sensor NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 669 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-236

< ECU DIAGNOSIS INFORMATION >[MOD]

ITS CONTROL UNIT

ECU DIAGNOSIS INFORMATION

ITS CONTROL UNIT

Reference ValueINFOID:0000000009951659

VALUES ON THE DIAGNOSIS TOOL

Monitor item Condition Value NISSAN TEANA 2014 Service Manual

DAS-236

< ECU DIAGNOSIS INFORMATION >[MOD]

ITS CONTROL UNIT

ECU DIAGNOSIS INFORMATION

ITS CONTROL UNIT

Reference ValueINFOID:0000000009951659

VALUES ON THE DIAGNOSIS TOOL

Monitor item Condition Value](/img/5/57390/w960_57390-668.png)

DAS-236

< ECU DIAGNOSIS INFORMATION >[MOD]

ITS CONTROL UNIT

ECU DIAGNOSIS INFORMATION

ITS CONTROL UNIT

Reference ValueINFOID:0000000009951659

VALUES ON THE DIAGNOSIS TOOL

Monitor item Condition Value/Status

ST ANGLE SENSOR

SIGNAL Ignition switch ON Steering angle signal is received On

Steering angle signal is not received Off

REVERSE SIGNAL Ignition switch ON Shift selector in R (reverse) On

Shift selector is not in R (reverse) Off

VEHICLE SPEED

SIGNAL While driving Vehicle speed signal is received On

Vehicle speed signal is not received Off

CAMERA SWITCH

SIGNAL Ignition switch ON Camera switch is pressed On

Camera switch is not pressed Off

CAMERA OFF SIG-

NAL Ignition switch ON Purpose switch is pressed On

Purpose switch is not pressed Off

ST ANGLE SENSOR

TYPE Ignition switch ON Steering angle sensor type is displayed Absolute

Steering angle sensor type is not received Not

STEERING GEAR

RATIO TYPE Ignition switch ON Pattern 1 type of steering gear ratio displayed Pattern 1

Pattern 2 type of steering gear ratio displayed Pattern 2

STEERING POSI-

TION Ignition switch ON It recognizes steering position is left LHD

It recognizes steering position is right RHD

R-CAMERA COMM

STATUS Ignition switch ON Rear camera serial status is OK OK

Rear camera serial status is not OK NG

R-CAMERA COMM

LINE Ignition switch ON Rear camera serial communication signal is received OK

Rear camera serial communication signal is not received NG

ILL Ignition switch ON Illumination is ON On

Illumination is OFF Off

ITS SW 1 Ignition switch ON ITS switch is pressed On

ITS switch is not pressed Off

ITS SW 1 IND Ignition switch ON Indicator of ITS switch 1 is lighting On

Indicator of ITS switch 1 is not lighting Off

TURN SIGNAL Ignition switch ON Turn signal left is received Left

Turn signal neutral is received N

Turn signal right is received Right

REAR CAMERA IM-

AGE SIGNAL Ignition switch ON Camera image signal is received On

Camera image signal is not received Off

ITS SW 2 Ignition switch ON For this vehicle, the displaying is fixed No setting

ITS SW 2 IND Ignition switch ON For this vehicle, the displaying is fixed No setting

WASH SW Ignition switch ON Wash switch signal is pressed On

Wash switch signal is not pressed Off

PUMP COMM STA-

TUS Ignition switch ON Pump communication signal is received On

Pump communication signal is not received Off

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 693 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-260

< DTC/CIRCUIT DIAGNOSIS >[MOD]

C1A03 VEHICLE SPEED SENSOR

DTC/CIRCUIT DIAGNOSIS

C1A03 VEHICLE SPEED SENSOR

DTC LogicINFOID:0000000009464910

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.P NISSAN TEANA 2014 Service Manual

DAS-260

< DTC/CIRCUIT DIAGNOSIS >[MOD]

C1A03 VEHICLE SPEED SENSOR

DTC/CIRCUIT DIAGNOSIS

C1A03 VEHICLE SPEED SENSOR

DTC LogicINFOID:0000000009464910

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.P](/img/5/57390/w960_57390-692.png)

DAS-260

< DTC/CIRCUIT DIAGNOSIS >[MOD]

C1A03 VEHICLE SPEED SENSOR

DTC/CIRCUIT DIAGNOSIS

C1A03 VEHICLE SPEED SENSOR

DTC LogicINFOID:0000000009464910

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition ON.

2. Perform “All DTC Reading” with CONSULT.

3. Check if the "C1A03" is detected as the current malfunction in "Self Diagnostic Result" of "AVM".

Is

“C1A03” detected as the current malfunction?

YES >> Refer to DAS-260, "Diagnosis Procedure".

NO >> Refer to GI-43, "Intermittent Incident"

.

Diagnosis ProcedureINFOID:0000000009464911

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS RESULTS

Check if any DTC is detected in “Self Diagnostic Result” of “ABS”.

Is any DTC detected?

YES >> Perform diagnosis on the detected DTC and repair or replace the malfunctioning parts. Refer to

BRC-45, "DTC Index"

.

NO >> GO TO 2.

2.CHECK ALL UNIT SELF-DIANOSIS RESULTS

Check if any DTC is detected exc ept for ITS control unit about VDC in "ALL DTC READING" with CONSULT.

Is any DTC detected except for ITS?

YES >> Replace ABS actuator and electr ic unit (control unit). Refer to BRC-128, "Removal and Installa-

tion".

NO >> Replace ITS control unit. Refer to DAS-68, "Removal and Installation"

.

DTCTrouble diagnosis

name DTC detecting condition Possible causes

C1A03 VHCL SPEED SEN

CIRC ITS control unit detects that the result of calcu-

lation about velocity has error. • ABS actuator and electric unit (control

unit)

• ITS control unit

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 695 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-262

< DTC/CIRCUIT DIAGNOSIS >[MOD]

C1A39 STEERING ANGLE SENSOR

C1A39 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464914

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMAT NISSAN TEANA 2014 Service Manual

DAS-262

< DTC/CIRCUIT DIAGNOSIS >[MOD]

C1A39 STEERING ANGLE SENSOR

C1A39 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464914

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMAT](/img/5/57390/w960_57390-694.png)

DAS-262

< DTC/CIRCUIT DIAGNOSIS >[MOD]

C1A39 STEERING ANGLE SENSOR

C1A39 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464914

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition ON.

2. Perform “All DTC Reading” with CONSULT.

3. Check if the "C1A39" is detected as the current malfunction in "Self Diagnostic Result" of "AVM".

Is

“C1A39” detected as the current malfunction?

YES >> Refer to DAS-262, "Diagnosis Procedure".

NO >> Refer to GI-43, "Intermittent Incident"

.

Diagnosis ProcedureINFOID:0000000009464915

1.CHECK STRG SENSOR SEL F-DIAGNOSIS RESULTS

Check if any DTC is detected in “Self Diagnostic Result” of “ABS”.

Is any DTC detected?

YES >> Perform diagnosis on the detected DTC and repair or replace the malfunctioning parts. Refer to

BRC-45, "DTC Index"

.

NO >> GO TO 2.

2.CHECK ALL UNIT SELF-DIANOSIS RESULTS

Check if any DTC is detected exc ept for ITS control unit about ABS in "ALL DTC READING" with CONSULT.

Is any DTC detected except for ITS?

YES >> Replace steering angle sensor. Refer to BRC-132, "Removal and Installation".

NO >> Replace ITS control unit. Refer to DAS-68, "Removal and Installation"

.

DTC Trouble diagnosis name DTC detecting condition Possible causes

C1A39 STRG SEN CIR ITS control unit receives the message that

means "Steering angle sensor is failed" from

steering angle sensor. • Steering angle sensor

• ITS control unit

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 698 of 4801

![NISSAN TEANA 2014 Service Manual

DAS

U0428 STEERING ANGLE SENSORDAS-265

< DTC/CIRCUIT DIAGNOSIS > [MOD]

C

D E

F

G H

I

J

K L

M B

N P

A

U0428 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464920

Diagnosis ProcedureINFOID:000000000 NISSAN TEANA 2014 Service Manual

DAS

U0428 STEERING ANGLE SENSORDAS-265

< DTC/CIRCUIT DIAGNOSIS > [MOD]

C

D E

F

G H

I

J

K L

M B

N P

A

U0428 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464920

Diagnosis ProcedureINFOID:000000000](/img/5/57390/w960_57390-697.png)

DAS

U0428 STEERING ANGLE SENSORDAS-265

< DTC/CIRCUIT DIAGNOSIS > [MOD]

C

D E

F

G H

I

J

K L

M B

N P

A

U0428 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464920

Diagnosis ProcedureINFOID:0000000009464921

1.ADJUST THE NEUTRAL POSITION OF THE STEERING ANGLE SENSOR

When U1232 is detected, adjust the neutral position of the steering angle sensor.

>> Perform adjustment of the neutral position of the steering angle sensor. Refer to BRC-33, "CON-

SULT Function (ABS)".

DTCDisplay contents of

CONSULT DTC detection condition Possible malfunction factor

U0428 ST ANGLE SENSOR

CALIBRATION [U0428] The neutral position adjustment of the steering angle sen-

sor is incomplete. Adjust neutral position of the steering

angle sensor.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 703 of 4801

![NISSAN TEANA 2014 Service Manual

DAS-270

< DTC/CIRCUIT DIAGNOSIS >[MOD]

U1232 STEERING ANGLE SENSOR

U1232 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464930

Diagnosis ProcedureINFOID:0000000009464931

1.REGISTER THE NEUTRAL POSIT NISSAN TEANA 2014 Service Manual

DAS-270

< DTC/CIRCUIT DIAGNOSIS >[MOD]

U1232 STEERING ANGLE SENSOR

U1232 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464930

Diagnosis ProcedureINFOID:0000000009464931

1.REGISTER THE NEUTRAL POSIT](/img/5/57390/w960_57390-702.png)

DAS-270

< DTC/CIRCUIT DIAGNOSIS >[MOD]

U1232 STEERING ANGLE SENSOR

U1232 STEERING ANGLE SENSOR

DTC LogicINFOID:0000000009464930

Diagnosis ProcedureINFOID:0000000009464931

1.REGISTER THE NEUTRAL POSITION

OF THE STEERING ANGLE SENSOR

1. Turn the ignition switch ON.

2. Perform registration of the neutral positi on of the steering angle sensor. Refer to DAS-233, "CONSULT

Function (AVM)".

3. Check “Self Diagnostic Result” of “AVM” with CONSULT. Refer to DAS-233, "CONSULT Function (AVM)"

.

Is

“ST ANGLE SEN CALIB” detected?

YES >> GO TO 2.

NO >> Inspection End.

2.CHECK STEERING ANGLE SENSOR

Check steering angle sensor.

Is the inspection result normal?

YES >> Replace ITS control unit. Refer to DAS-68, "Removal and Installation".

NO >> Repair or replace malfunctioning parts.

DTC Display contents of

CONSULT DTC detection condition Possible malfunction factor

U1232 ST ANGLE SEN CALIB The neutral position registration of the steering angle sen-

sor cannot finish. • Steering angle sensor

•ITS control unit

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 728 of 4801

PRECAUTIONSDEF-3

< PRECAUTION >

C

D E

F

G H

I

J

K

M A

B

DEF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951577

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service t he system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three mi nutes before performing any service.

Precaution for WorkINFOID:0000000009463020

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusabl e part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

-Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 771 of 4801

DLK-3

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

PASSENGER SIDE : Diagnosis Procedure (With

LH and RH Anti-Pinch) ........................................ ..

106

PASSENGER SIDE : Diagnosis Procedure (With

LH Anti-Pinch Only) ............................................. ..

107

OUTSIDE KEY ANTENNA (PASSENGER

SIDE) .............................................................. ..

109

Component Function Check ................................ ..109

Diagnosis Procedure .............................................109

OUTSIDE KEY ANTENNA (DRIVER SIDE) .....111

Component Function Check ................................ ..111

Diagnosis Procedure .............................................111

OUTSIDE KEY ANTENNA (REAR BUMPER) ..113

Component Function Check ................................ ..113

Diagnosis Procedure .............................................113

KEY CYLINDER SWITCH ................................115

Description .......................................................... ..115

Component Function Check ..................................115

Diagnosis Procedure (With LH and RH Anti-Pinch)

..

115

Diagnosis Procedure (With LH Anti-Pinch Only) ...116

Component Inspection ..........................................117

UNLOCK SENSOR ..........................................119

Description .......................................................... ..119

Component Function Check ................................119

Diagnosis Procedure .............................................119

Component Inspection ..........................................120

TRUNK LID OPENER SWITCH .......................122

Description .......................................................... ..122

Component Function Check ................................122

Diagnosis Procedure .............................................122

Component Inspection ..........................................123

TRUNK LID OPENER CANCEL SWITCH .......124

Description .......................................................... ..124

Component Function Check ................................124

Diagnosis Procedure .............................................124

Component Inspection ..........................................125

TRUNK LAMP SWITCH ...................................126

Description .......................................................... ..126

Component Function Check ................................126

Diagnosis Procedure .............................................126

Component Inspection ..........................................127

DOOR REQUEST SWITCH ..............................129

Description .......................................................... ..129

Component Function Check ................................129

Diagnosis Procedure .............................................129

Component Inspection ..........................................131

TRUNK OPENER REQUEST SWITCH ............132

Description .......................................................... ..132

Component Function Check ................................132

Diagnosis Procedure .............................................132

Component Inspection ..........................................133

DOOR LOCK ACTUATOR ..............................135

DRIVER SIDE ......................................................... ..135

DRIVER SIDE : Description ...................................135

DRIVER SIDE : Component Function Check ......135

DRIVER SIDE : Diagnosis Procedure ...................135

PASSENGER SIDE ..................................................136

PASSENGER SIDE : Descript ion ..........................136

PASSENGER SIDE :

Component Function Check .............................. ..

136

PASSENGER SIDE : Diagnosis Procedure ..........136

REAR LH ................................................................ ..137

REAR LH : Description ..........................................137

REAR LH : Component Function Check ..............137

REAR LH : Diagnosis Procedure ...........................137

REAR RH ............................................................... ..138

REAR RH : Description .........................................138

REAR RH : Component Function Check .............138

REAR RH : Diagnosis Procedure ..........................138

TRUNK LID OPENER ACTUATOR ................140

Description .............................................................140

Component Function Check ................................140

Diagnosis Procedure .............................................140

INTELLIGENT KEY WARNING BUZZER .......142

Description .............................................................142

Component Function Check ................................142

Diagnosis Procedure .............................................142

Component Inspection ...........................................143

REMOTE KEYLESS ENTRY RECEIVER .......144

Description .............................................................144

Component Function Check ................................144

Diagnosis Procedure .............................................144

INTELLIGENT KEY BATTERY AND FUNC-

TION ................................................................

146

Description ........................................................... ..146

Component Function Check ................................146

Diagnosis Procedure .............................................146

WARNING CHIME FUNCTION .......................148

Description .............................................................148

Component Function Check ................................148

Diagnosis Procedure .............................................148

HAZARD FUNCTION ......................................149

Description .............................................................149

Component Function Check ................................149

Diagnosis Procedure .............................................149

HOMELINK UNIVERSAL TRANSCEIVER .....150

Description .............................................................150

Component Function Check ................................150

Diagnosis Procedure .............................................150

SYMPTOM DIAGNOSIS ............................152

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 774 of 4801

DLK-6

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951560

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Procedure without Cowl Top CoverINFOID:0000000009663378

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc to prevent damage to

windshield.

Precaution for Servicing Doors and LocksINFOID:0000000009461762

WARNING:

Radio waves could adversely affect electric medical equipment. Those who use a pacemaker should

contact the electric medical eq uipment manufacturer for the possible influences before use,

• After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

• Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

PIIB3706J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 776 of 4801

DLK-8

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

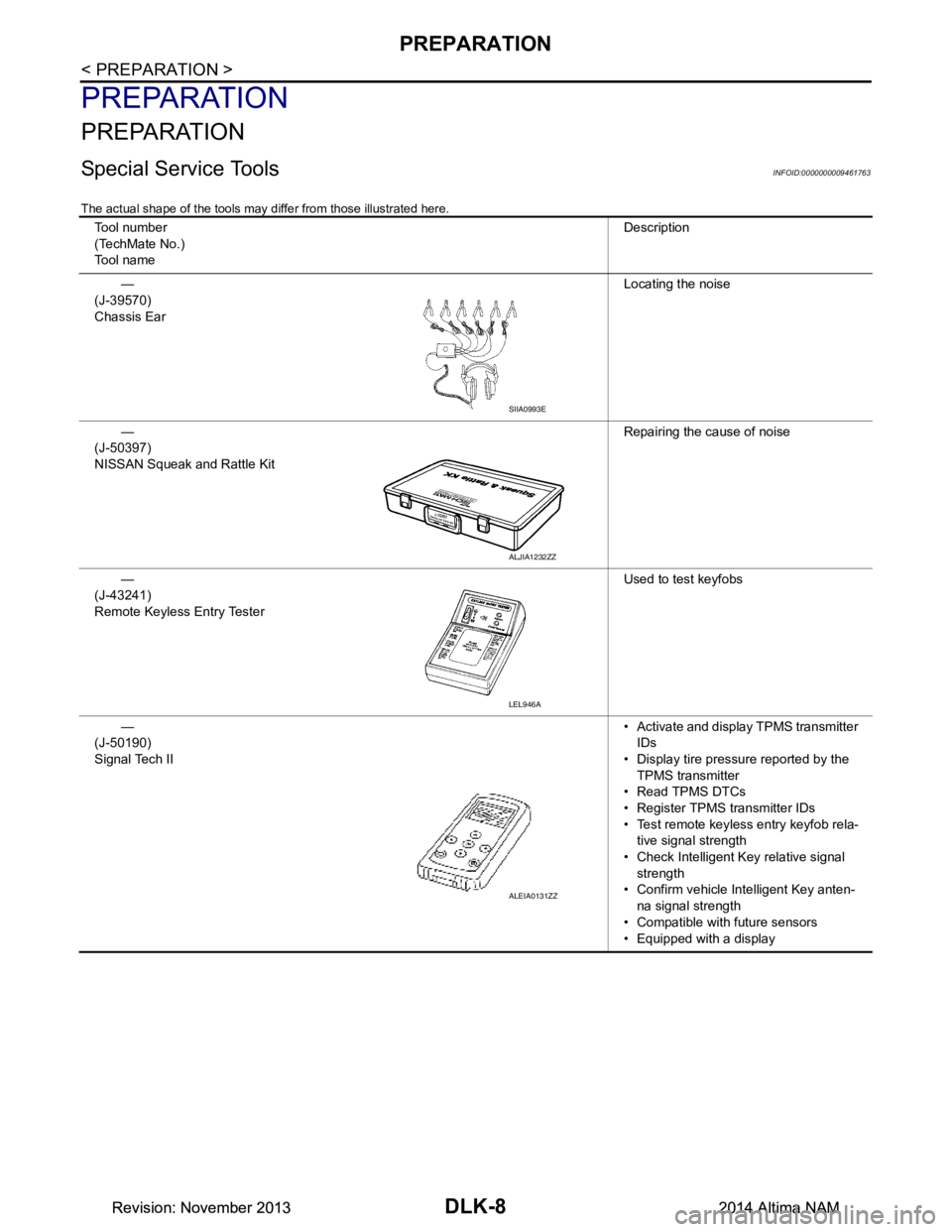

Special Service ToolsINFOID:0000000009461763

The actual shape of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name Description

—

(J-39570)

Chassis Ear Locating the noise

—

(J-50397)

NISSAN Squeak and Rattle Kit Repairing the cause of noise

—

(J-43241)

Remote Keyless Entry Tester Used to test keyfobs

—

(J-50190)

Signal Tech II • Activate and display TPMS transmitter

IDs

• Display tire pressu re reported by the

TPMS transmitter

• Read TPMS DTCs

• Register TPMS transmitter IDs

• Test remote keyless entry keyfob rela- tive signal strength

• Check Intelligent Key relative signal strength

• Confirm vehicle Intelligent Key anten-

na signal strength

• Compatible with future sensors

• Equipped with a display

SIIA0993E

ALJIA1232ZZ

LEL946A

ALEIA0131ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 777 of 4801

PREPARATIONDLK-9

< PREPARATION >

C

D E

F

G H

I

J

L

M A

B

DLK

N

O P

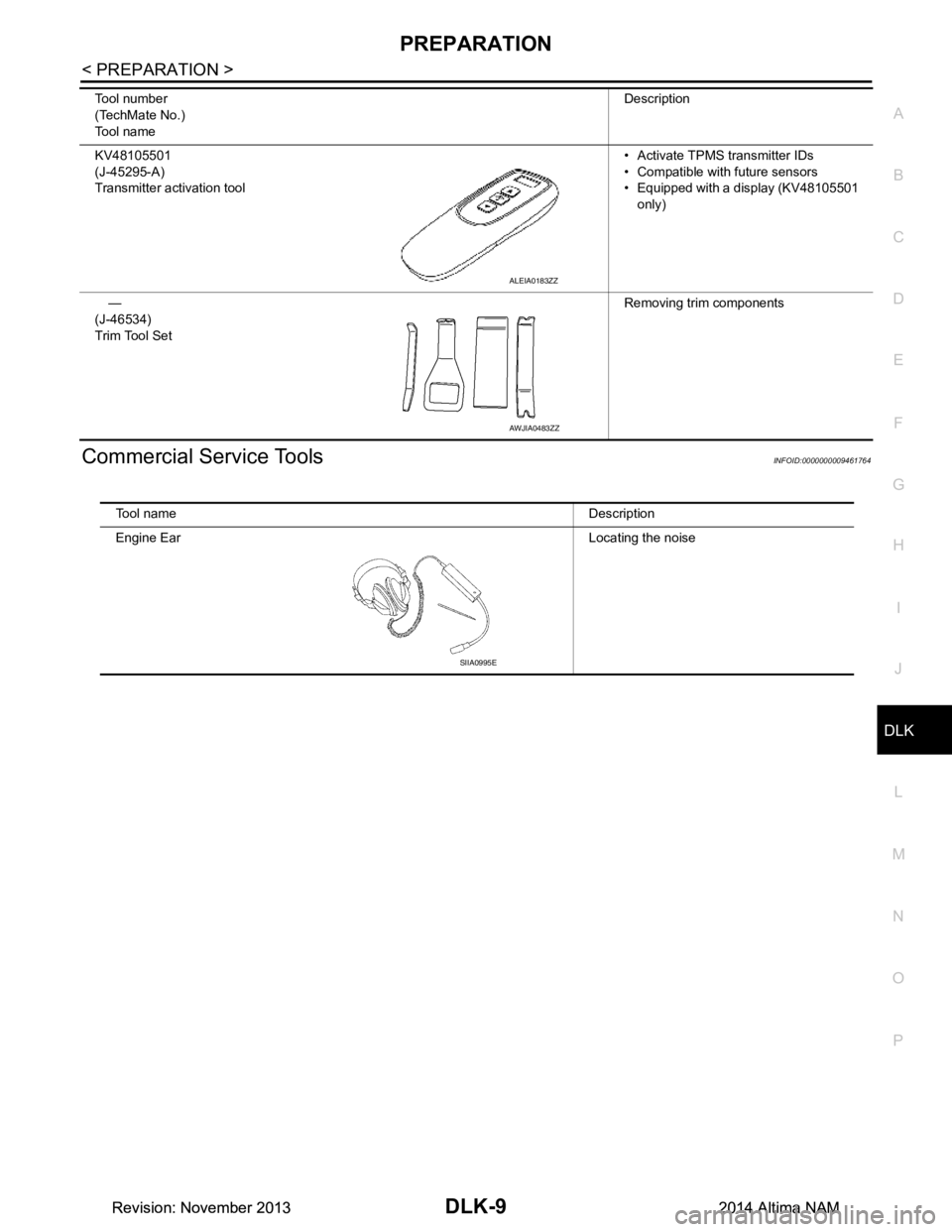

Commercial Service ToolsINFOID:0000000009461764

KV48105501

(J-45295-A)

Transmitter activation tool • Activate TPMS transmitter IDs

• Compatible with future sensors

• Equipped with a display (KV48105501

only)

—

(J-46534)

Trim Tool Set Removing trim components

Tool number

(TechMate No.)

Tool name Description

ALEIA0183ZZ

AWJIA0483ZZ

Tool name Description

Engine Ear Locating the noise

SIIA0995E

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM