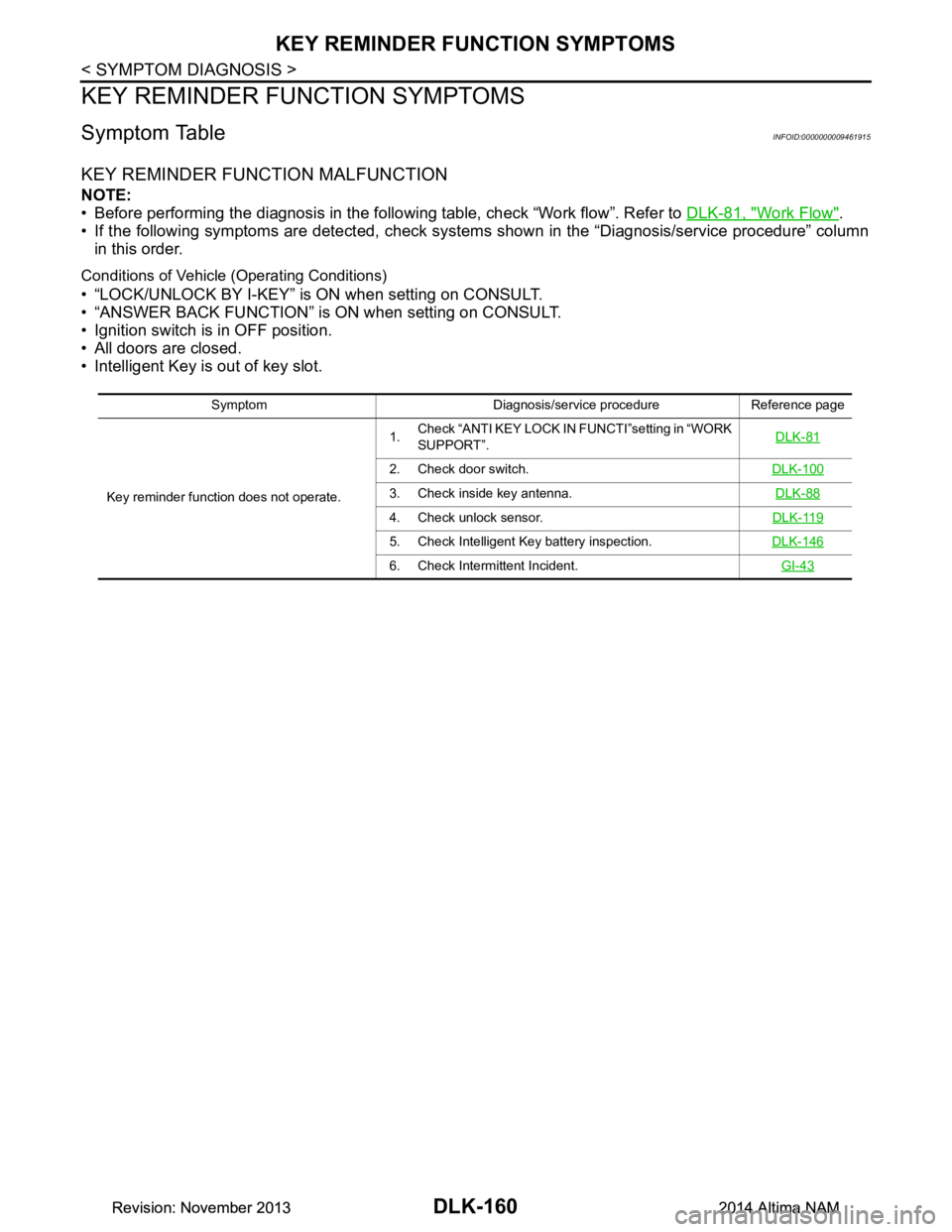

KEY REMINDER FUNCTION SYMPTOMS

Symptom TableINFOID:0000000009461915

KEY REMINDER FUNCTION MALFUNCTION

NOTE:

• Before performing the diagnosis in the follo wing table, check “Work flow”. Refer to DLK-81, "Work Flow"

.

• If the following symptoms are detected, check syst ems shown in the “Diagnosis/service procedure” column

in this order.

Conditions of Vehicle (Operating Conditions)

• “LOCK/UNLOCK BY I-KEY” is ON when setting on CONSULT.

• “ANSWER BACK FUNCTION” is ON when setting on CONSULT.

• Ignition switch is in OFF position.

• All doors are closed.

• Intelligent Key is out of key slot.

Symptom Diagnosis/service procedure Reference page

Key reminder function does not operate. 1.

Check “ANTI KEY LOCK IN FUNCTI”setting in “WORK

SUPPORT”. DLK-81

2. Check door switch.

DLK-100

3. Check inside key antenna. DLK-88

4. Check unlock sensor.DLK-119

5. Check Intelligent Key battery inspection.DLK-146

6. Check Intermittent Incident. GI-43

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 947 of 4801

RADIATOR CORE SUPPORTDLK-179

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

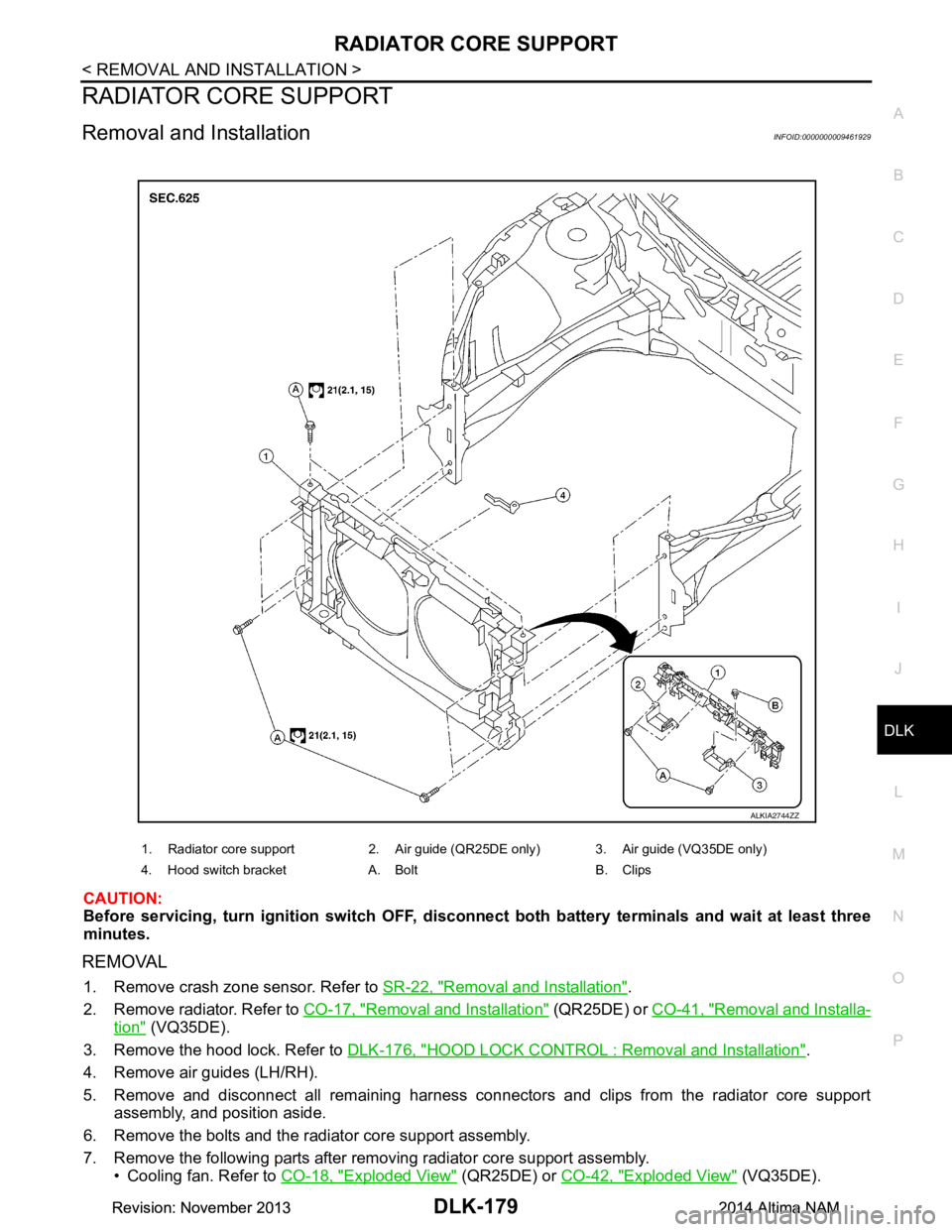

RADIATOR CORE SUPPORT

Removal and InstallationINFOID:0000000009461929

CAUTION:

Before servicing, turn igni tion switch OFF, disconnect both batt ery terminals and wait at least three

minutes.

REMOVAL

1. Remove crash zone sensor. Refer to SR-22, "Removal and Installation".

2. Remove radiator. Refer to CO-17, "Removal and Installation"

(QR25DE) or CO-41, "Removal and Installa-

tion" (VQ35DE).

3. Remove the hood lock. Refer to DLK-176, "HOOD LOCK CONTROL : Removal and Installation"

.

4. Remove air guides (LH/RH).

5. Remove and disconnect all remaining harness connectors and clips from the radiator core support assembly, and position aside.

6. Remove the bolts and the radiator core support assembly.

7. Remove the following parts after removing radiator core support assembly. • Cooling fan. Refer to CO-18, "Exploded View"

(QR25DE) or CO-42, "Exploded View" (VQ35DE).

1. Radiator core support 2. Air guide (QR25DE only) 3. Air guide (VQ35DE only)

4. Hood switch bracket A. Bolt B. Clips

ALKIA2744ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 952 of 4801

DLK-184

< REMOVAL AND INSTALLATION >

FRONT DOOR

FRONT DOOR

DOOR ASSEMBLY

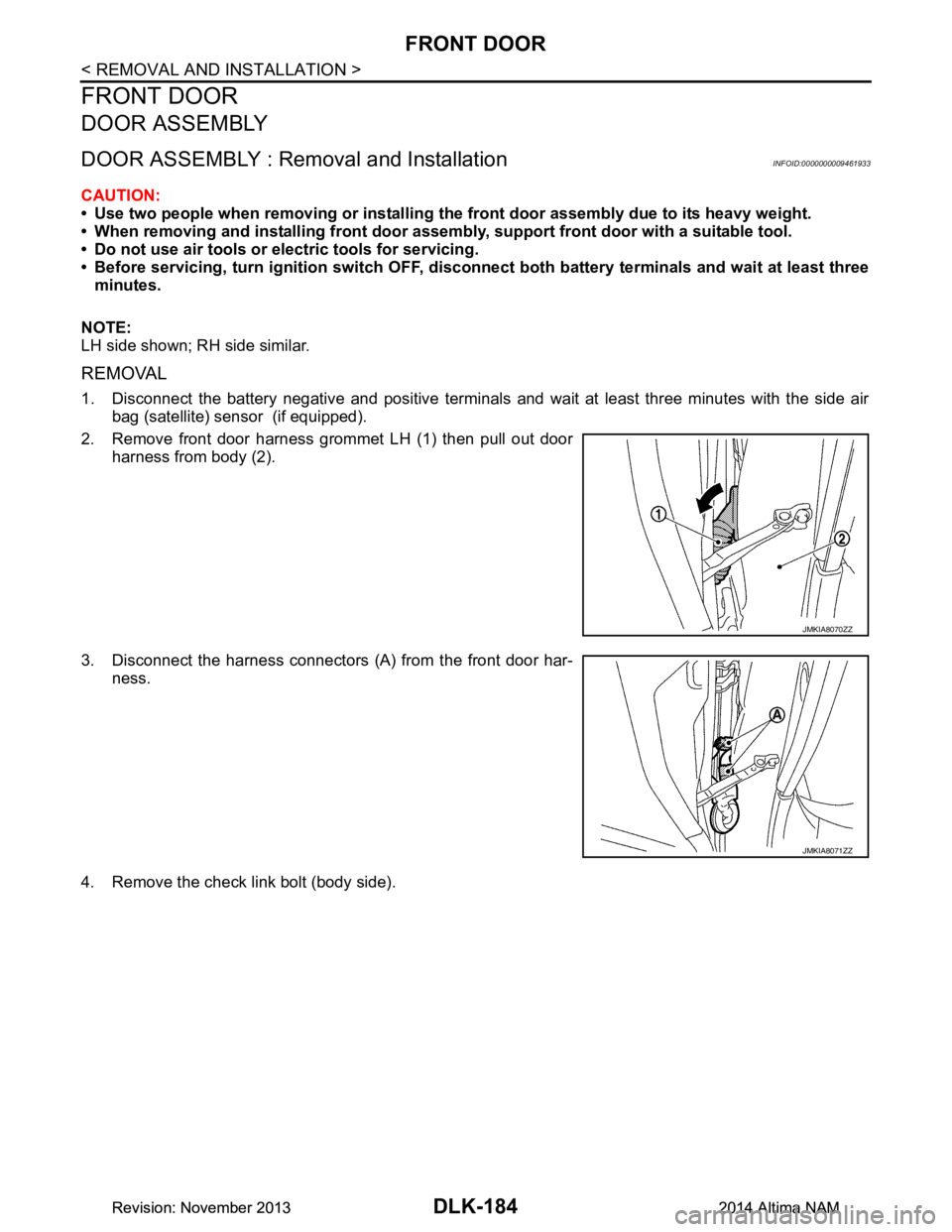

DOOR ASSEMBLY : Removal and InstallationINFOID:0000000009461933

CAUTION:

• Use two people when removing or installing the front door assembly due to its heavy weight.

• When removing and installing front door assembl y, support front door with a suitable tool.

• Do not use air tools or el ectric tools for servicing.

• Before servicing, turn ignition sw itch OFF, disconnect both battery terminals and wait at least three

minutes.

NOTE:

LH side shown; RH side similar.

REMOVAL

1. Disconnect the battery negative and positive terminals and wait at least three minutes with the side air bag (satellite) sensor (if equipped).

2. Remove front door harness grommet LH (1) then pull out door harness from body (2).

3. Disconnect the harness connectors (A) from the front door har- ness.

4. Remove the check link bolt (body side).

JMKIA8070ZZ

JMKIA8071ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1001 of 4801

EC-1

ENGINE

C

D E

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

QR25DE

PRECAUTION ................ ..............................

15

PRECAUTIONS .............................................. ....15

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

15

Precaution for Procedure without Cowl Top Cover ....15

On Board Diagnostic (OBD) System of Engine

and CVT .............................................................. ....

15

General Precautions ...............................................16

PREPARATION ...........................................19

PREPARATION .............................................. ....19

Special Service Tools .......................................... ....19

Commercial Service Tools ......................................19

SYSTEM DESCRIPTION .............................21

COMPONENT PARTS ................................... ....21

Component Parts Location ................................ ....21

ECM ........................................................................25

Accelerator Pedal Position Sensor ...................... ....25

Electric Throttle Control Actuator ........................ ....25

Ignition Coil With Power Transistor .........................26

Fuel Injector ........................................................ ....26

Fuel Level Sensor Unit and Fuel Pump .............. ....26

Fuel Tank Temperature Sensor .......................... ....27

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) ........................................................ ....

27

Manifold Absolute Pressure Sensor ........................28

Engine Coolant Temperature Sensor .................. ....28

Crankshaft Position Sensor (POS) ..........................29

Camshaft Position Sens or (PHASE) .......................29

Intake Valve Timing Cont rol Solenoid Valve ...........30

Intake Valve Timing Intermediate Lock Control

Solenoid Valve .................................................... ....

30

Exhaust Valve Timing Control Position Sensor .......30

Exhaust Valve Timing Control Solenoid Valve ........31

Intake Manifold Runner Control Valve ................. ....31

Intake Manifold Tuning Valve ..................................31

Air Fuel Ratio (A/F) Sensor 1 ..................................32

Heated Oxygen Sensor 2 ........................................32

Knock Sensor ..........................................................33

Engine Oil Pressure Sensor ....................................33

Engine Oil Temperature Sensor .......................... ....33

Cooling Fan .............................................................34

EVAP Canister .........................................................34

EVAP Canister Purge Volu me Control Solenoid

Valve .................................................................... ....

34

EVAP Canister Vent Control Valve ..........................35

EVAP Control System Pres sure Sensor ..................35

Battery Current Sensor (With Battery Tempera-

ture Sensor) ......................................................... ....

35

Malfunction Indicator lamp (MIL) .............................36

Oil Pressure Warning Lamp ....................................36

Refrigerant Pressure Sensor ............................... ....36

Stop Lamp Switch & Brake Pedal Position Switch ....36

ASCD Steering Switch .............................................37

Information Display ..................................................37

STRUCTURE AND OPERATION .....................38

Positive Crankcase Ventilation ................................38

On Board Refueling Vapor Recovery (ORVR) ........39

SYSTEM ............................................................40

ENGINE CONTROL SYSTEM ........................ ...........40

ENGINE CONTROL SYSTEM : System Descrip-

tion ....................................................................... ....

40

ENGINE CONTROL SYSTEM : Fail Safe ..............41

MULTIPORT FUEL INJECTION SYSTEM ................43

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description (with auto matic air conditioner) ......

43

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description (with manual air conditioner) .........

46

ELECTRIC IGNITION SYSTEM .................................48

ELECTRIC IGNITION SYSTEM : System De-

scription ............................................................... ....

48

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 1003 of 4801

EC-3

C

D E

F

G H

I

J

K L

M

EC A

N

O P

Description ..........................................................

..

181

Work Procedure ....................................................181

FUEL PRESSURE .......................................... ..182

Work Procedure .................................................. ..182

HOW TO SET SRT CODE ................................183

Description .......................................................... ..183

SRT Set Driving Pattern ........................................184

Work Procedure ....................................................186

HOW TO ERASE PERMANENT DTC ..............189

Description .......................................................... ..189

Work Procedure (Group A) ...................................190

Work Procedure (Group B) ...................................192

DTC/CIRCUIT DIAGNOSIS .......................195

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE ............................................................ ..

195

Description .......................................................... ..195

Component Function Check ..................................195

Diagnosis Procedure .............................................196

POWER SUPPLY AND GROUND CIRCUIT ....203

Diagnosis Procedure ........................................... ..203

U0101 CAN COMM CIRCUIT ...........................207

Description .......................................................... ..207

DTC Logic .............................................................207

Diagnosis Procedure .............................................207

U1001 CAN COMM CIRCUIT ...........................208

Description .......................................................... ..208

DTC Logic .............................................................208

Diagnosis Procedure .............................................208

P0011 IVT CONTROL ......................................209

DTC Logic ........................................................... ..209

Diagnosis Procedure .............................................210

Component Inspection ..........................................211

P0014 EVT CONTROL .....................................212

DTC Logic ........................................................... ..212

Diagnosis Procedure .............................................213

Component Inspection ..........................................214

P0031, P0032 A/F SENSOR 1 HEATER .........215

DTC Logic ........................................................... ..215

Diagnosis Procedure .............................................215

Component Inspection ..........................................216

P0037, P0038 HO2S2 HEATER .......................218

DTC Logic ........................................................... ..218

Diagnosis Procedure .............................................218

Component Inspection ..........................................219

P0075 INTAKE VALVE TIMING CONTROL ....221

DTC Logic ........................................................... ..221

Diagnosis Procedure .............................................221

Component Inspection (IVT Control Solenoid

Valve) .................................................................. ..

223

Component Inspection (IVT Intermediate Lock

Control Solenoid Valve) ....................................... ..

224

P0078 EVT CONTROL SOLENOID VALVE ...225

DTC Logic ..............................................................225

Diagnosis Procedure .............................................225

Component Inspection ...........................................226

P0101 MAF SENSOR .....................................228

DTC Logic ..............................................................228

Diagnosis Procedure .............................................228

Component Inspection ...........................................230

P0102, P0103 MAF SENSOR .........................232

DTC Logic ..............................................................232

Diagnosis Procedure .............................................232

Component Inspection ...........................................234

P010A MANIFOLD ABSOLUTE PRESSURE

SENSOR ..........................................................

236

DTC Logic ............................................................ ..236

Diagnosis Procedure .............................................236

Component Inspection (MAP Sensor) ...................237

P0111 IAT SENSOR .......................................239

DTC Logic ..............................................................239

Component Function Check ..................................240

Diagnosis Procedure .............................................240

Component Inspection ...........................................240

P0112, P0113 IAT SENSOR ...........................241

DTC Logic ..............................................................241

Diagnosis Procedure .............................................241

Component Inspection ...........................................242

P0116 ECT SENSOR ......................................243

DTC Logic ..............................................................243

Component Function Check ..................................244

Diagnosis Procedure .............................................244

Component Inspection ...........................................244

P0117, P0118 ECT SENSOR ..........................245

DTC Logic ..............................................................245

Diagnosis Procedure .............................................245

Component Inspection ...........................................246

P0122, P0123 TP SENSOR ............................248

DTC Logic ..............................................................248

Diagnosis Procedure .............................................248

Component Inspection ...........................................250

P0125 ECT SENSOR ......................................251

DTC Logic ..............................................................251

Diagnosis Procedure .............................................251

Component Inspection ...........................................252

P0127 IAT SENSOR .......................................253

DTC Logic ..............................................................253

Diagnosis Procedure .............................................253

Component Inspection ...........................................254

P0128 THERMOSTAT FUNCTION .................255

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM